10 Defects of Tablets

Diunggah oleh

HolihuaChua100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

2K tayangan3 halamanHak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

2K tayangan3 halaman10 Defects of Tablets

Diunggah oleh

HolihuaChuaHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

#13 Chua, Holiday O.

2E-PH PHAR 3 Lec HW 09/03/14

(10 Defects of Tablets)

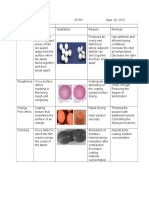

Name of Defect Illustration Definition Remedy

Sticking

This occurs in low

melting point

substances, and

moisture supports

defects, lower the

speed up of upper,

and lower punch

leads to weight

variation of tablets.

It produces rough

and chipping surface

tablets, and develops

material on both

punches. Lack of

drying is the cause of

this defect.

1) Selection of

Binding Agent is

essential to solve

sticking

2) Ideal selection of

lubricant in desired

proportion will

minimize this

problem.

Blistering

It is local

detachment of film

from the substrate

forming a blister

caused by

overheating during

spraying coating

solution.

Use mild drying

condition.

Filling

The monogram or

bisect is filled and

become narrow

caused by applying

too much solution

and of the higher

solution applying

rate.

Control fluid

application rate

Lamination

It is major problem

among of all defects

and it occurs upon

storage period, or

soon after

compression. This is

due to air

entrapment between

layers of tablet, low

levels of binding

agent.

It is minimized by

improving lubricant

concentration,

changing the method

of granulation and by

direct compression

technique, it is

prevented to some

extent. Use always

dry material (feed).

Chipped Edge

Tablets having sharp

edge, elongated

tablets are prone to

chipped edge. Due to

rough handling.

Tablet shape is

abnormal than

normal. Use optimum

level of binding

agent.

Granules subjected

to high temperature

will improve chipped

surface (high

drying). This defect

accompanied with

damaged surfaces at

its corners, are also

easily fragmented by

even smooth

handling.

Orange Peel

It is surface defect

resulting in the film

being rough and

nonglossy.

Appearance is similar

to that of an orange.

Use mild drying

conditions, and use

additional solvents to

decrease viscosity of

solution.

Erosion

Caused by over-

wetted tablet

surface, inadequate

drying, and lack of

tablet surface

strength

Control drying rate

and temperature

Twinning

A defect wherein two

tablets are sticking

together.

These are most

common in capsule-

shaped tablets.

This could be

remedied by

reducing spray rate

and increasing pan

speed.

Cracking

Small, fine cracks

observed on the

upper and lower

central surface of

tablets, or very rarely

on the sidewall.

Use low molecular

weight polymer and

adjust the plasticizer

& pigment types and

concentration to

minimize internal

stresses.

Bridging

This occurs when the

coating fills in the

lettering or logo

on the tablet and is

typically caused by

improper

application of the

solution, poor design

of the tablet

embossing, high

coating viscosity,

high percentage of

solids in the solution,

or improper

atomization pressure.

Increasing the

plasticizer content or

changing the

plasticizer can

decrease the

incidence of bridging.

Anda mungkin juga menyukai

- NMAT Practice Set Part 1 & Part 2 With Answer KeyDokumen64 halamanNMAT Practice Set Part 1 & Part 2 With Answer KeyLucid Lynx100% (1)

- Problems Associated in Tablet ManufacturingDokumen12 halamanProblems Associated in Tablet ManufacturingRajib Chowdhury100% (1)

- Manufacturing Operation and Control: Prepared By:-Punam R. Patil M Pharm (QA) Guided by:-G.B.Patil H.R.P.I.P.E.R, ShirpurDokumen29 halamanManufacturing Operation and Control: Prepared By:-Punam R. Patil M Pharm (QA) Guided by:-G.B.Patil H.R.P.I.P.E.R, ShirpurRohit ShirsathBelum ada peringkat

- C - 4 Dosage Form DesignDokumen67 halamanC - 4 Dosage Form DesignFelicity TineBelum ada peringkat

- Chapter 3. One-Compartment Open Model Intravenous Bolus AdministrationDokumen23 halamanChapter 3. One-Compartment Open Model Intravenous Bolus AdministrationbencleeseBelum ada peringkat

- Sterile Ophthalmic PreparationsDokumen20 halamanSterile Ophthalmic PreparationsJeanita100% (1)

- Modifiers of Human ActDokumen3 halamanModifiers of Human ActHolihuaChua60% (5)

- Summer Internship Project-NishantDokumen80 halamanSummer Internship Project-Nishantnishant singhBelum ada peringkat

- Name of DefectDokumen3 halamanName of DefectJana EncaboBelum ada peringkat

- Common Film Coating Defects and Their CausesDokumen2 halamanCommon Film Coating Defects and Their CausesLea Pesigan100% (1)

- Tablet DefectsDokumen2 halamanTablet Defectsophelion2112Belum ada peringkat

- Common Tablet DefectsDokumen2 halamanCommon Tablet DefectsMaiah Dinglasan0% (1)

- Problems and Remedies For Tablet CoatingDokumen7 halamanProblems and Remedies For Tablet CoatingAnowar HossainBelum ada peringkat

- Pharmaceutical Dosage (Lec) HWDokumen3 halamanPharmaceutical Dosage (Lec) HWKimberly Mae MesinaBelum ada peringkat

- Defects in Tablets and Coated TabletsDokumen36 halamanDefects in Tablets and Coated TabletsSunil DarjiBelum ada peringkat

- Tablet ManufactureDokumen10 halamanTablet ManufactureAdemola OgundiwinBelum ada peringkat

- Film DefectDokumen3 halamanFilm Defectamitrameshwardayal100% (2)

- Tablet ProblemsDokumen5 halamanTablet ProblemsAnup Bajracharya75% (8)

- Stability in PreformulationDokumen48 halamanStability in Preformulationmithaann2353Belum ada peringkat

- Topical GelDokumen4 halamanTopical GelBINDUBelum ada peringkat

- Quality Control of Tablets Lecture 1Dokumen15 halamanQuality Control of Tablets Lecture 1Muhammad AzeemBelum ada peringkat

- Tablet Technology EditedDokumen42 halamanTablet Technology EditedPramod Kc100% (1)

- Tablets Quality ControlDokumen18 halamanTablets Quality ControlThangabalan Than100% (2)

- Pharmaceutical TabletDokumen44 halamanPharmaceutical TabletMurtaza Choudhary100% (4)

- SuspensionsDokumen130 halamanSuspensionsHaroon Rahim0% (1)

- FORMULASI DAN TEKNOLOGI SEDIAAN CAIR DAN SEMIPADATDokumen28 halamanFORMULASI DAN TEKNOLOGI SEDIAAN CAIR DAN SEMIPADAT08Leonardo Demas Krisna Satria WijayaBelum ada peringkat

- Design of Dosage FormsDokumen17 halamanDesign of Dosage FormsMuhammad HilmiBelum ada peringkat

- 1.2 Pharmaceutical Dosage FormsDokumen41 halaman1.2 Pharmaceutical Dosage FormsHumanic GenesBelum ada peringkat

- Pharmaceutical PackagingDokumen63 halamanPharmaceutical PackagingMubarakDiedaBelum ada peringkat

- Expt - I - IpqcDokumen8 halamanExpt - I - IpqcaltinakhotBelum ada peringkat

- Tablet Coating PDFDokumen6 halamanTablet Coating PDFAsif Hasan Niloy100% (1)

- Rheology of SuspensionsDokumen16 halamanRheology of SuspensionsManoj Bansal100% (1)

- Powders For InjectionDokumen11 halamanPowders For InjectionAbigail Mayled LausBelum ada peringkat

- Modern Pharmaceutics Preformulation ConceptsDokumen35 halamanModern Pharmaceutics Preformulation ConceptsTarun ChauhanBelum ada peringkat

- Suspension Solution Emulsion: (Dosage Forms)Dokumen38 halamanSuspension Solution Emulsion: (Dosage Forms)Razi KhanBelum ada peringkat

- Preformulation NotesDokumen19 halamanPreformulation NotesAnkit Arora67% (3)

- Bioprocessing in The Pharmaceutical Industry: (An Engineering and Technological Overview)Dokumen39 halamanBioprocessing in The Pharmaceutical Industry: (An Engineering and Technological Overview)ManchowBelum ada peringkat

- Types of Additives Used in Parenteral FormulationsDokumen54 halamanTypes of Additives Used in Parenteral FormulationsMuhammad Hilmi50% (6)

- Sterile Opthalmic Preparations PDFDokumen6 halamanSterile Opthalmic Preparations PDFSundariBelum ada peringkat

- 06 - Emulsion 1Dokumen41 halaman06 - Emulsion 1amirBelum ada peringkat

- 6 Pharmaceutical AerosolsDokumen26 halaman6 Pharmaceutical Aerosolsdereje_kebebe100% (1)

- Chapter 27 Suspensions and EmulsionsDokumen49 halamanChapter 27 Suspensions and EmulsionsKate Montenegro67% (3)

- Tablet Coating With Its DefectsDokumen56 halamanTablet Coating With Its Defectsjoshirohan100% (1)

- Ophthalmic Dosage Forms Types and Characteristics 1) Liquid ...Dokumen6 halamanOphthalmic Dosage Forms Types and Characteristics 1) Liquid ...Kiran VemaBelum ada peringkat

- Techniques of SolubilizationDokumen33 halamanTechniques of SolubilizationSreekanth NamaBelum ada peringkat

- Oral Solid Dosage Forms: Tablets and Factors Affecting Their PropertiesDokumen86 halamanOral Solid Dosage Forms: Tablets and Factors Affecting Their Propertiesrosebelle1906Belum ada peringkat

- Phardose Report (Solutions)Dokumen59 halamanPhardose Report (Solutions)Anne Marion PerezBelum ada peringkat

- Total Quality Management in Pharma SectorDokumen33 halamanTotal Quality Management in Pharma Sectorgaurav_thakur50% (2)

- Preformulation MaterialDokumen10 halamanPreformulation MaterialRajesh NayakBelum ada peringkat

- Tablet by Lakhvir InsanDokumen83 halamanTablet by Lakhvir InsanLakhvir InsanBelum ada peringkat

- PRESERVATIVESDokumen25 halamanPRESERVATIVESimran aliBelum ada peringkat

- Tablet: Types of TabletsDokumen82 halamanTablet: Types of TabletsKema Akma100% (1)

- Super DisintegrantsDokumen19 halamanSuper Disintegrantsvikaskiran60Belum ada peringkat

- Tablet Coating Problems & SolutionDokumen3 halamanTablet Coating Problems & Solutionsiddpandit89100% (2)

- BPUT Preformulation Studies Chapter 1 SummaryDokumen18 halamanBPUT Preformulation Studies Chapter 1 Summarykartik sharmaBelum ada peringkat

- Pharmaceutical Solutions (Zara Khan BP0950212)Dokumen30 halamanPharmaceutical Solutions (Zara Khan BP0950212)Zara KhanBelum ada peringkat

- Roller Compactor Basic Principles and Applications in PharmaceuticalsDokumen3 halamanRoller Compactor Basic Principles and Applications in PharmaceuticalsTareq TareqBelum ada peringkat

- Tablet DefectsDokumen3 halamanTablet Defectsjeniccax17Belum ada peringkat

- Tablet Coating - Final 2Dokumen20 halamanTablet Coating - Final 2kayes_abuBelum ada peringkat

- Common tablet defects and remedies under 40 charactersDokumen3 halamanCommon tablet defects and remedies under 40 charactersLea PesiganBelum ada peringkat

- Processing ProblemDokumen3 halamanProcessing ProblemMeah PachecoBelum ada peringkat

- PHARDOSE Tablet DefectsDokumen2 halamanPHARDOSE Tablet DefectskarenBelum ada peringkat

- Problem Illustration Remidies 1. CappingDokumen4 halamanProblem Illustration Remidies 1. CappingMikee MeladBelum ada peringkat

- Republic Act 6675Dokumen16 halamanRepublic Act 6675HolihuaChuaBelum ada peringkat

- CHIKV: Deadly Mosquito-Borne VirusDokumen2 halamanCHIKV: Deadly Mosquito-Borne VirusHolihuaChuaBelum ada peringkat

- 2 - Smith - Clinical - Trial - Results - SAGE January Table PDFDokumen42 halaman2 - Smith - Clinical - Trial - Results - SAGE January Table PDFerian setiawanBelum ada peringkat

- Unit IV - Responding To Drug InquiryDokumen33 halamanUnit IV - Responding To Drug InquiryHolihuaChuaBelum ada peringkat

- Folkloric Uses of ChicoDokumen1 halamanFolkloric Uses of ChicoHolihuaChuaBelum ada peringkat

- Tallmanletters 2Dokumen6 halamanTallmanletters 2Desti SetyaningrumBelum ada peringkat

- Ra 10918 BsaDokumen19 halamanRa 10918 BsarimBelum ada peringkat

- Unwanted Anger - Poetry Submission PDFDokumen1 halamanUnwanted Anger - Poetry Submission PDFHolihuaChuaBelum ada peringkat

- Cost Benefit AnalysisDokumen46 halamanCost Benefit AnalysisluisynonBelum ada peringkat

- ASHP Guidelines: Minimum Standard For Pharmacies in HospitalsDokumen11 halamanASHP Guidelines: Minimum Standard For Pharmacies in HospitalsJarvin TanBelum ada peringkat

- Discrete ProbabilityDokumen2 halamanDiscrete ProbabilityHolihuaChuaBelum ada peringkat

- Added ResearchDokumen4 halamanAdded ResearchHolihuaChuaBelum ada peringkat

- Name: Reagents Used: Visible Result: Principle Involved:: (Ninhydrin + Ethanol)Dokumen2 halamanName: Reagents Used: Visible Result: Principle Involved:: (Ninhydrin + Ethanol)HolihuaChuaBelum ada peringkat

- Added ResearchDokumen4 halamanAdded ResearchHolihuaChuaBelum ada peringkat

- Protein Isolation and Hydrolysis TechniquesDokumen4 halamanProtein Isolation and Hydrolysis TechniquesHolihuaChuaBelum ada peringkat

- Octo Ge Sima Ad Ven IensDokumen2 halamanOcto Ge Sima Ad Ven IensHolihuaChuaBelum ada peringkat

- White Ointment ExDokumen1 halamanWhite Ointment ExHolihuaChua0% (1)

- Problem Set 5 T3 2013-2014Dokumen2 halamanProblem Set 5 T3 2013-2014HolihuaChuaBelum ada peringkat

- Chemats Plastic Quiz With AnswersDokumen3 halamanChemats Plastic Quiz With AnswersHolihuaChuaBelum ada peringkat

- Quiz CeramicsDokumen2 halamanQuiz CeramicsHolihuaChua100% (1)

- Midterm Assignment Academic WritingDokumen3 halamanMidterm Assignment Academic WritingHolihuaChuaBelum ada peringkat

- (Taeyang) - 눈, 코, 입 (Nun, Ko, Ib/Eyes, Nose, Lips)Dokumen3 halaman(Taeyang) - 눈, 코, 입 (Nun, Ko, Ib/Eyes, Nose, Lips)HolihuaChuaBelum ada peringkat

- BIOMATERIALS CHEMATS EA2 EXAM REVIEWDokumen1 halamanBIOMATERIALS CHEMATS EA2 EXAM REVIEWHolihuaChuaBelum ada peringkat

- English Book ReportDokumen9 halamanEnglish Book ReportHolihuaChuaBelum ada peringkat

- Current Issues For PHL5Dokumen5 halamanCurrent Issues For PHL5HolihuaChuaBelum ada peringkat

- Bactroban CreamDokumen5 halamanBactroban CreamHolihuaChuaBelum ada peringkat

- TypesOfAlcoholicBeveragesDokumen4 halamanTypesOfAlcoholicBeveragesHolihuaChuaBelum ada peringkat

- Marksmanship: Subject: III. Definition of TermsDokumen16 halamanMarksmanship: Subject: III. Definition of TermsAmber EbayaBelum ada peringkat

- OROLO & W. D. GannDokumen56 halamanOROLO & W. D. GannGaurav Garg100% (1)

- The Wafer-God and the Bloody History of the VaticanDokumen58 halamanThe Wafer-God and the Bloody History of the VaticanMin Hotep Tzaddik BeyBelum ada peringkat

- Lesson Plan 2018-2019 Term 1Dokumen205 halamanLesson Plan 2018-2019 Term 1Athlyn DurandBelum ada peringkat

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Dokumen1 halamanASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihBelum ada peringkat

- January 2013 Igcse Timetable 22-06-2012Dokumen2 halamanJanuary 2013 Igcse Timetable 22-06-2012Rizwanur RahmanBelum ada peringkat

- Electrocardiography - Wikipedia, The Free EncyclopediaDokumen18 halamanElectrocardiography - Wikipedia, The Free Encyclopediapayments8543Belum ada peringkat

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDokumen20 halamanPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateBelum ada peringkat

- 3.2 Probability DistributionDokumen38 halaman3.2 Probability Distributionyouservezeropurpose113Belum ada peringkat

- The Impact of Information Technology and Innovation To Improve Business Performance Through Marketing Capabilities in Online Businesses by Young GenerationsDokumen10 halamanThe Impact of Information Technology and Innovation To Improve Business Performance Through Marketing Capabilities in Online Businesses by Young GenerationsLanta KhairunisaBelum ada peringkat

- Donny UfoaksesDokumen27 halamanDonny UfoaksesKang Bowo D'wizardBelum ada peringkat

- Obat LasaDokumen3 halamanObat Lasaibnunanda29Belum ada peringkat

- Rescue Triangle PDFDokumen18 halamanRescue Triangle PDFrabas_Belum ada peringkat

- Jesus - The Creator Unleashes Our Creative PotentialDokumen1 halamanJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongBelum ada peringkat

- SIM5320 - EVB Kit - User Guide - V1.01 PDFDokumen24 halamanSIM5320 - EVB Kit - User Guide - V1.01 PDFmarkissmuzzoBelum ada peringkat

- Fundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDokumen35 halamanFundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDrMichelleHutchinsonegniq100% (15)

- Mba Project GuidelinesDokumen8 halamanMba Project GuidelinesKrishnamohan VaddadiBelum ada peringkat

- 01 Design of Flexible Pavement Using Coir GeotextilesDokumen126 halaman01 Design of Flexible Pavement Using Coir GeotextilesSreeja Sadanandan100% (1)

- Seminar #22 Vocabury For Speaking PracticeDokumen7 halamanSeminar #22 Vocabury For Speaking PracticeOyun-erdene ErdenebilegBelum ada peringkat

- Ne 01 20 09 2018Dokumen436 halamanNe 01 20 09 2018VaradrajBelum ada peringkat

- Khaton Prayer BookDokumen47 halamanKhaton Prayer BookKarma TsheringBelum ada peringkat

- Crash Cart - General Checklist For Medical Supplies On Crash CartsDokumen3 halamanCrash Cart - General Checklist For Medical Supplies On Crash CartsYassen ManiriBelum ada peringkat

- IT SyllabusDokumen3 halamanIT SyllabusNeilKumarBelum ada peringkat

- Bitcoin MambaDokumen17 halamanBitcoin MambaJean MilenixBelum ada peringkat

- CCEE SWD Basic Levers ToolDokumen28 halamanCCEE SWD Basic Levers ToolDivina Margarita Gómez AlvarengaBelum ada peringkat

- STERNOL Specification ToolDokumen15 halamanSTERNOL Specification ToolMahdyZargarBelum ada peringkat

- Pfrs 16 LeasesDokumen4 halamanPfrs 16 LeasesR.A.Belum ada peringkat

- Chapter 9-10 (PPE) Reinzo GallegoDokumen48 halamanChapter 9-10 (PPE) Reinzo GallegoReinzo GallegoBelum ada peringkat

- (App Note) How To Design A Programmable Gain Instrumentation AmplifierDokumen7 halaman(App Note) How To Design A Programmable Gain Instrumentation AmplifierIoan TudosaBelum ada peringkat