Gawish SPE Paper

Diunggah oleh

Erik Andres Garcia VillarroelDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gawish SPE Paper

Diunggah oleh

Erik Andres Garcia VillarroelHak Cipta:

Format Tersedia

This paper was prepared for presentation at the 2005 SPE Technical Symposiumof Saudi Arabia

Sectionheldin Dhahran, Saudi Arabia, 14-16May 2005.

Copyright 2005 Society of PetroleumEngineers

This paper was selected for presentation by the Technical SymposiumProgramCommittee following

review of information contained in full manuscript submitted by theauthor(s). Contents of thepaper, as

presented, havenot beenreviewed by theSociety of PetroleumEngineers and aresubject to correction

by theauthor(s). Thematerial, as presented, does not necessarily reflect any position of theSociety of

PetroleumEngineers, its officers, or members.

ABSTRACT

The influence of fluid viscosity on flow is especially important

in petroleum reservoirs. Gas is now a highly desirable

hydrocarbon resource. An accurate prediction of transport

properties of natural gases is very important in the design and

operation of fluid transportation, production, and processing.

Viscosity is one of these properties. Many viscosity

correlations are available but each has limitations in the range

of applicability

1-7

. Only the Carr et al

8-12

. charts include the

correction for gas impurities and reservoir pressure and

temperature. Using Carr et al. charts you have to follow five

steps to find the natural gas viscosity at any condition. As a

results, some errors and inaccurated will occur and more time

will be consumed. Standing

13,14

proposed a convenient

mathematical expressing for calculation the viscosity of the

natural gas at atmospheric pressure and reservoir temperature,

1

. Standing also presented equations for describing the effects

of impurities on

1.

Dempsey

15

expressed the viscosity ratio

(the viscosity at high pressure to the viscosity at 1 atm), by

using reduced pressure and temperature.

Using the Standing equation and the slightly revised Dempsey

equation, the natural gas viscosity at high pressure can be

found by one step only. It includes all corrections for gas

impurities. Its also includes any condition at the reservoir

pressure and temperature.

Background

Natural gas is a homogeneous fluid of low density and

viscosity. The high pressure and temperature cause a decrease

in viscosity even at temperatures above the critical. The

variation in viscosity with molecular weight of gases at

atmospheric pressure is opposite to the variation for liquids,

the viscosity decreases with increase in molecular weight of

gases. The natural gas properties may be obtained from

laboratory measurements. The rolling ball viscosimeter is used

for measuring viscosity, with the ball forcing the fluid through

the crescent between the ball and tube wall. The rolling ball

viscosimeter can give erroneous results when used with low

density fluids, because of turbulent flow through the crescent.

The Rolling-ball viscosimeter may give viscocities as much as

30% higher when measurment of gas viscosity is taken under

pressure. The preferred instrument for gases is the Rankine

viscosimeter in which the pressure gradient for the fluid

flowing through the capillary can be very small. The natural

gas viscosity is described by the following function,

( )

i g

Y T P f , , = 1

This relationship simply states that the viscosity of a pure gas

is function of pressure and temperature, but for gas mixture, it

is also a function of the gas composition. Gas viscosity can be

predicated from generalized mathematical expressions.

Herning and Zipperer

Herning and Zipperer

16

method proposed the following

equation to calculate the viscosity of a mixture of gaseous

components.

( )

=

i

i i

i i gi

g

M y

M y

) (

2

Where the analysis of the gas mixture is known and the

viscosities of the components are known at the pressure and

temperature of interest.

Dean and Stiel Method

Dean and Stiel

17

proposed the following mathematical

expressions for calculating the viscosity of natural gases at

atmospheric pressure and reservoir temperature.

m

r

T

9

8

5

1

) (

* ) 10 ( 34

=

, for T

r

=<1.5 3

m

r

T

9

5

5

1

] 0932 . 0 1338 . 0 )[ 10 ( 8 . 166

=

, for T

r

>1.5 4

Where the

m

is the viscosity parameter of the gas mixture and

defined by the following equation.

3

2

5 . 0

6

1

) ( ) (

) (

4402 . 5

c a

c

m

P MW

T

=

5

Dean and Stiel recommended the following equation for

calculating the natural gas viscosity at reservoir condations.

m

r r

g

EXP EXP

)] ) ( 111 . 1 ( ) 439 . 1 ( )[ 10 ( 8 . 10

888 . 1 5

1

+ =

6

SPE 106326

State of the Art - Natural Gases Viscosity under Reservoir Conditions

Ahmed Gawish and Emad Al-Homadhi

King Saud University

2

Where:

r

r

r

ZT

P 27 . 0

=

7

The Lee-Gonzalez Eakin Method

Lee et al

8,19

presented a semi-empirical relationship for

calculating the natural gases viscosity. The authors expressed

the gas viscosity in terms of reservoir temperature, gas gravity,

and molecular weight of the gases. Their proposed equation is

given by:

Y

g

g

X K

4 . 62

* exp * * 10

4

8

where:

( )

T M

T M

K

a

a

+ +

+

=

* 19 209

02 . 0 4 . 9

5 . 1

9

a

M

T

X 01 . 0

986

5 . 3 + + =

10

X Y 02 . 4 . 2 = 11

The proposed above correlation can predict viscosity values

with a standard deviation of 2.7% and a maximum deviation

of 8.99%. This correlation is valid for 10 <P <8000 psia , 100

<T <340

o

F, and 0.9 <CO

2

<3.2 mol.%.

Bicker and Katz

20

presented a plot of the viscosity of paraffin

gases at 1 atm as a function of molecular weight. This plot was

slightly revised by Carr, Kobayashi, and Burrows

1

. It provides

a rapid and reliable method for obtaining the viscosity of

natural gases at 1 atm pressure from knowledge of the gas

gravity and temperature alone. This viscosity must be

corrected for the presence of non-hydrocarbon fractions tends

to increase the viscosity of the gas. Insert plots on Carr et al

viscosity charts show corrections for the non-hydrocarbon, the

presence of low concentration of non-hydrocarbon gases, such

as hydrogen sulfide, nitrogen, and carbon dioxide. The effect

of the presence of each of the non-hydrocarbons is to increase

the viscosity of the hydrocarbon gas mixture.

Carr, Kobayashi, and Burrows

1

extended the correlation of

Comings et al

21

to higher pressures and to complex mixtures

of gases. For natural gases, the widely used Carr et al

correlations take the forms:

) . ... , (

1

GasGravity or T M f

g

=

and,

) , (

1

r r

g

g

T P f =

In 1954 Carr et

8

developed graphical correlations for

estimating the viscosity of natural gas as a function of

temperature, pressure and gas gravity or molecular weight.

The ratio (

g

1

) of the viscosity at high pressure to the

viscosity at 1 atm is shown as a function of the reduced

pressure P

r

and the reduced temperature T

r

.

Where: T

r

= T/T

c

and P

r

= P/P

c

When mixtures are involved, the pseudocritical pressures and

temperatures of typical natural gases may be estimated from

gas gravity alone. For gases with appreciable concentrations of

gas impurities, the pseudo critical conditions may be

computed from compositions. The gas viscosities can be

obtained from the charts of Carr et al. when gas gravity and

concentration of the non-hydrocarbon constituent are known.

Both pseudo-critical pressure and temperature are required

parameters for gas calculations. Available publications have

reported multi-equations to calculate these values for natural

gases. A new correlation was developed with wide

applications and efficient for gas specific gravities varyied

from 0.55 to 1.2.

22,23

The critical pressure and temperature equations are:

SG T

SG P

c

c

* 0864 . 308 7 . 173

* 541243 . 50 194514 . 703

+ =

=

12

The corrected pseudo-critical temperature and pressure are

presented below:

) 1 (

2 2

'

'

'

S H S H C

C C

C

C C

y y T

T P

P

T T

+

=

=

13

) ( 15 ) ) ( ) (( 120

4

2

5 . 0

2

6 . 1

2 2

9 . 0

2 2 S H S H S H CO S H CO

y y y y y y + + + =

14

Standing (1977)

6,7

proposed a convenient mathematical

expression for calculation the viscosity of the natural gas at

atmospheric pressure and reservoir temperature,

1

. Standing

also presented equations for describing effect of impurities on

1.

The proposed relationships are:

( ) ( ) ( ) ( )

S H N co d uncorrecte

2 2 2

1 1

+ + + = 15

) log( * 10 * 15 . 6 10 * 188 . 8 ) 460 (

* ) * 10 * 062 . 2 10 * 709 . 1 ( ) (

3 3

6 5

1

g

g

T

d uncorrecte

+

=

16

] 59 . 9 ) log( * 48 . 8 [ 10 * ), (

3

2 2

+ =

g N

y N

17

] 24 . 6 ) log( * 08 . 9 [ 10 * ), (

3

2 2

+ =

g CO

y CO 18

] 73 . 3 ) log( * 49 . 8 [ 10 * ), (

3

2 2

+ =

g S H

y S H 19

Dempsey

8

1965 expressed the viscosity ratio by the following

relationship.

) ( ) (

) (

3

15

2

14 13 12

3 3

11

2

10 9 8

2

3

7

2

6 5 4

3

3

2

2 1 0

1

r r r r r r r r

r r r r r r r

g

r

P a P a P a a T P a P a P a a T

P a P a P a a T P a P a P a a T Ln

+ + + + + + + +

+ + + + + + + =

20

A spread sheet program was designed in this study, to

calculate gas viscosity at reservoir conditions with one step

only using Standing equation after slightly and revising

Dempsey equation. It includes all corrections for gas

impurities.

3

X Ln

g

=

Where:

(X)=

+ + + + + + + +

+ + + + + + +

) ( ) ( ) (

) (

3

15

2

14 13 12

3 3

11

2

10 9 8

2

3

7

2

6 5 4

3

3

2

2 1 0

r r r r r r r r r

r r r r r r r

T Ln P a P a P a a T P a P a P a a T

P a P a P a a T P a P a P a a

21

) (

1

X

e

g

=

22

) (

* 1 1

X

g

e = 23

Results and discussion

The natural gas viscosity is computed from this program easily

by using the Standing and the revised Dempsey equations. The

natural gas viscosity is calculated at one atmospheric pressure

using the Standing equation, and all the corrections for gas

impurities are done by using equation (16). The natural gas

viscosity is corrected for any pressure value by using the

revised Dempsey equation (equation 23).

Figure (1) shows the natural gas viscosity at 1 atm for

different specific gas gravities (0.55-3.75) and temperature

(50-400

0

F) of the reservoir without impurties while figure (2)

shows the gas viscosity with corrections taking into

consideration the non-hydrocarbon impurities effects on gas

viscosity. The figures are the same as Carr et al. chart. Figure

(3) shows the ratio of gas viscosity at reservoir pressure to the

viscosity at 1 atm pressure as a function of the reduced

pressure and temperature. This figure is also the same as Carr

et al. chart. Figure (4) shows the gas viscosity for different

pressure values as a function in temperature. This chart is the

result of the spread sheet program in table (1). Figure (5)

shows the natural gas viscosity as a function of reduced

pressure and temperature for any gas gravity or molecular

weight. Fig. (5) is plotted at semi-log scale.

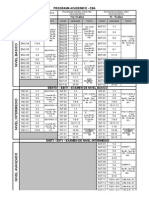

Table (1) represents a spread sheet program for all calculations

in order to find the natural gas viscosity with and without any

presence of impurities and at any pressure and temperature

values. By interring the values for impurities, gas gravity,

pressure, and temperature in overshadow cells (input data), the

critical pressure and temperature, and corrected critical

pressure and temperature for impurities, reduced pressure and

temperature are calculated. The natural gas viscosity at

reservoir conditions can be calculated directly without using

any charts.

Designing and evaluating existing correlations for gas

viscosity

In table (2) the spreed sheet program for calculating gas

viscosity by using different gas viscosity correlations includes

micros for solving z-factor. The figures (6 to 13) show the gas

viscosity as a function of pressure, temperature, and the gas

gravity. The gas gravity is studed from (0.7) to (1.4) by using

Dempsey, Lee, and Dean & Stiel correlations. All the

correlations are close but the Dempsey correlation gives good

results and is very close to the Carr et at chart.

The gas viscosity increase in a linear relation with increasing

reservoir pressure at a low gas gravity, but not a linear for a

higher gas gravity during the test pressure periods.

Conclusions

1. Many errors will be eliminated and time will be saved by

using the new charts and the spread sheet program.

2. The results become very important and will help to

calculate the value of the natural gas viscosity at any

condition.

3. This program can easily respond to the changes in the gas

fluid properties and impurities for producing tables and

charts, which can be used for the prediction of the natural

gas viscosity.

4. For any gas at different values of pressure and temperature,

and with any kind of impurities, it is easy to find the

natural gas viscosity from spread sheet program.

5. The design and evaluation of most gas correlations in one

sheet program become easy.

Nomenclatures

g=Gas viscosity at reservoir pressure and temperature, cp

1=Gas viscosity at atmospheric pressure and reservoir temperature, cp

r =Reduced gas density as defined by:

g =Ib/ft

3

, =cp, Ma=molecular weight of gas, and T= R

o

.

' '

,

c c

P T

are corrected critical temperature (

o

R) and pressure (psia).

T Rreservoir temperature,

o

R,

g Gas gravity, and, and

yN2, yCO2, and yH2S mole fraction of N2, CO2, and H2S.

Table (4 ) for constant used in gas correlations.

a0 -2.46211820 a8 -0.793385648

a1 2.970547414 a9 1.39643306

a2 -0.286264054 a10 -0.149144925

a3 0.00805420522 a11 0.00441015512

a4 2.080860949 a12 0.0839387178

a5 -3.49803305 a13 -0.18648848

a6 0.3603702 a14 0.0203367881

a7 -0.01044324 a15 -0.000609579263

References:

1. Kumar Sanjay,:"Gas Production Engineering" volume (4) Chapter

(1) Gulf Publication Company, Houston, Texas 1987.

2. Ikoku Chi U.,:"Natural Gas Production Engineering", Jone Wiley

& Sons Inc., Canada, Toronto, 1984.

3. Katz D. et al "Handbook of Natural Gas Engineering", 1959 by

McGraw-Hill Book Company, Inc. Printed in the USA, New

York, Toronto, and London.

4. Yaws C., Lin X., and Li Bu: "Calculate Viscosities for 335

liquids Using the Temperature and A starting Point", Chemical

Engineering, April 1994.

5. Awuy A.L., Bretz R.E.: "An Improved Viscosity Model for

Natural Gases: Application of the Free Volume Concept", SPE

4

68

th

Annual Conference and Exhibition held in New Orleans,

LA, USA., 25-28 September 1994, SPE paper (28636).

6. Awuy A.I., and Bretz R.E.,:An Improved Viscosity Model for

Natural Gases: Application of the Free Volume Concept,SPE

paper number (28636) presented at the SPE 69th Technical

Conference and Exhibition held in New Orleana, LA, U.S.A.,

25-28 Septemper 1994.

7. Erdogmus M. and Adewumi M.A.,:Viscosity Prediction of

Natural Gases, SPE paper number (39219) presented at the SPE

Eastern Regional Meeting held in Lexington, Kantucky. 22-24

October 1997.

8. Carr, N., Kobayashi, Ri, and Burrown, D., Viscosity of

hydrocarbon Bases under pressure, Trans.,

AIME,1954,VoL.201, PP., 270-275.

9. Tarek Ahmed,: "Reservoir Engineering Handbook)" Gulf

Publishing Company, Houston, Texas. 2000.

10. Tarek Ahmed,: "Hydrocarbon Phase Behavior" Gulf Publishing

Company, Houston, Texas. 1989.

11. WilliamD. McCain, J r.,: "PetroleumFluids", Second Edition,

PennWell Publishing Books Company, Tulsa, Oklahoma, 1990.

12. Charles R. Smith, G.W. Tracy, R. Lance Farrar,: "Applied

Reservoir Engineering", Volume 1, OGCI Publications, 1992.

13. Standing, M. B., "Volumetric and phase behavior of oil field

Hydrocarbon system", PP. 125-126. Dallas: SPE 1977.

14. Standing, M. B. and Katz, D.L., Density of Natural Gases, Trans.

AIME, 1942, Vol. 146, PP. 140-149.

15. Dempsey, J . R.,Computer Routine Treats Gas Viscosity as a variable.

Oil and Gas Journal, Aug. 16, 1965, PP. 141-143.

16. Herning and Zipperer, L.:Calculations of the Viscosity of Technical

Gas Mixtures from the Viscosity of Individual Gases. Gas and

Wasserfach (1936) 79, 49-69.

17. Dean, D.E. and Stiel. L. I., the Viscosity of non-polar Gas Mixtures at

Moderate and high pressure, AICHE J our., 1958, Vol.4, PP. 430-436.

18. Lee, A.L., Gonzalez, M.H., and Eakin, B.E.:The Viscosity of Natural

Gases, JPT (Aug. 1966) 997-1000, Trans., AMIE, 37.

19. Lee, J., and Wattenburger, R.A., Gas Reservoir Enginerring, SPE,

Richardson, TX, 1996.

20. Bicker, L.A., and Katz, D.L.,:Viscosity of Natural Gases, Trans.

AMIE, 155: 754 (1943).

21. Comings, E. W. , and Egly, R. S., :The Viscosity of Gases and Vapors

at High Pressure Ind. Eng. Chem., 32: 714 (1940)

22. Abd-El-Fattah Kh. A.,: "A New Equations computers the

Pseudo-Critical Temperature and Pressure for Natural Gases",

J ournal of Engineering and Applied Science, Vol. 45. NO. 5,

Oct. 1998. PP 857-864, Faculty of Engineering, Cairo

University.

23. Abd-El-Fattah Kh. A.: "Analysis Shows Magnitude of Z-Factor

error", Oil & Gas J ournal, Nov. 27, 1995

0.000

0.002

0.004

0.006

0.008

0.010

0.012

0.014

0.016

0.018

0 20 40 60 80 100

Molecular Weight

V

i

s

c

o

s

i

t

y

a

t

1

a

t

m

,

c

p

50 oF 100 oF 150 oF 200 oF

250 oF 300 oF 350 oF 400 oF

Fig. (1) Viscosity of the Sweet Natural Gases at 1.0 atm.

0.000

0.002

0.004

0.006

0.008

0.010

0.012

0.014

0.016

0.018

0 20 40 60 80 100

Mol ecul ar Wei ght

V

i

s

c

o

s

i

t

y

a

t

1

a

t

m

,

c

p

50 oF 100 oF 150 oF 200 oF

250 oF 300 oF 350 oF 400 oF

Fig. (2) Viscosity of the Natural Gases at 1.0 atm. with Impurities Corrections.

1

10

0.8 1 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3

Pseudo Reduced Temperature

V

i

s

c

o

s

i

t

y

R

a

t

i

o

1 2 3 4 5

6 8 10 15 20

Fig. (3) Viscosity Ratio versus Pseudo Reduced Temperature.

0.01

0.10

1.00

0 0.5 1 1.5 2 2.5 3

Pseudo Reduced Temperature

N

.

G

a

s

V

i

s

c

o

s

i

t

y

,

c

p

1 2 3 4 5

6 8 10 15

Fig. (4) Viscosity versus Pseudo Redued Temperature.

Pr

6

0.01

0.10

1.00

0 200 400 600 800 1000

Temper ature, oF

N

.

g

a

s

V

i

s

c

o

s

i

t

y

,

c

p

612 1225 1837 2450 3062 3675

4900 6125 9187

Pressure, psi

Fig. (5) Viscosity versus Temperature for Different Pressures .

Sp.Gr.=0.7

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, psi

V

i

s

c

o

s

i

t

y

,

c

p

Dempsey

Lee

Dean & Stiel

Fig. (6) Viscosity versus Temperature for Different Preesures at 0.7 Sp.Gr.

Sp.Gr.= 0.8

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, psi

N

.

G

a

s

V

i

s

c

o

s

i

t

y

Dempsey

Lee

Dean & Stiel

Fig. (7) Viscosity versus Temperature for Different Pressures at 0.8 Sp.Gr.

Sp.Gr.=0.9

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, psi

N

.

G

a

s

V

i

s

c

o

s

i

t

y

Dempsey

Lee

Dean & Stiel

Fig. (8) Viscosity versus Temperature for Different Pressures at 0.9 Sp.Gr

7

Sp.Gr.=1.0

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0.090

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, psi

G

a

s

V

i

s

c

o

s

i

t

y

,

c

p

Dempsey

Lee

Dean & Stiel

Fig. (9) Viscosity versus Temperature for Different Preesures at 1.0 Sp.Gr.

Sp. Gr. 1.1

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0.090

0.100

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, pai

N

.

G

a

s

V

i

s

c

o

s

i

t

y

Dempsey

Lee

Dean & Stiel

Fig. (10) Viscosity versus Temperature for Different Preesures at 1.1 Sp.Gr.

Sp.Gr.=1.2

0.000

0.020

0.040

0.060

0.080

0.100

0.120

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, psi

G

a

s

V

i

s

c

o

s

i

t

y

,

c

p

Dempsey

Lee

Dean & Stiel

Fig. (11) Viscosity versus Temperature for Different Preesures at 1.2 Sp.Gr.

Sp.Gr.=1.3

0.000

0.020

0.040

0.060

0.080

0.100

0.120

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, psi

G

a

s

V

i

s

c

o

s

i

t

y

Dempsey

Lee

Dean & Stiel

Fig. (12) Viscosity versus Temperature for Different Preesures at 1.3 Sp.Gr.

8

Sp.Gr=1.4

0.000

0.020

0.040

0.060

0.080

0.100

0.120

0.140

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Pressure, psi

G

a

s

V

i

s

c

o

s

i

t

y

,

c

p

Dempsey

Lee

Dean & Stiel

Fig. (13) Viscosity versus Temperature for Different Preesures at 1.4 Sp.Gr.

9

Table (1) Spread Sheet Program for Calculate Natural Gas Viscosity by Dempsey Correlation.

Step 1 Enter the values of impurties in overshadow cells

Y

N2

0.05 Y

CO2

0.05 Y

H2S

0.2 28.09

Step 2 Enter the value of gas sp. Gr.

SG 0.6 or Mw 17.4

Tc 358.55

Pc 672.87

T'c 330.46

P'c 612.48

Step 3 Enter pseudo reduced pressure and temperature

P 612 1225 1837 2450 3062 3675 4900 6125 9187 12250

Pr 1 2 3 4 5 6 8 10 15 20

T Tr ln(g/g1) ln(g/g1) ln(g/g1) ln(g/g1) ln(g/g1) ln(g/g1) ln(g/g1) ln(g/g1) ln(g/g1) ln(g/g1)

330 1 0.27 0.79 1.23 1.58 1.86 2.07 2.32 2.40 2.33 2.70

397 1.2 0.16 0.52 0.83 1.09 1.30 1.47 1.70 1.82 1.89 2.14

463 1.4 0.09 0.34 0.55 0.74 0.90 1.03 1.24 1.38 1.55 1.72

529 1.6 0.05 0.21 0.36 0.49 0.61 0.72 0.90 1.05 1.28 1.41

595 1.8 0.03 0.14 0.24 0.33 0.42 0.51 0.67 0.81 1.06 1.19

661 2 0.03 0.10 0.17 0.24 0.31 0.38 0.51 0.64 0.90 1.03

727 2.2 0.03 0.08 0.14 0.19 0.25 0.30 0.42 0.53 0.77 0.92

793 2.4 0.04 0.08 0.12 0.17 0.22 0.26 0.35 0.45 0.66 0.84

859 2.6 0.04 0.07 0.11 0.15 0.19 0.23 0.31 0.38 0.57 0.76

925 2.8 0.03 0.06 0.09 0.12 0.15 0.19 0.25 0.31 0.48 0.66

991 3 0.00 0.02 0.04 0.06 0.08 0.11 0.16 0.23 0.39 0.53

Step 4 Natural gas viscosity ratio will be calculated

P 612 1225 1837 2450 3062 3675 4900 6125 9187 12250

Pr 1 2 3 4 5 6 8 10 15 20

T Tr (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1)

330 1 1.31 2.21 3.42 4.87 6.42 7.91 10.17 11.07 10.30 2.70

397 1.2 1.17 1.69 2.30 2.98 3.68 4.36 5.48 6.17 6.65 2.14

463 1.4 1.09 1.40 1.74 2.09 2.45 2.81 3.45 3.96 4.70 1.72

529 1.6 1.05 1.24 1.43 1.64 1.84 2.05 2.46 2.84 3.58 1.41

595 1.8 1.03 1.15 1.27 1.40 1.53 1.67 1.95 2.24 2.90 1.19

661 2 1.03 1.10 1.19 1.27 1.36 1.46 1.67 1.90 2.45 1.03

10

Continues Table (1) Spread Sheet Program for Calculate Natural Gas Viscosity by Dempsey Correlation.

T Tr (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1) (g/g1)

727 2.2 1.03 1.09 1.15 1.21 1.28 1.36 1.52 1.69 2.15 0.92

793 2.4 1.04 1.08 1.13 1.18 1.24 1.30 1.43 1.56 1.94 0.84

859 2.6 1.04 1.08 1.12 1.16 1.21 1.26 1.36 1.47 1.77 0.76

925 2.8 1.03 1.06 1.09 1.13 1.17 1.20 1.28 1.37 1.62 0.66

991 3 1.00 1.02 1.04 1.06 1.09 1.11 1.18 1.25 1.47 0.53

Step 5 Natural gas viscosity at any pressure will be calculated

P 612 1225 1837 2450 3062 3675 4900 6125 9187 12250

Pr 1 2 3 4 5 6 8 10 15 20

T Tr g g g g g g g g g g

330 1 0.0206 0.0349 0.0539 0.0767 0.1011 0.1246 0.1602 0.1744 0.1622 0.0426

397 1.2 0.0197 0.0284 0.0387 0.0501 0.0619 0.0732 0.0921 0.1037 0.1118 0.0360

463 1.4 0.0195 0.0250 0.0310 0.0373 0.0438 0.0501 0.0616 0.0706 0.0840 0.0307

529 1.6 0.0199 0.0234 0.0271 0.0309 0.0349 0.0388 0.0466 0.0537 0.0677 0.0266

595 1.8 0.0206 0.0229 0.0253 0.0279 0.0305 0.0333 0.0389 0.0447 0.0578 0.0237

661 2 0.0216 0.0232 0.0249 0.0267 0.0287 0.0307 0.0351 0.0398 0.0515 0.0216

727 2.2 0.0228 0.0240 0.0253 0.0267 0.0283 0.0299 0.0335 0.0373 0.0475 0.0203

793 2.4 0.0239 0.0250 0.0261 0.0274 0.0286 0.0300 0.0329 0.0361 0.0448 0.0193

859 2.6 0.0250 0.0260 0.0270 0.0281 0.0292 0.0304 0.0328 0.0354 0.0427 0.0182

925 2.8 0.0259 0.0267 0.0276 0.0285 0.0294 0.0303 0.0323 0.0345 0.0408 0.0166

991 3 0.0263 0.0268 0.0273 0.0279 0.0285 0.0292 0.0309 0.0329 0.0386 0.0140

Table (2) Spread Sheet Program for Calculate of the Existing Correlations for Natural Gas Viscosity

Y

N2

0.05 Y

CO2

0.05 Y

H2S

0.2 28.09

Sp. Gr. 0.6 T

ABS.

600 T oF = 140

Tc 358.55

1

0.0127

Standing

Pc 672.87

1

0.0121

Dean & Stiel when Tr<=1.5

T'c 330.46

1

0.0122

Dean & Stiel when Tr>1.5

T

r

1.82

P'c 612.48

m 0.047581 Micro Dempsey Lee Dean & Stiel

K 125.760 P P

r

r

Program Z LN(mg) g(Dempsey) g g(Lee) g(Dean)

X 5.317 2000 3.265 0.681 1.000 0.713 -4.107 0.016 7.574 0.017 0.017

Y 1.337 2500 4.082 0.876 1.000 0.693 -4.031 0.018 9.736 0.020 0.019

3000 4.898 1.178 0.999 0.618 -3.958 0.019 13.096 0.024 0.024

3500 5.714 1.320 1.000 0.644 -3.889 0.020 14.677 0.027 0.027

4000 6.531 1.411 1.000 0.688 -3.822 0.022 15.687 0.029 0.029

4500 7.347 1.482 0.999 0.737 -3.758 0.023 16.478 0.031 0.031

5000 8.163 1.540 0.999 0.788 -3.697 0.025 17.123 0.032 0.033

5500 8.980 1.590 1.000 0.840 -3.639 0.026 17.676 0.034 0.034

6000 9.796 1.634 1.000 0.892 -3.585 0.028 18.160 0.035 0.036

6500 10.613 1.672 1.000 0.944 -3.533 0.029 18.592 0.036 0.037

7000 11.429 1.708 1.000 0.995 -3.485 0.031 18.982 0.037 0.039

7500 12.245 1.740 1.000 1.047 -3.440 0.032 19.339 0.038 0.040

8000 13.062 1.769 1.000 1.098 -3.399 0.033 19.667 0.039 0.041

Anda mungkin juga menyukai

- Concept of God in Major World Religions - Dr. Zakir NaikDokumen29 halamanConcept of God in Major World Religions - Dr. Zakir NaikArshad Farooqui100% (5)

- My Baptism Was A Small Ceremony PDFDokumen1 halamanMy Baptism Was A Small Ceremony PDFErik Andres Garcia VillarroelBelum ada peringkat

- 22.3 Drillstem TestingDokumen9 halaman22.3 Drillstem TestingErik Andres Garcia VillarroelBelum ada peringkat

- Lifestyle DiseasesDokumen2 halamanLifestyle DiseasesErik Andres Garcia VillarroelBelum ada peringkat

- Ingles - FLYING HOMEDokumen2 halamanIngles - FLYING HOMEErik Andres Garcia VillarroelBelum ada peringkat

- Lasers May Offer Alternativeto Conventional Wellbore Perforation TechniquesDokumen5 halamanLasers May Offer Alternativeto Conventional Wellbore Perforation TechniquesErik Andres Garcia VillarroelBelum ada peringkat

- Effortless English CoverDokumen1 halamanEffortless English CoverErik Andres Garcia VillarroelBelum ada peringkat

- Malla Curricular CBA 2008Dokumen10 halamanMalla Curricular CBA 2008Erik Andres Garcia VillarroelBelum ada peringkat

- How a Well is Drilled on Land in 19 StepsDokumen19 halamanHow a Well is Drilled on Land in 19 StepsJorge Melendrez0% (1)

- Effortles English ContensDokumen1 halamanEffortles English ContensErik Andres Garcia VillarroelBelum ada peringkat

- 22.3 Drillstem TestingDokumen9 halaman22.3 Drillstem TestingErik Andres Garcia VillarroelBelum ada peringkat

- Cover Unforgettable HitsDokumen1 halamanCover Unforgettable HitsErik Andres Garcia VillarroelBelum ada peringkat

- Introductión The Plunger LiftDokumen10 halamanIntroductión The Plunger LiftLuis Enrrique ArellanoBelum ada peringkat

- Well Testing and Interpretation For Horizontal WellsDokumen6 halamanWell Testing and Interpretation For Horizontal WellsGaboGagBelum ada peringkat

- Gas Reservoir Engineering Application ToolkitDokumen20 halamanGas Reservoir Engineering Application Toolkitnishant41288100% (1)

- Geofisica - Normal Move Out Correction and StackingDokumen4 halamanGeofisica - Normal Move Out Correction and StackingErik Andres Garcia VillarroelBelum ada peringkat

- Flying Home ActivityDokumen2 halamanFlying Home ActivityErik Andres Garcia VillarroelBelum ada peringkat

- GetDokumen16 halamanGetJL Valladares MendozaBelum ada peringkat

- Tech Note Multi Phase Flow ModelsDokumen5 halamanTech Note Multi Phase Flow ModelsAristides H Garcia ReyesBelum ada peringkat

- CTES - Coiled Tubing Hydraulics ModelingDokumen27 halamanCTES - Coiled Tubing Hydraulics Modelingmirza_munir_baig995Belum ada peringkat

- Casing Design Manual - BG (2001)Dokumen51 halamanCasing Design Manual - BG (2001)PetroleumEngineering100% (21)

- Braveheart FactsheetsDokumen4 halamanBraveheart FactsheetsErik Andres Garcia VillarroelBelum ada peringkat

- 06 Cementing EquipDokumen12 halaman06 Cementing EquipErik Andres Garcia VillarroelBelum ada peringkat

- Braveheart Answers KeyDokumen1 halamanBraveheart Answers KeyErik Andres Garcia VillarroelBelum ada peringkat

- Catalogo 07 2014Dokumen6 halamanCatalogo 07 2014Erik Andres Garcia VillarroelBelum ada peringkat

- Example 52a Formato OutDokumen206 halamanExample 52a Formato OutErik Andres Garcia VillarroelBelum ada peringkat

- Bottom Hole Pressure CalculationDokumen8 halamanBottom Hole Pressure CalculationErik Andres Garcia VillarroelBelum ada peringkat

- Relative PermeabilityDokumen5 halamanRelative PermeabilityErik Andres Garcia VillarroelBelum ada peringkat

- Iadcbitclassification PDFDokumen1 halamanIadcbitclassification PDFErik Andres Garcia VillarroelBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Chemical Arithmetic FundamentalsDokumen1.694 halamanChemical Arithmetic Fundamentalsbalarama murty SannidhiBelum ada peringkat

- Third Year Mechanical Engineering SyllabusDokumen54 halamanThird Year Mechanical Engineering SyllabusTonya WhitneyBelum ada peringkat

- G460 ManualDokumen36 halamanG460 Manualanders_axelsson8920Belum ada peringkat

- The Definitive Guide To Cryogenic EngineeringDokumen21 halamanThe Definitive Guide To Cryogenic EngineeringSamanthaPereraBelum ada peringkat

- Egs PDFDokumen7 halamanEgs PDFAhmed OmerBelum ada peringkat

- E 512 - 94 (2015)Dokumen14 halamanE 512 - 94 (2015)ruben carcamoBelum ada peringkat

- BEC PELC+2010+ +Science+and+HealthDokumen22 halamanBEC PELC+2010+ +Science+and+HealthFrancis A. Buenaventura50% (2)

- What SF6 Gas TestingDokumen4 halamanWhat SF6 Gas TestingAnonymous V1oLCBBelum ada peringkat

- BS 7346-5 - 2005Dokumen42 halamanBS 7346-5 - 2005Yaser ShabasyBelum ada peringkat

- Film-Wise and Drop-Wise Condensation of Steam On Short Inclined PlatesDokumen7 halamanFilm-Wise and Drop-Wise Condensation of Steam On Short Inclined PlatessabriinderasabarBelum ada peringkat

- Pneumatic and Slurry Transport Design CalculationsDokumen51 halamanPneumatic and Slurry Transport Design CalculationsDondon Irig100% (1)

- 15 TOP Compressors, Gas Turbines & Jet Engines LAB VIVA Questions and Answers PDF Gas Turbines & Jet Engines LAB VIVA Questions and AnswersDokumen4 halaman15 TOP Compressors, Gas Turbines & Jet Engines LAB VIVA Questions and Answers PDF Gas Turbines & Jet Engines LAB VIVA Questions and AnswersAB MalikBelum ada peringkat

- The Flow of Real Gases Through Porous MediaDokumen13 halamanThe Flow of Real Gases Through Porous MediaDivjot SinghBelum ada peringkat

- Ideal Gas PropertiesDokumen3 halamanIdeal Gas PropertiesVaanBelum ada peringkat

- Boyle's Law: Pressure-Volume Relationship in Gases: ComputerDokumen5 halamanBoyle's Law: Pressure-Volume Relationship in Gases: Computerkaren liewBelum ada peringkat

- Thermodynamics Fundamentals QuizDokumen17 halamanThermodynamics Fundamentals QuizWilma NaderaBelum ada peringkat

- Gas AbsorptionDokumen11 halamanGas AbsorptionNyamukBelum ada peringkat

- Sase ReviewerDokumen92 halamanSase ReviewerVince Breis100% (1)

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationDokumen11 halamanModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaBelum ada peringkat

- AIPMST SECONDARY Information BrochureDokumen36 halamanAIPMST SECONDARY Information BrochureAIPMST SecondaryBelum ada peringkat

- Slime Lesson PlanDokumen2 halamanSlime Lesson Planapi-296459811Belum ada peringkat

- 7132249A.01 Analyzer System Manual V1.0 (Kiln Inlet)Dokumen26 halaman7132249A.01 Analyzer System Manual V1.0 (Kiln Inlet)MinhThang SusumiBelum ada peringkat

- 9702 s08 QP 2 PDFDokumen20 halaman9702 s08 QP 2 PDFSzeYee OonBelum ada peringkat

- Solubility ChemistryDokumen1 halamanSolubility Chemistryavni jainBelum ada peringkat

- Mass Transfer PartDokumen36 halamanMass Transfer Partoctoviancletus90% (67)

- InTech-Lubrication and Lubricants PDFDokumen22 halamanInTech-Lubrication and Lubricants PDFHarish BishtBelum ada peringkat

- Physical and Chemical Change Virtual Lab ST Lesson Santellano Victoria ADokumen3 halamanPhysical and Chemical Change Virtual Lab ST Lesson Santellano Victoria Aapi-255434272Belum ada peringkat

- Ig ScienceSingleAward TRPDokumen71 halamanIg ScienceSingleAward TRPzunairaBelum ada peringkat

- Phase Behavior and Basic Data AnalysisDokumen27 halamanPhase Behavior and Basic Data AnalysisSelvakumar SubramanianBelum ada peringkat

- 9701 s07 QP 5Dokumen11 halaman9701 s07 QP 5G M Ali KawsarBelum ada peringkat