Flange Modeling Approaches

Diunggah oleh

anishsr0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

17 tayangan7 halamanAutoPipeFlange Modeling

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOC, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAutoPipeFlange Modeling

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

17 tayangan7 halamanFlange Modeling Approaches

Diunggah oleh

anishsrAutoPipeFlange Modeling

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 7

1.

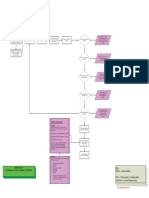

Modeling Approaches, Tips, Technique for Flanges

Piping Components in AutoPIPE

Attention: Please see the following AutoPIPE help section:

Help > Contents> Contents Tab> Modeling Approaches> Modeling Approaches>

This help has been provided in order to give users ideas for modeling tpical piping

arrangements! The steps shown in each e"ample should not be ta#en as the onl

method available to create models! In addition$ the intent of the e"amples is to present

was to create ade%uate models of speci&c piping components for analtical purposes!

Anchors 'ends

Cuts (le"ible )oints

(rames Hangers

*o++les Pipes

,educers ,otating E%uipment

-upports Tees

.alves .essels

2. Questions, and Answers:

3. Item #1. How to model typical fanges in AutoPIP !"i

#.$ and %ower:

Answer: In AutoPIPE ./i 0!1 and lower$ 2anges are a 3 point element with no

length> The program onl considers the 2ange weight and weld connection for

-I( calculations! Assuming 2ange sti4ness is same as the pipe is technicall

incorrect because a 2ange is more rigid than pipe! However$ it does *5T a4ect

analsis results to an signi&cant e"tent! 6ou can choose to model a 2ange as a

single point or ta#e into consideration the actual 2ange length!

-ee the following procedure to model the actual 2ange length:

A! Assuming a 2anged no++le connection to be anchord to a vessel$ insert

an anchor!

'! Insert a short run of pipe e%ual to the actual 2ange length!

C! Insert another pipe run and to the ne"t node point in the model!

7! Insert a 2ange at *o++le interface$ in this e"ample$ start of the

segment8anchor point! 5n the 2ange dialog$ change )oint End Tpe 9 :;ser

7e&ned:$ set :)oint -I(: 9 3!< =note: can use an >oint end tpe connection

so long as the -I( calculated is 3!< at the 2ange point?

E! -elect this short length of pipe representing the actual 2ange length$

press Insert & 'igid options o(er 'ange =Include @eight 9 o4$ Include

Thermal E"pansion 9 o4!!!pipe will be shown purple?$ and press 5A button

(! -elect the node point representing the 2ange connection to the pipe!

Press Insert > Btra 7ata> )oint Tpe user -I(! -elec the correct tpe of end

connection or enter a user -I(!

=(rom AutoPIPE ./i 0!C?

). Item #2. *odel a Anc+or fanges:

Answer: Anchor 2anges are considered to be buried within concrete!

Modeling approach:

A! 5n the segment where the 2ange is to be modeled$ insert a node point

=e"! '<D? as the welded connection between he pipe and 2ange

'! Insert a Pipe run half the total length of the Hanger 2ange =e"! '<C?!

C! Insert another Pipe run with the same length as in -tep ' above =e"!

'<1?!

7! -elect the middle point of the 2ange =e"! '<C?$ insert a 2ange

component! 5n the 2ange dialog$ change )oint End Tpe 9 :;ser 7e&ned:$

set :)oint -I(: 9 3!< =note: can use an >oint end tpe connection so long as

the -I( calculated is 3!< at the 2ange point?

E! -elect both pipe runs =e"! '<DE'<C F '<CE'<1?$ press Insert > ,igid

options over ,ange =Include @eight 9 o4$ Include Thermal E"pansion 9

o4!!!pipe will be shown purple?$ and press 5A button

(! -elect both 2ange end points =e"! '<D F '<1?$ Press Insert > Btra 7ata>

)oint Tpe user -I(! -elect the correct tpe of end connection or enter a user

-I(!

G! Connection to support: choose one of the following$ model connection as

simple supports or model with soil properties

*otes:

i! Model connection as simple support: add additional node points =e"! '<H

F '<I? with rigid pipe properties as done is step E to represent pipe

entombed in concrete! At the locations where the pipe enters the concrete

add AutoPIPE supports or anchors as needed!

ii! Model connection with soil properties: add additional node points to

represent pipe entombed in concrete! Insert -oil properties over same node

points added! -elect all the pipe with in the concrete and appl the correct

soil properties to mimic concrete!

,. Item #3. *odel a Hanger fanges:

Answer: Hanger 2anges are considered to be bolted to a structure!

Modeling approach:

A! 5n the segment where the 2ange is to be modeled$ insert a node point

=e"! '<D? as the welded connection between he pipe and 2ange

'! Insert a Pipe run half the total length of the Hanger 2ange =e"! '<C?!

C! Insert another Pipe run with the same length as in -tep ' above =e"!

'<1?!

7! -elect the middle point of the 2ange =e"! '<C?$ insert a 2ange

component! 5n the 2ange dialog$ change )oint End Tpe 9 :;ser 7e&ned:$

set :)oint -I(: 9 3!< =note: can use an >oint end tpe connection so long as

the -I( calculated is 3!< at the 2ange point?

E! -elect both pipe runs =e"! '<DE'<C F '<CE'<1?$ press Insert > ,igid

options over ,ange =Include @eight 9 o4$ Include Thermal E"pansion 9

o4!!!pipe will be shown purple?$ and press 5A button

(! -elect both 2ange end points =e"! '<D F '<1?$ Press Insert > Btra 7ata>

)oint Tpe user -I(! -elect the correct tpe of end connection or enter a user

-I(!

G! Connection to support: choose one of the following$ model connection as

simple supports or model with beam elements

*ote: i! Model connection as simple support: Insert AutoPIPE supports

as need at the 2ange center point =e"! '<C?!

ii! Model connection with beams: Insert rigid beam elements from

the 2ange center =e"! '<C? to the actual bolted support connection

=e" -% beam?! Add additional beams with the correct beam

properties from the bolted support connection to the support

structure that is correctl supported =e"! Angle beams?!

$. Item #), How to model a -tu. nd, -wi(el, or

*isalignment /lange

Answer: The swivel 2ange is used with medium service pressures at points where the

bolt holes in the mounting 2anges are not precisel aligned! The swivel 2ange simpli&es

&tting between J &"ed points!

Answer: (or strss analsis purpose$ the program needs to #now the weight and

-I( associated with a 2ange! Most A-ME piping codes do not have

established -I( values for these tpes of 2anges! @hilst A-ME 31!C and 31!DI

codes are applicable for weld nec# 2anges$ the are not applicable to swivel

ring 2anges beond the bolt pattern and bolt si+es! A-ME o4er alternative rules

that consider swivel ring 2anges as nonEstandard$ or loose tpe$ 2anges!

Therefore the modeling appraoch for these tpes of 2anges:

-elect the node point where the 2ange is to be located$ press Insert> (lange>$

on the 2ange dialog screen enter:

(lange tpe 9 *-

Pressure ,ating 9 *-

@eight 9 enter weight from vendor literature

)oint End Tpe: ;ser 7e&ned

)oint -I(: contact 2ange manufature for value to be used!

*ote: 5ne could argue to set )oint end tpe 9 :Kap >oint: in order to

automaticall calcuale the -I(! However$ since these tpes of >oints are not

covered b the applicable piping code$ ou will need to use engineering

>udgement or contact the manfacture! 'entle T-G cannot provide a de&native

value!

Anda mungkin juga menyukai

- E-catalogue-KeralaTourism - Part 1Dokumen35 halamanE-catalogue-KeralaTourism - Part 1anishsrBelum ada peringkat

- E-catalogue-KeralaTourism - Part 2Dokumen36 halamanE-catalogue-KeralaTourism - Part 2anishsrBelum ada peringkat

- Kerala Festivals E-CatalogueDokumen37 halamanKerala Festivals E-CatalogueanishsrBelum ada peringkat

- Material For Handling Chlorine ChemicalsDokumen38 halamanMaterial For Handling Chlorine ChemicalsanishsrBelum ada peringkat

- uPVC Pressure Pipes CatalogueDokumen30 halamanuPVC Pressure Pipes CatalogueanishsrBelum ada peringkat

- Kerala Tourism Videos E-CatalogueDokumen21 halamanKerala Tourism Videos E-CatalogueanishsrBelum ada peringkat

- Kerala Tourism Videos E-CatalogueDokumen12 halamanKerala Tourism Videos E-CatalogueanishsrBelum ada peringkat

- UPVC Pressure Pipes FittingspdfDokumen12 halamanUPVC Pressure Pipes FittingspdfpinaBelum ada peringkat

- Kerala Tourism Videos CatalogDokumen21 halamanKerala Tourism Videos CataloganishsrBelum ada peringkat

- Kerala Tourism Videos E-CatalogueDokumen48 halamanKerala Tourism Videos E-CatalogueanishsrBelum ada peringkat

- Broucher 1571983016Dokumen19 halamanBroucher 1571983016anishsrBelum ada peringkat

- Slutrapport 16-457 2Dokumen38 halamanSlutrapport 16-457 2anishsrBelum ada peringkat

- HDPE - Material PropertiesDokumen61 halamanHDPE - Material PropertiesanishsrBelum ada peringkat

- Bahrain Pipes CatalogueDokumen84 halamanBahrain Pipes CatalogueanishsrBelum ada peringkat

- GRVE Catalogue-PipingDokumen102 halamanGRVE Catalogue-PipinganishsrBelum ada peringkat

- Offshore Oil & Gas Facilities Decommissioning Pipeline CleaningDokumen1 halamanOffshore Oil & Gas Facilities Decommissioning Pipeline CleaninganishsrBelum ada peringkat

- Plasticon Catalogue PipingDokumen105 halamanPlasticon Catalogue PipinganishsrBelum ada peringkat

- GRVE Piping Installation GuideDokumen25 halamanGRVE Piping Installation GuideanishsrBelum ada peringkat

- General Spec For Pipline Riser DesignDokumen3 halamanGeneral Spec For Pipline Riser Designanishsr100% (1)

- International Standard: Plastics Piping Systems - Polyethylene (PE) Pipes and Fittings For Water Supply - GeneralDokumen8 halamanInternational Standard: Plastics Piping Systems - Polyethylene (PE) Pipes and Fittings For Water Supply - GeneralanishsrBelum ada peringkat

- Thermoplastics Pipes - ISO161Dokumen10 halamanThermoplastics Pipes - ISO161anishsrBelum ada peringkat

- Iso4427 5Dokumen12 halamanIso4427 5anishsrBelum ada peringkat

- Plastic Pipe - PE - Chapter01Dokumen9 halamanPlastic Pipe - PE - Chapter01garisa1963Belum ada peringkat

- ChemEngineering 03 00004 PDFDokumen12 halamanChemEngineering 03 00004 PDFanishsrBelum ada peringkat

- Input From Vendor For FEED Study Rev. 0 - Checklist PDFDokumen1 halamanInput From Vendor For FEED Study Rev. 0 - Checklist PDFanishsrBelum ada peringkat

- GS Ep PLR 404 PDFDokumen3 halamanGS Ep PLR 404 PDFanishsrBelum ada peringkat

- Cleanliness Standard PDFDokumen1 halamanCleanliness Standard PDFanishsrBelum ada peringkat

- Cleanliness Standard PDFDokumen1 halamanCleanliness Standard PDFanishsrBelum ada peringkat

- Input From Vendor For FEED Study Rev. 0 - Checklist PDFDokumen1 halamanInput From Vendor For FEED Study Rev. 0 - Checklist PDFanishsrBelum ada peringkat

- Pipeline System Cleaning PDFDokumen1 halamanPipeline System Cleaning PDFanishsrBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Glycol Dehydration UnitDokumen11 halamanGlycol Dehydration UnitarispriyatmonoBelum ada peringkat

- XYZ Murders (Aka Crimewave)Dokumen94 halamanXYZ Murders (Aka Crimewave)Danny Steel100% (1)

- Digestive Chamber: Scale NTSDokumen1 halamanDigestive Chamber: Scale NTSRomeo Beding Densen Jr.Belum ada peringkat

- Determining The Inclusion or Second-Phase Constituent Content of Metals by Automatic Image AnalysisDokumen8 halamanDetermining The Inclusion or Second-Phase Constituent Content of Metals by Automatic Image AnalysisWaqas RajaBelum ada peringkat

- GE - Mark V Turbine ControlDokumen1 halamanGE - Mark V Turbine ControlAdil Butt0% (1)

- Astm d4694 09 Def FWDDokumen3 halamanAstm d4694 09 Def FWDJuan Casia Boza100% (1)

- Johnson ManualDokumen108 halamanJohnson Manualfirebird197286% (7)

- CN398 - Dual ESSP Interface To Both Smart Payout and HopperDokumen1 halamanCN398 - Dual ESSP Interface To Both Smart Payout and HopperAymen CheffiBelum ada peringkat

- Charles Rennie MackintoshDokumen14 halamanCharles Rennie MackintoshRadu Stefan100% (1)

- Demand Side Management and Its ProgramsDokumen15 halamanDemand Side Management and Its ProgramsAhmad H Qinawy100% (1)

- NFL NANGAL Urea Plant Process & SpecsDokumen35 halamanNFL NANGAL Urea Plant Process & SpecsAkhil AklBelum ada peringkat

- Price ListDokumen141 halamanPrice ListAriane Llantero0% (1)

- 3 28 19 NtapDokumen199 halaman3 28 19 Ntapfikri fikriBelum ada peringkat

- Pet-704 704PDokumen38 halamanPet-704 704Papi-3702225100% (1)

- Memory OrganisationDokumen34 halamanMemory OrganisationricketbusBelum ada peringkat

- Serway Physics II Example Questions Chapter 8Dokumen1 halamanSerway Physics II Example Questions Chapter 8AizuddinBelum ada peringkat

- Transponder Test and Configuration Unit: Kongsberg MaritimeDokumen2 halamanTransponder Test and Configuration Unit: Kongsberg MaritimecheloBelum ada peringkat

- Effectof Cyclic Loadingsonthe Shear StrengthandDokumen14 halamanEffectof Cyclic Loadingsonthe Shear StrengthandAbel MulugetaBelum ada peringkat

- Lcra Drought Contingency Plan For Firm Water Customers Update Pres 2024-02-21Dokumen10 halamanLcra Drought Contingency Plan For Firm Water Customers Update Pres 2024-02-21Anonymous Pb39klJBelum ada peringkat

- Properties of Spider SilkDokumen9 halamanProperties of Spider SilkArifah PujiatiBelum ada peringkat

- ECEN 310 Tutorial 5Dokumen7 halamanECEN 310 Tutorial 5Haris Ãlï0% (1)

- Sika AnchorFix 1 PDSDokumen8 halamanSika AnchorFix 1 PDSAchilleas21Belum ada peringkat

- Python TutorialDokumen12 halamanPython TutorialSazzad HossainBelum ada peringkat

- UDN6118ADokumen8 halamanUDN6118AkizonzBelum ada peringkat

- Human Resource BBPB2103 - English Module PDFDokumen290 halamanHuman Resource BBPB2103 - English Module PDFVignash100% (1)

- 4unsafe Unhealthy Act Conditions PDFDokumen41 halaman4unsafe Unhealthy Act Conditions PDFej constantino100% (1)

- Expt 2 - Thevenin-NortonDokumen10 halamanExpt 2 - Thevenin-NortonNitin KhetadeBelum ada peringkat

- 76 5500 1 I1Dokumen152 halaman76 5500 1 I1shawn allen100% (4)

- NDIR Type Infrared Gas Analyzer Type ZKJ-3Dokumen97 halamanNDIR Type Infrared Gas Analyzer Type ZKJ-3Yoga SanBelum ada peringkat

- Arch 43465Dokumen65 halamanArch 43465Jackson BergBelum ada peringkat