VSL Slab On Grade PDF

Diunggah oleh

Ahmed Hussein KamelDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

VSL Slab On Grade PDF

Diunggah oleh

Ahmed Hussein KamelHak Cipta:

Format Tersedia

V S L S L A B O N G R A D E

PROJECT ANALYSIS

DESIGN

POST-TENSIONING

CONSTRUCTION

FINISHING

Plaq Slab:Heavy Lifting 15/01/10 11:43 Page1

2 V S L S L A B O N G R A D E

The Company

VSLs special construction systems have been

used throughout the world since 1956. The

company operates on five continents as a

multinational group of companies through

35 subsidiaries. This worldwide network

ensures that clients benefit from the technical

THE VSL EXPERTISE AND SPECIALIST

CONSTRUCTION SERVICES

experience and knowledge developed and

shared between all of the subsidiaries. Clients

operating anywhere in the world can rely on the

leverage of VSLs commercial networking.

VSLs strength is its people, with more than

900 engineers worldwide focusing their efforts

on providing state-of-the-art and cost-

effective construction technologies.

Tailor-made solutions

VSLs approach is to provide a solution tailored

to the particular needs of each project. The VSL

Slab on grade system provides a high-quality

solution for concrete slabs that are placed

directly on the ground and offers great value

for money.

VSL guided by a strong QSE culture

VSLs leading position is based on a rigorous

and committed quality culture. The QSE

(quality, safety, environment) policy represents

a major focus for every service provided. Local

teams ensure co-ordination of actions,

encourage sharing of experience and promote

best practice, with the aim of continuously

improving performance. In VSLs culture,

employees are vitally important to the

competitiveness and prosperity of the

company. VSL is committed to maintaining the

highest levels of client satisfaction and

personnel safety.

Wal-Mart, Mexico - 2007

VSL is committed to being a valuable, reliable and trusted

construction partner, delivering high-quality performance

and efficiency for its customers.

Tenax project, Italy - 2006

Nestl Distribution Plant, Chile - 2002

Plaq Slab:Heavy Lifting 15/01/10 11:43 Page2

V S L S L A B O N G R A D E 3

Post-tensioned slabs on grade are used in

industrial structures where the main objective

is to eliminate most of the joints that are the

major weakness in concrete structures. The

VSL Post-Tensioning System allows a reduction

in the number of joints while keeping the

structure within allowable tensile stresses,

which leads to lower maintenance costs over

the design life of the slab.

Factors affecting industrial facilities

Differential temperature variations

Heavy traffic, such as trucks, forklifts

High abrasion from vehicle movements

Heavy loads from stocks

Risks of failure with conventional

solutions

The images above show failures in

conventionally reinforced concrete slabs on

grade or slabs with steel fibre reinforcement.

Requirements for an industrial

slab on grade

An industrial floor slab on grade should be

durable, free of excessive cracking, suitably

flat and able to withstand traffic loads.

Achieving these aims requires consultation

between the slab designer, owner,

geotechnical specialist and builder.

VSL deems it important to consider factors

including:

Environmental conditions

Site conditions

Traffic requirements

Loads on the slab

Slab thickness and reinforcement

requirements

Joint location and spacing

Method of slab construction.

Each of these considerations affects one or

more of the others.

PREVENTING

COSTLY REPAIRS

Abrasion

Expensive consequences of failures

Greater requirement for maintenance

of the joints

Slabs requiring repair

More frequent repair to rolling equipment

such as trucks and forklifts

Loss of productivity

Consequences of these failures can be expensive

to the owner. Large areas may become unusable,

which restricts operations and in some extreme

cases leads to closure of the facility.

The right solution

The VSL post-tensioned Slab on grade greatly

diminishes the risk of failures and is therefore

widely used in the construction of such

structures.

The system uses post-tensioning technology in

the design and construction of slab-on-grade

flooring and pavements. Compared with

conventional reinforcement, post-tensioning

provides a long service life and high loading

capacity, requires almost no maintenance and

retains a high resale value. The VSL Slab on

grade system has been used successfully

worldwide in various types of logistics and

manufacturing facilities, workshops and other

structures.

Delamination and spalling

Curling

Deformations

Cracking

Plaq Slab:Heavy Lifting 15/01/10 11:43 Page3

Providing the ultimate choice

in surface coatings

VSL Slab on grade produces the best possible

base for surface finish and gives the customer

the ultimate freedom of choice in coatings. The

eventual finish of the slab can be selected for

appropriate texture, hardness and colouring,

making it not only serviceable but also attractive.

Control of cracks

Post-tensioned slabs reduce

the risk of cracking more

effectively than other

reinforced slabs because of the

compressive forces that are

applied by the post-tensioning

cables.

Supporting any load

The VSL Slab on grade can be designed to

accommodate any loading requirement.

Fast-track construction

Post-tensioned slabs can be constructed much

faster than conventional reinforced slabs. Time

is also saved by using fewer joints and narrower

footings with less digging and less concrete.

Large pours of more than 2,500m

2

are a common

feature of post-tensioned slabs on grade.

4 V S L S L A B O N G R A D E

THE LIGHT SOLUTION FOR ANY CONDITIO N

Up to 30,000m

2

without joints

Large concrete areas can have their joint

spacing increased to minimise the costs of the

joints as well as the long-term maintenance and

operational costs. Use of the Slab on grade

solution also reduces the wear and tear caused

by moving equipment, extending the life of the

joints.

Providing customers with the optimum efficient structure is at the heart of the VSL Sl

The VSL Slab on grade system is economic to construct and maintain.

Plaq Slab:Heavy Lifting 15/01/10 11:43 Page4

V S L S L A B O N G R A D E 5

ON

More flexible slabs

A thinner slab is more flexible. In the event of

a large overload that may induce cracking,

the prestressing ensures that the slab returns

to its previous state when the load is removed.

In comparison, a weak point is more likely to

remain in the substructure with a conventional

reinforced slab, leading inevitably to

deterioration.

Flatter slabs

The risk of slab curling is greatly reduced with

fewer joints and greater joint spacing.

This produces a smoother ride and

less maintenance for forklifts.

Deflection control

Expansive soils, which expand when wet and

shrink when dry, can cause foundation

movements and cracking. Post-tensioning

increases the slabs flexural and tensile

capacities, making it more resistant to

problematic soils.

SL Slab on grade solution.

Reduced maintenance

The use of fewer - or even no - joints

significantly reduces the need for future

maintenance. Studies have shown that the

major costs over the life of a structure

involve joint maintenance. With a post-

tensioned slab, the costs of joint and crack

repair are reduced as too is the damage to

plant caused by breakdown of joints.

Plaq Slab:Heavy Lifting 15/01/10 11:43 Page5

6 V S L S L A B O N G R A D E

OPTIMISED COSTS

WITH POST-TENSIONING

Post-tensioning achieves the highest

efficiency, based on:

the external effects that apply to the structure

(including temperature, temperature

differential and loadings);

the internal effects such as concrete shrinkage;

the size of the structure;

the quality of the supporting ground, which

may require additional preparation to reach a

given standard.

The design of the VSL Slab on grade optimises

the overall cost to the client of the entire

structure, including cost of ground preparation

and the cost for the slab itself. The cost

optimisation is enhanced by the application and

effects of the post-tensioning that compensate

for any excess of tensile stresses in the structure.

The system uses an optimum combination of

post-tensioning, slab thickness and concrete

tensile strength to produce a cost-effective slab

on grade solution. Moreover, the design provides

a wider joint-free and crack-free area with

improved durability.

VSL Slab on grade:

Resisting tensile stresses

Concrete has limited capacity to resist tensile

stresses. For conventional reinforced concrete

slabs or slabs with steel fibre reinforcement,

the thickness and primary reinforcement are

increased so that the stresses do not exceed the

concrete tensile strength and satisfy the design

code requirements. Post-tensioning allows

balancing of the tensile stresses in the

concrete, leading to thinner slab and a great

reduction of conventional reinforcement.

Terminal Logistica MBopicua, Uruguay 2003

Coca Cola Megaplanta, Mexico - 2004

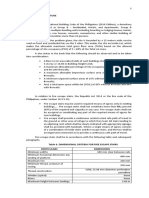

T1

L

P

P = Post-tensioning force

L = Live load

T1 = Temperature gradient

and concrete shrinkage

T2 = Differential of temperature

F = Subgrade friction

P

F

T2

Internal and external force that may affect a slab on grade.

Plaq Slab:Heavy Lifting 15/01/10 11:43 Page6

V S L S L A B O N G R A D E 7

ADAPTABLE AND VERSATILE

VSL Slab on grade can be applied to many

commercial and industrial situations, including

but not limited to:

Cool rooms and freezer storage facilities

Taxiways

Aircraft hangars

Heavy vehicle workshops

Manufacturing facilities

Lorry parks and roads

Warehouses and distribution centres

Rail and seaport container terminals

Water tanks

JOINT FREE

Aircraft hangars

HEAVY LOADS

Truck parks and roadways

AGRESSIVE ENVIRONMENTS

Seaport container terminals

WATER TIGHTNESS

Water tanks

HEAVY LOADS

Warehouse

and distribution centres

HEAVY LOADS

Manufacturing facilities

WIDE TEMPERATURE RANGE

Cool rooms and freezer

storage facilities

Plaq Slab:Heavy Lifting 15/01/10 11:44 Page7

8 V S L S L A B O N G R A D E

VSL YOUR PARTNER FOR A TURN KEY S

VSLs scope of work

VSL offers complete design, supply, installation

and stressing services to produce the finished

product:

1. Ground analysis

2. Preliminary design and quotations

3. Final design

4. Subgrade preparation

5. Supply and placing of the sand base and

plastic layer

6. Supply and installation of the normal

reinforcement associated with the

post-tensioned slab

7. Supply and placement of the post-tensioning

components and carrying out the post-

tensioning works

8. Supply, placing, finishing and curing of concrete

9. Final coating if required

Key aspects considered

by VSL include:

use of few or no joints depending on the

dimensions of the slab;

sub-base design to optimise slab and sub-

base costs for individual site conditions;

concrete properties to maximise durability and

strength while minimising the combined cost

of the concrete and post-tensioning;

pour size to provide a slab that has buildability

characteristics that match local capabilities;

1, 2, 3

4

5

9

design detailing to match project-specific

requirements such as a range of jointing

treatments depending on usage and tendon

positioning to suit fixed racking layouts.

Plaq Slab:Heavy Lifting 15/01/10 11:44 Page8

V S L S L A B O N G R A D E 9

Y SOLUTION

COATINGS AND FINISHING

The ultimate freedom of choice

The VSL Slab on grade with fewer joints and crack control

does not only produce a smoother ride for forklifts, but is

also the best possible base for eventual coatings.

Finishing is the operation of creating a concrete surface of

a desired texture, smoothness and durability. The finishing

can be strictly functional or decorative.

Warehouses and industrial floors usually have greater

durability requirements and need to be flat and level, while

other interior floors that are covered with floor coverings

such as epoxy finishing have to be smooth and durable.

A slab on grade that shows defects such as curling, cracks,

delaminations and spallings will have severe consequences

on the coating.

Different finishings and coatings are possible depending

on the appearance and material characteristics (polished

mirror finishing, half polished finishing, quartz finishing...).

The slabs mechanical properties also allow the best base

for particular coatings as the ones that belong to the three

overall coating families: synthetics (polyurethane or epoxy),

bitumen and cement.

6, 7

8

Hangar Mosnov, Czech Republic - 2007

Plaq Slab:Heavy Lifting 15/01/10 11:44 Page9

10 V S L S L A B O N G R A D E

SUSTAINABILITY

The VSL Slab on grade

uses up to 30% less

concrete, resulting

in 30% less CO2

emission, compared to

conventional reinforced

structures.

The quality of the VSL Slab on

grade system has been recognized

through a number of Awards:

2000

IVOR certificate stating that the VSL Slab

on grade System is a recognised technique

with regards to its durability.

2002

Award of the Concrete Institute and

Association of US engineers for the world s

flattest pavement.

2003

Award by Lockwood Greene Engineers

J.A. Jones Co. for the largest and flattest

post-tensioned pavement system in the

world.

2007

Golden Trowel Award issued by Face

for

the flattest and most level of the year.

VSL has shown that sustainable practices and

economic success can go hand-in-hand. The

VSL Slab on grade system offers a number of

advantages over traditional reinforced

concrete slabs:

Reduced concrete volumes

Reduced energy demand

Reduced emissions of greenhouse gases (CO2).

In addition to providing all the benefits that

customers are looking for and at a lower cost,

the VSL Slab on grade system offers further

advantages with regards to sustainable

development:

lower maintenance and repair costs through

the life of the slab due to the inherent

crack-inhibition properties of using

prestressing.

lower whole-life costs due to the extended

longevity of the VSL Slab on grade system

compared with plain reinforced concrete

slabs.

reduced volume of end-of-life demolition

and waste disposal with corresponding

reductions in costs.

Changing the way we do business

For VSL, sustainable development means

striking a balance in its development model

between the economic profitability of its

businesses and their social and

environmental impacts. This commitment

has been formalised into the VSL

Sustainability Development programme.

Plaq Slab:Heavy Lifting 15/01/10 11:44 Page10

V S L S L A B O N G R A D E 11

SYSTEMS & TECHNOLOGIES

Post-tensioning strand systems

Bars & post-tensioning bar systems

Stay cable systems

Damping systems (stays & buildings)

Ductal

UHP concrete

Bearings & Joints

www.vsl.com

Ground

anchors

GROUND ENGINEERING

VSoL

walls

D-walls

& Piles

Ground

improvement

Buildings

Slab on grade

Containment

structures

Bridges

Special

structures

CONSTRUCTION

Formwork &

Equipment

Heavy lifting

REPAIR, STRENGTHENING

& PRESERVATION

Repair &

Strengthening

Protection &

Preservation

Structural

diagnostics

& Monitoring

36.25

3178.25

Plaq Slab:Heavy Lifting 15/01/10 11:45 Page11

Copyright 2010, VSL International Ltd.

Printed in France patented.

The information set forth in this brochure including technical and

engineering data is presented for general information only. While every

effort has been made to insure its accuracy, this information should not be

used or relied upon for any specific application without independent

professional examination and verification of its accuracy , suitability and

applicability. Anyone using this material assumes any and all liability

resulting from such use. VSL disclaims any and all express or implied

warranties of merchantability fitness for any general or particular purpose or

freedom from infringement of any patent, trademark, or copyright in regard

to the information or products contained or referred to herein. Nothing

herein contained shall be construed as granting a license, express or

implied under any patents.

VSL LOCATIONS

www.vsl.com

Printed on paper

from sustainably

managed forests.

PHILIPPINES

VSL Philippines Inc.

PASIG CITY

Phone/Fax: +632 672 13 95

SINGAPORE

VSL Singapore Pte. Ltd.

SINGAPORE

Phone: +65 6559 12 22

Fax: +65 6257 77 51

TAIWAN

VSL Taiwan Ltd.

TAIPEI

Phone: +886 2 2759 6819

Fax: +886 2 2759 6821

THAILAND

VSL (Thailand) Co. Ltd.

BANGKOK

Phone: +66 2 679 76 15 - 19

Fax: +66 2 679 76 45

VIETNAM

VSL Vietnam Ltd.

HANOI

Phone: +84 4 3976 5088

Fax: +84 4 3976 5089

HO CHI MINH CITY

Phone: +84 8 810 6817

Fax: +84 8 810 6818

Australia

/

VSL Australia Pty. Ltd.

NEW SOUTH WALES

Phone: +61 2 9484 5944

Fax: +61 2 9875 3894

QUEENSLAND

Phone: +61 7 3265 64 00

Fax: +61 7 3265 75 34

VICTORIA

Phone: +61 3 979 503 66

Fax: +61 3 979 505 47

SOUTH AUSTRALIA

Phone: +61 8 8354 4884

Fax: +61 8 8354 4883

TASMANIA

Phone: +61 3 6225 3567

Fax: +61 3 6225 2226

PERTH

Phone/Fax: +61 8 9523 4686

Americas

/

ARGENTINA

VSL Sistemas Especiales de

Construccin Argentina SA

BUENOS AIRES

Phone: +54 11 4326 06 09

Fax: +54 11 4326 26 50

BOLIVIA

Postensados de Bolivia

SAN MIGUEL, LA PAZ

Phone: +591 2 27 70 338

Fax: +591 2 27 96 183

CHILE

VSL Sistemas Especiales de

Construccin S.A.

SANTIAGO

Phone: +56 2 571 67 00

Fax: +56 2 571 67 01

COLOMBIA

Sistemas Especiales de

Construccin S.A.S

BOGOTA

Phone: +57 1 226 62 30

Fax: +57 1 271 50 65

MEXICO

VSL Corporation Mexico S.A de C.V

MEXICO

Phone: +52 55 55 11 20 36

Fax: +52 55 55 11 40 03

PERU

Sistemas Especiales de Construccin

Peru S.A.

LIMA

Phone: +51 1 349 38 38

Fax: +51 1 348 28 78

UNITED STATES

VStructural LLC

BALTIMORE, MD

Phone: +1 410 850 7000

Fax: +1 410 850 4111

VENEZUELA

Gestin de Obras

y Construcciones C.A.

CARACAS

Phone/Fax: +58 212 941 86 75

Africa

/

EGYPT

Matrix Engineering Company

CAIRO

Phone: +20 2 344 19 00

Fax: +20 2 346 04 57

SOUTH AFRICA

Tsala-RMS Construction Solutions

(Pty) Ltd

JOHANNESBURG

Phone: +27 11 878 6820

Fax: +27 11 878 6821

Europe

/

AUSTRIA

Grund-Pfahl- und Sonderbau

GmbH

HIMBERG

Phone: +43 2235 87 777

Fax: +43 2235 86 561

CROATIA

Tehnicki projekt d.o.o.

ZAGREB

Phone: +385 1 4664 586

Fax: +385 1 4664 549

CZECH REPUBLIC

VSL Systems (CZ) Ltd.

PRAGUE

Phone: +420 2 51 09 16 80

Fax: +420 2 51 09 16 99

FRANCE

VSL France S.A.

LABGE

Phone: +33 05 61 00 96 59

Fax: +33 05 61 00 96 62

GERMANY

VSL Systems GmbH

BERLIN

Phone: +49 30 530 28 06-0

Fax: +49 30 530 28 06-99

GREAT BRITAIN

VSL Systems (UK) Ltd.

BEDFORDSHIRE

Phone: +41 58 456 30 30

Fax: +41 58 456 30 35

NETHERLANDS

Heijmans Beton en Waterbouw B.V.

ROSMALEN

Phone: +31 73 543 66 02

Fax: +31 73 543 66 11

NORWAY

Spennarmering Norge AS

RUD

Phone: +47 98 21 02 66

Fax: +47 67 17 30 01

Middle East

/

UNITED ARAB EMIRATES

VSL Middle East LLC

DUBAI, UAE

Phone: +971 4 885 7225

Fax: +971 4 885 7226

Asia

/

BRUNEI

VSL Systems (B) Sdn. Bhd.

BRUNEI DARUSSALAM

Phone: +673 2 380 153 / 381 827

Fax: +673 2 381 954

CHINA PRC

VSL (China) Engineering

Corp., Ltd.

HEFEI

Phone: +86 551 382 29 18

Fax: +86 551 382 28 78

HONG KONG

VSL Hong Kong Ltd.

CHAI WAN

Phone:+852 2590 22 88

Fax: +852 2590 02 90

Intrafor Hong Kong Ltd.

CHAI WAN

Phone:+852 2836 31 12

Fax: +852 2591 61 39

FT Laboratories Ltd.

PING CHE

Phone: +852 2758 48 61

Fax: +852 2758 89 62

INDIA

VSL India PVT Ltd.

CHENNAI

Phone: +91 44 4225 11 11

Fax: +91 44 4225 10 10

INDONESIA

PT VSL Indonesia

JAKARTA

Phone: +62 21 570 07 86

Fax: +62 21 573 75 57

JAPAN

VSL Japan Corporation

TOKYO

Phone: +81 3 3346 8913

Fax: +81 3 3345 9153

KOREA

VSL Korea Co. Ltd.

SEOUL

Phone: +82 2 553 8200

Fax: +82 2 553 8255

MALAYSIA

VSL Engineers (M) Sdn. Bhd.

KUALA LUMPUR

Phone: +603 7981 47 42

Fax: +603 7981 84 22

PORTUGAL

VSL Sistemas Portugal

Pre-Esforo, Equipamento

e Montagens S.A.

PAO DE ARCOS

Phone: +351 21 445 83 10

Fax: +351 21 444 63 77

VSL GEO

Sistemas de Aplicao

em Geotecnia SA

PAO DE ARCOS

Phone: + 351 21 445 83 10

Fax: + 351 21 445 83 28

SPAIN

CTT Stronghold

BARCELONA

Phone: +34 93 289 23 30

Fax: +34 93 289 23 31

VSL-SPAM, S.A.

BARCELONA

Phone: +34 93 846 70 07

Fax: +34 93 846 51 97

SWEDEN

Internordisk Spnnarmering AB

VSTERHANINGE

Phone: +46 10 448 74 29

Fax: +46 8 753 49 73

SWITZERLAND

VSL (Switzerland) Ltd.

SUBINGEN

Phone: +41 58 456 30 30

Fax: +41 58 456 30 35

VSL (Suisse) SA

SAINT LEGIER

Phone: +41 58 456 30 00

Fax: +41 58 456 30 95

TURKEY

Mega Yapi Construction &

Trade Co. Ltd

ANKARA

Phone: +90 312 490 90 66

Fax: +90 312 490 90 55

Headquarters

VSL International Ltd.

Scheibenstrasse 70

CH-3014 Bern

Switzerland

Phone: +41 58 456 30 00

Fax: +41 58 456 30 95

^

Plaq Slab:Heavy Lifting 15/01/10 11:45 Page12

Anda mungkin juga menyukai

- Basic Concepts, Rectangular and T Beams PDFDokumen49 halamanBasic Concepts, Rectangular and T Beams PDFAhmed Hussein KamelBelum ada peringkat

- Designers' Guide To en 1992-1-1 and en 1992-1-2Dokumen234 halamanDesigners' Guide To en 1992-1-1 and en 1992-1-2Ahmed Hussein Kamel100% (4)

- Statics of Bending Shear and Bending Moment DiagramsDokumen12 halamanStatics of Bending Shear and Bending Moment Diagramsapi-3710585100% (1)

- Design of Concrete Structures, 13th Edition (Arthur Nilson, Et - Al)Dokumen783 halamanDesign of Concrete Structures, 13th Edition (Arthur Nilson, Et - Al)Kashif ShamasBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- ECON 304 Course ContentDokumen2 halamanECON 304 Course ContentAanand JhaBelum ada peringkat

- Final PaperDokumen12 halamanFinal PaperReikooBelum ada peringkat

- Storage Tank Design Calculation - Api 650: Close Floating RoofDokumen32 halamanStorage Tank Design Calculation - Api 650: Close Floating RoofhgagBelum ada peringkat

- A Research Paper On DormitoriesDokumen5 halamanA Research Paper On DormitoriesNicholas Ivy EscaloBelum ada peringkat

- 107 01 Covers and Side Doors A SideDokumen38 halaman107 01 Covers and Side Doors A Sideben vervuurtBelum ada peringkat

- English Action Plan 2023-2024Dokumen5 halamanEnglish Action Plan 2023-2024Gina DaligdigBelum ada peringkat

- Mini Riset Bahasa Inggris BisnisDokumen10 halamanMini Riset Bahasa Inggris BisnissyahsabilahBelum ada peringkat

- FC Exercises3Dokumen16 halamanFC Exercises3Supertj666Belum ada peringkat

- Bibliografi 3Dokumen3 halamanBibliografi 3Praba RauBelum ada peringkat

- Executive Shirt CompanyDokumen6 halamanExecutive Shirt CompanyPramod kBelum ada peringkat

- Vernacular in Andhra PradeshDokumen1 halamanVernacular in Andhra PradeshNandyala Rajarajeswari DeviBelum ada peringkat

- D4530Dokumen5 halamanD4530rimi7al100% (1)

- Faculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityDokumen59 halamanFaculty of Civil Engineering and Planning Civil Engineering Department Petra Christian Universitykenny lieBelum ada peringkat

- Chemistry Project Paper ChromatographyDokumen20 halamanChemistry Project Paper ChromatographyAmrita SBelum ada peringkat

- What Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?Dokumen3 halamanWhat Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?miretade titoBelum ada peringkat

- Class 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDokumen12 halamanClass 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDiksha TBelum ada peringkat

- LV SWBDQualityInspectionGuideDokumen72 halamanLV SWBDQualityInspectionGuiderajap2737Belum ada peringkat

- GS Ep Tec 260 enDokumen61 halamanGS Ep Tec 260 enCesarBelum ada peringkat

- Final Exam DiassDokumen9 halamanFinal Exam Diassbaby rafa100% (3)

- Unit 3 Approaches To The Study of Medieval Urbanisation : StructureDokumen20 halamanUnit 3 Approaches To The Study of Medieval Urbanisation : StructureSunil SunilBelum ada peringkat

- Imarest 2021 Warship Development 1997Dokumen43 halamanImarest 2021 Warship Development 1997nugrohoBelum ada peringkat

- Rail Inspection Vehicle Using Ir Sensor and Spot Marking SystemDokumen63 halamanRail Inspection Vehicle Using Ir Sensor and Spot Marking SystemNarayananNanuBelum ada peringkat

- Nteq Lesson PlanDokumen4 halamanNteq Lesson Planeva.bensonBelum ada peringkat

- Student Material CN Version - 2017.11.10Dokumen25 halamanStudent Material CN Version - 2017.11.10Jagaddeesha BRBelum ada peringkat

- Integrated Curriculum For Secondary Schools: Mathematics Form 2Dokumen139 halamanIntegrated Curriculum For Secondary Schools: Mathematics Form 2Izawaty IsmailBelum ada peringkat

- Floor DiaphragmDokumen24 halamanFloor DiaphragmChristian LeobreraBelum ada peringkat

- Straightforward Pre-Intermediate Progress Test 4: Language Section VocabularyDokumen8 halamanStraightforward Pre-Intermediate Progress Test 4: Language Section VocabularyStrange BrawlerBelum ada peringkat

- Preview - ISO+8655 6 2022Dokumen6 halamanPreview - ISO+8655 6 2022s7631040Belum ada peringkat

- Gravitational Fields 1Dokumen18 halamanGravitational Fields 1Smart linkBelum ada peringkat

- Headworks & Barrage: Chapter # 09 Santosh Kumar GargDokumen29 halamanHeadworks & Barrage: Chapter # 09 Santosh Kumar GargUmer WaheedBelum ada peringkat