Kaiser Aluminum Alloy 2011 Hard Alloy Rod and Bar Technical Data

Diunggah oleh

weltwindDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Kaiser Aluminum Alloy 2011 Hard Alloy Rod and Bar Technical Data

Diunggah oleh

weltwindHak Cipta:

Format Tersedia

R O D & B A R A L L O Y 2 0 1 1

www.kaiseraluminum.com | KA-RBH-2011-8.10

Technical Data

2011-T3 is a RoHS compliant, free machining alloy and temper combination that compares favorably with free cutting brass.

2011 is the alloy of choice when good strength and high machining rates are desired. It can be machined to very close tolerances

and produces excellent machined surface nishes. Resistance welding, corrosion resistance and anodizeability are only fair.

Other forms of welding are not recommended. Additional strength, without a sacrice in machinability, can be achieved

through the use of the T8 temper.

ALLOY DESCRIPTION

Temper Tensile (.500 Dia. Specimen) Hardness Shear Fatigue* Modulus

Ultimate Yield Elongation/4D

Brinell

500 kg

10 mm

Ultimate

Shearing

Strength

Endurance Limit -

R.R. Moore Type

Modulus of

Elasticity

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

3

Gpa

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

TYPICAL MECHANICAL PROPERTIES

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

KSI MPa KSI MPa % KSI MPa KSI MPa KSI x 10

T3 55 379 43 296 15 95 32 221 18 124 10.2 70

T8 59 407 45 310 12 100 35 241 18 124 10.2 70

Temper Corrosion Resistance Cold Workability

3

Machinability

3

Anodize Response

3

Brazeability

4

General

1

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

COMPARATIVE CHARACTERISTICS

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

Weldability

4

T3 D D C A C D D D D

T451 D D B A C D D D D

T8 D B D A C D D D D

Stress

2

Gas Arc Spot

*5 x 10E8 cycles of reversed stress

Alloys with A and B ratings can be used in industrial and seacoast atmospheres without protection. Alloys with C, D and E ratings generally should be protected

at least on faying surfaces.

2 Stress-corrosion cracking ratings are based on service experience and on laboratory tests of specimens exposed to the 3.5% sodium chloride alternate

immersion test.

A= No known instance of failure in service or in laboratory tests.

B= No known instance of failure in service; limited failures in laboratory tests of short transverse specimens.

C= Service failures with sustained tension stress acting in short transverse direction relative to grain structure; limited failures in laboratory tests of long

transverse specimens.

D= Limited service failures with sustained longitudinal or long transverse areas.

3 Ratings A through D for Workability (cold), A through E for Machinability and A through C for Anodize Response, are relative ratings in decreasing order of merit.

4 Ratings A through D for Weldability and Brazeability are relative ratings dened as follows:

A= Generally weldable by all commercial procedures and methods.

B= Weldable with special techniques or for specic applications that justify preliminary trials or testing to develop welding procedure and weld performance.

C= Limited weldability because of crack sensitivity or loss in resistance to corrosion and mechanical properties.

D= No commonly used welding methods have been developed.

Additional product data sheets including alloys 2014, 2017, 2219 and 7X49 are available at

Cold Finished

ASTM B211

AMS-QQ-A-225/3

APPLICABLE SPECIFICATIONS

Others

Weight %

Minimum

Maximum

CHEMICAL COMPOSITION LIMITS

Si

0.40

Fe

0.70

Cu

5.00

6.00

Pb*

0.20

0.4

Bi

0.20

0.6

Zn

0.30

Each

0.05

Total

0.15

R O D & B A R A L L O Y 2 0 1 1

Technical Data

Nominal Density (68 F / 20 C)

Melting Range

Specic Heat (212 F / 100 C)

Coefcient of Thermal Expansion

Thermal Conductivity (68 F / 20 C)

Electrical Conductivity (68 F / 20 C)

Characteristic

TYPICAL PHYSICAL PROPERTIES

English Metric

2.82 Mg/m

3

541 C - 638 C

864 J/kg - K

23.1 micro m/m - K

67 x 10

-6

m

3

/m

3

- K

152 W/m - K

173 W/m - K

0.102 lbs./in.

3

1005 F - 1180 F

0.206 BTU/lb. - F

12.8 micro in./in. - F

3.72 x 10

-5

in.

3

/in.

3

- F

88 BTU/ft. - hr. - F

100 BTU/ft. - hr. - F

45% IACS

39% IACS

142% IACS

123% IACS

Linear

68 F - 212 F

20 C - 100 C

Volumetric

68 F / 20 C

T3, T451

T8

Equal Volume

Equal Weight

T8

T3

T8

T3

*Effective May 1, 2009, the lead maximum limit was changed from 0.6% to 0.4% to be RoHS compliant. Material produced prior to that date may not be

RoHS compliant. If in doubt refer to the material certication that was supplied with the material.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Astm B 124 PDFDokumen5 halamanAstm B 124 PDFweltwind100% (1)

- Interpreting Phase DiagramsDokumen131 halamanInterpreting Phase Diagramsweltwind100% (2)

- Heat Treatment Procedure Qualification 836878 R20070802BDokumen96 halamanHeat Treatment Procedure Qualification 836878 R20070802BrecnessBelum ada peringkat

- The Florida Foreclosure Judge's Bench BookDokumen53 halamanThe Florida Foreclosure Judge's Bench BookForeclosure Fraud100% (4)

- TCDS E2gl CFM56 2 3Dokumen8 halamanTCDS E2gl CFM56 2 3weltwindBelum ada peringkat

- 7044M47G0X, TURBINE-CLEARANCE-CONTROL-CFM56-7061M31G0X 75-21-11 Rev 11, 10-31-99Dokumen175 halaman7044M47G0X, TURBINE-CLEARANCE-CONTROL-CFM56-7061M31G0X 75-21-11 Rev 11, 10-31-99weltwind100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Borehole Stability Analysis in Deepwater Shallow Sediments: Yan ChuanliangDokumen7 halamanBorehole Stability Analysis in Deepwater Shallow Sediments: Yan ChuanliangJose Leo MissionBelum ada peringkat

- NCHRP RPT 628Dokumen99 halamanNCHRP RPT 628cags15Belum ada peringkat

- Flexural TestDokumen8 halamanFlexural TestNawaf Al-TamimiBelum ada peringkat

- Perhitungan Struktur Pondasi Tower PLN Dengan Software AFES PDFDokumen28 halamanPerhitungan Struktur Pondasi Tower PLN Dengan Software AFES PDFwidyo saptotoBelum ada peringkat

- Declaration of Performance: DOP/BP/SC-Wall ElementsDokumen2 halamanDeclaration of Performance: DOP/BP/SC-Wall ElementsNickBelum ada peringkat

- LongitudinalShearReinforcementDesign C10 bk800 PDFDokumen7 halamanLongitudinalShearReinforcementDesign C10 bk800 PDFBehairy AhmedBelum ada peringkat

- GRADE 302: Element Content (%)Dokumen3 halamanGRADE 302: Element Content (%)Shashank Saxena100% (1)

- Reinforced Concrete DesignDokumen993 halamanReinforced Concrete DesignRizal RifdoBelum ada peringkat

- Investigation On The Mechanical Properties of A356 Alloy Reinforced Altib/Sic Composite by Semi-Solid Stir Casting MethodDokumen12 halamanInvestigation On The Mechanical Properties of A356 Alloy Reinforced Altib/Sic Composite by Semi-Solid Stir Casting MethodNatalino FonsecaBelum ada peringkat

- Timber 07Dokumen11 halamanTimber 07Mohammed Safaa Al SarrafBelum ada peringkat

- Analysis and Design of Slab Culvert With ManualDokumen3 halamanAnalysis and Design of Slab Culvert With ManualChaitanya KumbharBelum ada peringkat

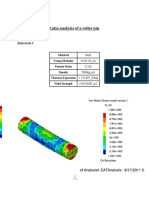

- Catia Analysis of A Roller PinDokumen15 halamanCatia Analysis of A Roller Pinanteneh tesfayeBelum ada peringkat

- Sizing Textile LearnerDokumen32 halamanSizing Textile Learnerfazrimajid13100% (1)

- Qatar Expressways Group 3 Design Basis Report For Bridge StructuresDokumen53 halamanQatar Expressways Group 3 Design Basis Report For Bridge StructuresReginaDeGuzmanBelum ada peringkat

- Modeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysDokumen26 halamanModeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysAhmed GomaaBelum ada peringkat

- Leaf SpringDokumen34 halamanLeaf SpringjonBelum ada peringkat

- 3 1 at The Proportional Limit A 12 InchDokumen34 halaman3 1 at The Proportional Limit A 12 InchAustin Duke100% (3)

- Melect 2: Strength of Materials, Shafting, Keys & Coupling, Belts, Chains & Sprockets, Bolts & ScrewsDokumen88 halamanMelect 2: Strength of Materials, Shafting, Keys & Coupling, Belts, Chains & Sprockets, Bolts & ScrewsLordesBelum ada peringkat

- ANSYS Static Structural AnalysisDokumen11 halamanANSYS Static Structural Analysissaravana kumarBelum ada peringkat

- Material Allowables Material AllowablesDokumen35 halamanMaterial Allowables Material AllowablesElzainie ShehabBelum ada peringkat

- Evaluation of Seismic Response Modification Factors For RCC Frames by Non Linear AnalysisDokumen6 halamanEvaluation of Seismic Response Modification Factors For RCC Frames by Non Linear AnalysisPrashant SunagarBelum ada peringkat

- AGK - Brosur CombigridDokumen15 halamanAGK - Brosur Combigridfahri fazriBelum ada peringkat

- Ultimate Load Capacity of Reinforced Concrete SlabDokumen8 halamanUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- CLT USA-Chapter-3 0Dokumen35 halamanCLT USA-Chapter-3 0Adam BartonBelum ada peringkat

- Zone of Infulence For Tunnel Intersection1Dokumen32 halamanZone of Infulence For Tunnel Intersection1roshansm1978Belum ada peringkat

- Chapter 10Dokumen41 halamanChapter 10cgctsBelum ada peringkat

- Strength of Material LabDokumen44 halamanStrength of Material LabDeepak SahBelum ada peringkat

- A Study of Metallurgical Factors For Defect Formation in Electric Resistance Welded API Steel PipesDokumen12 halamanA Study of Metallurgical Factors For Defect Formation in Electric Resistance Welded API Steel PipesSinan ChenBelum ada peringkat

- Exploring The Impact of Chloride-Induced Corrosion On Limit States and Residual Capacity of RC StructuresDokumen46 halamanExploring The Impact of Chloride-Induced Corrosion On Limit States and Residual Capacity of RC StructuresSofía Córdoba SáenzBelum ada peringkat

- Simulation On High Velocity Impact Process of Windshield by SPH/FEM Coupling MethodDokumen5 halamanSimulation On High Velocity Impact Process of Windshield by SPH/FEM Coupling MethodOlivier GouveiaBelum ada peringkat