3 Element Strategy

Diunggah oleh

Sunil ChouhanHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3 Element Strategy

Diunggah oleh

Sunil ChouhanHak Cipta:

Format Tersedia

3 Element Strategy

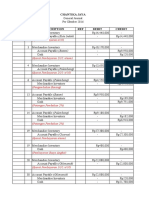

As shown below (click for large view), most boilers of medium to high pressure today

use a 3-element boiler control strategy !he term 3-element control refers to the

number of process variables ("#s) that are measured to effect control of the boiler

feedwater control valve !hese measured "#s are$

% li&uid level in the boiler drum,

% flow of feedwater to the boiler drum, and

% flow of steam leaving the boiler drum

'aintaining li&uid level in the boiler steam drum is the highest priority (t is critical

that the li&uid level remain low enough to guarantee that there is ade&uate

disengaging volume above the li&uid, and high enough to assure that there is water

present in every steam generating tube in the boiler !hese re&uirements typically

result in a narrow range in which the li&uid level must be maintained

!he feedwater used to maintain li&uid level in industrial boilers often comes from

multiple sources and is brought up to steam drum pressure by pumps operating in

parallel )ith multiple sources and multiple pumps, the supply pressure of the

feedwater will change over time *very time supply pressure changes, the flow rate

through the valve, even if it remains fi+ed in position, is immediately affected

,o, for e+ample, if the boiler drum li&uid level is low, the level controller will call for

an increase in feedwater flow -ut consider that if at this moment, the feedwater

supply pressure were to drop !he level controller could be opening the valve, yet the

falling supply pressure could actually cause a decreased flow through the valve and

into the drum

!hus, it is not enough for the level controller to directly open or close the valve

.ather, it must decide whether it needs more or less feed flow to the boiler drum

!he level controller transmits its target flow as a set point to a flow controller !he

flow controller then decides how much to open or close the valve as supply pressure

swings to meet the set point target

!his is a /-element (boiler li&uid level to feedwater flow rate) cascade control

strategy -y placing this feedwater flow rate in a fast flow control loop, the flow

controller will immediately sense any variations in the supply conditions which

produce a change in feedwater flow !he flow controller will ad0ust the boiler

feedwater valve position to restore the flow to its set point before the boiler drum

li&uid level is even affected !he level controller is the primary controller (sometimes

referred to as the master controller) in this cascade, ad0usting the set point of the

flow controller, which is the secondary controller (sometimes identified as the slave

controller)

!he third element in a 3-element control system is the flow of steam leaving the

steam drum !he variation in demand from the steam header is the most common

disturbance to the boiler level control system in an industrial steam system

-y measuring the steam flow, the magnitude of demand changes can be used as a

feed forward signal to the level control system !he feed forward signal can be added

into the output of the level controller to ad0ust the flow control loop set point, or can

be added into the output of the flow control loop to directly manipulate the boiler

feedwater control valve !he ma0ority of boiler level control systems add the feed

forward signal into the level controller output to the secondary (feedwater flow)

controller set point !his approach eliminates the need for characteri1ing the feed

forward signal to match the control valve characteristic

Actual boiler level control schemes do not feed the steam flow signal forward directly

(nstead, the difference between the outlet steam flow and the inlet water flow is

calculated !he difference value is directly added to the set point signal to the

feedwater flow controller !herefore, if the steam flow out of the boiler is suddenly

increased by the start up of a turbine, for e+ample, the set point to the feedwater

flow controller is increased by e+actly the amount of the measured steam flow

increase

,imple material balance considerations suggest that if the two flow meters are

e+actly accurate, the flow change produced by the flow control loop will make up

e+actly enough water to maintain the level without producing a significant upset to

the level control loop ,imilarly, a sudden drop in steam demand caused by the trip

of a significant turbine load will produce an e+actly matching drop in feedwater flow

to the steam drum without producing any significant disturbance to the boiler steam

drum level control

2f course, there are losses from the boiler that are not measured by the steam

production meter !he most common of these are boiler blow down and steam vents

(including relief valves) ahead of the steam production meter (n addition, boiler

operating conditions that alter the total volume of water in the boiler cannot be

corrected by the feed forward control strategy 3or e+ample, forced circulation boilers

may have steam generating sections that are placed out of service or in service

intermittently !he level controller itself must correct for these unmeasured

disturbances using the normal feedback control algorithm

Notes on Firing Control Systems

(n general, firing control is accomplished with a "lant 'aster that monitors the

pressure of the main steam header and modulates the firing rate (and hence, the

steam production rate) of one or more boilers delivering steam to the steam header

!he firing demand signal is sent to all boilers in parallel, but each boiler is provided

with a -oiler 'aster to allow the "lant 'aster demand signal to be overridden or

biased )hen the signal is overridden, the steam production rate of the boiler is set

manually by the operator, and the boiler is said to be base-loaded 'ost boilers on a

given header must be allowed to be driven by the "lant 'aster to maintain pressure

control -oilers that have the -oiler 'aster set in automatic mode (passing the

steam demand from the "lant 'aster to the boiler firing control system) are said to

be swing boilers as opposed to base-loaded boilers

!he presence of heat recovery steam boilers on a steam header raises new control

issues because the steam production rate is primarily controlled by the horsepower

demand placed on the gas turbine providing the heat to the boiler (f the heat

recovery boiler operates at a pressure above the header pressure, a separate

pressure control system can be used to blow off e+cess steam from the heat

recovery boiler when production is above the steam header demand 4ote that for

ma+imum efficiency, most heat recovery boilers are fitted with duct burners to

provide additional heat to the boiler !he duct burner is controlled with a -oiler

'aster like any other swing boiler As long as there are other large swing boilers

connected to the steam header, the other fired boilers can reduce firing as re&uired

when output increases from the heat recovery boiler

Anda mungkin juga menyukai

- Universal GatewayDokumen38 halamanUniversal GatewaySunil ChouhanBelum ada peringkat

- PH TheoryDokumen38 halamanPH Theorygimenes_rBelum ada peringkat

- ArticleDokumen4 halamanArticleSunil ChouhanBelum ada peringkat

- PH Analyser Manual PH-13-SDokumen22 halamanPH Analyser Manual PH-13-SSunil Chouhan100% (1)

- Class 12 - Indian History1 Unit01 NCERT Text Book Hindi EditionDokumen27 halamanClass 12 - Indian History1 Unit01 NCERT Text Book Hindi EditionRavi ShuklaBelum ada peringkat

- Durag Series150Dokumen4 halamanDurag Series150Sunil Chouhan100% (1)

- GA55 90GA75 90VSD - enDokumen16 halamanGA55 90GA75 90VSD - enSunil ChouhanBelum ada peringkat

- PROFIBUS Design and Installation EssentialsDokumen0 halamanPROFIBUS Design and Installation EssentialscatalinccBelum ada peringkat

- Basic Electronic & Transistor Circuits PDFDokumen54 halamanBasic Electronic & Transistor Circuits PDFSandeep GoyalBelum ada peringkat

- Computer BasicsDokumen4 halamanComputer BasicsDhiraj RajputBelum ada peringkat

- Sports cups & trophies from around the worldDokumen2 halamanSports cups & trophies from around the worldSunil ChouhanBelum ada peringkat

- Radiation BasicsDokumen2 halamanRadiation BasicsSunil ChouhanBelum ada peringkat

- Benchmarking: Understanding The Basics: The Coastal Business JournalDokumen6 halamanBenchmarking: Understanding The Basics: The Coastal Business JournalSunil ChouhanBelum ada peringkat

- UPSC Civil Services Exam SyllabusDokumen231 halamanUPSC Civil Services Exam Syllabusvssridhar99100% (1)

- AN ABCs of ADCDokumen64 halamanAN ABCs of ADCkiran445Belum ada peringkat

- Rajasthan Folk DancesDokumen7 halamanRajasthan Folk DancesSunil ChouhanBelum ada peringkat

- Cable ModemsDokumen33 halamanCable ModemsSunil ChouhanBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Oracle Database Performance: Vmware Cloud On AwsDokumen14 halamanOracle Database Performance: Vmware Cloud On Awscatelor419Belum ada peringkat

- Dan John Case Study - Scaling with Facebook AdsDokumen5 halamanDan John Case Study - Scaling with Facebook AdsZeynep ÖzenBelum ada peringkat

- Borang Permohonan Pinjaman Pendidikan FMM Tunku Tan Sri Mohamed Study Loan Application FormDokumen10 halamanBorang Permohonan Pinjaman Pendidikan FMM Tunku Tan Sri Mohamed Study Loan Application FormJom StadiBelum ada peringkat

- Seminar On Biodegradable PolymersDokumen19 halamanSeminar On Biodegradable Polymerskeyur33% (3)

- PT Amar Sejahtera General LedgerDokumen6 halamanPT Amar Sejahtera General LedgerRiska GintingBelum ada peringkat

- Thesis 2Dokumen98 halamanThesis 2Chala WayesaBelum ada peringkat

- Digital Signature Certificate Subscription FormDokumen7 halamanDigital Signature Certificate Subscription FormAneesh VelluvalappilBelum ada peringkat

- The Cucumber Book Behaviour-Driven Development For Testers and DevelopersDokumen28 halamanThe Cucumber Book Behaviour-Driven Development For Testers and DevelopersGursharan AulakhBelum ada peringkat

- Danh sách đ tài Đ c nglunvăn ề ề ươ ậ HK1/19-20Dokumen47 halamanDanh sách đ tài Đ c nglunvăn ề ề ươ ậ HK1/19-20LONG Trương MinhBelum ada peringkat

- An Internship Report on Customer Service of Prabhu BankDokumen48 halamanAn Internship Report on Customer Service of Prabhu BankKaran PandeyBelum ada peringkat

- Vestige Frequently Asked QuestionsDokumen2 halamanVestige Frequently Asked Questionsmadhu77Belum ada peringkat

- The Mechanisms of Alloxan-And Streptozotocin-Induced DiabetesDokumen11 halamanThe Mechanisms of Alloxan-And Streptozotocin-Induced DiabetesOktaviani Fitria Susanti SusantiBelum ada peringkat

- Parliamentary Procedure in The Conduct of Business MeetingDokumen14 halamanParliamentary Procedure in The Conduct of Business MeetingEstephanie SalvadorBelum ada peringkat

- Drilling and Demolition: Hilti. Outperform. OutlastDokumen48 halamanDrilling and Demolition: Hilti. Outperform. OutlastVinicius CoimbraBelum ada peringkat

- Eaton: Medium Duty Piston PumpDokumen25 halamanEaton: Medium Duty Piston PumprazvanBelum ada peringkat

- PNMT (Pasolink) Operation ManualDokumen52 halamanPNMT (Pasolink) Operation ManualAsrar Zaffar50% (2)

- Amado Vs Salvador DigestDokumen4 halamanAmado Vs Salvador DigestEM RGBelum ada peringkat

- Blackman Et Al 2013Dokumen18 halamanBlackman Et Al 2013ananth999Belum ada peringkat

- Admissions To MUNDokumen2 halamanAdmissions To MUNImran KamalBelum ada peringkat

- Module 1 The Nature of Strategic Management2Dokumen8 halamanModule 1 The Nature of Strategic Management2Julienne LobchoyBelum ada peringkat

- Win Server 2008 Manual Installation PDFDokumen20 halamanWin Server 2008 Manual Installation PDFFery AlapolaBelum ada peringkat

- GETT Breen Records - RedactedDokumen1.141 halamanGETT Breen Records - RedactedRobert LeeBelum ada peringkat

- Hydro Skimming Margins Vs Cracking MarginsDokumen78 halamanHydro Skimming Margins Vs Cracking MarginsWon Jang100% (1)

- Datasheet LG-ICR18650D1 PDFDokumen9 halamanDatasheet LG-ICR18650D1 PDFPedro Militao CoboBelum ada peringkat

- Contrafund 31-07-2020Dokumen12 halamanContrafund 31-07-2020b1OSphereBelum ada peringkat

- Top 70 CCNA Interview QuestionsDokumen10 halamanTop 70 CCNA Interview QuestionsRekha SharmaBelum ada peringkat

- ACCT601 Australian Auditing and Assurance Services 201660Dokumen15 halamanACCT601 Australian Auditing and Assurance Services 201660Rafayel MarufBelum ada peringkat

- QRHDokumen12 halamanQRHNwe OoBelum ada peringkat

- Smartviewer 4.9.6: User ManualDokumen71 halamanSmartviewer 4.9.6: User ManualPaginas Web AdministrablesBelum ada peringkat

- Negligence PRIMA FACIE CASEDokumen107 halamanNegligence PRIMA FACIE CASEHarry KastenbaumBelum ada peringkat