TI - GB5497-1985 Inspection of Grain and Oilseeds - Methods For Determination of Moisture Content

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TI - GB5497-1985 Inspection of Grain and Oilseeds - Methods For Determination of Moisture Content

Hak Cipta:

Format Tersedia

Regional Economic Cooperation and Integration in Asia

Technical Inputs

National Standard of Peoples Republic of China

GB5497-85

Inspection of grain and oilseeds

Methods for determination of moisture content

Imprint

Published by the

Deutsche Gesellschaft fr

Internationale Zusammenarbeit (GIZ) GmbH

Registered offices

Bonn and Eschborn, Germany

Regional Economic Cooperation and Integration in Asia

China Office

TaYuan Diplomatic Office

14 Liangmahe South Street, Chaoyang District

10600 Beijing, PR China

T +86-10-8532-5344

F +86-10-8532-5744

Office Mongolia

Naiman Zovkhi Building

Seoul Street 21

Ulaanbaatar 14251, Mongolia

rci-asia@giz.de

www.giz.de

As at

September 2014

Photo credits

Copyrights for all pictures: GIZ

Copyright for cover picture: GIZ/ Ursula Meissner

Text

Shenzhen Institute of Standards and Technology (SIST), Shenzhen, PR China

The findings and conclusions expressed in this documentation are entirely those of the authors. They do not necessarily repre-

sent the view of the Deutsche Gesellschaft fr Internationale Zusammenarbeit (GIZ) or further organising parties. The informa-

tion provided is without warranty of any kind.

On behalf of the German Federal Ministry for Economic Cooperation and Development (BMZ)

UDC (633.1+633.85)

.001.4

National Standard of the Peoples Repuli of China

GB 5497-85

Inspection of grain and oilseeds

Methods for determination of moisture content

Issue Date: Nov 2, 198 Implementation Date: July 1, 1985

Issued by Standardization Administration of the Peoples Republic of China (SAC)

The standard is applicable to determination of moisture content in commodity grain

and oilseeds.

1. 105 burning constant weight method

1.1 Apparatus

1.1.1 Electric thermostatic box;

1.1.2 Analytical balance: precision is 0.001 g;

1.1.3 Electric or manual grinder used in laboratory;

1.1.4 Sieve;

1.1.5 Desiccator with an allochroic silicagel (the allochroic silicagel could

not be used if it turns red. It could be used after it is baked at the

temperature between 130-140and turns into blue);

1.1.6 Aluminum box: diameter 4.5 cm, height 2.0 cm.

1.2 Test sample preparation

To choose some samples from the average samples, and prepare by the

following methods:

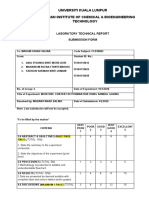

List of sample preparation methods

Grain type Quantity, g Preparation methods

Granular

unprocessed

grain or

processed grain

30~50 Remove big foreign matter and mineral

substances, grinding fineness sieve

through 1.5mm hole no less than 90%

Soybean 30~50 Remove big foreign matter and mineral

substances, grinding fineness sieve

through 2.0mm hole no less than 90%

Peanuts, etc.

About 50 Take clean kernels and use manual

grinder or small knife to cut them into

slices which are less than 0.5mm

Peanut, tea seed,

seed of tung

tree, seed of

castor,

shiny-leaved

yellowhorn, etc.

About 100 Take clean kernels (seeds) and remove

the shell, weight them separately to

calculate the percentage of kernel and

shell; grated the shell; cut the kernels

into slices

Cotton seed,

sunflower seed,

etc.

About 30 Take clean seeds and cut them or crack

them

Rapeseed,

sesame, etc.

About 30 Remove the big foreign matter

Sweet potato

slices

About 100 Take clean slices then grinding into the

same size with granular grains

Sweet potato

silk, sweet

About 100 Take clean silk, strip then grinding into

the same size with granular grains

potato strip

1.3 Operation methods

1.3.1 Set temperature: put the mercury ball of the thermometer which is

in the drying box 2.5 cm away from the drying net, set the

temperature at 1052.

1.3.2 Dry the aluminum box: take a clean aluminum box, put it on the

drylng neL below Lhe LhermomeLers mercury ball in the drying box.

Heat the aluminum box for 30min to 1 hour then take it out. Put it

into the desiccator and cool it down. Take it out and weigh it, reheat

it for 30min. If the weight difference between two results is no

more than 0.005 g, such weight shall be regarded as constant

weight.

1.3.3 Weigh the sample: heat the aluminum box (W

0

) to constant weight

and put 3 g sample into the box. The samples of oilseeds which are

in husk can be weighed by the proportion of kernels and shells, or

the samples of kernels and shells can be weighed separately.

1.3.4 Dry the sample: put the aluminum cover under the bottom of the

aluminum box. Put it on the drying net around the thermometer in

the drying box, heat the aluminum box for 3 hours (90min for

oilseeds) at 105and take it out of the drying box, put on the cover,

let it cool down in the desiccator then weight it. Repeat the process

in every 30min till the weight difference is less than 0.005 g

between two results. If the second weight is heavier than the first

one, then calculate the water content by the first weight (W

2

).

1.4 Result calculation

The water content of grain and oilseed is calculated by formula (1):

Water content (%)=

100(1)

Where:

W

0

---- weight of aluminum box, g

W

1

--- sample before heating and weight of aluminum box, g

W

2

--- sample after heating and weight of aluminum box, g

If the water content of the kernels and shell of the oilseed in husk is

determined separately, the water content of oilseeds in husk is calculated

by formula (2):

Water content (%)=M1A+M2(1-A)..(2)

Where:

M

1

--- water percentage in kernels, %

M

2

--- water percentage in shells, %

A---percentage of total kernels, %

If the acceptable difference between two test results is no more than 0.2%,

the average of the two results should be regarded as the determination

result, which keeps 1 bit behind the decimal point. If other methods are

taken to measure the water content, the difference between the two

results should not be more than 0.5%.

2. Constant time and temperature drying method

2.1 Instrument and appliance: same with 1.1

2.2 Sample preparation: same with 1.2

2.3 Calculate the constant sample: quantitative samples are used in this

method. Firstly, calculate the bottom area of the aluminum box. Then,

calculate the quantity of samples by 0.126 g/square centimeter (bottom

area0.126). If aluminum box with diameter of 4.5 cm is used, the

quantity of samples is 2 g; if aluminum box with diameter of 5.5 cm is used,

the quantity of samples is 3 g.

2.4 Operation methods

Use the aluminum box which has already been heated to constant weight

to calculate constant sample (precise to 0.001 g). After the temperature of

the drying box reaches 135~145C put the aluminum box with samples in

it on the drying net around the thermometer in the drying box. Turn the

temperature in the drying box to 1302C in 5min and start counting. After

40min, take the aluminum box out of the drying box and put it into the

desiccator. Calculate its weight after it cools down.

2.5 Result calculation: same with 1.4

3. Tunnel drying box method

3.1 Apparatus

3.1.1 Tunnel drying box

3.1.2 Stopwatch

3.2 Sample preparation: same with 1.2.

3.3 Operation methods

3.3.1 Setting temperature: Level the instrument. Put the thermometer

into the drying box and let the mercury ball be 1 cm away from the

entry of the drying box, turn on power and set the temperature.

3.3.2 Weigh the sample in the drying box: Put three clean drying boxes

into the drying room, put one more in after 10min. So, the first

drying box will be pushed out of the tunnel. Put this drying box on

the weighing pan and add a 10 g weight. Adjust the screws on the

quadrant balance and make the pointer pointing at 0. Take off the

weight in the drying box and put some samples in it to make the

pointer pointing at 0 again. Then, level the sample in the drying box

evenly and put it into the drying room. Close the left door and start

timing.

3.3.3 Dry the sample: if the samples are heated at 160C for 20min, put a

drying box with sample in it into the drying room every 6min and

40s. If the samples are heated at 130C for 30min, put a drying box

with samples in it into the drying room every 10min. When the

fourth sample box is put in, the first sample box has already

finished heating. Then, weigh the first box, observe the number to

which the pointer points. The number is the water percentage

measured.

The difference between the two test results shall be no more than

0.5%.

4. Twice drying method

If the moisture of grain is more than 18%, bean and sweet potato slices 14%,

oil moisture 13%, twice drying method could be used.

4.1 First drying: weigh sample of complete kernel for 20 g (W

1

accurate to

0.001), put it into a drying box with diameter of 10 or 15 cm, and height of

2 cm and level the sample. Heat for 30~40min at 105for grain and at 70

for bean and oilseeds. Take out the drying box, let it cool down to constant

weight, the result will be the weight of first drying (W

1

).

4.2 Second drying: sample preparation and operation methods are the same

as 1.2 and 1.3.

4.3 Result calculation

Calculation of water content by twice drying method should follow the

formula (3):

Moisture content (%) =

WWWW

WW

100(3)

Where:

W=weight before first drying, g;

W

1

= weight after first drying, g;

W

2

= weight before second drying, g;

W

3

= weight after second drying, g.

The difference between two test results should be no more than 0.2%. The

average of the two test data will be regarded as the test result, which keeps 1 bit

behind the decimal point.

Additional information

The standard is proposed by Ministry of Business of the People's Republic of China

1

.

1he sLandard ls drafLed by MlnlsLry of 8uslness of Lhe eoples 8epubllc of Chlna

Bureau of Grain Storage and Transportation.

Main drafters of this standard: Gao Xiuwu, Yang Haoran, Wu Yanxia and Lv Guifen.

1

Replaced by the present Ministry of Commerce of the People's Republic of China

Registered offices

Bonn and Eschborn, Germany

T +49 228 44 60-0 (Bonn)

T +49 61 96 79-0 (Eschborn)

Dag-Hammarskjld-Weg 1-5

65760 Eschborn, Germany

T +49 61 96 79-0

F +49 61 96 79-11 15

E info@giz.de

I www.giz.de

Regional Economic Cooperation and Integration in Asia

Office China

Ta Yuan Diplomatic Office

14 Liangmahe South Street, Chaoyang District

100600 Beijing, PR China

Office Mongolia

Naiman Zovkhis Building

Seoul Street 21,

Ulaanbaatar 14251, Mongoli

E rci-asia@giz.de

Anda mungkin juga menyukai

- Pressure Canning for Beginners: The Ultimate Guide on How to Can Meals, Vegetables and Meat in a JarDari EverandPressure Canning for Beginners: The Ultimate Guide on How to Can Meals, Vegetables and Meat in a JarPenilaian: 3 dari 5 bintang3/5 (2)

- Method 2.1 2014Dokumen3 halamanMethod 2.1 2014Thanh HươngBelum ada peringkat

- Gravimetric Analysis TechniquesDokumen23 halamanGravimetric Analysis TechniquesJAN JERICHO MENTOYBelum ada peringkat

- 5 2012JPN105DEG YabeDokumen18 halaman5 2012JPN105DEG Yabekomang ayu ratnawatiBelum ada peringkat

- NDF - AnkomDokumen2 halamanNDF - AnkomSilva, M.S.J.Belum ada peringkat

- Determination of Moisture in FoodsDokumen9 halamanDetermination of Moisture in Foodsagdwiyanti100% (1)

- Determinationofseedmoisture Usharani 170731103129Dokumen32 halamanDeterminationofseedmoisture Usharani 170731103129Sabrina CruzBelum ada peringkat

- method_2.2_2014Dokumen4 halamanmethod_2.2_2014FelisbertoBelum ada peringkat

- Determination of Dry Matter and AshDokumen2 halamanDetermination of Dry Matter and AshLochi GmBelum ada peringkat

- Moisture ContentDokumen8 halamanMoisture ContentHafrizDaniel0% (1)

- Solubility and Softening Point TestsDokumen22 halamanSolubility and Softening Point Testsসামিউল হাসান শান্তBelum ada peringkat

- Manual HL-340 Series 2017Dokumen16 halamanManual HL-340 Series 2017mathias scheuat100% (3)

- Practical Manual - Processing of Spices and Plantation CropsDokumen26 halamanPractical Manual - Processing of Spices and Plantation CropsDhaya VBelum ada peringkat

- Wa0001Dokumen27 halamanWa0001RamyaBelum ada peringkat

- 34) Extraction of Bitumen From Paving MixturesDokumen6 halaman34) Extraction of Bitumen From Paving MixturesPn EkanayakaBelum ada peringkat

- Proximate Analysis in 4 StepsDokumen4 halamanProximate Analysis in 4 StepsDhvanit JoshiBelum ada peringkat

- Important Dry Matter Analysis Techniques for Forage Nutrient DeterminationDokumen15 halamanImportant Dry Matter Analysis Techniques for Forage Nutrient DeterminationHikmat UllahBelum ada peringkat

- Fat-Soxhlet, by Acid HydrolysisDokumen2 halamanFat-Soxhlet, by Acid HydrolysisAnju DoraisamyBelum ada peringkat

- Grain Size Analysis Procedure 06-12-26Dokumen9 halamanGrain Size Analysis Procedure 06-12-26anthonyBelum ada peringkat

- Moisture ContentDokumen3 halamanMoisture ContentAli RazuBelum ada peringkat

- 10 MW TPP Coal TestingDokumen13 halaman10 MW TPP Coal TestingUmesh ShahBelum ada peringkat

- Aplication Fat Extraction FoodDokumen6 halamanAplication Fat Extraction FoodKu BonBelum ada peringkat

- Procedure For Water Sorptivity Test: 1.1 Personnel, Material, and Equipment RequirementsDokumen5 halamanProcedure For Water Sorptivity Test: 1.1 Personnel, Material, and Equipment RequirementsShyamBelum ada peringkat

- Water Sorptivity Test ProcedureDokumen5 halamanWater Sorptivity Test ProcedureShyamBelum ada peringkat

- Determination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process SamplesDokumen9 halamanDetermination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process SamplesShahram HawramiBelum ada peringkat

- Method Acid Hydrolysis AnkomDokumen2 halamanMethod Acid Hydrolysis AnkomThamrongsak HannarongBelum ada peringkat

- Methods For The Determination of Overall Migration Into Aqueous Simulants Using A PouchDokumen7 halamanMethods For The Determination of Overall Migration Into Aqueous Simulants Using A PouchRamSagareBelum ada peringkat

- Tss LabDokumen6 halamanTss LabnurinBelum ada peringkat

- MFIDokumen14 halamanMFIAnuj GuptaBelum ada peringkat

- Total Suspended SolidsDokumen3 halamanTotal Suspended SolidsOpata OpataBelum ada peringkat

- Study The Effect of Material/temperature On Rate of DryingDokumen23 halamanStudy The Effect of Material/temperature On Rate of DryingNayyerShahBelum ada peringkat

- Humidade Cereais AACC44-15Dokumen4 halamanHumidade Cereais AACC44-15G_ASantosBelum ada peringkat

- Waqtc BookDokumen117 halamanWaqtc BookHaftari HarmiBelum ada peringkat

- Energy production and managementDokumen21 halamanEnergy production and managementsyliviamaureenameedeBelum ada peringkat

- Moisture Content of Paper and Paperboard by Oven Drying: Standard Test Method ForDokumen2 halamanMoisture Content of Paper and Paperboard by Oven Drying: Standard Test Method ForfrostestBelum ada peringkat

- Dryer Setup ProcessDokumen2 halamanDryer Setup ProcessnoelBelum ada peringkat

- Experiment On: Extrusion Cooking AIMDokumen8 halamanExperiment On: Extrusion Cooking AIMShobikaBelum ada peringkat

- ASTM D644 Moisture Content of PapperDokumen3 halamanASTM D644 Moisture Content of PapperheobukonBelum ada peringkat

- Bitumen ExtractorDokumen7 halamanBitumen ExtractorNirmal NayakBelum ada peringkat

- Extraction Procedure GuideDokumen12 halamanExtraction Procedure GuideZiauddeen NoorBelum ada peringkat

- Stas American Astm d2974-87 Material OrganicDokumen3 halamanStas American Astm d2974-87 Material OrganicAlexandra PopBelum ada peringkat

- Tray Dryer Objectives: Calculate The Percentage Moisture Content of Wet Rice Husk Removed in A Rotary Drier byDokumen4 halamanTray Dryer Objectives: Calculate The Percentage Moisture Content of Wet Rice Husk Removed in A Rotary Drier byHajra AamirBelum ada peringkat

- Moisture Exp1Dokumen10 halamanMoisture Exp1Fadhlin Sakinah100% (1)

- Fat determination in animal feed by hot extraction according to European Directive 98/64/ECDokumen6 halamanFat determination in animal feed by hot extraction according to European Directive 98/64/ECRosa VelásquezBelum ada peringkat

- Acid Detergent Fiber MethodDokumen2 halamanAcid Detergent Fiber MethodMábio SilvanBelum ada peringkat

- Method 1:0: Preparation of The Sample For AnalysisDokumen4 halamanMethod 1:0: Preparation of The Sample For AnalysisgabisoBelum ada peringkat

- Moisture Content by Air OvenDokumen2 halamanMoisture Content by Air OvenKate Dianne HugoBelum ada peringkat

- Whirlpool Dryer Manual 01Dokumen2 halamanWhirlpool Dryer Manual 01anon_249833401Belum ada peringkat

- Materials and Methods Extraction of Golden Shower Seed and PulpDokumen5 halamanMaterials and Methods Extraction of Golden Shower Seed and PulpPetra NwaoyoBelum ada peringkat

- Analyze Coal Moisture ContentDokumen4 halamanAnalyze Coal Moisture ContentM ZarakBelum ada peringkat

- Observation and CalculationDokumen6 halamanObservation and CalculationluqmancivilBelum ada peringkat

- African Elemi Seed Characterization MethodsDokumen18 halamanAfrican Elemi Seed Characterization MethodsStephanie ChidinmaBelum ada peringkat

- Experiment 3 - Loss On IgnitionDokumen5 halamanExperiment 3 - Loss On IgnitionSeth Aboagye JnrBelum ada peringkat

- Volatile Matter in Green Petroleum Coke Quartz Crucible ProcedureDokumen4 halamanVolatile Matter in Green Petroleum Coke Quartz Crucible ProcedureAli VarmazyarBelum ada peringkat

- Moisture Content Determination Using Forced Draft OvenDokumen2 halamanMoisture Content Determination Using Forced Draft OvenAfi HazimBelum ada peringkat

- Discussion Experiment Moisture Content...Dokumen2 halamanDiscussion Experiment Moisture Content...Nur Asiah70% (10)

- Lab Report FoodDokumen11 halamanLab Report FoodMuskaan Fatima fatimaBelum ada peringkat

- Gravimetric Determination of Moisture and Phosphorus in Fertilizer SampleDokumen6 halamanGravimetric Determination of Moisture and Phosphorus in Fertilizer SampleGelo Buligan100% (3)

- Expert Hearing: Special Economic Zones in A Regional and Global Context - Economic Significance and ImpactDokumen89 halamanExpert Hearing: Special Economic Zones in A Regional and Global Context - Economic Significance and ImpactRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB5502-2008 Inspection of Grain and Oils - Determination of Processing Degree of Rice and Other Grain KernelsDokumen11 halamanTI - GB5502-2008 Inspection of Grain and Oils - Determination of Processing Degree of Rice and Other Grain KernelsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Regional Infrastructure Investment Initiatives: Zero-Sum Game or Win-Win Collaboration? Proceedings of The Roundtable Meeting On 11-12 September 2015 in Hangzhou, PR ChinaDokumen71 halamanRegional Infrastructure Investment Initiatives: Zero-Sum Game or Win-Win Collaboration? Proceedings of The Roundtable Meeting On 11-12 September 2015 in Hangzhou, PR ChinaRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Study Tour and Workshop: Building Capacities For Labour Migration Management in Cambodia and Lao PDRDokumen24 halamanStudy Tour and Workshop: Building Capacities For Labour Migration Management in Cambodia and Lao PDRRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB5491-1985 Inspection of Grain, Oilseeds and Vegetable OilsDokumen10 halamanTI - GB5491-1985 Inspection of Grain, Oilseeds and Vegetable OilsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB1350-2009 PaddyDokumen10 halamanTI - GB1350-2009 PaddyRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Study Tour and Technical Training On Single Window ImplementationDokumen34 halamanStudy Tour and Technical Training On Single Window ImplementationRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Potential For Development and Cooperation in The ACPBG Region: A Study On Ports and LogisticsDokumen96 halamanPotential For Development and Cooperation in The ACPBG Region: A Study On Ports and LogisticsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Connect Asia Newsletter, No. 04Dokumen6 halamanConnect Asia Newsletter, No. 04Regional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB2715-2005 Hygienic Standard For GrainsDokumen17 halamanTI - GB2715-2005 Hygienic Standard For GrainsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB5749-2006 Standards For Drinking Water QualityDokumen16 halamanTI - GB5749-2006 Standards For Drinking Water QualityRegional Economic Cooperation and Integration (RCI) in Asia67% (3)

- TI - GB-T5496-1985 Inspection of Grain and Oilseeds - Methods For Determination of Yellow-Colored Rice and Cracked KernelsDokumen6 halamanTI - GB-T5496-1985 Inspection of Grain and Oilseeds - Methods For Determination of Yellow-Colored Rice and Cracked KernelsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB5490-2010 Inspection of Grain and Oils - General RulesDokumen18 halamanTI - GB5490-2010 Inspection of Grain and Oils - General RulesRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB1354-2009 RiceDokumen13 halamanTI - GB1354-2009 RiceRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB5503-2009 Inspection of Grain and Oils - Determination of Broken KernelsDokumen9 halamanTI - GB5503-2009 Inspection of Grain and Oils - Determination of Broken KernelsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB7718-2011 National Standard of Food Safety - General Standard For The Labelling of Prepackaged FoodDokumen21 halamanTI - GB7718-2011 National Standard of Food Safety - General Standard For The Labelling of Prepackaged FoodRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB5494-2008 Inspection of Grain and Oils - Determination of Foreign Matter and Unsound Kernels of Grain and OilseedsDokumen14 halamanTI - GB5494-2008 Inspection of Grain and Oils - Determination of Foreign Matter and Unsound Kernels of Grain and OilseedsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB15682-2008 Inspection of Grain and Oils - Method For Sensory Evaluation of Paddy or Rice Cooking and Eating QualityDokumen18 halamanTI - GB15682-2008 Inspection of Grain and Oils - Method For Sensory Evaluation of Paddy or Rice Cooking and Eating QualityRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB17891-1999 High Quality PaddyDokumen16 halamanTI - GB17891-1999 High Quality PaddyRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB15683-2008 Rice - Determination of Amylose ContentDokumen20 halamanTI - GB15683-2008 Rice - Determination of Amylose ContentRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB14881-1994 General Hygienic Regulation For Food EnterprisesDokumen20 halamanTI - GB14881-1994 General Hygienic Regulation For Food EnterprisesRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- TI - GB17109-2008 Package of Grain SellsDokumen9 halamanTI - GB17109-2008 Package of Grain SellsRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Inputs and Materials: Mapping Workshop & Trade Capacity Building - ASEAN-China Free Trade AgreementDokumen40 halamanInputs and Materials: Mapping Workshop & Trade Capacity Building - ASEAN-China Free Trade AgreementRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Input and Materials: Development of Ferry Boat Routes in Northeast Asia - Utilizing European Examples of Regional ConnectivityDokumen16 halamanInput and Materials: Development of Ferry Boat Routes in Northeast Asia - Utilizing European Examples of Regional ConnectivityRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Inputs and Materials - Guideline On How To Successfully Implement Special Economic Zones in Lao PDRDokumen76 halamanInputs and Materials - Guideline On How To Successfully Implement Special Economic Zones in Lao PDRRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Inputs and Materials: Second Expert Hearing On Cross-Border Cooperation and Trade Facilitation in AsiaDokumen43 halamanInputs and Materials: Second Expert Hearing On Cross-Border Cooperation and Trade Facilitation in AsiaRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Inputs and Materials: Potentials For Port Cooperation in The Pan-Beibu Gulf RegionDokumen23 halamanInputs and Materials: Potentials For Port Cooperation in The Pan-Beibu Gulf RegionRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Inputs and Materials: Background Paper China (Shanghai) Free Trade ZoneDokumen18 halamanInputs and Materials: Background Paper China (Shanghai) Free Trade ZoneRegional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Connect Asia, No 03Dokumen6 halamanConnect Asia, No 03Regional Economic Cooperation and Integration (RCI) in AsiaBelum ada peringkat

- Primary 2 (Grade 2) - GEP Practice: Contest Problems With Full SolutionsDokumen24 halamanPrimary 2 (Grade 2) - GEP Practice: Contest Problems With Full Solutionswenxinyu1002100% (1)

- Matrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEDokumen41 halamanMatrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEkhateeb ul islam qadriBelum ada peringkat

- A. Hardened Concrete (Non-Destructive Tests) : The SAC Programme Is Managed by Enterprise SingaporeDokumen2 halamanA. Hardened Concrete (Non-Destructive Tests) : The SAC Programme Is Managed by Enterprise Singaporeng chee yongBelum ada peringkat

- Financial Services : An OverviewDokumen15 halamanFinancial Services : An OverviewAnirudh JainBelum ada peringkat

- English For Academic Purposes (EAP) : Lecture 5: Past SimpleDokumen11 halamanEnglish For Academic Purposes (EAP) : Lecture 5: Past Simplealmastar officeBelum ada peringkat

- The Pathogenic Basis of Malaria: InsightDokumen7 halamanThe Pathogenic Basis of Malaria: InsightRaena SepryanaBelum ada peringkat

- Re: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesDokumen1 halamanRe: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesMayada OsmanBelum ada peringkat

- Chapter 7 - The Political SelfDokumen6 halamanChapter 7 - The Political SelfJohn Rey A. TubieronBelum ada peringkat

- Canterburytales-No Fear PrologueDokumen10 halamanCanterburytales-No Fear Prologueapi-261452312Belum ada peringkat

- BBRC4103 - Research MethodologyDokumen14 halamanBBRC4103 - Research MethodologySimon RajBelum ada peringkat

- The Seven Kings of Revelation 17Dokumen9 halamanThe Seven Kings of Revelation 17rojelio100% (1)

- ANAPHYDokumen23 halamanANAPHYYu, Denise Kyla BernadetteBelum ada peringkat

- Joel Werner ResumeDokumen2 halamanJoel Werner Resumeapi-546810653Belum ada peringkat

- Horizontal Vertical MarketDokumen4 halamanHorizontal Vertical MarketVikasBelum ada peringkat

- 7 Tools for Continuous ImprovementDokumen202 halaman7 Tools for Continuous Improvementvivekanand bhartiBelum ada peringkat

- Project Report VajDokumen15 halamanProject Report VajTamil SelvanBelum ada peringkat

- GEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1Dokumen73 halamanGEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1mrzdravko15Belum ada peringkat

- Book3 79 111000 0000100120 DAH MPL RPT 000005 - ADokumen101 halamanBook3 79 111000 0000100120 DAH MPL RPT 000005 - ANassif Abi AbdallahBelum ada peringkat

- HUMAN RIGHTS, RATIONALITY, AND SENTIMENTALITYDokumen13 halamanHUMAN RIGHTS, RATIONALITY, AND SENTIMENTALITYJohn HunterBelum ada peringkat

- The Secret Language of AttractionDokumen278 halamanThe Secret Language of Attractionsandrojairdhonre89% (93)

- Barry Wylant: Design Thinking and The Experience of InnovationDokumen13 halamanBarry Wylant: Design Thinking and The Experience of InnovationVanesa JuarezBelum ada peringkat

- Strata KT Office OpportunityDokumen41 halamanStrata KT Office OpportunitySanskar SurekaBelum ada peringkat

- Organizing and Delivering A Memorized SpeechDokumen9 halamanOrganizing and Delivering A Memorized SpeechJanice L. Langit100% (4)

- Reading in Philippine History (Chapter 3)Dokumen14 halamanReading in Philippine History (Chapter 3)AKIO HIROKIBelum ada peringkat

- MacEwan APA 7th Edition Quick Guide - 1Dokumen4 halamanMacEwan APA 7th Edition Quick Guide - 1Lynn PennyBelum ada peringkat

- SAP SD Course Content PDFDokumen4 halamanSAP SD Course Content PDFshuku03Belum ada peringkat

- 2.7.3 Lab Use Steganography To Hide Data Answer KeyDokumen3 halaman2.7.3 Lab Use Steganography To Hide Data Answer KeyVivek GaonkarBelum ada peringkat

- History of English Prose PDFDokumen21 halamanHistory of English Prose PDFMeisyita QothrunnadaBelum ada peringkat

- Management and Breeding of Game BirdsDokumen18 halamanManagement and Breeding of Game BirdsAgustinNachoAnzóateguiBelum ada peringkat

- S 212 Pre Course WorkDokumen5 halamanS 212 Pre Course Workafiwierot100% (2)