Mathematical and Computational Applications, Vol. 18, No. 2, pp.122-131, 2013

Diunggah oleh

Ilman FauzaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Mathematical and Computational Applications, Vol. 18, No. 2, pp.122-131, 2013

Diunggah oleh

Ilman FauzaHak Cipta:

Format Tersedia

Mathematical and Computational Applications, Vol. 18, No. 2, pp.

122-131, 2013

FINITE ELEMENT MODELING OF FRICTION STIR WELDING IN

ALUMINUM ALLOYS JOINT

Binnur Gren Kral

1,*

, Mustafa Tabanolu

2

, H. Tark Serinda

2

1

Dokuz Eylul University, Department of Mechanical Engineering, 35397, Tnaztepe,

Izmir, Turkey

2

Dokuz Eylul University, The Graduate School of Natural and Applied Sciences,

Izmir, Turkey

binnur.goren@deu.edu.tr, mustafa_tabanoglu@yahoo.com, tarik.serindag@deu.edu.tr

Abstract - This study aims to model friction stir welding of the aluminum alloys using

the finite element method. For this purpose, transient thermal finite element analyses are

performed in order to obtain the temperature distribution in the welded aluminum plate

during the welding operation. Heat input from the tool shoulder and the tool pin are

considered in the finite element model. A moving heat source with a heat distribution

simulating the heat generated from the friction between the tool shoulder and the work

piece is used in the heat transfer analysis. Three-dimensional models are carried out by

using ANSYS and HyperXtrude commercial softwares. APDL (ANSYS Parametric

Design Language) code is developed to model moving heat source and change boundary

conditions.

Key Words: Friction stir welding, Finite element analyses, Al6061, Transient thermal

analysis.

1. INTRODUCTION

Friction stir welding (FSW) is a novel solid-state joining process that may have

significant advantages compared to the fusion processes as follow: Joining of

conventionally non-fusion weldable alloys, reduced distortion and improved mechanical

properties of weldable alloys joints due to the pure solid-state joining of metals. In a

typical FSW, a rotating cylindrical pin tool is forced to plunge into the plates to be

welded and moved along their contact line. During the welding, heat is generated by

contact friction between the tool and workpiece softens the material. Since no melting

occurs during FSW, the process is performed at much lower temperatures than

conventional welding techniques. Because of the highest temperature is lower than the

melting temperature of the material, FSW yields fine microstructure [1].

Although it is a new welding technology, the FSW has been extensively studied

both numerically and experimentally. Chen and Kovacevic studied on the finite element

analysis of the thermal history and thermomechanical process in the butt-welding of

aluminum alloy 6061- T6 [2]. Buffa et al. proposed a 3D FEM model for the FSW

process that is thermo-mechanically coupled and with rigid-viscoplastic material

behavior [3]. Nandan et al. modeled three-dimensional viscoplastic flow and

temperature field during FSW of 304 austenitic stainless steel mathematically [4].

Chao et al. formulated the heat transfer of the FSW process into two boundary value

problems (BVP)-a steady state BVP for the tool and a transient BVP for the workpiece.

Finite Element Modeling of Friction Stir Welding 123

They carried out the finite element analyses to determine the heat flux generated from

the friction to the workpiece and the tool [5]. Zhang et al. developed solid mechanics-

based finite element models and computational procedures to study the flowpatterns and

the residual stresses in FSW. They presented two-dimensional results of the material

flow patterns and the residual stresses and investigated the flow of metal during FSW.

They showed that the flows on the advancing side and retreating side are different. They

investigated the residual stresses of the welded plate. They concluded that with the

increase of the translational velocity, the maximum longitudinal residual stress can be

increased [6]. Hamilton et al. developed a thermal model of FSW that utilizes a new slip

factor based on the energy per unit length of weld. The slip factor was derived from an

empirical, linear relationship observed between the ratio of the maximum welding

temperature to the solidus temperature and the welding energy [7]. Song and Kovacevic

presented a three-dimensional heat transfer model for FSW. They introduced a moving

coordinate to reduce the difficulty of modeling the moving tool and considered heat

input from the tool shoulder and the tool pin in their model. The finite difference

method was applied in solving the control equations. They concluded that preheat to the

workpiece is beneficial to FSW [8]. Rajamanickam et al. investigated the effect of

process parameters such as tool rotation and weld speed on temperature distribution and

mechanical properties of aluminum alloy AA2014 joined by friction stir welding. A

three dimensional transient thermal model using finite element code ANSYS was

developed and experimentally validated to quantify the thermal history [9].

Soundararajan et al. developed a thermo-mechanical model with both tool and

workpiece using mechanical loading with thermal stress to predict the effective stress

development at the bottom of workpiece with uniform boundary conditions. They used

the stress to define the adaptable contact conductance values in the thermal model at the

workpiece-backing plate interface and measured the temperatures at various locations

during experiment using thermocouples to validate the finite element model predictions

[10].

In the present study, the modeling of FSW process is carried out using the finite

element method. Transient thermal finite element analyses are performed in order to

obtain the temperature distribution in the welded aluminum plate during the welding

operation. A moving heat source with a heat distribution simulating the heat generated

from the friction between the tool shoulder and the work piece is used in the heat

transfer analysis. Three-dimensional models are carried out by using ANSYS and

HyperXtrude commercial softwares. APDL (ANSYS Parametric Design Language)

code is developed to model moving heat source and change boundary conditions. The

usage of APDL code removes the necessity of using ANSYS user interface. Advantage

of ANSYS software is that the temperature outputs can be obtained at every desired

time step.

2. HEAT GENERATION

Heat source during welding is considered as the friction between the rotating tool and

the welded workpieces. The heat is generated at the interface of the tool shoulder and

workpiece and tool pin and workpiece due to friction. The heat generated at the surface

124 B. Gren Kral, M. Tabanolu and H. T. Serinda

of the tool is transferred into the tool following the Fouriers law of heat conduction

[10]. The heat transfer equation for the tool in a static coordinate system is

|

.

|

\

|

c

c

c

c

+

|

|

.

|

\

|

c

c

c

c

+

|

.

|

\

|

c

c

c

c

=

c

c

z

T

k

z y

T

k

y x

T

k

x t

T

C

z y x p

(1)

where T is the temperature, C

p

is heat capacity, is the density and k is the heat

conductivity that varies with temperature in the calculations. The aluminum workpiece

is an isotropic material properties, so that the identical value of thermal conductivity is

used for all three directions.

Convection at the sides of the workpiece and tool is represented based on Newtons law

of cooling as

( )

amb

T T h

n

T

k =

c

c

(2)

where T

amb

is ambient temperature.

The torque required to rotate a circular shaft relative to the plate surface under the

action of an axial load is given by [11]

3

R

0

2

M

0

PR

3

2

dr r 2 ) r ( P dM

R

t = t =

} }

(3)

where M is the interfacial torque, is the friction coefficient, R is the surface radius,

and P(r) is the pressure distribution across the interface. If all the shearing work at the

interface is converted into frictional heat, the average heat input per unit area and time

becomes

} }

t e = e =

R

0

2

M

0

1

dr r 2 ) r ( P dM Q

R

(4)

where Q

1

is the net power [W], is the angular velocity [rad/s] and P is the pressure

[MPa]. The pressure P cannot exceed the actual flow stress of the material at the

operating temperature [11]. Q

1

is the heat generated by the shoulder.

Figure 1. Three-dimensional model of the friction stir welding process.

Heat input depends both on rotational speed and the shoulder radius. These parameters

are the main process variables in friction stir processing. The ratio of heat generated

from the pin, Q

2

and the heat generated from the shoulder, Q

1

is 0.128 [11, 12].

Shoulder

Pin

Finite Element Modeling of Friction Stir Welding 125

The initial temperature of the workpiece is assumed to be equal to the ambient

temperature (25

o

C). A convection coefficient of 30 W/m

2

C is applied at the top and

side surfaces of the workpiece. Since the value of conductive coefficient between the

workpiece and the backing plate is not known, convective coefficient of 300 W/m

2

C is

applied to the bottom surface of the work piece [11].

3. FINITE ELEMENT ANALYSES

3.1. Modeling

Two 6061-T6 Al alloy plates, each with a dimension of 150 200 3.1 mm are

butt welded in the adapted vertical milling machine for FSW when HyperXtrude

program is used. Because of the symmetry only one plate is modeled in ANSYS

program. In the present thermal analysis, the workpiece is meshed using a brick element

called SOLID70 when ANSYS software is used. This element has a three-dimension

thermal conduction capability and can be used for a three-dimensional, steady-state or

transient thermal analysis. The element is defined by eight nodes with temperature as

single degree of freedom at each node and by the orthotropic material properties [13].

An advantage of using this element is that, the element can be replaced by an equivalent

structural element for the structural analysis. Figure 2 shows the finite element model of

the aluminum workpiece generated by ANSYS software. For the finite element analyses

by ANSYS, APDL (ANSYS parametric design language) is used to develop a

subroutine for a transient moving heat source model. Transient finite element analyses

are performed considering moving heat source.

Results obtained using ANSYS are compared to the results obtained using

Friction Stir Welding Module of HyperXtrude software. Figure 3 shows the modeling of

FSW carried out using HyperXtrude software.

Figure 2. Finite element model of the aluminum workpiece by ANSYS software.

126 B. Gren Kral, M. Tabanolu and H. T. Serinda

Figure 3. Modeling of FSW by HyperXtrude software.

3.2. Defining of Material Properties and Boundary Conditions

Thermal conductivity, k and heat capacity, C

p

are dependent on temperature. Table 1

presents the variation of material properties of AA6061-T6 with respect to temperature

used in the finite element analyses.

Table 1. Variation of material properties of AA6061-T6 with respect to temperature.

T (

o

C) k (W/m

o

C) C

p

(J/kg

o

C)

-17.8 162 904

37.8 162 945

93.3 177 978

148.9 184 1004

204.4 192 1028

260 201 1052

315.6 207 1078

371.1 217 1104

426.7 223 1133

571.1 253 1230

Figure 4 presents the boundary conditions of FSW process modeled. As seen from the

figure, heat flux is applied on the interface of tool shoulder and pin and workpiece.

Convection coefficients of 30 W/m

2

C and 300 W/m

2

C are applied at the top and side

surfaces of the work piece and to the bottom surface of the workpiece, respectively.

Figure 4. Boundary conditions.

Finite Element Modeling of Friction Stir Welding 127

The flowchart for transient thermal analysis is shown in Figure 5.

Figure 5. Flowchart for transient thermal finite element analysis

4. RESULTS

In the present study, the modeling of friction stir welding is carried out using

both ANSYS and HyperXtrude commercial softwares. APDL (ANSYS Parametric

Design Language) code is developed for transient thermal analyses. Transient thermal

finite element analyses are performed in order to obtain the temperature distribution in

the welded aluminum plates during the welding operation.

Figures 4 and 5 show the temperature profiles in the workpiece during the

welding operation for e=800 rev/min, v= 2.5 mm/s and v= 5 mm/s. As seen from the

figures, temperature values obtained by ANSYS and HyperXtrude agree with each

other.

Start

Preprocessing

Generating of Geometry of

Workpiece

Preprocessing

Defining of Element Type and Materials Properties

Solution

Applying of Boundary Conditions and

Heat Generation, Start Solution

Postprocessing

Reading of Nodal Temperatures

Solution

Calculating of nodal temperatures

Last Load Step

Solution

Moving of Heat Source and Changing of

Thermal Boundary Conditions

128 B. Gren Kral, M. Tabanolu and H. T. Serinda

Figure 4. Temperature distributions obtained (a) by ANSYS (b) HyperXtrude softwares

in welded AA 6061-T6 plates for e=800 rev/min and v= 2.5 mm/s.

Figure 5. Temperature distributions obtained (a) by ANSYS (b) HyperXtrude softwares

in welded AA 6061-T6 plates for e=800 rev/min and v= 5 mm/s.

The input welding parameters used in the finite element calculations are presented in

Table 2.

Table 2. Input welding parameters.

A B C D E F

Rotational speed (rev/min) 800 1000 1200 800 1000 1200

Transverse speed (mm/s) 2.5 2.5 2.5 5 5 5

Table 3. Temperature values obtained by HyperXtrude software.

Rotational speed (rev/min) Transverse speed (mm/s) Temperature (

o

C)

A 800 2.5 440.355

B 1000 2.5 460.778

C 1200 2.5 484.401

D 800 5 430.572

E 1000 5 452.443

F 1200 5 478.449

Finite Element Modeling of Friction Stir Welding 129

Table 3 shows the maximum temperatures obtained by finite element analyses using

HyperXtrude software. The transverse speeds considered are 2.5 and 5 mm/s while the

tool rotational speeds are 800, 1000 and 1200 rev/min. As seen from the table,

temperature during the welding increases as the rotational speed increases and the

transverse speed decreases.

Figure 6. Comparison of results obtained by ANSYS and HyperXtrude.

Figure 6 shows the comparison of the maximum temperature occurred during friction

stir welding modeled by ANSYS and HyperXtrude. As seen from the figure, the

maximum temperature increases gradually as the rotational speed increases and

transverse speed decreases when HyperXtrude software is used. Dotted lines show the

results obtained running APDL code developed in ANSYS software. The differences

between the results stem from the mathematical models used in the softwares.

0

100

200

300

400

500

600

0 50 100 150 200

Time (s)

T

e

m

p

e

r

a

t

u

r

e

(

o

C

)

A_N1 B_N1 C_N1

D_N1 E_N1 F_N1

Figure 7. Temperaturetime profile for location N1.

130 B. Gren Kral, M. Tabanolu and H. T. Serinda

Figures 7 and 8 show the transient temperatures from the numerical calculations

carried out using ANSYS for locations N1 and N2. As seen from the figures,

temperature increases while the rotational speed of the tool increases and transverse

speed decreases. The maximum temperatures obtained from the numerical analyses near

the weld are higher than recrystalizing temperature of the aluminum.

The relation between tool holding time and temperature during FSW process is

shown in Figure 9. As seen from the figure, as the tool holding time is increased, the

maximum temperature near the weld increases. The increase of this processing

parameter results in more extensive stirring or sufficient heat input during the FSW

process. The weld microstructures vary significantly depending on tool holding time as

well as tool rotational and transverse speeds.

0

50

100

150

200

250

300

350

400

450

500

0 50 100 150 200

Time (s)

T

e

m

p

e

r

a

t

u

r

e

(

o

C

)

A_N2 B_N2 C_N2

D_N2 E_N2 F_N2

Figure 8. Temperaturetime profile for location N2.

0

50

100

150

200

250

300

350

400

450

0 50 100 150 200

time (s)

T

e

m

p

e

r

a

t

u

r

e

(

o

C

)

10 s

20 s

30 s

40 s

Figure 9. Temperaturetime profile for location N1 with respect to holding time.

5. CONCLUDING REMARKS

In the present study, the modeling of friction stir welding is carried out using the

transient finite element analyses. A moving heat source with a heat distribution

simulating the heat generated from the friction between the tool shoulder and the

Finite Element Modeling of Friction Stir Welding 131

workpiece is used in the heat transfer analysis. It is observed that the maximum

temperature near the weld increases as the tool holding time and rotational speed are

increased. Temperature decreases as the tool transverse speed increases. Additionally, it

can be concluded that use of a moving heat source technique is proved to be a reliable

method to simulate friction stir processing.

Acknowledgement- Authors wish to thank TIRSAN Kardan Inc. for invaluable helps in

the use of HyperXtrude Software.

6. REFERENCES

1. M.B. Bilgin, C. Meran, The effect of tool rotational and traverse speed on friction stir

weldability of AISI 430 ferritic stainless steels, Materials&Design 33, 376383, 2012.

2. C.M. Chen, R. Kovacevic, Finite element modeling of friction stir welding-thermal

and thermomechanical analysis, International Journal of Machine Tools & Manufacture

43, 13191326, 2003.

3. G. Buffa, J. Hua, R. Shivpuri, L. Fratini, A continuum based fem model for friction

stir weldingmodel development, Materials Science and Engineering A 419 389396,

2006.

4. R. Nandan, G.G. Roy, T. J. Lienert and T. DebRoy, Numerical modelling of 3D

plastic flow and heat transfer during friction stir welding of stainless steel, Science and

Technology of Welding and Joining 11, 5 52-537, 2006.

5. Y.J. Chao, X. Qi, W. Tang, Heat transfer in friction stir welding-Experimental and

numerical studies, Transactions of the ASME 125, 138-145, 2003.

6. H.W. Zhang, Z.Zhang, J.T.Chen, The finite element simulation of the friction stir

welding process. Materials Science and Engineering A 403, 340348, 2005.

7. C. Hamilton, S. Dymek, A. Sommers (2008) A thermal model of friction stir welding

in aluminum alloys, International Journal of Machine Tools & Manufacture 48, 1120

1130, 2008.

8. M. Song, R. Kovacevic, Thermal modeling of friction stir welding in a moving

coordinate system and its validation, International Journal of Machine Tools &

Manufacture 43, 605615, 2003.

9. N. Rajamanickam, V.Balusamy, G.Madhusudhanna Reddy, K.Natarajan, Effect of

process parameters on thermal history and mechanical properties of friction stir welds,

Materials&Design 30 27262731, 2009.

10. V. Soundararajan, S. Zekovic, R. Kovacevic, Thermo-mechanical model with

adaptive boundary conditions for friction stir welding of Al 6061, International Journal

of Machine Tools & Manufacture 45 15771587, 2005.

11. K.H. Vepakomma, Three dimensional thermal modeling of friction stir processing

MSc Thesis, The Florida State University College of Engineering, 2006.

12. H. Schmidt, J. Hattel, J. Wert, An Analytical Model for the Heat Generation in

Friction Stir Welding, Modelling and Simulation in Material Science Engineering 12

143157, 2004.

13. ANSYS 10.0 Documentation.

Anda mungkin juga menyukai

- 7206 9292 1 PB PDFDokumen11 halaman7206 9292 1 PB PDFMichael SerraBelum ada peringkat

- Thermal Analysis On Butt Welded Aluminium Alloy AA7075 Plate Using FEMDokumen5 halamanThermal Analysis On Butt Welded Aluminium Alloy AA7075 Plate Using FEMInnovative Research PublicationsBelum ada peringkat

- 2005 - Karpat - Workpiece Material Model Based Predictions For Machining ProcessesDokumen8 halaman2005 - Karpat - Workpiece Material Model Based Predictions For Machining ProcessesKiran KolluruBelum ada peringkat

- Residual Stress Evaluation in Butt-Welded IN718 Plates: M. Jeyakumar, T. Christopher, R. Narayanan and B. Nageswara RaoDokumen12 halamanResidual Stress Evaluation in Butt-Welded IN718 Plates: M. Jeyakumar, T. Christopher, R. Narayanan and B. Nageswara RaoCJBAS ManagerBelum ada peringkat

- Finite Element Prediction of Temperature Rise Distribution in Turning Process of AISI 1045 Carbon SteelDokumen19 halamanFinite Element Prediction of Temperature Rise Distribution in Turning Process of AISI 1045 Carbon Steelasitzone4uBelum ada peringkat

- Analysis of Friction Stir Welds. Part I: Transient Thermal Simulation Using Moving Heat SourceDokumen10 halamanAnalysis of Friction Stir Welds. Part I: Transient Thermal Simulation Using Moving Heat SourceZahi AekBelum ada peringkat

- Numerical Simulation of Friction Stir WeldingDokumen6 halamanNumerical Simulation of Friction Stir WeldingJitender KunduBelum ada peringkat

- PJST13 1 48Dokumen15 halamanPJST13 1 48Jeevanandam ShanmugasundaramBelum ada peringkat

- Ijmet: ©iaemeDokumen9 halamanIjmet: ©iaemeIAEME PublicationBelum ada peringkat

- Transient Temperature Distribution in A Steel Rod Subjected To Friction WeldingDokumen11 halamanTransient Temperature Distribution in A Steel Rod Subjected To Friction WeldingMuhammad Fatka FirmansyahBelum ada peringkat

- Study On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationDokumen7 halamanStudy On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationAr PanBelum ada peringkat

- Int Journal LisDokumen24 halamanInt Journal LissaranBelum ada peringkat

- An Improved Thermal Model For Machine Tool Bearings: Xu Min, Jiang Shuyun, Cai YingDokumen10 halamanAn Improved Thermal Model For Machine Tool Bearings: Xu Min, Jiang Shuyun, Cai Yingemreali1Belum ada peringkat

- 1 s2.0 S0735193323004682 MainDokumen17 halaman1 s2.0 S0735193323004682 Maina84407151Belum ada peringkat

- 3D Modelling of A Multi Pass Dissimilar Tube Welding and Post Weld Heat Treatment of Nickel Based Alloy and Chromium SteelDokumen7 halaman3D Modelling of A Multi Pass Dissimilar Tube Welding and Post Weld Heat Treatment of Nickel Based Alloy and Chromium Steelkaliappan45490Belum ada peringkat

- Pengelasan FadliDokumen8 halamanPengelasan Fadliumi kulsumBelum ada peringkat

- Manuscript R 1 FDokumen30 halamanManuscript R 1 FNaser KhalidBelum ada peringkat

- Mathematical Model To Predict Heat Flow in Underwater Friction Stud WeldingDokumen4 halamanMathematical Model To Predict Heat Flow in Underwater Friction Stud WeldingArun KumarBelum ada peringkat

- An Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningDokumen8 halamanAn Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed Machiningkuba DefaruBelum ada peringkat

- Welding Distortion Control in Thin Metal Plates by Altering Heat Input Through Weld ParametersDokumen7 halamanWelding Distortion Control in Thin Metal Plates by Altering Heat Input Through Weld ParametersGanesh R NairBelum ada peringkat

- 6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysDokumen12 halaman6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysMuhammad Umer Farooq AwanBelum ada peringkat

- Mathematical Modeling of Surface Heat Flux During Quenching - MMTB, 2010 PDFDokumen11 halamanMathematical Modeling of Surface Heat Flux During Quenching - MMTB, 2010 PDFtazzBelum ada peringkat

- Study On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationDokumen7 halamanStudy On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationManuel CarreñoBelum ada peringkat

- 3-Dimensional Nonlinear Finite Element Analysis of Both Thermal and Mechanical Response of Friction Stir Welded 6061-T6 Aluminum PlatesDokumen6 halaman3-Dimensional Nonlinear Finite Element Analysis of Both Thermal and Mechanical Response of Friction Stir Welded 6061-T6 Aluminum PlatesspiritveluBelum ada peringkat

- An Investigation of Analytical Modelling of Friction Stir WeldingDokumen12 halamanAn Investigation of Analytical Modelling of Friction Stir WeldingTJPRC PublicationsBelum ada peringkat

- Study of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsDokumen12 halamanStudy of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsMuhammad Fatka FirmansyahBelum ada peringkat

- Determination of Temperature Distribution in The Cutting Zone PDFDokumen8 halamanDetermination of Temperature Distribution in The Cutting Zone PDFJuri JurieBelum ada peringkat

- Finite Element Analysis of Heat Flow inDokumen5 halamanFinite Element Analysis of Heat Flow inWilly Villa SalsavilcaBelum ada peringkat

- Finite Difference Simulation of Low Carbon Steel Manual Arc WeldingDokumen8 halamanFinite Difference Simulation of Low Carbon Steel Manual Arc WeldingRami GhorbelBelum ada peringkat

- Komanduri Part 1Dokumen38 halamanKomanduri Part 1El Mehdi MakaveliBelum ada peringkat

- Finite Element Simulation of Temperature and Strain Distribution in Al2024 Aluminum Alloy by Friction Stir WeldingDokumen5 halamanFinite Element Simulation of Temperature and Strain Distribution in Al2024 Aluminum Alloy by Friction Stir Weldingabhilash sharanBelum ada peringkat

- A Computational Approach To Evaluate Temperature and Heat Partition in Machining With Multilayer Coated ToolsDokumen7 halamanA Computational Approach To Evaluate Temperature and Heat Partition in Machining With Multilayer Coated Toolsamit chapagainBelum ada peringkat

- Z. Gao, F. Krumphals, P. Sherstnev, N. Enzinger, J.T. Niu, C. SommitschDokumen7 halamanZ. Gao, F. Krumphals, P. Sherstnev, N. Enzinger, J.T. Niu, C. SommitschmaximBelum ada peringkat

- Finite Element Analysis On Temperature Distribution of Turning ProcessDokumen6 halamanFinite Element Analysis On Temperature Distribution of Turning ProcessIJMERBelum ada peringkat

- Sensors 15 01274Dokumen18 halamanSensors 15 01274Hugo CostaBelum ada peringkat

- A Study On Numerical Analysis of The Resistance Spot Welding ProcessDokumen6 halamanA Study On Numerical Analysis of The Resistance Spot Welding Processkiran_wakchaureBelum ada peringkat

- Finite Element Modelling of Temperature Distribution in The Cutting Zone in Turning Processes With Differently Coated Tools - 2005 - Journal of MaterialsDokumen8 halamanFinite Element Modelling of Temperature Distribution in The Cutting Zone in Turning Processes With Differently Coated Tools - 2005 - Journal of MaterialsRiston SinagaBelum ada peringkat

- Numerical Simulation of Titanium Alloy Machining in Electric Discharge Machining ProcessDokumen6 halamanNumerical Simulation of Titanium Alloy Machining in Electric Discharge Machining Processchiru1431Belum ada peringkat

- Effect of Temperature Distribution in UltrasonicallyDokumen13 halamanEffect of Temperature Distribution in Ultrasonicallyyangyaqing121Belum ada peringkat

- Materials Science and TechnologyDokumen27 halamanMaterials Science and TechnologyzainyousafzaiBelum ada peringkat

- Temperature Distribution Modeling of Friction Stir Spot Welding of Aa 6061-T6 Using Finite Element TechniqueDokumen14 halamanTemperature Distribution Modeling of Friction Stir Spot Welding of Aa 6061-T6 Using Finite Element TechniqueBosco BeloBelum ada peringkat

- Study of The Gaussian Distribution Heat Source Model Applied To Numerical Thermal Simulations of TIG Welding ProcessesDokumen8 halamanStudy of The Gaussian Distribution Heat Source Model Applied To Numerical Thermal Simulations of TIG Welding ProcessesCabra VolklingenBelum ada peringkat

- CFD Analysis of An Elliptical Pin Fin Heat Sink Using Ansys Fluent v12.1Dokumen8 halamanCFD Analysis of An Elliptical Pin Fin Heat Sink Using Ansys Fluent v12.1Kelsey RyanBelum ada peringkat

- Heat Transfer Analysis During Friction Stir Welding of Al6061-T6 AlloyDokumen8 halamanHeat Transfer Analysis During Friction Stir Welding of Al6061-T6 AlloyfabiskrujaBelum ada peringkat

- 2 Arm ThermalDokumen11 halaman2 Arm ThermalnguyenphucthuanBelum ada peringkat

- Estimation of Thickness in Thermal Barrier Coatings by Using Pulse Phase ThermographyDokumen6 halamanEstimation of Thickness in Thermal Barrier Coatings by Using Pulse Phase ThermographyInternational Journal of Application or Innovation in Engineering & ManagementBelum ada peringkat

- Optimization of Tool Wear: A ReviewDokumen8 halamanOptimization of Tool Wear: A ReviewIJMERBelum ada peringkat

- Transient Thermal Analysis of Different Types of IC Engine Cylinder Fins by Varying Thickness and Introducing SlotsDokumen18 halamanTransient Thermal Analysis of Different Types of IC Engine Cylinder Fins by Varying Thickness and Introducing SlotsTERALA BHANUPRAKASHBelum ada peringkat

- 3d Heat Transfer Analysis and Numerical Modeling of LENSTM Process For One End Stepped Cylindrical Wall by Using Stainless Steel 304Dokumen5 halaman3d Heat Transfer Analysis and Numerical Modeling of LENSTM Process For One End Stepped Cylindrical Wall by Using Stainless Steel 304IJMERBelum ada peringkat

- An Experimental and Coupled Thermo-Mechanical Finite Element Study of Heat Partition Effects in MachiningDokumen17 halamanAn Experimental and Coupled Thermo-Mechanical Finite Element Study of Heat Partition Effects in Machiningamit chapagainBelum ada peringkat

- Welding Process Simulation Model For Temperature and Residual Stress AnalysisDokumen8 halamanWelding Process Simulation Model For Temperature and Residual Stress AnalysisOmar MasmoudiBelum ada peringkat

- Electrothermal Analysis OfElectric Resistance Spot Welding Processes by A 3-D Finite ElementDokumen6 halamanElectrothermal Analysis OfElectric Resistance Spot Welding Processes by A 3-D Finite ElementBharadwajaChennupatiBelum ada peringkat

- Calculation of T by Response Surface Methodology For Electric Arc Welding ApplicationsDokumen10 halamanCalculation of T by Response Surface Methodology For Electric Arc Welding ApplicationsRicardo HernandezBelum ada peringkat

- Modeling of Electro Discharge Machining in Aisi 304 Material Ijariie1221 Volume 1 13 Page 188 197Dokumen10 halamanModeling of Electro Discharge Machining in Aisi 304 Material Ijariie1221 Volume 1 13 Page 188 197Eric CookBelum ada peringkat

- Casting-Mold Thermal Contact Heat Transfer During Solidification of Al-Cu-Si Alloy (LM21) Plates in Thick and Thin MoldsDokumen6 halamanCasting-Mold Thermal Contact Heat Transfer During Solidification of Al-Cu-Si Alloy (LM21) Plates in Thick and Thin MoldsJinsoo KimBelum ada peringkat

- Pressure Vessel Cylinder Thermal StressDokumen9 halamanPressure Vessel Cylinder Thermal Stresstabloid07Belum ada peringkat

- Heat Transfer Analysis of Pin Fin Array: March 2014Dokumen6 halamanHeat Transfer Analysis of Pin Fin Array: March 2014Dinu ChoudharyBelum ada peringkat

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsDari EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilBelum ada peringkat

- Autodesk WorkshopDokumen1 halamanAutodesk WorkshopIlman FauzaBelum ada peringkat

- Avenged Sevenfold - Dear GodDokumen2 halamanAvenged Sevenfold - Dear GodMade Dwiana SwulungganiBelum ada peringkat

- Rumus ChainDokumen2 halamanRumus ChainIlman FauzaBelum ada peringkat

- 14.5 Ansys CFX TutorialsDokumen792 halaman14.5 Ansys CFX TutorialsIlman Fauza0% (1)

- KELEN HB 07 eDokumen40 halamanKELEN HB 07 enhblinh100% (2)

- NLG CKP FG 22 Sep 2021 1734Dokumen614 halamanNLG CKP FG 22 Sep 2021 1734Operational NLGBelum ada peringkat

- Beneficiation of AvocadoDokumen10 halamanBeneficiation of AvocadoJUANBelum ada peringkat

- 5 Electricity Test AnswersDokumen4 halaman5 Electricity Test AnswersnajehBelum ada peringkat

- Hybrid Geosynthetic Paving Mat For Highway ApplicationsDokumen4 halamanHybrid Geosynthetic Paving Mat For Highway ApplicationsmithileshBelum ada peringkat

- Electrical Actuator 21 31 42 Datasheet English PDFDokumen4 halamanElectrical Actuator 21 31 42 Datasheet English PDFHeru Purwanto HeruBelum ada peringkat

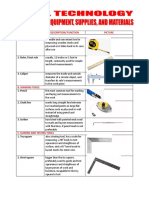

- Tool/ Equipment Description/ Function Picture A. Measuring ToolsDokumen13 halamanTool/ Equipment Description/ Function Picture A. Measuring ToolsNicolas AntiguaBelum ada peringkat

- Activity 2 - Erika Liliana Verdugo Aguilar.Dokumen3 halamanActivity 2 - Erika Liliana Verdugo Aguilar.Erika AguilarBelum ada peringkat

- Dalipay and Plastics As An Alternative Components of Hollow BlocksDokumen21 halamanDalipay and Plastics As An Alternative Components of Hollow BlocksJoross CuadraBelum ada peringkat

- Checklist To Design AssembliesDokumen1 halamanChecklist To Design AssembliesRobert GalarzaBelum ada peringkat

- Non-Cycling Refrigerated Dryer 200-800 SCFMDokumen24 halamanNon-Cycling Refrigerated Dryer 200-800 SCFMCarlos Jiménez100% (1)

- Jurnal SanitasiDokumen12 halamanJurnal SanitasiAnnisa FadlilahBelum ada peringkat

- Datasheet, Fittings 2Dokumen40 halamanDatasheet, Fittings 2happyhackBelum ada peringkat

- Nonferrous Nuts For General UseDokumen10 halamanNonferrous Nuts For General Usejuniuni18100% (2)

- Ce 326 Principles of Environmental Engineering: SPRING 2010Dokumen2 halamanCe 326 Principles of Environmental Engineering: SPRING 2010Jorge Gomez RamirezBelum ada peringkat

- Contractor Job Safety PlanDokumen15 halamanContractor Job Safety PlanAnonymous ocCa18RBelum ada peringkat

- Tutorial Sheets-CHEM2002-2017-2018 PDFDokumen18 halamanTutorial Sheets-CHEM2002-2017-2018 PDFajali1957Belum ada peringkat

- Toyota Cressida/Supra 7m Service ManualDokumen98 halamanToyota Cressida/Supra 7m Service Manualmidgo100% (2)

- Pipe Standrad ASTMDokumen4 halamanPipe Standrad ASTMTrà Nguyễn100% (1)

- Elements - turbine-Turbo-TOC KaydonDokumen3 halamanElements - turbine-Turbo-TOC KaydonnguyenanhtuanbBelum ada peringkat

- Prepare Plumbing Materials and ToolsDokumen9 halamanPrepare Plumbing Materials and ToolsDanjo Fernandez0% (1)

- Is 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsDokumen10 halamanIs 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsNadeem KhanBelum ada peringkat

- Linear ScaleDokumen19 halamanLinear ScaleHà ChínhBelum ada peringkat

- Waste Water Treatment Using Electrocoagulation TechnologyDokumen4 halamanWaste Water Treatment Using Electrocoagulation TechnologyKetan V. JoshiBelum ada peringkat

- Xseries Wrap Around Bottle HeaterDokumen2 halamanXseries Wrap Around Bottle HeaterNoneBelum ada peringkat

- Untitled DocumentDokumen3 halamanUntitled DocumentRoxan MoraBelum ada peringkat

- Hoja Técnica Lanco 1890 CDokumen2 halamanHoja Técnica Lanco 1890 CBryan GavilanezBelum ada peringkat

- Dow Coring Asia ManualDokumen69 halamanDow Coring Asia ManualGULJAR SINGHBelum ada peringkat

- CountryProfile ProductMetadataforSectorDokumen232 halamanCountryProfile ProductMetadataforSectorMeenakshi JaikrishnanBelum ada peringkat

- Spaulding Lighting Tequesta (Square) Spec Sheet 1-83Dokumen2 halamanSpaulding Lighting Tequesta (Square) Spec Sheet 1-83Alan Masters100% (1)