Reinforced Conc

Diunggah oleh

Asghar Hussain ShahHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Reinforced Conc

Diunggah oleh

Asghar Hussain ShahHak Cipta:

Format Tersedia

C

o

n

s

t

r

u

c

t

i

o

n

Technology and Concepts

for the Repair and Protection

of Reinforced Concrete

Technology and Concepts for the Repair

and Protection of Reinforced Concrete

S

&

W

0

9

.

0

5

/

0

5

S

I

C

2

1

.

2

7

/

S

i

k

a

S

e

r

v

i

c

e

s

A

G

,

S

w

i

t

z

e

r

l

a

n

d

C

e

rtifie

d

Quality

S

y

s

te

m

I

S

O

9

0

01/ EN

2

9

0

0

1

since 1986

C

e

r

t

ifie

d

M

anagemen

t

S

y

s

t

e

m

I

S

O

140

0

1

since 1997

Sika Services AG

Corporate Construction

CH-8048 Zrich

Switzerland

Phone +41 44 436 40 40

Fax +41 44 436 46 86

www.sika.com

Your local Sika Company

Our most current General Sales Conditions shall apply. Please

consult the Product Data Sheet prior to any use and processing.

C

o

n

s

t

r

u

c

t

i

o

n

Also available from Sika

Sika is a globaly active company in the speciality and construction

chemicals business. It has subsidiary manufacturing, sales and

technical support facilities in over 70 countries around the world.

Sika is THE global market and technology leader in waterproong,

Sika Your Local Partner with a Global Presence

sealing, bonding, dampening, strengthening and protection of

buildings and civil engineering structures.

Sika has more than 9200 employees worldwide and is therefore

ideally positioned to support the success of its customers.

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 10:59 Uhr Seite 2

Corrosion Management in

Reinforced Concrete Structures

The Key Stages in the Process

Following review of the original design,

construction methods and programme,

and the assessment survey, identify the

root causes of damage:

Identify mechanical, chemical and

physical damage to the concrete.

Identify concrete damage due to

reinforcement corrosion.

The assessment of the condition of a

damaged or deteriorated reinforced

concrete structure should only be made

by qualied and experienced people.

The process of assessment will always

include the following aspects:

The current condition of the structure

including visible, non-visible and

potential defects.

Review of the past, current and future

exposure.

Corrosion

Management

NO NOISE

LIMITED HOURS

1 2

With most damaged or deteriorated struc-

tures the owner has a number of options

which will effectively decide the appropriate

repair and protection strategy to meet the

future requirements of the structure.

The options include:

Do nothing.

Downgrade the structure or its capacity.

Prevent or reduce further damage

without repair.

Improve, refurbish or strengthen all or

part of the structure.

Demolition.

3

It is necessary to clarify the owners re-

quirements and instructions in relation to:

The required durability, requirements

and performance.

Intended design life.

How loads will be carried before, during

and after the repair.

The possibility for future repair works

including access and maintenance.

Costs of the alternative solutions.

The consequences and likelihood of

structural failure.

The consequences and likelihood of

partial failure (falling concrete, water

ingress, etc).

And environmentally:

The need for protection from sun, rain,

frost, wind, salt and/or other pollutants

during the works.

The environmental impact or restric-

tions on the works in progress, partic-

ularly the noise and the time taken

to carry out the work.

The likely environmental/aesthetic

impact of the improved/reduced

appearance of alternative solutions.

4

What is the mode and result of the

selected materials deterioration, i.e.

chalking, embrittlement, discoloura-

tion, delamination?

What surface preparation and access

systems will eventually be required

and when?

Who is responsible and how will it be

nanced?

5 Assessment Survey of the

Condition of the Structure

Diagnosis of the Cause

of Deterioration

Determine the Repair

and Protection Objectives

Select the appropriate

Repair and Protection

Strategy

Denition of the future

Maintenance Requirements

and Procedures

The successful repair and

protection of concrete

structures which have been

damaged or which have

deteriorated requires pro-

fessional assessment, then

design, supervision and

execution of technically

correct principals according

to the forthcoming European

Standard being developed

by EN 1504.

This brochure is intended

to give guidance on the

correct procedure and on

the appropriate products

and systems for the selected

strategy. The key stages in

the process are:

2 I 5

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 10:59 Uhr Seite 4

Cracking caused by incorrect handling or xing of

precast panels.

Chemical attack (and subsequent reinforcement corro-

sion) on a factory roof.

Freeze/thaw effect on a parking structure.

Assessment Survey and Diagnosis of Damage

Reinforcement corrosion following reduction of the

passivating concrete alkalinity by carbonation.

Reinforcement corrosion showing as rust staining from

cracks after galvanized steel railings were xed into

the parapet.

The damaging effects of steel corrosion accelerated

by chloride ingress from deicing salts.

Concrete Damage due

to Reinforcement Corrosion

Concrete Damage and Defects

Mechanical Chemical

Carbon dioxide (CO2) in the atmos-

phere reacting with calcium hydroxide

in the concrete pore liquid.

CO2 + Ca(OH)2 >CaCO3 + H2O

Soluble and pH 1213 >Almost

insoluble and pH 9

Steel passivated >Steel unprotected

Metals of different electropotential

are connected to each other in

the concrete and corrosion occurs.

Corrosion can also be due to stray

electrical currents from transmission

networks.

Chlorides accelerate the corrosion

process however originally caused.

At above 0.2 0.4% they break

down the passive oxide.

Chlorides can be from marine expo-

sure or deicing salts.

Their use to accelerate concrete

setting at low temperatures is now

mostly banned in reinforced

concrete.

Corrosive Contaminants

e.g. Chlorides

Stray/Electrical Current Carbonation

Impact, vibration and explosion

Abrasion and wear

Overloading

Earthquake

Alkali aggregate reaction

Chemical exposure

Bacterial action

Physical

Thermal movement

Freeze/thaw action

Eforescence/Leaching

Salt crystal expansion

Erosion

4 I 7

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 10:59 Uhr Seite 6

Determine the Objectives and select

the Appropriate Strategy

Provide Additional Concrete

Cover

Advantages

The old traditional approach.

Disadvantages

Very expensive if correctly applied

over all of the concrete surface.

Has no effect on further aggressive

inuence ingress.

Provides no protection against latent

damages.

Very poor appearance.

Overcladding and Insulation

Advantages

Greatly improves appearance.

Provides the additional benet of

insulation.

Provides a long-term solution.

Disadvantages

Very expensive.

Can hide latent defects.

Extended contract period.

Conventional Repair and

Protection

Advantages

Meets existing national standards

(DIN/BBA/SIS/NF, etc.).

Proven performance (over 20 years

with Sika systems).

Provides some protection against

latent carbonation damages.

Cost effective.

Disadvantages

No protection against latent chloride

damage.

Requires extensive concrete break-out.

Considerable noise, vibration and dust.

Apply Cathodic Protection

Advantages

The only way to completely stop steel

corrosion.

Permanent solution (with full repairs

and monitoring).

Disadvantages

Ongoing cost to maintain.

Many structures not suitable (access,

non-continuous reinforcement, pre-

stressing steel, etc).

Having fully considered their

options, owners normally

face having to improve,

refurbish or strengthen all

or part of the structure:

For structural strengthening

requirements refer to Sika

Technical Services for full

details of the innovative

Sika

CarboDur

structural

strengthening system.

For concrete structures there

are now alternative solutions

proposed for improvement

and refurbishment that are

considered as corrosion

management. These include:

Realkalization

or Desalination

Advantages

Based on reversing the principles of

cathodic protection.

Limited concrete removal.

No ongoing maintenance (except

protective coatings).

Disadvantages

Very high installation cost.

Not all structures are suitable (as

cathodic protection).

Where there is potential for ASR/AAR.

Not environmentally sound (caustic

waste disposal).

Average concrete quality

with Sika

FerroGard

-903

Average concrete quality

without Sika

FerroGard

Doubling of the service life

Service life

Visible damage

Limit of service life

years

D

e

v

e

l

o

p

m

e

n

t

o

f

c

o

r

r

o

s

i

o

n

y = rate

of corrosion

y

/2 = rate

of corrosion

Onset of corrosion Onset of corrosion

Average concrete quality after

application of Sika

FerroGard

-903

Average concrete quality

without Sika

FerroGard

Service life

Visible damage

Limit of service life

years

D

e

v

e

l

o

p

m

e

n

t

o

f

c

o

r

r

o

s

i

o

n

y = rate

of corrosion

y

/2 = rate

of corrosion

Onset of corrosion Onset of corrosion

Extension of service life

New start after Sika

FerroGard

-903 application

Concrete Repair and Protection

with Corrosion Inhibitors

Advantages

All the advantages of conventional

concrete repair and protection.

Greatly reduced concrete break-out.

Greatly reduced noise vibration and dust.

Reduced contract periods.

Provides protection against residual

chlorides and against incipient anode

formation.

Extremely cost effective.

Most structures suitable.

No ongoing maintenance (except re-

fresher top coatings after 10 15 years).

System Positioning with

Sika

FerroGard

-903 Corrosion Inhibitor

In New Construction

Protection before visible Damage

As part of a Complete Repair and Protection Strategy after visible Concrete Damage

Average concrete quality

without Sika FerroGard

Service life

Visible damage

Limit of service life

years

D

e

v

e

lo

p

m

e

n

t

o

f

c

o

r

r

o

s

io

n

y = rate

of corrosion

ny = rate

of corrosion

New start after repair

Extension of service life

Onset of corrosion Onset of corrosion

Average concrete quality with

concrete repair and protection

including application

of Sika FerroGard-903

6 I 9

FerroGard

FerroGard

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 10:59 Uhr Seite 8

Sika

MonoTop

Levelling Mortars

coarse/ne

One-component levelling and repro-

ling mortar.

Sikagard

Elastic Coatings

All the special properties of

Sikagard

Coatings:

Bridges dynamically moving cracks

even at low temperatures.

Water and solvent based primers.

Sikagard

Impregnations

Prevents water and chloride ingress.

Allows each way water vapour diffusion.

The Sika

Principles of Concrete Repair

and Protection

Select the appropriate Sika

System

Levelling the Prole and

lling Surface Pores

Protecting against

the Development of latent

Damage

Sealing and Coating

preventing the Ingress of

aggressive Inuences

Protecting exposed

Reinforcement

Remove damaged Concrete

and prepare exposed Steel

Replacing damaged

Concrete

Hydrophobic Impregnations

Anti-Carbonation Coatings

SikaTop

-Armatec

110 EpoCem

Protects reinforcement in a highly

alkaline cementitious environment.

Can be applied on damp surfaces.

Increases barrier to chlorides and

carbonation.

Steel reinforcement primer and

bonding bridge.

Fully complies with load transfer

requirements.

SikaTop

Repair Mortars

Two-component prebatched polymer-

modied repair mortars.

Lower modulus for increased dura-

bility.

SikaTop

Levelling Mortars coarse/ne

Use to ll surface defects to ensure

continuous protective coating.

Produce the desired surface texture.

Provides uniform substrate.

Sika

MonoTop

One-component steel reinforcement

primer and bonding bridge.

Sika

MonoTop

Mortars

One-component polymer-modied

repair mortars.

Suitable for hand and wet spray

machine application.

Sikagard

Coatings

Effectively halts carbonation.

Allows each way water vapour diffusion.

Prevents water and chloride ingress.

Outstanding colour retention.

Sikagard

-720 EpoCem

Unique epoxy cement technology.

Integral curing ability.

Also as a protective coating.

Ideal for levelling and reproling after

application of Sika Ferrogard

-903.

Sika

FerroGard

-903

Penetrates via liquid and vapour

diffusion.

Film forming inhibitor.

Mixed inhibitor acting on anodic and

cathodic sites.

Blended inhibitor combining special

amino-alcohol and inorganic inhibitors.

Sika

Technology

SikaCem

Gunite Mortars

Ideal for use with Aliva dry-sprayed

concrete equipment.

Tested for application to structures

subject to vibration under load.

Tested for use with most cathodic

protection systems.

8 I 11

FerroGard

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 10:59 Uhr Seite 10

The worldwide independent Proof Statements

Independent Assessment and Approval

An international review was undertaken

by leading independent consultants and

testing institutes. Major projects repaired

and protected with Sika Systems between

1977 and 1986 were inspected

and their durability and

performance

assessed

in 1997.

System Performance

There are functional and performance

requirements which must be met by both

the individual products and components

of a system and by the system together

as a whole.

Quality Assurance

It is necessary for any product or compo-

nent or system to meet well dened

quality assurance and control standards

in production. This is why Sika produces

to ISO Standards at its factories throughout

the world.

Application Criteria

In addition to their performance in place,

it is also essential to dene and test the

application properties of products and

systems to ensure that they can actually

be applied practically on site, and in the

differing conditions that will be necessary.

For example: Sika mortars must be suit-

able for differing thicknesses and

areas/volumes of repair and applied in

as few layers as possible. Sikagard

coatings must have adequate thixotropy

to obtain the desired wet and dry lm

thicknesses in the minimum number

of coats, and with these they must also

achieve adequate opacity. C

e

rtified

Quality S

y

s

te

m

IS

O

9000/EN 29

0

0

1

Sika undertakes extensive Durability Testing

In the Laboratory

Low Temperature dynamic Crack

Bridging Testing of Coatings

Machine Application of Repair Mortars

Spray application for test under live dynamic loading.

Sikagard

products are tested for their

performance as anti-carbonation and

water vapour diffusable coatings, both

when freshly applied, and also after up

to 10000 hours accelerated weathering

(equivalent to in excess of 15 years).

Only this can give a complete picture of

the products true performance.

Sikagard

coatings therefore continue

to perform long after other coatings have

ceased to provide effective protection.

In the Field

Product Performance

The specic criteria that

Sika uses to evaluate all of

its products and systems

for concrete repair and

protection, are in accordance

with the requirements of

the European Standard

EN 1504 where appropriate.

They include the following:

Sika has developed Product Performance Testing

The Bnziger Block for Testing Repair Mortars

Direct comparison worldwide

Application horizontal, vertical and overhead

Realistic site dimensions

Additional lab testing by coring

Crack-free performance under different

conditions

Replacing damaged

Concrete

Bond strength

Compressive and exural strengths

Permeability to water

Elastic modulus (stiffness)

Restrained shrinkage

Thermal compatibility

Protecting exposed

Reinforcement

Bond strength to steel and concrete

Corrosion protection

Permeability to water

Permeability to water vapour

Permeability to carbon dioxide

Protecting against the

Development of latent

Damage

Penetration ability

Film forming ability

Corrosion inhibition

Chloride displacement

Hydroxide displacement

(carbonation induced)

Levelling the Prole and

lling Surface Pores

Bond strength

Permeability to carbon dioxide

Water permeability and absorption

Sealing and Coating

preventing the Ingress of

aggressive Elements

Sealing with Hydrophobic

Impregnations

Penetration ability

Permeability to water

Permeability to water vapour

Freeze/thaw resistance

Anti-Carbonation Coatings

Bond strength

Cross hatch performance

Permeability to carbon dioxide

Permeability to water vapour

U.V. light resistance

Alkaline resistance

Freeze/thaw resistance

Fire resistance

Cleanability

Crack Bridging Anti-Carbonation

Coatings

As above for anti-carbonation coatings, plus:

Crack bridging ability: statically, dynamic-

ally, at low temperatures (20C/20F)

10 I 13

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 11:00 Uhr Seite 12

International Case Studies

Sika Solution

Removal of damaged concrete and

preparation of exposed reinforcement.

Protect reinforcement with SikaTop

-

Armatec

110 EpoCem

.

Replace damaged concrete:

SikaCem

-133 Gunite.

Protect the surface from future

aggressive chemicals with

Sikagard

high performance

coating.

Structure

24 storey housing block. Reinforced con-

crete frame with architectural precast

concrete cladding panels.

Problem

Loading and impact damaged architectural

precast cladding panels (from time of

original construction). Cracks and inade-

quate cover over steel reinforcement.

Sika Solution

Removal of loose concrete and

preparation of exposed reinforcement.

Protect reinforcement with:

SikaTop

-Armatec

110

EpoCem

.

Replace damaged concrete with:

Sika repair mortar.

Provide a uniform, attractive surface

nish and protection with:

Sikagard

-550W.

Chemical Damage

Mechanical Damage

Structure

Factory roof over production facilities.

Problem

Aggressive chemical attack on the concrete.

Followed by corrosion of the steel reinforce-

ment in a high temperature, high humidity

environment.

Chemical Damage

Physical Damage

Structure

Multi-storey concrete parking structure.

Problem

Freeze/thaw damage on concrete

columns and softs from condensation

and deicing salts exposure.

Sika Solution

High pressure water jetting followed

by blast cleaning.

Repair and reproling with SikaTop

mortars.

Protection against future water and

deicing salt ingress with

Sikagard

-680S (columns and

softs) and Sikagard

-550W

(areas subject to cracking parapets

and external facades).

Joint sealing with Sikaex

sealants.

Steel corrosion protection with

Icosit

coatings.

12 I 15

Structure

Mnchaltorf sewage treatment plant,

preliminary sedimentation, aeration and

nal sedimentation tanks.

Problem

The concrete surfaces of the sedimentation

tanks were damaged by attack from the

sewage (acids, sulphates, fats, etc.) and

the routine high-pressure water cleaning.

The surface of the concrete was severely

eroded. A few reinforcement bars near the

surface were also exposed following this

erosion and were also now corroding from

the chemical attack.

The existing joint sealants had embrittled

and had disbonded from the sides of the

joints.

Sika Solution

Removal of the damaged and contam-

inated concrete by blastcleaning.

Breaking out to fully expose the cor-

roding reinforcement and the removal of

all corrosion products by blastcleaning.

Application of Sika

MonoTop

-610

for corrosion protection and as a bond

coat for patch repairs,

Localized patch repairs with

Sika

MonoTop

repair mortar.

Watertight sealing of the joints

by overbanding with the

Sikadur

-Combiex

System.

Overall surface restoration and levelling

with Sikagard

-720 EpoCem

.

Overall surface protective coating with

Sikaoor

-390 Thixo on the oors

and walls and with Icosit

277 on

the top horizontal surfaces of the walls.

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 11:00 Uhr Seite 14

International Case Studies

Physical Damage

Structure

150 metre (500 feet) long major road

bridge.

Problem

Concrete damage on the parapet and

underside of the bridge due to freeze/

thaw action accelerated by deicing salts.

Sika Solution

Surface preparation and defective

concrete removal by high pressure

water jetting.

Parapet: Sika

MonoTop

-610

as corrosion protection for exposed

reinforcement and as a bonding bridge

followed by Sika

MonoTop

repair

mortar at 3 6 cm thickness.

Substructure: SikaTop

-Armatec

110 EpoCem

as corrosion

protection, allowed to cure, and then

repair by dry spray application of

SikaCem

-133 Gunite repair

mortar.

Carbonation Damage

Structure

Multi-storey residential housing block

with concrete frame and precast cladding

panels.

Problem

Inadequate concrete cover to steel rein-

forcement with extensive cracking and

spalling after depth of carbonation

reached the steel.

Sika Solution

Concrete surface preparation by high

pressure water jetting.

Exposed steel reinforcement prepared

by blast cleaning.

Steel reinforcement protection and

bonding bridge with SikaTop

-

Armatec

110 EpoCem

.

Repair and reproling with Sika repair

mortar.

Crack-bridging anti-carbonation

protection on large concrete surfaces

with Sikagard

-550Wcoating.

Joint sealing with Sikaex

sealants.

Galvanized balcony handrail protection

with Icosit

coatings.

Carbonation Damage

Carbonation Damage

Structure

Historic reinforced concrete drinking water

tower.

Problem

Externally carbonation depth had reached

the main steel reinforcement allowing

expansive rusting to occur with subsequent

concrete cracking and spalling.

Sika Solution

Surface preparation by blast cleaning.

Steel reinforcement protection

and bonding bridge with

SikaTop

-Armatec

110

EpoCem

.

Repair and levelling with SikaTop

mortars.

Anti-carbonation protection and

enhanced appearance with

Sikagard

-680S.

14 I 17

Surface patch repairs using

Sika

MonoTop

-600 PCC

mortars.

Levelling and sealing the whole surface

with Sika

MonoTop

-620, and

on the chimney annulus area with

Sikagard

-720 EpoCem

.

Elastic protective coatings on the lower

zone with 3 Sikagard

-550W

Elastic and chemically resistant

protection on the upper zone with

1 Icosit

2406 Primer,

1 Icosit-Poxicolor

and

1 Icosit

EG 5.

The most chemically exposed chimney

annulus area coated with

2 Icosit

-277 and

2 Icosit

EG 5.

Structure

Existing chimney H = 140 m in a com-

bined heat and power station.

Problem

Exposed reinforcing steel corrosion from

atmospheric carbonation of concrete

in the lower zone, chemical attack of

the concrete by sulphates eroding the

concrete in the upper zone. Existing pro-

tective coatings deteriorated, with very

poor adhesion and no longer providing any

protective function. Many hairline cracks

on the concrete surface in the lower zone.

Sika Solution

Replacement of damaged concrete

with dry spray ne concrete using

EM I 42.5 N HSE, with

Sikacrete

-PP1 TU and

Sigunit

-49 AF.

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 11:00 Uhr Seite 16

18

Structure

1200 metre (3/4 mile) viaduct consisting

of 10 bridges over road and rail tracks.

Problem

Extensive chloride accelerated

reinforcement corrosion particularly

below expansion joints in the deck.

Sika Solution

Following replacement of bridge

deck joints.

Removal of all damaged concrete.

High pressure water jetting (also

to reduce residual chloride levels).

Blast cleaning to prepare exposed

steel reinforcement.

Repair and reproling with

SikaCem

-133 Gunite dry spray

mortar.

International Case Studies

Electrical Damage

Structure

Concrete parapet wall at an airport

parking structure.

Problem

Galvanized steel handrail xed into the

steel reinforced concrete edge beam with

direct contact between galvanizing and

reinforcing steel leading to corrosion.

Sika Solution

Remove and reinstall Sikagard

epoxy paint coated steel handrails.

with SikaGrout

-42 (epoxy grout).

Patch repair and level damaged

concrete with SikaTop

repair

mortars.

Protect against future water ingress

with Sikagard

-550W.

Corrosive Contaminants

Corrosive Contaminants

Structure

Second oor pedestrian walkway/bridge

at a hospital.

Problem

Concrete damaged by freeze/thaw action

and reinforcement corrosion accelerated

by chlorides from deicing salts.

Sika Solutions

Surface preparation by high pressure

water jetting and exposed steel

reinforcement prepared by blast

cleaning.

Steel reinforcement protection with

SikaTop

-Armatec

110

EpoCem

.

Repair with SikaTop

mortars.

Protection against latent damages

by impregnation with

Sika

Ferrogard

-903 corrosion

inhibitor.

Crack-bridging surface protection with

Sikagard

-550W.

16 I 19

Corrosive Contaminants

Project

Saint Josephs church in Le Havre.

Problem

Concrete surfaces had become stained,

cracked and started to spall.

Sika Solution

After the necessary preparation work,

a complete Sika Repair and Protection

System was applied, consisting of

Sika

MonoTop

Primer,

SikaTop

and SikaLatex

modied repair mortars,

Sika

FerroGard

corrosion

inhibitor with Sika

Conservado

and Sikagard

protective impreg-

nations.

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 11:00 Uhr Seite 18

Sika Deck Coatings

For crack-bridging balcony, podium and

deck waterproong plus elastic wearing

surfaces.

Sikaex

Joint Sealing

A unique range of one-component sealants,

specically designed for compatibility with

the Sika repair and protection systems.

Icosit

Steel Coatings

For the protection of steel and galvanized

steel surfaces such as handrails, window

frames and support structures.

Additional Complementary Sika

Systems

Sika Structural Waterproong

Well proven systems that provide internal

waterproong for both new and refurbish-

ment projects in basements, lift pits,

cellars, car parks, etc.

Sikadur

Resin Injection

Structural resins for the injection and

bonding of cracks and voids to restore

integrity.

Sika

CarboDur

Structural

Strengthening

Externally bonded composite reinforce-

ment system for structural strengthening

and to increase load bearing capacity of

oors, walls, beams, etc.

International Case Studies

18 I 21

Corrosive Contaminants

Structure

Concrete viaduct, serving as motorway

feeder.

Problem

Steel corrosion, bridge deck and parapets,

in parts destroyed by frost and de-icing

salts, need extensive repair and renovation

under permanent trafc.

Sika Solution

Concrete for re-decking and repair

of parapets, resistant to freeze/thaw

cycles and de-icing salts, with

Sikament

-10/-12 PLUS

and Fro-V10.

Pier cap strengthening with SCC

(self-compacting concrete) with

Sika

ViscoCrete

-1/-2.

Thin-layer mortar coating with mois-

ture barrier for edge connections with

Sikagard

-720 EpoCem

.

Bridge deck priming and sealing

with Sikadur

-186 and quartz sand

Sikadur

-501.

Edge connections and sealing of bridge

draining system with liquid membrane and

melt primer Sikalastic

-821/-823.

Concrete rehabilitation work in the

girder boxes with

Sika

MonoTop

-610/

SikaTop

-Armatec

110

EpoCem

and SikaRep

-3N

repair mortar.

Steel plate bonding for shear strength-

ening with Sikadur

-30 Epoxy adhesive

Type Rapid.

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 13:51 Uhr Seite 20

C

o

n

s

t

r

u

c

t

i

o

n

Technology and Concepts

for the Repair and Protection

of Reinforced Concrete

Technology and Concepts for the Repair

and Protection of Reinforced Concrete

S

&

W

0

9

.

0

5

/

0

5

S

I

C

2

1

.

2

7

/

S

i

k

a

S

e

r

v

i

c

e

s

A

G

,

S

w

i

t

z

e

r

l

a

n

d

C

e

rtifie

d

Quality

S

y

s

te

m

I

S

O

9

0

01/ EN

2

9

0

0

1

since 1986

C

e

r

t

ifie

d

M

anagemen

t

S

y

s

t

e

m

I

S

O

140

0

1

since 1997

Sika Services AG

Corporate Construction

CH-8048 Zrich

Switzerland

Phone +41 44 436 40 40

Fax +41 44 436 46 86

www.sika.com

Your local Sika Company

Our most current General Sales Conditions shall apply. Please

consult the Product Data Sheet prior to any use and processing.

C

o

n

s

t

r

u

c

t

i

o

n

Also available from Sika

Sika is a globaly active company in the speciality and construction

chemicals business. It has subsidiary manufacturing, sales and

technical support facilities in over 70 countries around the world.

Sika is THE global market and technology leader in waterproong,

Sika Your Local Partner with a Global Presence

sealing, bonding, dampening, strengthening and protection of

buildings and civil engineering structures.

Sika has more than 9200 employees worldwide and is therefore

ideally positioned to support the success of its customers.

05SIC_21_27_Techn_e3.Bqxd 23.09.2005 10:59 Uhr Seite 2

Anda mungkin juga menyukai

- Lecture#15: Sub Structure: Sub-Structure or Foundation Is The Lower Portion of The Building, UsuallyDokumen3 halamanLecture#15: Sub Structure: Sub-Structure or Foundation Is The Lower Portion of The Building, UsuallyAsghar Hussain ShahBelum ada peringkat

- Lec 11 Bituminous MaterialsDokumen6 halamanLec 11 Bituminous Materialsamjad aliBelum ada peringkat

- ACI The New Model Code Feb 2013Dokumen87 halamanACI The New Model Code Feb 2013Asghar Hussain ShahBelum ada peringkat

- EE150 Network Analysis-II Course OutlineDokumen1 halamanEE150 Network Analysis-II Course OutlineAsghar Hussain ShahBelum ada peringkat

- Lecture #01: BY Engineer Asghar Hussain ShahDokumen9 halamanLecture #01: BY Engineer Asghar Hussain ShahAsghar Hussain ShahBelum ada peringkat

- High Voltage Technology - EE463Dokumen1 halamanHigh Voltage Technology - EE463Asghar Hussain ShahBelum ada peringkat

- Lecture #01: BY Engineer Asghar Hussain ShahDokumen9 halamanLecture #01: BY Engineer Asghar Hussain ShahAsghar Hussain ShahBelum ada peringkat

- Lec 2 AggregatesDokumen8 halamanLec 2 AggregatesAsghar Hussain ShahBelum ada peringkat

- Lecture #01: BY Engineer Asghar Hussain ShahDokumen9 halamanLecture #01: BY Engineer Asghar Hussain ShahAsghar Hussain ShahBelum ada peringkat

- New Microsoft Office Word DocumentDokumen5 halamanNew Microsoft Office Word DocumentAsghar Hussain ShahBelum ada peringkat

- Chapter 03Dokumen16 halamanChapter 03Iqbal HossainBelum ada peringkat

- ASTM Standards Catalog 2013Dokumen22 halamanASTM Standards Catalog 2013dassoumennBelum ada peringkat

- Electromagnetic Feild Theory - EE315 - 14-07-2008Dokumen2 halamanElectromagnetic Feild Theory - EE315 - 14-07-2008Asghar Hussain ShahBelum ada peringkat

- Industrial Management MGT 427Dokumen2 halamanIndustrial Management MGT 427Asghar Hussain ShahBelum ada peringkat

- Physics I - GS111Dokumen2 halamanPhysics I - GS111Asghar Hussain ShahBelum ada peringkat

- High Voltage Technology - EE463Dokumen1 halamanHigh Voltage Technology - EE463Asghar Hussain ShahBelum ada peringkat

- Communications Skills - ENG 112Dokumen1 halamanCommunications Skills - ENG 112Asghar Hussain ShahBelum ada peringkat

- Computer Architecture - CS252Dokumen2 halamanComputer Architecture - CS252Asghar Hussain ShahBelum ada peringkat

- K.G Topics For DecorationDokumen13 halamanK.G Topics For DecorationAsghar Hussain ShahBelum ada peringkat

- Syllabus Class NurseryDokumen1 halamanSyllabus Class NurseryAsghar Hussain ShahBelum ada peringkat

- Abid 1 PDFDokumen1 halamanAbid 1 PDFAsghar Hussain ShahBelum ada peringkat

- Class 7thDokumen15 halamanClass 7thAsghar Hussain ShahBelum ada peringkat

- Abid 2 PDFDokumen1 halamanAbid 2 PDFAsghar Hussain ShahBelum ada peringkat

- New Microsoft Office Word DocumentDokumen5 halamanNew Microsoft Office Word DocumentAsghar Hussain ShahBelum ada peringkat

- Abid 1Dokumen1 halamanAbid 1Asghar Hussain ShahBelum ada peringkat

- Lec 3 CementsDokumen7 halamanLec 3 CementsAsghar Hussain ShahBelum ada peringkat

- Kaka G Tangarr-ModelDokumen1 halamanKaka G Tangarr-ModelAsghar Hussain ShahBelum ada peringkat

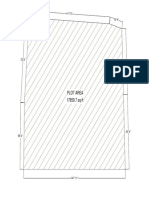

- Large residential plot plan layout dimensionsDokumen1 halamanLarge residential plot plan layout dimensionsAsghar Hussain ShahBelum ada peringkat

- 2.final Structure25.07.2015-Model PDFDokumen1 halaman2.final Structure25.07.2015-Model PDFAsghar Hussain ShahBelum ada peringkat

- Lec 2 AggregatesDokumen8 halamanLec 2 AggregatesAsghar Hussain ShahBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- df-550 O2 AnalyzerDokumen4 halamandf-550 O2 AnalyzerCaleb SpiderBelum ada peringkat

- Comparison of Architectural Coating SpecificationsDokumen5 halamanComparison of Architectural Coating SpecificationsvopyrupyrBelum ada peringkat

- HPLCDokumen22 halamanHPLCKafi Mahmood NahinBelum ada peringkat

- Summary KH2134 Fluid MechanicsDokumen4 halamanSummary KH2134 Fluid MechanicsAzman SamerBelum ada peringkat

- CHEM 18 PROBLEM SET CHEMICAL THERMODYNAMICS AND EQUILIBRIUMDokumen4 halamanCHEM 18 PROBLEM SET CHEMICAL THERMODYNAMICS AND EQUILIBRIUMDaniel Jann CotiaBelum ada peringkat

- Ferritic and Martensitic Casting Materials SpecificationsDokumen2 halamanFerritic and Martensitic Casting Materials SpecificationsSinan YıldızBelum ada peringkat

- Real Heat Engines and RefrigeratorsDokumen11 halamanReal Heat Engines and RefrigeratorsMario MikulandraBelum ada peringkat

- A Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Dokumen6 halamanA Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Vera Brok-VolchanskayaBelum ada peringkat

- Recyclingand Reuseof TextileDokumen47 halamanRecyclingand Reuseof TextileRey100% (1)

- Patent UV Refurbish BrochureDokumen20 halamanPatent UV Refurbish BrochureAnonymous HNs2dr76jEBelum ada peringkat

- Fiitjee Rit 2Dokumen11 halamanFiitjee Rit 2Baljeet SinghBelum ada peringkat

- Science - Form 4 - Chapter 5Dokumen12 halamanScience - Form 4 - Chapter 5Marcia PattersonBelum ada peringkat

- Liquid Penetrant Testing Method Level II QuestionsDokumen14 halamanLiquid Penetrant Testing Method Level II Questionskingston50% (2)

- Turton - Appb 30 37Dokumen8 halamanTurton - Appb 30 37asadBelum ada peringkat

- Qe 22 A PDFDokumen10 halamanQe 22 A PDF孙俊磊Belum ada peringkat

- Experiment 6Dokumen6 halamanExperiment 6Sobana Kanthi33% (3)

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDokumen5 halamanMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrBelum ada peringkat

- Heavy Oil Upgrading - A Key Solution For Heavy Oil Upstream and Midstream Operations - IVANHOE ENERGY PDFDokumen44 halamanHeavy Oil Upgrading - A Key Solution For Heavy Oil Upstream and Midstream Operations - IVANHOE ENERGY PDFGustavo Gonzalez ServaBelum ada peringkat

- Introduction To Laser TechnologyDokumen31 halamanIntroduction To Laser TechnologyJames Sullivan100% (1)

- Ankit Topic - Using Cast Iron For Machine PartsDokumen12 halamanAnkit Topic - Using Cast Iron For Machine PartsAnkit BhadesiaBelum ada peringkat

- TDS - Mastertile 550 - DgroutDokumen3 halamanTDS - Mastertile 550 - DgroutVenkata RaoBelum ada peringkat

- 1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionDokumen3 halaman1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionroxanaBelum ada peringkat

- Bioplastic ProjectDokumen15 halamanBioplastic ProjectSarthak Verma100% (1)

- PESSAT-Chemistry-Model-PaperDokumen12 halamanPESSAT-Chemistry-Model-PaperpullagalkBelum ada peringkat

- Msds - Marpozol W-505 (GHS) Eng 130409Dokumen5 halamanMsds - Marpozol W-505 (GHS) Eng 130409Syafarul Mohammad100% (1)

- Bref Polymer EsDokumen319 halamanBref Polymer EsMaFher JimenezBelum ada peringkat

- 맥머리유기화학8판Dokumen1.177 halaman맥머리유기화학8판이경식Belum ada peringkat

- Project Carburizing Lupu Stefan EnglezaDokumen5 halamanProject Carburizing Lupu Stefan EnglezaStefan LupuBelum ada peringkat

- QS607 220310Dokumen3 halamanQS607 220310Jet ToledoBelum ada peringkat

- Week No.2 - CLO-1 Size ReductionDokumen18 halamanWeek No.2 - CLO-1 Size ReductionkhalifaBelum ada peringkat