D LMK382 Submerisble Level Transmitter Ceramic Sensor

Diunggah oleh

Crystal Rice0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

33 tayangan5 halamanfgnb

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inifgnb

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

33 tayangan5 halamanD LMK382 Submerisble Level Transmitter Ceramic Sensor

Diunggah oleh

Crystal Ricefgnb

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

LMK 382

Stainless Steel Probe

Ceramic Sensor

accuracy according to IEC 60770:

standard: 0.35 % FSO

option: 0.25 % FSO

Nominal pressure

from 0 ... 40 cmH

2

O up to 0 ... 200 mH

2

O

Output signals

2-wire: 4 ... 20 mA

3-wire: 0 10 V

others on request

Speci al characteri stics

diameter 39.5 mm

especially for sewage, viscous

and pasty media

Optional versions

IS-protection zone 0

mounting with stainless steel pipe

flange version

diaphragm 99.9 % AI

2

O

3

different kinds of cables

different kinds of elastomers

The stainless steel probe LMK 382 has been

designed for continous level measurement in

waste water, waste and higher viscosity media.

Basic element is a robust and high overpressure

capable capacitive ceramic sensor e.g. for low

levels easily.

Preferred areas of use are

Water

drinking water abstraction

Sewage

waste water treatment

water recycling

Fuel / Oil

level monitoring in open tanks

with low filling heights

fuel storage

tank farms / biogas plants

LMK 382

Stainless Steel Probe Technical Data

pressure measurement

Input pressure range

Nominal pressure gauge [bar] 0.04 0.06 0.1 0.16 0.25 0.4 0.6 1 1.6 2.5 4 6 10 16 20

Level [mH2O] 0.4 0.6 1 1.6 2.5 4 6 10 16 25 40 60 100 160 200

Overpressure [bar] 2 2 4 4 6 6 8 8 15 25 25 35 35 45 45

Output signal / Suppl y

Standard

2-wire: 4 ... 20 mA / VS =9 ... 32 VDC

Option IS-protection

2-wire: 4 ... 20 mA / VS =14 ... 28 VDC

Option 3-wire

3-wire: 0 ... 10 V / VS =12.5 ... 32 VDC

Performance

Accuracy

1

standard: 0.35 % FSO

option: 0.25 % FSO

Permissible load

Rmax =[(VS VS min) / 0.02 A]

Influence effects supply: 0.05 % FSO / 10 V

load: 0.05 % FSO / k

Long term stability 0.1 % FSO / year at reference conditions

Turn-on time 700 msec

Mean response time <200 msec measuring rate 5/sec

Max. response time 380 msec

1

accuracy according to IEC 60770 limit point adjustment (non-linearity, hysteresis, repeatability)

Thermal effects (Offset and Span)

Thermal error 0.1 % FSO / 10 K

in compensated range 0 ... 70 C

Permissible temperatures

Permissible temperatures medium: -25 ... 125 C

electronics / environment: -25 ... 125 C

storage: -25 ... 125 C

Electrical protection

2

Short-circuit protection permanent

Reverse polarity protection no damage, but also no function

Electromagnetic compatibility emission and immunity according to EN 61326

2

additional external overvoltage protection unit in terminal box KL 1 or KL 2 with atmospheric pressure reference available on request

Electrical connection (onl y for 4 20 mA / 2-wire)

Cable with sheath material

3

PVC (-5 70 C) grey

PUR (-25 70 C) black

FEP (-25 70C) black

TPE (-25 125 C) blue

3

shielded cable with integrated air tube for atmospheric pressure reference

Materials (media wetted)

Housing stainless steel 1.4404 (316 L)

Seals FKM

FFKM

EPDM

others on request

Diaphragm standard: ceramics Al2O3 96 %

Option: ceramics Al2O3 99.9 %

Nose cone POM

Explosion protection

Approval DX14-LMK 382 zone 0

4

: II 1G Ex ia IIB T4 Ga

zone 20: II 1D Ex iaD 20 T 85C

Safety technical maximum values Ui =28 V, Ii =93 mA, Pi =660 mW, Ci =27 nF, Li =5 H

Permissible media temperature in zone 0: -10 ... 60 C with patm 0.8 bar up to 1.1 bar

zone 1 and higher: -10 ... 70 C

Connecting cables

(by factory)

cable capacitance: signal line/shield also signal line/signal line: 160 pF/m

cable inductance: signal line/shield also signal line/signal line: 1 H/m

4

for optional stainless steel pipe following designation is valid: "II 1G Ex ia IIC T4 Ga" (zone 0)

Miscellaneous

Current consumption max. 21 mA

Weight approx. 400 g (without cable)

Ingress protection IP 68

CE-conformity EMC Directive: 2004/108/EC

LMK 382

Stainless Steel Probe Technical Data

Wiring diagram

2-wire-system (current) 3-wire-system (voltage)

Pin configuration

Electrical connection cable colours (DIN 47100)

Supply +

Supply

Signal +(only for 3-wire)

wh (white)

bn (brown)

gn (green)

Shield gn/ye (green / yellow)

Dimensions (in mm)

LMK 382 standard LMK 382 with thread R1"

for stainless steel pipe

LMK 382

flange version

dimensions in mm

dimen-

sions

DN25 /

PN40

DN40/

PN40

DN50 /

PN40

DN80 /

PN16

D 115 150 165 200

k 85 110 125 160

d4 68 88 102 138

b 18 18 20 20

f 2 3 3 3

n 4 4 4 8

d2 14 18 18 18

supply +

supply

VS

p

I

A

supply +

signal +

VS

p

U

supply

V

LMK 382

Stainless Steel Probe Technical Data

Transmitter flange for flange version

Technical data

Suitable for LMK 382, LMK 382H, LMK 458, LMK 458H

Flange material stainless steel 1.4404 (316L)

Hole pattern according to DIN 2507

Version Size (in mm) Weight

DN25 / PN40 D =115, k =85, b =18, n =4, d=14 1.2 kg

DN50 / PN40 D =165, k =125, b =20, n =4, d=18 2.6 kg

DN80 / PN16 D =200, k =160, b =20, n =8, d=18 4.1 kg

Ordering type Ordering code

Transmitter flange DN25 / PN40 ZFS2540

Transmitter flange DN50 / PN40 ZFS5040

Transmitter flange DN80 / PN16 ZFS8016

Mounting flange with cable gland

Technical data

Suitable for all probes

Flange material stainless steel 1.4404 (316L)

Material of cable gland

standard: brass, nickel plated

on request: stainless steel 1.4305 (303); plastic

Seal insert material: TPE (ingress protection IP 68)

Hole pattern according to DIN 2507

Version Size (in mm) Weight

DN25 / PN40 D =115, k =85, b =18, n =4, d=14 1.4 kg

DN50 / PN40 D =165, k =125, b =20, n =4, d=18 3.2 kg

DN80 / PN16 D =200, k =160, b =20, n =8, d=18 4.8 kg

Ordering type Ordering code

DN25 / PN40 with cable gland brass, nickel plated ZMF2540

DN50 / PN40 with cable gland brass, nickel plated ZMF5040

DN80 / PN16 with cable gland brass, nickel plated ZMF8016

Terminal clamp

Technical Data

Suitable for all probes with cable 5.5 ... 10.5 mm

Material standard: steel, zinc plated

optionally: stainless steel 1.4301 (304)

Weight approx. 160 g

Ordering type Ordering code

Terminal clamp, steel, zinc plated Z100528

Terminal clamp, stainless steel 1.4301 (304) Z100527

T

h

i

s

d

a

t

a

s

h

e

e

t

c

o

n

t

a

i

n

s

p

r

o

d

u

c

t

s

p

e

c

i

f

i

c

a

t

i

o

n

,

p

r

o

p

e

r

t

i

e

s

a

r

e

n

o

t

g

u

a

r

a

n

t

e

e

d

.

S

u

b

j

e

c

t

t

o

c

h

a

n

g

e

w

i

t

h

o

u

t

n

o

t

i

c

e

.

cable gland M16x1.5 with

seal insert (for cable- 4 ... 11 mm)

Accessories

LMK382_E_010613

- - - - - - - - -

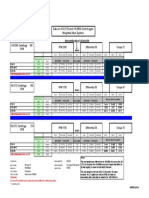

Pressure

5 6 5

5 6 6

Input [mH

2

O] [bar]

0.40 0.04 0 4 0 0

0.60 0.06 0 6 0 0

1.0 0.10 1 0 0 0

1.6 0.16 1 6 0 0

2.5 0.25 2 5 0 0

4.0 0.40 4 0 0 0

6.0 0.60 6 0 0 0

10 1.0 1 0 0 1

16 1.6 1 6 0 1

25 2.5 2 5 0 1

40 4.0 4 0 0 1

60 6.0 6 0 0 1

100 10 1 0 0 2

160 16 1 6 0 2

200 20 2 0 0 2

9 9 9 9 consult

Housing

1

9 consult

Diaphragm

2

C

9 consult

Output

1

3

E

9 consult

Seals

1

3

FFKM 7

9 consult

Electrical connection

1

2

3

TPE-cable 4

9 consult

Accuracy

standard 0.35 % 3

option 0.25 % 2

9 consult

Cable length

in m

standard: 3 m PVC 0 0 3

standard: 5 m PVC 0 0 5

standard: 10 m PVC 0 1 0

standard: 15 m PVC 0 1 5

standard: 20 m PVC 0 2 0

special length PVC 9 9 9

standard: 3 m PUR 0 0 3

standard: 5 m PUR 0 0 5

standard: 10 m PUR 0 1 0

standard: 15 m PUR 0 1 5

standard: 20 m PUR 0 2 0

special length PUR 9 9 9

standard: 5 m FEP 0 0 5

standard: 10 m FEP 0 1 0

special length FEP 9 9 9

special length TPE 9 9 9

Special version

0 0 0

5 1 0

9 9 9 consult

1

cable with integrated air tube for atmospheric pressure reference

2

stainless steel pipe is not part of the supply

Standard lengths 3 / 5 / 10 / 15 / 20 m are available from stock, special lengths are manufactured order-related, price per meter (see above).

01.06.2013

0 10 V / 3-wire

in bar

LMK 382

Ordering code LMK 382

in mH

2

O

Ceramics Al

2

O

3

99.9%

Ceramics Al

2

O

3

96%

customer

customer

Stainless steel 1.4404 (316L)

customer

4 20 mA / 2-wire

Intrinsic safety 4 20 mA / 2-wire

FEP-cable

PUR-cable

customer

customer

FKM

customer

customer

EPDM

2

prepared for mounting

customer

flange version

T

h

i

s

p

r

i

c

e

l

i

s

t

c

o

n

t

a

i

n

s

p

r

o

d

u

c

t

s

p

e

c

i

f

i

c

a

t

i

o

n

;

p

r

o

p

e

r

t

i

e

s

a

r

e

n

o

t

g

u

a

r

a

n

t

e

e

d

.

D

e

t

a

i

l

e

d

i

n

f

o

r

m

a

t

i

o

n

a

b

o

u

t

o

p

t

i

o

n

s

a

r

e

d

e

f

i

n

e

d

i

n

t

h

e

d

a

t

a

s

h

e

e

t

.

S

u

b

j

e

c

t

t

o

c

h

a

n

g

e

w

i

t

h

o

u

t

n

o

t

i

c

e

.

1

standard

with stainless steel pipe

0

1

1

2

5

PVC-cable

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Grey Nomads Guide To AustraliaDokumen3 halamanThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- AOAC 2012.11 Vitamin DDokumen3 halamanAOAC 2012.11 Vitamin DPankaj BudhlakotiBelum ada peringkat

- Ebrosur Silk Town PDFDokumen28 halamanEbrosur Silk Town PDFDausBelum ada peringkat

- Shapes FlashcardsDokumen5 halamanShapes FlashcardsHome Organising by JRBelum ada peringkat

- Pentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessDokumen156 halamanPentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessStanley JohnsonBelum ada peringkat

- المحاضرة الرابعة المقرر انظمة اتصالات 2Dokumen31 halamanالمحاضرة الرابعة المقرر انظمة اتصالات 2ibrahimBelum ada peringkat

- Anxiolytics Sedatives Hypnotics Pharm 3Dokumen38 halamanAnxiolytics Sedatives Hypnotics Pharm 3Peter Harris100% (1)

- Three Bucket Method & Food ServiceDokumen4 halamanThree Bucket Method & Food Servicerose zandrea demasisBelum ada peringkat

- BS en 12201 5 2011Dokumen20 halamanBS en 12201 5 2011fatjon31100% (4)

- Chapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Dokumen29 halamanChapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Aries SattiBelum ada peringkat

- GSM Modernization Poster2Dokumen1 halamanGSM Modernization Poster2leonardomarinBelum ada peringkat

- Techniques for Studying FossilsDokumen11 halamanTechniques for Studying FossilsP. C. PandeyBelum ada peringkat

- Function and Euqations - Quantitative Aptitude Questions MCQDokumen4 halamanFunction and Euqations - Quantitative Aptitude Questions MCQAnonymous v5QjDW2eHxBelum ada peringkat

- EiaDokumen14 halamanEiaRamir FamorcanBelum ada peringkat

- MUCLecture 2021 10311889Dokumen11 halamanMUCLecture 2021 10311889Ramon Angelo MendezBelum ada peringkat

- Measuring and calculating dimensions for pipes, plates, cylinders and moreDokumen100 halamanMeasuring and calculating dimensions for pipes, plates, cylinders and moreGarcia MaybelleBelum ada peringkat

- Textile Pretreatment and Finishing 2023Dokumen205 halamanTextile Pretreatment and Finishing 2023Aweru gebremariamBelum ada peringkat

- Chapter-8 Turbine and Governor TestingDokumen10 halamanChapter-8 Turbine and Governor Testingafru2000Belum ada peringkat

- Datta Das FET ExplanationDokumen2 halamanDatta Das FET ExplanationJulie HaydenBelum ada peringkat

- Digestion Unit 1 QDokumen15 halamanDigestion Unit 1 QKajana Sivarasa ShenthanBelum ada peringkat

- Abb 60 PVS-TLDokumen4 halamanAbb 60 PVS-TLNelson Jesus Calva HernandezBelum ada peringkat

- Navmesh Plus: How ToDokumen7 halamanNavmesh Plus: How TobladimirBelum ada peringkat

- P&id BoilerDokumen1 halamanP&id BoilerBagus AryowibowoBelum ada peringkat

- Datasheet Optris XI 410Dokumen2 halamanDatasheet Optris XI 410davidaldamaBelum ada peringkat

- Animal Names in English and IndonesianDokumen7 halamanAnimal Names in English and IndonesianAndi KurniawanBelum ada peringkat

- Thank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3Dokumen3 halamanThank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3DhivyaBelum ada peringkat

- Fatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftDokumen4 halamanFatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftMohamed IbrahimBelum ada peringkat

- HS-2172 Vs HS-5500 Test ComparisonDokumen1 halamanHS-2172 Vs HS-5500 Test ComparisonRicardo VillarBelum ada peringkat

- Instruction Manual: E2M40 and E2M80 Rotary Vacuum PumpsDokumen46 halamanInstruction Manual: E2M40 and E2M80 Rotary Vacuum PumpsVicki NugrohoBelum ada peringkat

- BELL B40C - 872071-01 Section 2 EngineDokumen38 halamanBELL B40C - 872071-01 Section 2 EngineALI AKBAR100% (1)