NRDC Unofficial English Summary

Diunggah oleh

Vikas Kumar PandeyDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

NRDC Unofficial English Summary

Diunggah oleh

Vikas Kumar PandeyHak Cipta:

Format Tersedia

Summary of the Air Emission Standards on Thermal Power Plants

Unofficial Translation

The Emission Standard of Air Pollutants for Thermal Power Plants (GB 13223-2011) (The

Standard) was adopted by Chinas Ministry of Environmental Protection (MEP) on July 18, 2011,

and will be effective starting January 1, 2012. The Standard stipulates limitations on

concentrations of air pollutants in emissions from thermal power plants, including soot, SO2,

NOx, mercury and mercury compounds. The Standard does not apply to thermal power plants

using domestic waste or hazardous waste as fuels. The full text of the Standard is available

below: http://www.zhb.gov.cn/gkml/hbb/qt/201109/t20110921_217526.htm

KEY IMPROVEMENTS:

Compared to the earlier version, which was established in 2003, the Standard makes the

following major improvements:

The standards for soot, SO2, and NOx have been tightened considerably.

The Standard distinguishes existing and new sources for SO2 and NOx emissions; it

provides a 2.5-year grace period for existing sources.

Hg emissions will be controlled for the first time, starting January 1, 2015.

The Standard stipulates special limitations which are more stringent over air emissions

for key regions, where development is concentrated and environmental capacity is low.

These areas are defined by their weak atmospheric environmental capacity, vulnerable

ecological environment and major air pollution problems. However, the specific

geographic scope and timeline of these special limitations is subject to MEPs further

regulation.

EMISSION STANDARDS OF AIR POLLUTANTS FOR THERMAL POWER PLANTS

I. Pollutant emission control requirements

(Existing sources) From July 1, 2014, existing thermal power boilers and gas turbines

must be controlled under the limits of soot, sulfur dioxide, nitrogen oxides emissions

and blackness of smoke set forth in Table 1 below.

(New sources) From January 1, 2012, new thermal power boilers and gas turbines must

be controlled under the limits of soot, sulfur dioxide, nitrogen oxides emissions and

blackness of smoke set forth in Table 1.

(Mercury and mercury compound emissions) From January 1, 2015, coal-fired boilers

must be controlled under the limits of mercury and mercury compound emissions as

shown in Table 1.

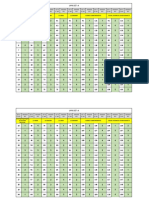

Table 1: Thermal Power Boiler and Gas Turbine Air Pollutant Emission Concentration Limits

Unitmg/m

3

not for smoke blackness level

No. Type of Energy

Conversion Facility

and Fuel

Pollutant Conditions Limits Location of

Emission

Control

1

Coal-fired boilers Soot All 30 Stack or flue

Sulfur Dioxide New Boiler 100

200

(1)

Existing Boiler 200

400

(1)

Nitrogen Oxides

(NO

2)

All 100

200

(2)

Mercury and

mercury

compounds

All 0.03

2 Oil-fired boilers or gas

turbines

Soot All 30

Sulfur Dioxide New boilers and

gas turbines

100

Existing boilers and

gas turbines

200

Nitrogen Oxides

(NO

2)

New oil-fired boiler 100

Existing oil-fired

boiler

200

Gas turbine 120

3 Gas-fired boilers or

gas turbines

Soot Natural gas boilers

and gas turbines

5

Other gas-fired

boilers and gas

turbines

10

Sulfur Dioxide Natural gas boilers

and gas turbines

35

Other gas fired

boilers and gas

turbines

100

Nitrogen Oxides

(NO

2)

Natural gas boiler 100

Other gas-fired

boiler

200

Natural gas turbine 50

Other gas-fired gas

turbine

120

4 Coal-fired, oil-fired,

gas-fired boilers or gas

turbines

Smoke Degree

(Ringelmann Smoke

Chart)

All 1 Stack Vent

Notes:

(1) to be located in Guangxi Zhuang Autonomous Region, Chongqing Municipality, Sichuan Province and

Guizhou Province, where the limits will be implemented with coal-fired boilers.

(2) Implementing limits on W-type thermal power generation boilers or furnace chamber flame boilers,

circulating fluidized bed (CFB) boilers, and boilers put into operation as of December 31, 2003 or through

the construction projects environmental impact reports approval of coal-fired power boilers.

II. Special Pollutant emission control requirements for key regions

Thermal power boilers and gas turbines located in key regions shall implement special air

pollutant emission limits set forth in Table 2. The geographic scope of key regions, timeline of

the special limits are subject to MEPs further regulation.

Table 2: Special Limits of Air Pollutant Emission Concentration for Key Regions

Unitmg/m

3

not for smoke blackness level

No. Type of Energy

Conversion

Facility and Fuel

Pollutant Conditions Limits Location of

Emission

Control

1 Coal-fired boilers Soot All 20 Stack or Flue

Sulfur Dioxide All 50

Nitrogen Oxides

(NO

2)

All 100

Mercury and mercury

compounds

All 0.03

2 Oil-fired boilers

or gas turbines

Soot All 20

Sulfur Dioxide All 50

Nitrogen Oxides

(NO

2)

Oil-fired boiler 100

Gas turbine 120

3 Gas-fired boilers

or gas turbines

Soot All 5

Sulfur Dioxide All 35

Nitrogen Oxides

(NO

2)

Gas boiler 100

Gas turbine 50

4 Coal-fired, oil-

fired, gas-fired

boilers or gas

turbines

Smoke Degree

(Ringelmann Smoke

Chart)

All 1 Stack Vent

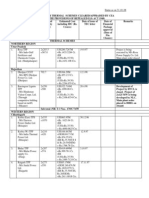

III. Environmental departments responsibilities over sensitive zones

The environmental departments are responsible for environmental quality monitoring in

surrounding residences, educational institutions, hospitals and other sensitive areas during the

operation of an existing thermal power boiler or gas turbine, and during environmental review

upon the completion of a construction project and its subsequent operation.

- The range of the monitoring should be the surrounding sensitive zones defined in the

EIA of the construction project;

- If there has not been an EIA conducted on an existing thermal power plant, the

environmental department should act in accordance with the characteristics and nature

of the discharge company and the local natural weather conditions and factors, with

reference to the environmental impact assessment guidelines.

The local government should be responsible for the environmental quality of its jurisdiction and

should take measures to ensure meeting the ambient environmental quality standards.

IV. The most stringent emission limits should be implemented over emission sources

with boilers established at different times, using a hybrid approach for smoke

discharge and choosing a monitoring location so that one can only monitor the

mixture of air pollutants in the stack emissions.

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- CG 13Dokumen1 halamanCG 13Vikas Kumar PandeyBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- VinuDokumen1 halamanVinuVamsi Krishna100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Exclusive Study Content of IBCS (Indian BOE Coaching Services)Dokumen8 halamanExclusive Study Content of IBCS (Indian BOE Coaching Services)Vikas Kumar PandeyBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Exclusive Study Content of IBCS (Indian BOE Coaching Services)Dokumen13 halamanExclusive Study Content of IBCS (Indian BOE Coaching Services)Vikas Kumar PandeyBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- TodaytvseriesDokumen1 halamanTodaytvseriesVikas Kumar PandeyBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- TodaytvseriesDokumen1 halamanTodaytvseriesVikas Kumar PandeyBelum ada peringkat

- UPTET Upper PRI - 2017AnswerKeyDokumen8 halamanUPTET Upper PRI - 2017AnswerKeyNDTV100% (1)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- BOE SyllabusDokumen2 halamanBOE Syllabussr_muleBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Orient Paper Mill Cpp-Amlai 25 MW Tripping HistoryDokumen4 halamanOrient Paper Mill Cpp-Amlai 25 MW Tripping HistoryVikas Kumar PandeyBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Trip or Failure Analysis ReportDokumen2 halamanTrip or Failure Analysis ReportVikas Kumar PandeyBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Afbc Boiler Light Up ProcedureDokumen4 halamanAfbc Boiler Light Up ProcedureRaj Kumar Ahmed86% (14)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- 1 ADokumen11 halaman1 AVikas Kumar PandeyBelum ada peringkat

- Course 15Dokumen2 halamanCourse 15Neelam NathBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Afbc Boiler Light Up ProcedureDokumen4 halamanAfbc Boiler Light Up ProcedureRaj Kumar Ahmed86% (14)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Sfantul Justin Popovici Omul Si Dumnezeul Om Abisurile Si Culmile FilozofieiDokumen220 halamanSfantul Justin Popovici Omul Si Dumnezeul Om Abisurile Si Culmile FilozofieinectarinaBelum ada peringkat

- TRG IstitututesDokumen5 halamanTRG IstitututesVikas Kumar PandeyBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Uttar Pradesh Papo Postal AssistantDokumen3 halamanUttar Pradesh Papo Postal Assistantarr_mnnitBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Uttar Pradesh Papo Postal AssistantDokumen3 halamanUttar Pradesh Papo Postal Assistantarr_mnnitBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- BOE SyllabusDokumen2 halamanBOE Syllabussr_muleBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- S No. Roll No Application No Candidate Name Category Disability DomainDokumen1 halamanS No. Roll No Application No Candidate Name Category Disability DomainVikas Kumar PandeyBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Private Thermal PPDokumen8 halamanPrivate Thermal PPmaheshwariinfraBelum ada peringkat

- International StrategyDokumen34 halamanInternational StrategymanicatewatiaBelum ada peringkat

- ITC Classmate-Market Research in MaduraiDokumen26 halamanITC Classmate-Market Research in Maduraipriyatrs06Belum ada peringkat

- RISC Vs CISC - The Post-RISC Era - Jon "Hannibal" StokesDokumen26 halamanRISC Vs CISC - The Post-RISC Era - Jon "Hannibal" Stokesjlventigan100% (1)

- Brochure 7900E EN PDFDokumen16 halamanBrochure 7900E EN PDFabvs97Belum ada peringkat

- Employee Departure Clearance FormDokumen1 halamanEmployee Departure Clearance FormJery TomBelum ada peringkat

- GET OA Doc - Batch 2Dokumen3 halamanGET OA Doc - Batch 2Ganesh Sai VelidiBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Improving Lives of South Sudanese Communities Through Water and Sanitation: The Story of Salva DutDokumen1 halamanImproving Lives of South Sudanese Communities Through Water and Sanitation: The Story of Salva DutUNICEF South SudanBelum ada peringkat

- Ee503 - Ic Fabrication and Packaging TechnologyDokumen34 halamanEe503 - Ic Fabrication and Packaging TechnologyPrevenaManiamBelum ada peringkat

- Serdes HandbookDokumen98 halamanSerdes HandbookRamesh YadavBelum ada peringkat

- 00 Its A OrderDokumen5 halaman00 Its A OrderJunky FoolBelum ada peringkat

- ESD PPT HKDokumen11 halamanESD PPT HKHarshvardhan MishraBelum ada peringkat

- C3704 2018 PDFDokumen122 halamanC3704 2018 PDFHaileyesus Kahsay100% (1)

- DC 850 X12 5010 I01 Purchase OrderDokumen40 halamanDC 850 X12 5010 I01 Purchase OrderGeervani SowduriBelum ada peringkat

- Manual - Submersible PumpDokumen4 halamanManual - Submersible PumpcodersriramBelum ada peringkat

- Acquisitions Bentley SystemsDokumen3 halamanAcquisitions Bentley SystemsPramit Kumar SenapatiBelum ada peringkat

- Oops-Program 10-MduDokumen6 halamanOops-Program 10-MduAtul MalhotraBelum ada peringkat

- Mamuli N22Dokumen28 halamanMamuli N22doubeBelum ada peringkat

- PSM 1-6-7 (Ic) Emma Work Cards R 20 (30-11-18)Dokumen322 halamanPSM 1-6-7 (Ic) Emma Work Cards R 20 (30-11-18)Héctor SánchezBelum ada peringkat

- Kapil Sharma ResumeDokumen4 halamanKapil Sharma ResumeKapil SharmaBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Dokumen43 halaman120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Mazariegôs JJBelum ada peringkat

- A1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767Dokumen16 halamanA1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767MuseBelum ada peringkat

- Electrical Equipment in Hazardous LocationsDokumen41 halamanElectrical Equipment in Hazardous LocationsSAYEDBelum ada peringkat

- Curriculum Vitae: Contact DetailsDokumen3 halamanCurriculum Vitae: Contact DetailsDhileepBelum ada peringkat

- Traditional Healer in Carletonville, Germiston, Johannesburg, Krugersdorp South Africa+27782669503Dokumen139 halamanTraditional Healer in Carletonville, Germiston, Johannesburg, Krugersdorp South Africa+27782669503mama shifahBelum ada peringkat

- Project SynopsisDokumen2 halamanProject SynopsisEkam JotBelum ada peringkat

- The Hydraulic Pumping SystemDokumen12 halamanThe Hydraulic Pumping SystemCarlos Lopez DominguezBelum ada peringkat

- 5065-Article Text-17890-1-10-20230110Dokumen18 halaman5065-Article Text-17890-1-10-20230110Januar KristianBelum ada peringkat

- TRIVAL ANTENE - General Catalogue 2015-10-0Dokumen232 halamanTRIVAL ANTENE - General Catalogue 2015-10-0Stanko Recek100% (1)

- Fully Automated Luxury CommunismDokumen8 halamanFully Automated Luxury CommunismNicoleta MeruțiuBelum ada peringkat