EHS Overview Share

Diunggah oleh

Muhammad Taufik0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

546 tayangan214 halamanThe document contains details of clauses from ISO14001 and OHSAS 18001 standards for environmental and occupational health and safety management systems. It includes requirements for environmental policy, planning, implementation, checking, and management review. It also lists hazards identified at various production stations, including risks of injury from moving objects, manual handling, repetitive work, sharp objects, electricity, and suspended loads. Control measures listed include safety interlocks, machine guarding, personal protective equipment, and administrative controls.

Deskripsi Asli:

HSE

Hak Cipta

© © All Rights Reserved

Format Tersedia

XLSX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThe document contains details of clauses from ISO14001 and OHSAS 18001 standards for environmental and occupational health and safety management systems. It includes requirements for environmental policy, planning, implementation, checking, and management review. It also lists hazards identified at various production stations, including risks of injury from moving objects, manual handling, repetitive work, sharp objects, electricity, and suspended loads. Control measures listed include safety interlocks, machine guarding, personal protective equipment, and administrative controls.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai XLSX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

546 tayangan214 halamanEHS Overview Share

Diunggah oleh

Muhammad TaufikThe document contains details of clauses from ISO14001 and OHSAS 18001 standards for environmental and occupational health and safety management systems. It includes requirements for environmental policy, planning, implementation, checking, and management review. It also lists hazards identified at various production stations, including risks of injury from moving objects, manual handling, repetitive work, sharp objects, electricity, and suspended loads. Control measures listed include safety interlocks, machine guarding, personal protective equipment, and administrative controls.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai XLSX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 214

Clause ISO14001 Clause

4.1General Requirements 4.1

4.2Environmental Policy 4.2

4.3 Planning

4.3

4.3.1 Environmental Aspects 4.3.1

4.3.2 Legal and other requirements 4.3.2

4.3.3 Objectives, Targets & Programme(s) 4.3.3

4.4 Implementation And Operation 4.4

4.4.1 Resources, roles, responsibility and authority 4.4.1

4.4.2 Competence, Training and Awareness 4.4.2

4.4.3 Communication 4.4.3

4.4.3.1

4.4.3.2

4.4.4 Documentation 4.4.4

4.4.5 Control of Documents 4.4.5

4.4.6 Operational control 4.4.6

4.4.7 Emergency preparedness and response 4.4.7

4.5 Checking 4.5

4.5.1 Monitoring and measurement 4.5.1

4.5.2 Evaluation Of Compliance 4.5.2

4.5.3 Nonconformity, corrective action and preventive

action

4.5.3

4.5.3.1

4.5.3.2

4.5.4 Control of Records 4.5.4

4.5.5 Internal Audit 4.5.5

4.6 Management Review 4.6

OHSAS18001 Clause

General Requirements 3.1

OHS Policy 3.1.1

Planning

3.1.2

Hazard identification, risk assessment and

determining controls

3.2

Legal and other requirements 3.2.1

Objectives and programs 3.2.2

3.2.3

Implementation and operation 3.2.4

Resources, roles,responsibility,accountability

and authority

3.3

3.3.1

3.3.2

Competence, training and awareness 3.3.3

Communication, participation and consultation 3.3.4

Communication 3.4

Participation and consultation

3.4.1

3.4.2

Documentation 3.4.3

Control of documents 3.4.4

Operational Control 3.5

Emergency preparedness and response 3.5.1

Checking 3.5.2

Performance measure and monitoring

Evaluation of compliance 3.3.4.3

Incident investigation, nonconformity, corrective

action and preventive action

Incident investigation

Nonconformity, corrective action and preventive

action

Control of record

Internal audit

Management Review

OHSMS 1722

Policy

Occupational safety and health policy

Employee participation

Organising

Responsibility and accountability

Competence and training

OSH MS documentation

Communication

Planning and implementation

Initial review

System planning, development and implementation

OSH objective

Hazard prevention

Evaluation

Performance monitoring and measure

Investigation of work related injuries, disabilities, ill

health, disease and near misses, and their impact on

safety and health performance

Audit

Management review

Action for improvement

Preventive and corrective action

Continual improvement

Emergency prevention, preparedness and response

Eliminate

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Eliminate

4 S0 F2

4 S0 F2

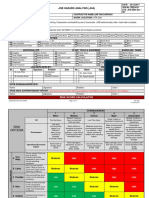

Risk Rating

Consequenc

e

Likelihood

STATUS DUE PIC

Control Measure

Risk Assessment

Dept: C Prepared by: Me Date: 06.07.11Rev: 1

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

4

4 S0 F2

S0 F2

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

Substitute

Isolate

Engineering

control

Admin

Control

PPE

4 S0 F2

Eliminate

4 S0 F2

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

Eliminate

4 S0 F2

F2

Eliminate

4 S0

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

4 S0 F2

Eliminate

4 S0 F2

4 S0 F2

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

F2

Eliminate

4 S0

Eliminate

4 S0 F2

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

4 S0 F2

Eliminate

4 S0 F2

F2 4 S0

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

Eliminate

4 S0 F2

Eliminate

4 S0 F2

PPE

Eliminate

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

4 S0 F2

S0 F2

Eliminate

4 S0 F2

4

4 S0 F2

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate 4 S0 F2

Eliminate

4 S0 F2

Eliminate

4 S0 F2

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

4 S0 F2

Eliminate

4 S0 F2

Eliminate 4 S0 F2

Substitute

Isolate

Engineering

control

Admin

Control

PPE

4 S0 F2

Eliminate

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

F2

4 S0 F2

Eliminate

4 S0

Eliminate

4 S0 F2

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

4 S0 F2

Eliminate

4 S0 F2

F2 4 S0

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Substitute

Isolate

Engineering

control

Admin

Control

PPE

Eliminate

4 S0 F2

Eliminate

4 S0 F2

4 S0 F2

Substitute

Isolate

Engineering

control

Admin

Control

PPE

4 S0 F2

Hazard Identification

Station 1

- 26P

Connector

Riveting &

Housing

Assembly

Circuit

breaker

Physical

hazard:

Moving

object .

Station 2

- Main PCB

Clinching

Use 2 hands

safety

operation

switch

Safety

interlock

manual

handling,

repetitive

work (risk:

injurys to

fingers and

hands)

Existing

control

Hazard &

Potential

Activity/

Product/

Services

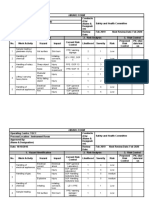

HIRADC : Hazard Identification Risk Assessment and Determine Control

Environmental Aspect Impact Register

Circuit

breaker - As

above

Risk: Hand

injury,

repetitive

work,

electricution

Station 3

Use 2 hands

safety

operation

switch

Safety

interlock

manual

handling,

repetitive

work (risk:

injurys to

fingers and

hands)

Circuit

breaker - As

above

- Housing

Frame

Screwing

Station 4

Circuit

breaker - As

above

- PCB Visual

Inspection

Station 5

- Flash

Programmin

g

Circuit

breaker

Splicing tool

secure/setup

station

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

Safety

interlock

manual

handling,

repetitive

work (risk:

injurys to

fingers and

hands)

manual

handling,

repetitive

work (risk:

injurys to

fingers and

hands)

Station 6

Circuit

breaker - As

above

- Finetune

alignment

Station 7

Safety

interlock

sharp object

(risk:injury to

fingers and

hands),

physical

injury

Splicing tool

secure/setup

station

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

- Mechanism

to radio

assembly

Circuit

breaker - As

above

Station 8

Circuit

breaker - As

above

- Bracket to

Mechanism

Screwing

Station 9

Safety

interlock

manual

handling,rep

etitive work

(risk: injurys

to fingers

and hands)

manual

handling,

repetitive

work (risk:

injurys to

fingers and

hands)

Safety

interlock

Safety

interlock

sharp object

(risk:injury to

fingers and

hands),

physical

injury

Circuit

breaker - As

above

- Bottom

Cover

Screwing

Station 10 Safety

interlock

sharp object

(risk:injury to

fingers and

hands),

physical

injury

Safety

interlock

manual

handling,rep

etitive work

(risk: injurys

to fingers

and hands)

- Mechanism

to radio

assembly

and

inspection

Station 11

Circuit

breaker - As

above

- Mechanism

to radio

screwing

Station 12

manual

handling,

repetitive

work (risk:

injurys to

fingers and

hands)

Safety

interlock

Safety

interlock

repetitive

work, manual

handling,

electricution

Safety

interlock

sharp object

(risk:injury to

fingers and

hands),

physical

injury

Circuit

breaker - As

above

- Front Cover

to radio

assembly

Station 13

Safety

interlock

manual

handling

manual

handling,

repetitive

work (risk:

injurys to

fingers and

hands)

Safety

interlock

- Top Cover

assembly

Station 14

Circuit

breaker - As

above

- Top Cover

screwing

Station 15 Splicing tool

secure/setup

station

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

Use 2 hands

safety

operation

switch

Using

engineering

board for

setup

manual

handling,

repetative

work,

chemical

subs material

(glue)

Safety

interlock

manual

handling

Circuit

breaker - As

above

- Holding

Spring

screwing

Station 16

Circuit

breaker - As

above

- Finetune

alignment

Station 17 Splicing tool

secure/setup

station

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

Splicing tool

secure/setup

station

Splicing tool

secure/setup

station

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

Circuit

breaker - As

above

- Functional

check

Station 18

Circuit

breaker - As

above

- Functional

check

Station 19

Using

engineering

board for

setup

manual

handling

Splicing tool

secure/setup

station

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

Splicing tool

secure/setup

station

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution)

Circuit

breaker - As

above

- Functional

check

Station 20

Safety

interlock

Suspended

object

Ear plug

expose to

electrical

energy

(Risk=lelectri

cal

burn/electroc

ution). Noise

Sound Room

Using

engineering

board for

setup

manual

handling

Circuit

breaker - As

above

- Sticker

Assembly

Station 21

- Visual

check

Station 22

repetitive

work and

manual

handling,fall

Safety

interlock

Safety

interlock

repetitive

work and

manual

handling,fall

Safety

interlock

Suspended

object

- Default

setting

Station 23

- Frame

assembly

Station 24

None

Physical

hazard:

Improper

Conveyor

width setting

. Risk :

damage

board

Safety

interlock

repetitive

work and

manual

handling,fall

repetitive

work and

manual

handling,fall

Safety

interlock

- Packing

None

Physical

hazard:

Improper

Conveyor

width setting

. Risk :

damage

board

Use of

natural

resouces

(electricity)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(plastic

reel/bag)

Use of

natural

resouces

(electricity)

Picture

Input Amount/yr

HIRADC : Hazard Identification Risk Assessment and Determine Control

Environmental Aspect Impact Register

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of

natural

resouces

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(Finger coat)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(Glove)

Use of raw

material

(plastic

reel/bag)

Use of

natural

resouces

(electricity)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(barcode reel

waste paper)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of

natural

resouces

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(Finger coat)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

Resources

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

Resources

(electricity)

Use of

natural

Resources

(electricity)

Use of

natural

Resources

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of

natural

resouces

(electricity)

Use of

natural

Resources

(electricity)

Use of raw

material

(plastic

reel/bag)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of raw

material

(Glove)

Use of

natural

Resources

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(Finger coat)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(paper)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

Use of

natural

resouces

(electricity)

Use of

natural

resouces

(electricity)

Use of raw

material

(Glove)

Use of raw

material

(Finger coat)

x x x

x x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

Normal Abnormal Emergency

Depletion Of

natural

resources Output Amount/yr **Legal

Condition Impact to Environment

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

x x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

x x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

x x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste paper

? x x

x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

x x x

Waste

plastic

reel/bag 0 x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste

plastic

reel/bag 0 x x

x

x x x

Waste glove 52 pcs x x

x x x

x x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x

x x

x

x x x

x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

x x x

x x x

Waste

plastic

reel/bag 0 x x

x

x x x

Waste glove 52 pcs x x

x x x

x x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x

x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x x

x x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x x

waste paper

? x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

x

x

x x

x x

x x x

Waste glove 52 pcs x x

x x x

Waste

rubber 7300 pcs x x

Evaluation

Significant

Yes/No

S0-ADB , F2

= 4 (NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

Air Pollution

Others (Pls

mention) Soil Pollution

Water

Pollution

Impact to Environment

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO) x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO) x

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

x S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

S0 , F2 = 4

(NO)

x

S0 , F2 = 4

(NO)

LEGAL REQUIREMENT BY AREA

L

E

G

A

L

/D

E

P

T

H

R

-

T

r

a

in

in

g

C

lin

ic

C

a

n

te

e

n

M

O

E

-

P

g

P

1

M

F

G

-

P

g

P

2

M

a

in

t. B

a

y

S

e

c

u

r

ity

Q

A

-

R

e

l L

a

b

s

F

A

L

a

b

IQ

C

D

C

C

C

a

l L

a

b

E

H

S

A

d

m

in

/F

in

a

n

c

e

/O

th

e

r

s

E

n

g

in

e

e

r

in

g

S

c

h

e

d

u

le

d

W

a

s

te

D

is

p

o

s

a

l A

r

e

a

S

to

r

e

-

R

e

c

e

iv

in

g

/S

h

ip

p

in

g

S

to

r

e

-

C

h

e

m

ic

a

l

S

to

r

e

-

G

a

s

S

o

lid

W

a

s

te

A

r

e

a

F

a

c

s

-

S

e

w

a

g

e

/C

e

n

t P

la

n

t/O

th

e

r

s

G

e

n

. S

e

t

C

o

o

lin

g

T

o

w

e

r

W

a

te

r

S

to

r

a

g

e

T

N

B

r

o

o

m

A

H

U

/F

C

U

INDEX OF MALAYSIA EHS LEGISLATION : June 2004

1 Atomic Energy Licensing Act 1984 Act 304 4.4 X X

2

Atomic Energy Licecing (Exemption) (Exemption) (Low Activity Radioactive Material)

Order 2002 PU(A) 182/2002 4.4 X

3 Environmental Quality Act 1974 Act 127 1 X X X X X X X X X X X X X X

4

Environmental Quality (Clean Air) (Amendment) Regulations 2000 PU(A) 309/2000

2 X X X X

5

Environmental Quality (Compounding of Offences) (Amendment) Rules 1999 PU(A)

512/1999 2

6

Environmental Quality (Control of Emission From Diesel Engines)(Amendment)

Regulations 2000 PU(A) 488/2000 2 X

7 Environmental Quality (Dioxin and Furan) Regulations 2004 PU(A) 104/2004 2 X

8 Environmental Quality (Halon Management) Regulation 1999 PU(A) 452/1999 2 X

9

Environmental Quality (Delegation of Powers) (Halon Management)Regulation 2000

PU(A) 490/2000 2 X

10 Environmental Quality (Licensing) Regulations 1977 PU(A) 198/1977 1 X X

11 Environmental Quality (Motor Vehicle Noise) Regulations 1987 PU(A) 244/1987 2

12

Environmental Quality (Prescribed Activities) (Environmental Impact Assessment)

Order 1987 PU(A) 362/1987 6

13

Environmental Quality (Prescribed Premises) (Scheduled Wastes Treatment and

Disposal Facilities) Regulations 1989 PU(A) 141/1989 5 X X

14

Environmental Quality (Prohibition on the Use of Chlorofluorocarbons and other

Gases as Propellants and Blowing Agents) Order 1993 and other Gases as

Propellants and Blowing Agents) Order 1993 2

X

15

Environmental Quality (Prohibited on the Use of the Controlled Substance in Soap,

Synthetic Detergent and Other Cleaning Agents) Order 1995 PU(A) 115/1995 3

X X

16

Environmental Quality (Refrigerant Management) Regulation 1999 PU(A) 451/1999

2 X X

17

Environmental Quality (Scheduled Wastes) Regulations 1989 PU(A) 139/1989 5

X X X X

18

Environmental Quality (Sewage and Industrial Effluents) Regulations 2000 PU(A)

398/2000 3

X X

19 Factories and Machinery Act, 1967 Act 139 7.2 X X X

20 Factories and Machinery (Exemption) (No.3) Order 2004 PU(A)185/2004 7.2

21 Factories and Machinery (Asbestos Process) Regulations 1986 7.2 X

22

Factories and Machinery (Building Operations and Works of Engineering

Construction) (Safety) Regulations 1986 PU(A) 5/1970 7.2

X

23

Factories and Machinery (Fencing of Machinery and Safety) Regulations 1970

PU(A) 10/1970 7.2

X X X X X X

24 Factories and Machinery (Lead) Regulations 1984 PU(A) 60/1984 7.2 X X X X X X

25 Factories and Machinery (Mineral Dust) Regulations 1989 PU(A) 2/1989 7.2 X X X X X

26 Factories and Machinery (Noise Exposure) Regulations 1989 PU(A)1/1989 7.2 X X X X X X X X X X

27

Factories and Machinery (Notification, Certificate of Fitness and Inspection)

Regulations 1970 PU(A) 444/1970 7.2 X X

28

Factories and Machinery (Persons-In-Charge) Regulations 1970 PU(A) 11/1970 7.2

X X

29

Factories and Machinery (Revocation of Exemption) Order 2000 PU(A) 22/2000 7.2

30

Factories and Machinery (Safety, Health and Welfare) Regulation 1970 PU(A)

32/1970 7.2 X X X X

31

Factories and Machinery (Steam Boiler and Unfired Pressure Vessel) (Amendment)

Regulations 1999 PU(A) 323/1999 7.2

X

32 Fire Services Act 1988 Act 341 8 X X X X

33 Fire Services (Amendment) Act 1991 Act A799 8

34 Fire Services (Amendment) Act 1994 Amending Act A879 8

35 Fire Services (Compounding of Offences) Regulations 2000 PU(A) 313/2000 8

36 Fire Services (Fire Certificate) Regulation 2001 PU(A) 241/2001 8 X

37 Local Government Act 1976 Act 171 5 X X

38 Local Government (Amendment) Act 1991 Amending Act A806 5

39 Local Government (Amendment) Act 1993 Amending Act A865 5

40 Merchant Shipping (Oil Pollution) Act 1994 3 Act 515

41 Merchant Shipping Ordinance 1952 3

42 Occupational Safety and Health Act 1994 Act 514 7.1 X X X X X X X X X X X X X X X X X X X X X X X X X X

43

Occupational Safety and Health Act 1994 Declaration of Occupational Diseases

X X

44

Occupational Safety and Health (Classification, Packaging and Labelling of

Hazardous Chemicals) Regulations 1997 PU(A) 143/1997 7.1

X X X X X X X X X X X X X

45

Occupational Safety and Health (Control of Industrial Major Accident Hazards)

Regulations 1996 PU(A) 39/96 7.1

46

Occupational Safety and Health (Employers Safety and Health General Policy

Statements) (Exception) Regulations 1995 PU(A) 78/1995 7.1

X X

47

Occupational Safety and Health (Prohibition of Use of Substance) Order 1999 PU(A)

303/1999 7.1 X X

48

Occupational Safety and Health (Safety and Health Committee) Regulations 1996

X X

49

Occupational Safety and Health (Safety and Health Officer) Regulations 1997PU(A)

315/1997 7.1

X

50

Occupational Safety and Health (Safety and Health Officer) Order 1997 PU(A)

316/1997 7.1

51

Occupational Safety and Health (Use and Standard of Exposure of Chemicals

Hazardous to Health) Regulations 2000 PU(A) 131/2000 7.1

X

52

Occupational Safety and Health (Notification of Accident, Dangerous Occurrence,

Occupational Poisoning and Occupational Disease) Regulations 2004

PU(A)128/2004 7.1 X X X

53 Poisons Act 1952 Act 366 4.1 X X

54 Poison List (Amendment) Order 2004 PU(A) 39/2004 4.1

55 Poisons List (Exemption) Order 2001 4.1

56 Poisons Regulations 1952 PU(A) 233/2003 4.1

57 Poisons (Psychotropic Substances) Regulations 1989 PU(A) 260/1998 4.1

58

Poisons (Psychotropic Substances) (Amendment) Regulations 1999 PU(A) 19/1999

4.1

59 Poisons (Sodium Arsenite) Ordinance 1949

60 Poisons (Sodium Arsenite) Regulations 1949

61 Poisons (Sodium Hydroxide) Regulations 1962

62 Pesticides Act 1974 Act 149 X

63 Pesticides (Amendment of First Schedule) Order 2003 PU(A) 16/2003

64 Pesticides (Amendment of Second Schedule) Order 2001

65 Pesticides (Advertisement) Regulations 1996

66 Pesticides (Exemption) Order 2004 PU(A) 13/2004

67

Pesticides (Importation for Education or Research Purposes) (Amendment) Rules

1987 PU(A) 87/1987

68 Pesticides (Labelling) Regulations)1984 PU(A) 251/1984 X

69 Pesticides (Licensing for Sale and Storage for Sale) Rules 1988

70 Pesticides (Pest Control Operator) Rules 2004 PU (A) 70/2004 X

71 Petroleum (Safety Measures) Act 1984 Act 302

72 Petroleum (Safety Measures) (Amendment) Act 1993 Act A843

73 Radiation Protection (Basic Safety Standards) Regulation 1988 X X

74 Radiation Protection (Licensing) Regulation 1986 X

75

Revision of Laws (Rectification of Pesticides Act 1974) Order 2003 PU(A)364/2003

76

Sewerage Services Act 1993 Act 508 3

X

77

Sewerage Services (Authorisation Of Collection Of Charges) Order 1994 PU(A)

116/1994

X

78 Sewerage Services (Charges) Regulations 1994 PU(A) 115/1994 3

79 Sewerage Services (Charges) (Amendment) Regulations 1999 PU(A) 67/1999 3

80

Sewerage Services (Compounding of Offences) Regulations 2001 PU(A) 201/2001

81 Sewerage Services (Licensing) Regulations 1994 PU(A) 114/1994 3 X

82 Street Drainage and Building Act 1974 Act 133 3 X

83 Street, Drainage and Building (Amendment) Act 1993 Amending Act A867 3 X

84

REACH - Registration, Evaluation, Authorization & Restriction of Chemical

Substances EU Directive

85 RoHS

86 WEEE

UPDATE : Nov 30,2010

JAN FEBMARAPRMAYJUNJUL AUGSEPOCTNOVDECJANFEBMARAPRMAYJUNJUL AUGSEPOCTNOVDECJANFEB

AI link to legal

Mechanism 1. Subscribtion

2. Frequent visit to - DOSH, DOE , website - need to show prove of visit

3. Frepencha meeting - Put on of meeting agenda update on legal and other requiremnents

Environmental Aspect/OHS

Regulations/topic

Environmental/OHS Law

(Act; Section; Regulation; Requirements)

1)Register entry of Generator set DOE.Ref no

: AP/E/3S (P 71/2010)

AP/E/3S (P 72/2010)

EQA1974 Regulations 1978 (Control of Emissions from Diesel

Engines)

2) Sewage discharge EQA 1974 (Sewage) Regulation 2009

Environmental Quality (Refrigerant Management) Regulation 1999

Environmental Quality (Halon Management) Regulation 1999

4) Air emission

DOE.Ref no : AK(CR 140/2007)

EQA 1978 (Clean Air)

LEGAL REGISTER AND EVALUATION OF COMPLIANCE (Legal and other requirements)

3) Halon

5) Disposal of Scheduled Wastes:

Environmental Quality

( Scheduled Waste Regulations) 2005

OSHA 1994 (Dec 2002): Act 514 Part IV, Sec.16 Duty to

Formulate Safety and Health Policy

Occupational Safety and Health (Employers Safety and Health

General Policy Statements) (Exception) Regulations 1995

OSHA 1994 (Dec 2002): Act 514 Part VII, Sec.30 Establishment

of Safety and Health Committee at Place of Work

Occupational Safety and Health (Safety and Health Committee)

Regulations 1996

OSHA 1994 (Dec 2002): Act 514 Part VII, Sec.29

Occupational Safety and Health (Safety and Health Officer) Order

1997

5) Safety and Health Officer

3) Safety and Health Policy

4) Safety and Health Committee

OSHA 1994 (Dec 2002): USECHH 2000, Regulation 9

OSHA 1997 (Classification, Packaging & Labeling of Hazardous

Chemicals)

OSHA 1994 (Dec 2002): USECHH 2000, Regulation 16

FMA 1967 (June 2003): Act 139 - Factories and Machinery

(Safety, Health and Welfare) Regulations 1970 Regulation 32

6) Chemical Health Risk Assessment

(CHRA)

7) Implementation of PPE

8) Initial Noise Monitoring

FMA 1967 (June 2003): Act 139 Factories and Machinery (Noise

Exposure) Regulations 1989, Part III Exposure Monitoring

FMA 1967(June 2003): Act 139 Factories and Machinery

(Safety, Health & Welfare) Regulations 1970 Regulation 13.

Code of Practice For Safe Working In A Confined Space 2010

OSHA 1994 (Dec 2002): Act 514, Section 15 (1)

FMA 1967 (June 2003): Act 139 - Sec. 25 (1) (c)

Factories and Machinery (Safety, Health and Welfare) Regulations

1970 Regulation 38

12) Certificate of Fitness for Oil Separator,

Air Compressor, Air Receiver, Good Lifts and

Passenger Lifts

Factories and Machinery (Notification, Certificate of Fitness and

Inspection) Regulation 1970 Part II, Certificate of Fitness.

13) Building Operations and Works of

Engineering Construction

Factories and Machinery (Building Operations and Works of

Engineering Constructions) ( Safety) Regulation 1986

11) Occupational Health Clinic / First Aid

Room and First Aid Box

10) Working in Confined Space

9) Lead Exposure Monitoring

FMA 1967 (June 2003): Act 139 Factories and Machinery (Lead)

Regulations 1984, Part III Exposure Monitoring.

14)Environmental Management Systems MS ISO14001: 1997 (ISO/TC 207)

15) Occupational Health and Safety Standard

& Requirement

AS/NZS 4801:2001

OHSAS 18001:1999

16) Notification of Accident, Dangerous

Occurrence, Occupational Poisoning and

Occupational Disease

Guidelines on Safety and Health ( Notification of Accident,

Dangerous Occurrence, Occupational Poisoning and

Occupational Disease) Regulations 1994

17) Cooling Water Tower Environmental Quality (Sewage and Industrial Effluent)

Regulations 1979 Second Schedule

18) Bomba Certificate

Fire Act

19) Radiation

Radiation Act 1984

20) Solid and General Wastes (Non-

Scheduled Wastes

Environmental Quality Act 1974

1. Regulation (24) Restriction of pollution of the soil.

2. Regulation (25) Restrictions on pollution of inland waters.

21) Diesel Properties

Environmental Quality ( Control of Petrol and Diesel Properties )

Regulation 2007

Document number Title

N93 A1 N93-Preparation and control

Bosch-Norm | 4497025164 | N93 A | 2011-03-30

N93 A1.1 Basic requirements for occupational health and safety, fire and

environmental protection

N93 A2 Responsibility for occupational health and safety, fire and

environmental protection

(HSE); Transferring contractor obligations

N93 A3 Representatives for occupational health and safety, fire and

environmental

protection; Tasks and responsibilities

N93 A4 Legal specifications

N93 A5 Evaluation of environmental aspects

N93 A5.1 Evaluation of environmental aspects; Classification scheme for

defining priorities

N93 A5.2 Evaluation of environmental aspects; Overview of "Environmental

impact"

N93 A6 Audit management and performance assessment of occupational

health and safety,

fire and environmental protection

N93 A8 Employee instruction and training

N93 A8.1 Training and Instruction Matrix; Environmental Protection and

Safety

N93 A9 Emergency control; Evacuating Buildings

N93 A11 Hazard assessment International version

N93 A11.1 Hazard assessment - RBI

N93 A12 Supplier audits

N93 A13 Waste management

N93 A14 Soil and water conservation

N93 A18 Chemical working substances

N93 A19 Performing environmental and occupational safety - due diligence

(HSE-Due

diligence)

N93 A20 Contractor companies (CC)

N93 A21 Post-Merger-Integration (HSE-PMI)

N93 A22 Fire protection

N93 A23 Procedure for closing of locations focusing on environmental

issues

N93 B1 Directive; General rules for employees

N93 B1.1 Directive; General rules for employees; Safety identification

N93 B1.2

N93 B1.2 Directive; Hazard prevention

N93 B1.3 Directive; Accident notification; Occupational accident notification

scheme

N93 B1.4 Directive; Hazardous substance identification; Hazardous

substances

N93 B1.4.1 Directive; Labeling elements acc. to GHS/CLP (Regulation EC

1272/2008)

Bosch-Norm | 4497039248 | N93 B | 2011-03-30

Document number Title

N93 B1.4.2 Directive; Comparison of hazard symbols/pictograms

N93 B1.5 Directive; Skin protection plan; Example

N93 B1.6 Directive; Use of personal protective equipment (PPE); Examples

for department /workshop

N93 B10 Directive; Working on electrical machines and equipment (MAE)

N93 B11 Directive; Battery charging installations

N93 B14 Directive; Setting up working equipment (MAE)

N93 B16 Directive; Centrifuges

N93 B17 Directive; EDM machines

N93 B18 Directive; Welding, flame cutting, soldering

N93 B19 Directive; Material-removing processing machines

N93 B20 Directive; Grinder tools

N93 B21 Directive; Electrochemical machining installations (ECM)

N93 B26 Directive; Dust detrimental to health

N93 B28 Directive; Ladders and Steps

N93 B29 Directive; Lifting platforms

N93 B29.1 Directive; Lending and written assignment of hydraulic platforms

to contractor companies; sample

N93 B30 Directive; Handling lifting tools and load carrying devices

N93 B33 Directive; Compressed-gas cylinders

N93 B35 Directive; Powered industrial vehicles

N93 B38 Directive; Working alone

N93 B39 Directive; Circular saws and band saws

N93 B43 Directive; Storing and provision

N93 B44 Directive; Warehouse facilities

N93 B47 Directive; Work on systems using pressurized media

N93 B48 Directive; Kitchen / canteen

N93 B53 Directive; X-ray systems and equipment with stray radiation effect

N93 B54 Directive; Maintenance / machine cleaning

N93 B59 Directive; Jet stream machines

N93 B65 Directive; Scooters, bicycles and similar vehicles

N93 B69 Directive; Docking stations / loading ramps

N93 B70 Directive; Shears

N93 B71 Directive; Press containers

N93 B72 Directive; Firefighting systems; (Building/room protection systems)

N93 B73 Directive; Workstations with visual display units

N93 B74 Directive; Working in rooms / areas subject to explosion hazard

N93 I1 Safety Marking; Overview

N93 I1.1 General

N93 I1.1.1 Preamble

N93 I1.1.2 Guidelines for safety marking

N93 I1.2 Safety marking at work place

N93 I1.2.1 Prohibition signs; Plasticized PVC film; self-adhesive

N93 I1.2.2 Mandatory signs; Plasticized PVC film; self-adhesive

N93 I1.2.3 Warning signs; Plasticized PVC film; self-adhesive

N93 I1.2.4 Fire safety signs

N93 I1.2.5 Signs for fire brigade services

N93 I1.2.6 Safe condition signs; Plasticized PVC film; self-adhesive

N93 I1.2.7 Marking of dangerous substances; Plasticized PVC film; self-

adhesive

N93 I1.2.9 Inspection stickers

N93 I1.2.10 Minisymbols; Plasticized PVC film; self-adhesive

N93 I1.2.11 Environmental protection signs; Plasticized PVC film; self-

adhesive

N93 I2 Personal protective equipment; Overview

N93 I2.1 Personal protective equipment; General

N93 I2.1.1 Compulsory personal protective equipment

N93 I2.1.2 List of authorized suppliers

N93 I2.2.0 Eye and face protection; General

N93 I2.2.1 Eye and face protection; Mechanical impact

Bosch-Norm | 4497025215 | N93 I | 2011-03-30

Document number Title

N93 I2.2.2 Eye and face protection; Optical impact

N93 I2.2.3 Eye and face protection; Chemical impact

N93 I2.2.4 Eye and face protection; Thermal impact

N93 I2.2.5 Eye and face protection; Combined impact

N93 I2.3.0 Head protection; General

N93 I2.3.1 Head protection; Mechanical/thermal impact

N93 I2.4.0 Respiratory protection; General

N93 I2.4.1 Respiratory protection

N93 I2.5.0 Hand and finger protection; General

N93 I2.5.1 Hand and finger protection; Mechanical impact

N93 I2.5.2 Hand and finger protection; Chemical impact

N93 I2.5.3 Hand and finger protection; Thermal impact

N93 I2.5.4 Hand and finger protection; Electrical impact

N93 I2.5.5 Hand and finger protection; General impacts

N93 I2.6.0 Foot protection; General

N93 I2.6.1 Foot protection; Mechanical impact

N93 I2.6.2 Foot protection; Chemical impact

N93 I2.6.3 Foot protection; Thermal impact

N93 I2.6.4 Foot protection; Mechanical impact and ESD protection

N93 I2.7.0 Body protection; General

N93 I2.7.1 Body protection; Mechanical impact

N93 I2.7.2 Body protection; Chemical impact

N93 I2.7.3 Body protection; Thermal impact

N93 I2.8.0 Hearing protection; General

N93 I2.8.1 Hearing protection

N93 I2.10.1 Skin protection; General

N93 I2.10.2 Example for skin protection plan

N93 I3 Best practice solutions

N93 I3.1 Environmental management system (not yet available

N93 I3.2 Health and safety management system

N93 I3.2.1 Recording and analyzing of occupational accidents

N93 I3.3 Soil and water protection

N93 I3.3.1.1 Machinery and equipment or handling substances hazardous to

water; Sealing of bottom surface

N93 I3.3.1.2 Machinery and equipment or handling substances hazardous to

water; Design of retention system

N93 I3.3.1.3 Machinery and equipment or handling substances hazardous to

water; Example:

Safety program for MAE w. individual feed

N93 I3.3.1.4 Machinery and equipment or handling substances hazardous to

water; Example:

Safety program f. MAE w. central feed

N93 I3.4 Waste (not yet available)

N93 I3.5 Air quality (not yet available)

N93 I3.6 Hazardous materials and goods (not yet available)

N93 I3.7 Fire protection and emergency control

N93 I3.7.1 Maintenance of fire protection systems

N93 I3.7.1.1 Maintenance of fire protection systems; Maintenance contents and

intervals

N93 I3.8 Inspection intervals for working equipment (MAE)

N93 I3.8.1 Inspection of working equipment (MAE) acc. to Ord. on Industrial

Safety and Health

N93 I3.8.2 Inspection of working equipment (MAE) and installations that

require monitoring;

Recommendations

N93 I3.9 Machinery and equipment safety

N93 I3.9.1 Machinery and equipment safety; Safety standard

N93 I3.9.1.0 Minimum requirements for operating work equipment; Appendix 1

on Ordinance on

Industrial Safety and Health

N93 I3.9.1.1 Machinery and equipment safety; Observance Machine VO

N93 I3.9.1.2 EU-Machine directive/9th ordinance on the Equipment Safety Act;

Procedure with

deviations from CE

N93 I3.9.2 Separating protective installations; Safety standard

N93 I3.9.3 Two-hand operation units; Safety standard

N93 I3.9.4 Key-operated adjuster; Safety standard

N93 I3.9.5 Hydraulic hose assemblies; Safety standard

N93 I3.9.6 Polycarbonate (PC-) inspection windows on machine tools; Safety

standard

N93 I3.9.7 Safety-related planning and inspection of working equipment and

construction

projects; Examples

N93 I3.10 Training and instruction

N93 I3.10.1 Operator training for powered industrial vehicle

N93 I3.10.2 Tips and hints for our employees (leaflet)

N93 I3.11 Safety standards informative

N93 I3.11.2 Presses; Safety standard

N93 I3.11.3 Noise; Safety standard

N93 I3.11.3.1 Acoustic, machine acceptance; Safety standard

N93 I3.11.4 Industrial robots; Safety standard

N93 I3.11.5 Laser installations; Safety standard

N93 I3.11.6 Storing of hazardous substances; Safety standard

N93 I3.11.9 Setting up and operating electroplating shops; Safety standard

N93 I3.11.10 Machines with stock removal using mineral oil as metal working

fluid (KSS); Safety

standard

N93 I3.11.10.1 Checklist; Machinery with stock removal using cooling lubricants

oil; Safety

standard

N93 I3.11.10.2 Switch off matrix; Machinery and equipment MAE using cooling

lubricants oil CL; Safety standard

N93 I3.11.11 Electromagnetic fields; Safety standard

N93 I3.11.11.1 Electromagnetic fields; Identification of workshops

N93 I3.11.12.1 Traffic and escape routes; Safety standard

N93 I3.11.13 Inspection/assembly installations with combustible liquids; Safety

standard

N93 I3.11.13.1 Inspection and supply rooms with combustible liquids; Safety

standard

N93 I3.11.13.2 Inspection and assembly installations with combustible liquids

(minimum

requirements); Safety standard

N93 I3.11.16 Handling biological working materials; Safety standard

N93 I3.11.16.1 Handling biological working materials, hazard assessment; Safety

standard

N93 I3.11.18 Remote maintenance of machine controls; Safety standard

N93 I3.11.18.1 Remote maintenance of machine data; Protocol

N93 I3.11.19 Working alone; Safety standard

N93 I3.11.20 Design and equipment of storage facilities for compressed-gas

cylinders (gas

cylinder storage)

N93 I3.12 Explosion protection

N93 I3.12.1 Hazardous explosive atmosphere; General

N93 I3.12.1.1 Explosion protection document acc. to Ordin. on Ind. Safety and

health (BetrSichV)

N93 I3.12.1.1.1 Explosion protection document; Assessment of explosion hazard

from gases,

fumes or mist

N93 I3.12.1.1.2 Explosion protection document acc. to Ordin. on Ind. Safety and

health

(BetrSichV); Installations relevant for ex. Protection (samples)

N93 I3.13 HSE-relevant specifications

N93 I3.13.1 Identification, evaluation and documentation of HSE specifications

N93 I3.14 Environment-related product data

N93 I3.14.1 Environment-related product data; Data format and process

N93 S1 Safety-related planning and inspection of working equipment and

construction

projects

N93 S14 Machinery and equipment (MAE) for handling substances

hazardous to the

environment

N93 S17 Work subject to prior authorization; Safety standard

N93 S21 Battery installations for electro-powered industrial vehicles; Safety

standards

N93 S22.1 Fire protection - constructional; Safety standards

Bosch-Norm | 4497017384 | N93 S | 2011-03-30

Document number Title

N93 S22.2 Fire protection - operational; Safety standards

N93 S22.3 Fire protection - organizational; Safety standards

Bosch -Norm N93 C

N93 C 1 Check Lists for Superiors

N93 C 1.1 Check Duties

N93 C2 Check Lists for Safety Representatives (SHB)

N93 C2.1 Personal Protection Equipment (PPE)/Skin Protection

N93 C2.2 Traffic, Escape and Rescue Routes

N93 C2.3 Hazardous Substances

N93 C2..4 Safety of Machines/Equipment

N93 C2.5 Electrical Installations and Tooling

N93 C2.6 Ladders and Steps

N93 C2.7 Lifting Tools, Loading and Stop Equipment

N93 C2.8 Fire and Explosion Protection

N93 C2.9 Transporting and Storing

N93 C3 Check Lists for Safety specialists and planners

N93 C3.1 Assessing floor/installation plans

Registration

Number

Bosch

Compliance

Compliance

related

Monitoring or action

required

Area

Responsibility

Yes Refer comment Baseline monitoring: Done Facilities

Yes Refer comment Monthly monitoring: Facilities

Yes

-

Facilities

Yes

Refer comment -

Yes Quarterly

Facilities, Wave

soldering, lacquering

, oven re-flow.

standby generators

LEGAL REGISTER AND EVALUATION OF COMPLIANCE (Legal and other requirements)

Yes Refer comment

Monthly sent Waste to KA

Monthly Scheduled waste

inventory report to

Department of Environment

Waste Generator

Waste Management

Center

Yes

To have a safety

policy for a

Penang in both

English and

Bahasa

Policy formulated and

published plant wide.

Revision will be done when

there are changes in process

and activities within the plant.

HSE

Yes - None HSE

Yes

Yes

Yes

Monthly report to MD

Assist Quarterly Audit by

Safety Committee

Yes

Yearly Safety training

HSE

Monthly meeting

Meeting minute sent to

management for reference.

HSE

Yes

IH Monitoring

Hygiene Tech

HSE

Yes

Labeling Maintenance

Yes

PPE HSE

Yes

Yes

Initial noise monitoring &

Additional noise monitoring

HSE

Yes

1All operation

processes,

standby generators

HSE

ENG, PUR

Confined Space SOP

Yes

Yes

Yes

Yes PMA/PMT yearly permit Facilities

Yes None Facilities

Nurse

Yes Facilities

Yes

Yes

Yearly Management Review

Yearly Internal audit

Yearly Surveillance audit

3 yearly Re-assessment audit

HSE-MS Area rep

Yes

Yearly Management Review

Yearly Internal audit

Yearly Surveillance audit

3 yearly Re-assessment audit

HSE-MS Area rep

Yes Yearly Report to DOSH

Headquarter

24 hours notification of any

incident of accident occurred

in the workplace

HSE

Yes Legionella analysis Facilities, sewage

treatment plant

Yes Yearly Renewal Facility

Yearly renewal

RPO

QA

Yes All

Refer comment 6 months Facilities

Yes None HSE-PT,C/PS

Bosch-Norm | 4497025164 | N93 A | 2011-03-30

Evaluation

process

In their area of responsibility

executives have to ensure

that there are no deviations

from legal

requirements or from Bosch

requirements that might be

avoided or prevented by

adequate monitoring.

EHS-basic requirements

which have to be observed by

all locations are listed in

attachment B

HSE

Yes The subordinate managers

have to provide adequate

operational facilities conform

to HSE requirements, to

check and monitor their

proper functioning and to

allocate

funds tailored to the

requirements for a hazard

minimized, environmental

sound and proper operation .

HSE have to ensure that

associates are appropriately

qualified and trained as well

as prescribed medical

examinations

of associates are provided.

Ensure that legal

requirements and Bosch

regulations on occupational,

health and safety, fire and

environmental protection. are

observed. Ensure,

that company doctors and

first-aid personnel as

required by local law are

appointed

HSE,Subordinate

manager

Yes BOSH-Norm to be implented

within a period of a 6 months.

Deviations

require coordination with

C/PS and have to be

documented.

2 Terms

HSE

Yes Identify clear requirements

for MAE or processes.

Prepare an information sheet

containing the actual

specifications for

the operator and to update as

required.

Process and detail in N93 A5

no 4

Facility

operator,HSE

Yes Identify the environmental

aspects related of its

activities, products and

services, that it can control

and influence.

Determine those which have,

or can have significant

impacts on the environment

HSE, All

Yes Establishing environment all

objective

HSE

None

Yes With regard to minor and

major non-conformities the

audited area will have to

generate an action plan.

Auditors have to be

knowledgeable and trained in

the relevant techniques and

management systems and

the audit principles of ISO

19011. All the topics

relevant for the location have

to be evaluated.

HSE-Question catalog.

HSE, Auditor, All

Yes Employee instruction and

training shall be organized on

location. Supervisor on site

responsible for conducting

the instruction

Instruction and training to be

carried out are listed in N93

A8.1. Performance of

instruction and training must

be documented

Document form 1: Example

"List of Signatures"

HSE,PUR

Yes It depend on the group to

conducting the training.

All

Yes Escape and rescue plans

shall be made and

evacuation drills have to take

place if one of the following

criteria

applies:

Conduct every 2 year

All

Yes For new MAE and building

investments, an overall final

acceptance process at the

plant level has to be set

up, carried out and

documented.

Document form 1: Sample

hazard assessment .

doc

Documentation form 2:

Hazard characteristics .

HSE,All

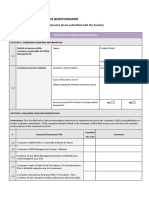

Yes The questionnaire Supplier

Audits (attachment 1)

provides the minimum

standard. Refer

4.3 the process and detail in

N93 A12 supplier audits

Documentation :

Questionnaire

HSE

Measures for the protection

of ground and waters for the

case of leakages have to be

taken With dangerous

goods transports the

corresponding national

regulations have to be

observed. Material samples

of pharmaceuticals,

cosmetics, food and

stimulants that manufacturers

and customers make

available for testing have to

be returned to the

manufacturer or disposed of

properly.

All waste disposal contractors

that are to be contracted by

Bosch for the first time have

to undergo a review

Those responsible must have

undergone sufficient training

as required.

Document form

1: Sample info-

questionnaire.

Document form

2: Hazard characteristics.

HSE and FCM

Yes The requirements to the

properties of surfaces and

retention volume for escaping

substances that are

hazardous

to the environment, including

performance examples, are

specified in BoschNorm

N93S14 in 4.2.1 Machinery

and equipment (MAE) and

4.2.2 Wastewater discharge

HSE

Yes Deviations require

coordination with C/PS and

have to be documented.

Directory of chemical working

substances, Safety data

sheets, Hazard assessment,

Packaging and identification,

Storage areas have to be

designed according to N93

S14.

Document Form Hazard

assessment of work with

chemical working materials.

Form-GHS Hazard

assessment of work with

chemical working materials.

HSE,All

Yes Monitoring contract

performance,

Process and flow chart detail

in 4.2.

Check list HSE-DD long

(encrypted) .

HSE

Yes The Bosch coordinator

conducts random checks to

verify that employees receive

the required instruction and

that instructions and rules are

observed,

Work with particular hazards

, the protective measures

have to be documented

according to site

requirements, assistance e.

g. through N93 S17 Work

subject to prior authorization

.

Document of the hazards

assessment and check

performance are to be

achieved for at least 2 year.

Form 1: Sample Safety

instruction .

Form 2: Sample

Determination of the

environmental hazard as well

as the hazards when dealing

with CC, protective measures

HSE

Yes The implementation of all

Bosch-internal requirements

(GF-guidelines, central

directives, Bosch-Norms)

must have been concluded

18 months after

acquisition.N93 Document

A21 Form 1 HSE-PMI-check

list (

N93 A21 Form 1 HSE-PMI-

check list

PDF Example:

Implementation Timeline

(RBNA)

Yes Stricter insurers

requirements have to be

assessed by the plant.

Requirements from location-

specific regulations (building /

operating permit) have to be

harmonized accordingly

in the fire protection concept

FCN,PUR,HSE,All

Yes Process Scheme GE,HSE

Yes Protective measures/rules of

conduct

HSE and All

Yes None HSE and All

Yes None HSE and All

Yes None HSE, Clinic

Yes None HSE

Yes None HSE

Bosch-Norm | 4497039248 | N93 B | 2011-03-30

Yes None HSE

Yes None HSE

Yes None HSE

Yes Protective measure code/

behavior

HSE

Yes Protective measure code/

behavior

HSE and LOG

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE

Yes Protective measure code/

behavior

HSE,FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and LOG/PUR

Yes None

Yes Protective measure code/

behavior

HSE and LOG/PUR

Yes Protective measure code/

behavior

HSE

Yes Protective measure code/

behavior

Yes Protective measure code/

behavior

HSE and All

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE, LOG/PUR

Yes Protective measure code/

behavior

HSE, LOG/PUR

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE

,FCM,LOG/PUR

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure code/

behavior

HSE and FCM

Yes Protective measure/ code

beviour

HSE and FCM

Yes Protective measure/ code

beviour

HSE and LOG/PUR

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

Bosch-Norm | 4497025215 | N93 I | 2011-03-30

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

None ; information HSE, All

National requirements for

responsibilities, deadlines,

content and documentation of

accident causes have to be

observed. There are process

sequence for the record and

analysis of accident in N93

I3.2.1 no 4

HSE

None HSE and FCM

None HSE and FCM

None HSE and FCM

None HSE and FCM

None HSE

None HSE

None HSE

None HSE, FCM

None HSE

None HSE , FCM

None; information All

None HSE , FCM

None; information HSE

None; information HSE

None; information All

None; information ESH

None; information ESH

fire department emergency

control forces must have

access to working equipment

internal spaces.

ESH,FCM

None;Information All

None;Information All

None;Information All

None;Information ESH

None;Information All

None;Information ESH

None;Information All

Heated baths must have a

protection against

overheating

All

None;Information All

None;Information ESH,FCM

None;Information ESH,FCM

None;Information All

None;Information ESH,FCM

None;Information All

None HSE

None;Information ESH

None HSE

None HSE and FCM

None HSE and FCM

None: Construction /

equipment / protective

measures

None; Information HSE and FCM

Employers have to identify

and assess their employees

hazards due to explosions

and to decide on the required

protective measures.

The required explosion

protection measures have to

be selected and evaluated

within an explosion protection

concept that is free from

inherent contradictions

HSE and All

None HSE

None HSE

None HSE

None.4 Refer N93 i3.14

Process description and

process responsibilities

(overview) for more

information

HSE

None HSE

Yes Planning instructions target

specification or Internal target

specification and planning

and procuring of working

equipment and building of

structures. Working

equipment and buildings

have to be acquired or built in

accordance with the safety-

related requirements,

Deviations require

coordination with C/PS and

have to be documented.

Working equipment and

structures have to comply

with internal and external

requirements.

HSE and All

Yes None

Yes See Fire Protective " Best

Proactive"

Yes None HSE

Planning and approval

requirements are available at

all times and have to be

adhered to. Facilities on roof

areas (mechanical / technical

equipment) have to be

accessible at least in two

places, opposite ones if

possible. Marked

emergency exits have to

open in escape direction

Bosch-Norm | 4497017384 | N93 S | 2011-03-30

Yes Location must have a safe

water supply for firefighting.

Primarily sprinkler systems

have to be provided

according to requirements.

Sprinkler systems have to be

maintained.

All areas in Bosch buildings

have to be designed with a

smoke release system.

Sprinkler protected buildings

fire alarm systems have to be

implemented only in selected

areas.

Automatic fire alarm systems

have to be installed in

production plants

FCM, HSE

Fire fighting systems with

gaseous agents have to

comply with the requirements

regarding protection of

persons

and the environment strictly.

Gas detection systems have

to be carried out as required

by law Design and

installation of smoke and

heat release systems with

natural action have to comply

with state-of-the art

technology

A location must have a safe

water supply for firefighting

Yes Emergency plans have to be

designed and to be

coordinated with the specific

emergency response teams.

Incidents have to be

categorized, assessed and

evaluated (extent of

damage).

A sufficient number of

employees will have to be

trained in behavior during a

fire and in firefighting with

firefighting equipment

All installations and

equipment for fire protection

needs to be maintained

(including reporting) . Fire

safety audits have to be

conducted at regular intervals

and preferably in combination

with health, safety and

environmental site visits.

Evaluation requirements

have to be at state-of-the-art

level . First response

activities have to be ensured

by site-own qualified teams.

HSE, ERT Team

Required fire compartments

(e. g. due to legal

requirements) have to be

separated by spatial distance

(minimum

distance from neighboring

building the height of the

higher of the two structures)

or by constructional

measures.

Fire walls must have a

minimum fire resistance of 90

minutes and be continued for

at least 30 cm

above the roof; stability of the

wall must be guaranteed also

with external loads (e. g.

collapsing racks, crane

systems).

New constructions

separations of required

stairways have to be at least

90 minutes fire resistant

None None

None None

None None

None None

None None

None None

None None

None None

None None

None None

None None

None None

None None

None None

Record

Evaluation of

compliance

Document /

Record review

Inspection Interview

Facilities

Monitoring data :4/4/07

1st: