Building Material R-Values

Diunggah oleh

ronfrendHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Building Material R-Values

Diunggah oleh

ronfrendHak Cipta:

Format Tersedia

Tables 3-17 (10/00)

E

n

v

e

l

o

p

e

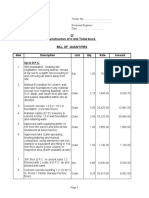

WALL FRAMING & INSULATION R-VALUES

Table 3a

Wall

Framing

This table can be

used to find the R-

value for wall

framing with

insulation. The

values can be

added to the R-

values of other

layers to calculate

the total R-value

(R

t

) of the wall.

Wood framing

values are based

on 20 percent and

15 percent framing

factors for 16- and

24-inch spacing

with compression of

insulation if

necessary. Framing

factor is the

percentage of a wall

surface backed by

framing. R-value for

wood is based on

fir, pine and similar

softwood.

Metal framing

values are from

ASHRAE 90.1-1989

Table 402.1.2.1b.

Type of Insulation Effective

Framing Spacing R-value R-value

Wood, 2 x 2 16" o.c. 5 3.75

7 4.55

24" o.c. 5 4.00

7 4.97

Wood, 2 x 4 16" o.c. 11 8.47

13 9.36

15 10.13

24" o.c. 11 8.99

13 10.06

15 11.03

Wood, 2 x 6 16" o.c. 19 13.64

21 14.94

24" o.c. 19 14.52

21 16.10

Wood, 2 x 8 16" o.c. 19 15.81

21 16.88

30 20.51

24" o.c. 19 16.50

21 17.75

30 22.13

Metal, 2 x 4 16" o.c. 11 5.50

13 6.00

24" o.c. 11 6.60

13 7.20

Metal, 2 x 6 16" o.c. 19 7.10

24" o.c. 19 8.60

Cavity

Filled

Some R-values are

not included

because the

Oregon code

requires that wall

cavities 6 inches or

less be filled

completely.

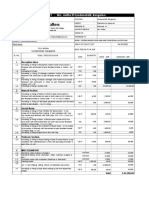

3-18 Tables (10/00)

E

n

v

e

l

o

p

e

Type of Insulation Effective

Framing Spacing R-value R-value

Wood, 2 x 6 16" o.c. 11 10.39

13 11.95

15 13.44

19 15.52

21 17.46

24" o.c. 11 10.63

13 12.35

15 14.02

19 16.43

21 18.72

Wood, 2 x 8 16" o.c. 13 12.53

19 17.26

25 20.12

24" o.c. 13 12.71

19 17.91

25 21.18

Wood, 2 x 10 16" o.c. 19 17.95

25 22.55

30 26.07

38 31.21

24" o.c. 19 18.35

25 23.47

30 27.51

38 33.61

Wood, 2 x 12 16" o.c. 19 18.43

25 23.31

30 27.10

38 32.70

24" o.c. 19 18.65

25 23.96

30 28.19

38 34.63

Table 3a (cont.)

ROOF & FLOOR FRAMING R-VALUES

Roof/

Ceiling and

Floor

Framing

Use this table to

find the R-value for

insulation and

framing in roofs,

ceilings or floors.

The values in this

table can be added

to the R-values of

other layers to

calculate the total

effective R-value of

the framing

assembly.

Wood framing

values are based

on 10 percent and 6

percent framing

factors for 16- and

24-inch spacing

with compression of

insulation if

necessary. R-value

for wood is based

on fir, pine and

similar softwood.

Tables 3-19 (10/00)

E

n

v

e

l

o

p

e

Table 3a (cont.)

Type of Insulation Effective

Framing Spacing R-value R-value

Metal Truss 4'0" o.c. or greater 5 4.8

10 9.2

15 13.2

20 17.0

25 20.3

30 23.7

35 26.6

40 29.2

Engineered wood 16" o.c. 11 10.2

composite I-beam 13 12.0

19 17.5

25 23.0

30 27.6

24" o.c. 11 10.5

13 12.3

19 18.0

25 23.7

30 28.4

48" o.c. 11 10.7

13 12.7

19 18.5

25 24.3

30 29.2

ROOF & FLOOR FRAMING R-VALUES

Roof/Ceiling

and Floor

Framing

Use this table to find

the R-value for

framing and framing

cavity in roofs,

ceilings or floors.

The values in this

table can be added

to the R-values of

other layers to

calculate the total

effective R-value of

the framing

assembly.

For compressed-

type batt insulation,

see page 3-25 for

effective U-factors.

Metal truss values

are from ASHRAE

90.1-1989, Table

402.1.2.1a. Values

are based on 0.66-

inch diameter cross

members every one

foot.

Engineered wood

composite I-beams

(e.g.,silent floor)

are composite wood

materials with an I-

beam cross section.

These are typically

made of strandboard

or plywood with

small dimensional

lumber on the top

and bottom cords.

3-20 Tables (10/00)

E

n

v

e

l

o

p

e

Building

Board

Description Detail R-value lb/ft

2

Cement Board

Cement board 0.125 0.03 1.25

Cement board 0.25 0.06 2.50

Cement board 0.375 0.09 3.75

Ceiling finishes

Acoustic tile

3

8" mineral fiberboard 0.95 0.56

Acoustic tile

3

4" mineral fiberboard 2.48 1.31

Gypsum or plaster board

Gypsum wallboard

3

8" 0.32 1.56

Gypsum wallboard

1

2" 0.45 2.08

Gypsum wallboard

5

8" 0.50 2.33

Gypsum wallboard

3

4" 0.56 2.60

Hardboard

Medium density

1

4" 0.34 1.04

High density

1

4" 0.25 1.31

High density

1

2" 0.50 2.62

High density

3

4" service tempered 0.92 3.43

Particleboard

Low density 1" (per inch value) 1.41 3.08

Medium density 1" (per inch value) 1.06 4.17

High density 1" (per inch value) 0.85 5.20

Underlayment grade

5

8" underlayment 0.82 2.08

Waferboard 1" (per inch value) 1.59 3.08

Plywood

Douglas-fir

1

4" 0.31 0.71

Douglas-fir

3

8" 0.47 1.06

Douglas-fir

1

2" 0.62 1.42

Douglas-fir

5

8" 0.77 1.77

Douglas-fir

3

4" 0.93 2.13

Douglas-fir 1" 1.25 2.84

Vegetable fiber board

Sheathing, regular density

1

2" 1.32 0.75

Sheathing, intermediate density

1

2" 1.09 0.92

Sheathing, regular density

25

32" 2.06 1.17

Nail-base sheathing

1

2" 1.06 1.04

Sound deadening board

1

2" 1.35 1.25

Tile and lay-in panels, plain or acoustic

1

2" 1.25 1.50

Laminated paperboard 1" 2.00 2.50

Building membrane

Vapor-permeable felt 0.06

Vapor seal 2 layers/mopped 15 lb felt 0.12

Vapor seal Plastic film 0.00

Floor finishes

Carpet with fibrous pad 2.08

Carpet with rubber pad 1.23

Cork tile

1

8" 0.28

Terrazzo 1" 0.08 11.67

Resilient tile 0.05

Hardwood

3

4" 0.68 2.00

Table 3b

BUILDING MATERIAL R-VALUES

Building

Membrane

Finish

Flooring

Materials

Tables 3-21 (10/00)

E

n

v

e

l

o

p

e

BUILDING MATERIAL R-VALUES

Insulating

Materials

Table 3b (cont.)

Description Detail R-value lb/ft

2

Cement BoardBatt and blanket insulation uncompressed

Mineral fiber batt approx. 2 to 2

3

4" 7 0.25

Mineral fiber batt approx. 3 to 4" 11 0.30

Mineral fiber batt approx. 3

1

2" 13 0.35

Mineral fiber batt approx. 3

1

2" 15 0.40

Mineral fiber batt approx. 5

1

2 to 6

1

2" 19 0.60

Mineral fiber batt approx. 5

1

2" 21 0.65

Mineral fiber batt approx. 6 to 7

1

2" 22 0.65

Mineral fiber batt approx. 8

1

4 to 10" 30 0.95

Mineral fiber batt approx. 10 to 13" 38 1.20

Board and slab insulation

Cellular glass 1" 3.03 0.67

Glass fiber, organic bonded 1" 4.00 0.50

Expanded perlite, organic bonded 1" 2.78 0.09

Expanded rubber (rigid) 1" 4.55 0.35

Foamed urethane board 1" 7.15 0.54

Fiberglass urethane board 1" 5.56 0.36

Polystyrene, extruded (smooth skin) 1", 1.8 to 3.5 lb/ft

3

5.00 0.22

Expanded polystyrene, molded beads 1", 1.0 lb/ft

3

3.85 0.08

Expanded polystyrene, molded beads 1", 1.25 lb/ft

3

4.00 0.10

Expanded polystyrene, molded beads 1", 1.5 lb/ft

3

4.17 0.13

Expanded polystyrene, molded beads 1", 1.75 lb/ft

3

4.17 0.15

Expanded polystyrene, molded beads 1", 2.0 lb/ft

3

4.35 0.17

Cellular polyisocyanurate 1", with foil face, 2.0 lb/ft

3

7.04 0.17

Cellular polyisocyanurate 1", gas-perm. facers, 1.5 lb/ft

3

5.56 0.13

Cellular polyisocyanurate 1" unfaced, 1.5 lb/ft

3

5.56 0.13

Cellular phonolic 1", 3.0 lb/ft

3

closed cell 8.20 0.25

Cellular phonolic 1", 1.8 to 2.2 lb/ft

3

open cell 4.40 0.16

Mineral fiber 1", 15.0 lb/ft

3

with resin binder 3.45 1.25

Mineral fiber 1", 16 to 17 lb/ft

3

, not felted 2.94 1.35

Cement fiber slabs (shredded wool) 1", 25 to 27 lb/ft

3

with Portland cement 1.89 2.12

Cement fiber slabs (shredded wool) 1", 22 lb/ft

3

with magnesia oxysulfide 1.75 1.86

Loose fill

Cellulosic (milled paper and wood pulp) 1" loose fill 3.20 0.24

Mineral fiber (rock, slab or glass) approx. 3

3

4 to 5", 0.6 to 2.0 lb/ft

3

11.00 0.40

Mineral fiber (rock, slab or glass) approx. 6

1

2 to 8

3

4", 0.6 to 2.0 lb/ft

3

19.00 0.80

Mineral fiber (rock, slab or glass) approx. 7

1

2 to 10", 0.6 to 2.0 lb/ft

3

22.00 1.00

Mineral fiber (rock, slab or glass) approx. 10

1

4 to 13

3

4", 0.6 to 2.0 lb/ft

3

30.00 1.20

Perlite, expanded 1", 7.4 to 11.0 lb/ft

3

2.4 0.48

Vermiculite 1" exfoliated 7 to 8.2 lb/ft

3

2.13 0.63

Vermiculite 1" exfoliated 4 to 6 lb/ft

3

2.27 0.42

Spray applied

Ureaformaldehyde foam 1" sprayed, 0.7 to 1.6 lb/ft

3

3.57 0.07

Cellulosic fiber 1" spray applied 2.94 0.30

Polyurethane foam 1" sprayed 5.56 0.20

Glass fiber 1" sprayed 3.70 0.30

3-22 Tables (10/00)

E

n

v

e

l

o

p

e

BUILDING MATERIAL R-VALUES

Table 3b (cont.)

Description Detail R-value lb/ft

2

Brick

Paver

3

8" thick, 120 lb/ft

3

0.30 10.00

Face brick, fired clay 4", medium weight (110 lb/ft

3

) 0.68 37.00

Face brick, fired clay 4", heavy weight (140 lb/ft

3

) 0.44 47.00

6" hollow brick unfilled 1.23 34.00

6" hollow brick perlite filled cores 3.80 35.00

6" hollow brick vermiculite filled cores 3.50 36.00

6" hollow brick solid grouted 0.76 59.00

8" hollow brick unfilled 1.28 39.00

8" hollow brick perlite filled cores 4.60 41.00

8" hollow brick vermiculite filled cores 4.21 41.00

8" hollow brick solid grouted 0.94 82.00

Concretes

Sand and gravel 1" thick 0.08 11.67

Concrete heavy 1" thick, 140 lb/ft

3

0.09 11.67

Concrete medium 1" thick, 120 lb/ft

3

0.14 10.00

Concrete light 1" thick, 100 lb/ft

3

0.19 8.33

Concrete mortar, stucco 1" thick, 120 lb/ft

3

0.10 10.00

Concrete mortar, stucco 1" thick, 100 lb/ft

3

0.15 8.33

Concrete mortar, stucco 1" thick, 80lb/ft

3

0.22 6.67

Foam concrete (non-structural) 1" thick, 100 lb/ft

3

0.24 8.33

Foam concrete (non-structural) 1" thick, 60 lb/ft

3

0.48 5.00

Stone

Slag or stone 1" 0.10 14.00

Slate

1

2" 0.05 5.83

Clay tile

4" hollow 1 cell deep 1.11

6" hollow 2 cells deep 1.52

8" hollow 2 cells deep 1.85

10" hollow 2 cells deep 2.22

12" hollow 3 cells deep 2.50

Gypsum tile

Gypsum partition tile 3" x 12" x 30", 3 cells 1.35

Gypsum partition tile 3" x 12" x 30", 4 cells 1.67

Gypsum partition tile 3" x 12" x 30", solid 1.26

Glass block

4" thick block 8" x 8" x 4" 0.51

Gypsum plaster

Cement 120 lb/ft

3

0.21 7.5

Lightweight aggregate

1

2", 45 lb/ft

3

0.32 1.9

Lightweight aggregate on metal lath

3

4", 45 lb/ft

3

0.47 4.0

Perlite aggregate

1

2", 45 lb/ft

3

0.34 1.9

Sand aggregate

1

2", 105 lb/ft

3

0.09 4.4

Sand aggregate

5

8", 105 lb/ft

3

0.11 5.5

Sand aggregate on metal lath

3

4", 105 lb/ft

3

0.13 5.0

Vermiculite aggregate

1

2", 45 lb/ft

3

0.30 1.9

Masonry

Materials

Plastering

Tables 3-23 (10/00)

E

n

v

e

l

o

p

e

BUILDING MATERIAL R-VALUES

Table 3b (Cont.)

Description Detail R-value lb/ft

2

CMU Block - Light-weight (100 lb/ft

3

concrete)

6"block all cores filled solid grouted 0.70 55.8

8" block 40" o.c. no insulation 1.23 47.4

loose fill 2.31 48.6

foam 2.50 48.6

32" o.c. no insulation 1.21 49.1

loose fill 2.16 50.2

foam 2.32 50.2

24" o.c. no insulation 1.17 52.0

loose fill 1.94 52.9

foam 2.05 52.9

16" o.c. no insulation 1.10 57.6

loose fill 1.59 58.3

foam 1.65 58.3

all cores filled solid grouted 0.90 74.9

12" block 40" o.c. no insulation 1.54 76.9

loose fill 3.33 78.9

foam 3.55 78.9

32" o.c. no insulation 1.53 80.8

loose fill 3.11 82.6

foam 3.29 82.6

24" o.c. no insulation 1.51 87.2

loose fill 2.78 88.8

foam 2.92 88.8

16" o.c. no insulation 1.47 99.7

loose fill 2.29 101.0

foam 2.36 101.0

all cores filled solid grouted 1.35 115.4

CMU Block Medium-weight (120 lbs/ft

3

concrete)

6"block all cores filled solid grouted 0.55 60.6

8" block 40" o.c. no insulation 1.00 53.6

loose fill 1.77 54.8

foam 1.87 54.8

32" o.c. no insulation 0.98 55.4

loose fill 1.66 56.5

foam 1.74 56.5

24" o.c. no insulation 0.94 58.2

loose fill 1.50 59.2

foam 1.56 59.2

16" o.c. no insulation 0.88 63.8

loose fill 1.24 64.6

foam 1.27 64.6

all cores filled solid grouted 0.70 81.2

12" block 40" o.c. no insulation 1.29 86.3

loose fill 2.59 88.3

foam 2.71 88.3

32" o.c. no insulation 1.28 90.2

loose fill 2.43 92.1

foam 2.53 92.1

24" o.c. no insulation 1.26 96.8

loose fill 2.20 98.4

foam 2.28 98.4

16" o.c. no insulation 1.22 109.5

loose fill 1.83 110.8

foam 1.88 110.8

all cores filled solid grouted 1.10 124.2

Concrete-filled

cores may contain

rebar or other

reinforcements.

Grout fill used is

assumed to have a

density of 140 lb/ff

3

.

R-values for CMU

blocks are based on

National Concrete

and Masonry

Association

publication: R-

Values for Single

Wythe Concrete

Masonry Walls, TEK

6-2A. Values are

based upon the mid-

range values.

Loose-fill insulation

values are based on

vermiculite.

Horizontal bond-

beams (grout/steel)

located every 48".

CMU Block

3-24 Tables (10/00)

E

n

v

e

l

o

p

e

BUILDING MATERIAL R-VALUES

Table 3b (cont.)

Siding

Materials

Roofing

Wood and

Wood

Products

Description Detail R-value lb/ft

2

Roofing

Asphalt roll roofing 0.15 5.83

Asphalt shingles 0.44 5.83

Built-up roofing

3

8" 0.33 5.83

Slate

1

2" 0.05 5.83

Wood shingles Plain and plastic film-faced 0.94 1.50

Ceramic tile

1

4" 0.20 5.83

Metal, any 0.00

Shingles

Cement 0.21 7.5

Wood 16", 7.5" exposure 0.87 1.3

Wood double 16", 12" exposure 1.19 2.3

Wood plus 0.312" insulated backer board 1.40 2.0

Siding

Cement

1

4" lapped 0.21 8.0

Asphalt roll siding 0.15 10.0

Asphalt insulating siding

1

2" bed. 1.46

Hardboad siding 0.4375 inch 0.67

Wood, drop 1" by 8" 0.79 2.13

Wood, bevel

1

2" by 8" lapped 0.81 1.30

Wood, bevel

3

4" by 10" lapped 1.05 2.00

Plywood

3

8" lapped 0.59 1.00

Glass

1

4" curtain wall 0.43

Aluminum or steel siding Hollow-backed 0.61

Aluminum or steel siding

3

8" insulation board backed 1.80

Aluminum or steel siding

3

8" insulation and foil backed 2.96

Plywood

1

4" Douglas-fir 0.31 0.71

3

8" Douglas-fir 0.47 1.06

1

2" Douglas-fir 0.62 1.42

5

8" Douglas-fir 0.77 1.77

3

4" Douglas-fir 0.93 2.13

1" Douglas-fir 1.24 2.84

Woods

Hardwoods 1" 0.91 2.67

Fir, pine and similar softwoods

3

4" 0.94 2.00

1

1

2" 1.89 4.00

2

1

2" 3.12 6.67

3

1

2" 4.35 9.33

5

1

2" 6.88 14.66

7

1

4" 9.04 19.32

9

1

4" 11.56 24.65

11

1

4" 14.06 29.99

Tables 3-25 (10/00)

E

n

v

e

l

o

p

e

System 1

(Roof and Wall)

METAL BUILDING U-FACTORS

Table 3c

NAIMA 202

Insulation

NAIMA 202

Insulation

Cross band

System 2

(Roof only)

System 3

(Roof only)

NAIMA 202 insulation

Filler

Insulation

Thermal block

System 4

(Roof only)

Filler

Insulation

Bands to support

insulation

NAIMA 202 insulation

Cross band

Bands to support insulation

Vapor retarder overlap

System 1

In this system, NAIMA 202 fiber glass blanket insulation

is rolled out over, and perpendicular to the structural

frame. The metal covering sheets are fastened to the

frame, holding the insulation in place.

U-factors

R10 R11 R13 R19

0.133 0.127 0.114 0.091

System 2

This method accommodates thicker insulation without

compression at the structural members by applying the

faced NAIMA 202 between the purlins rather than

perpendicular to them. There is, however, the problem

of thermal bridging through the structural members in

direct contact with the metal covering sheets.

U-factors

R10 R11 R13 R19

0.131 0.123 0.107 0.079

System 3

Vapor retarder faced NAIMA 202 insulation is installed

over and perpendicular to the structure (joists or purlins)

prior to applying the roof. Additional unfaced fiber glass

blanket filler insulation can then be applied between the

purlins and over the first layer to fill the space formed by

the roof sheet standoffs. Thermal blocks of rigid foam

are placed over joists or purlins where faced insulation

will be compressed.

U-factors

R10 R11 R13 R19

0.102 0.096 0.084 0.065

System 4

This system uses a vapor retarder faced NAIMA 202

blanket between the purlins with the retarder overlapping

on the top face of the purlins. Plain filler blanket is

installed as a second layer, also between the purlins.

Rigid foam thermal blocks are placed on top of the

purlins to create a thermal break at the structural

members.

U-factors

R10 R11 R13 R19 R30

0.099 0.093 0.080 0.059 0.041

Vapor retarder overlap

and thermal block

3-26 Tables (10/00)

E

n

v

e

l

o

p

e

Table 3d

SURFACE AND AIR SPACE R-VALUES

Description Detail R-value lb/ft

2

Still air to surface

Wall 0.68

Roof 0.61

Floor 0.92

Vaulted ceiling 0.62

Moving air to surface

15 mph 0.17

7.5 mph 0.25

Walls

3

4" 0.94

1

1

2" 0.90

3

1

2" 0.91

Roofs

3

4" 0.77

1

1

2" 0.80

3

1

2" 0.84

Floors

3

4" 1.02

1

1

2" 1.14

3

1

2" 1.22

Vaulted Ceilings

3

4" 0.82

1

1

2" 0.84

3

1

2" 0.86

Surfaces

Air Spaces

Tables 3-27 (10/00)

E

n

v

e

l

o

p

e

Table 3e

WINDOW U-FACTORS

Values are based

on the 1997

ASHRAE Handbook

of Fundamentals

Table 29-5, for

fixed-frame

windows. Operable

windows will have

higher U-factors.

Many window types

are not represented

in the table, and the

user must provide

manufacturer test

results.

Interpolate between

emissivities when

needed. When

manufacturers data

are not available,

assume that glass

with a pyrolytic

(hard) coating has

an emissivity of

0.40, and that glass

with a sputtered

(soft) coating has

an emissivity of

0.10.

Krypton gas fills, or

krypton/argon

combinations, can

be substituted for

argon.

For glazing gaps

between

1

4 inch and

1

2 inch, use

1

4 inch.

For glazing gaps

over

1

2 inch, use

1

2 inch.

U-Factors

Single Glazing

1

8" glass 1.04 1.13 1.07 0.98 0.98 0.94

1

4" acrylic/polycarb 0.88 0.99 0.92 0.84 0.84 0.81

1

8" acrylic/polycarb 0.96 1.06 1.00 0.91 0.91 0.87

Double Glazing

1

4" airspace 0.55 0.69 0.63 0.56 0.56 0.53

1

2" airspace 0.48 0.64 0.57 0.50 0.50 0.48

1

4" argon space 0.51 0.66 0.59 0.53 0.52 0.50

1

2" argon space 0.45 0.61 0.54 0.48 0.48 0.45

Double Glazing, e=0.40

1

4" airspace 0.49 0.64 0.58 0.51 0.51 0.49

1

2" airspace 0.40 0.57 0.50 0.44 0.44 0.41

1

4" argon space 0.43 0.59 0.53 0.46 0.46 0.44

1

2" argon space 0.36 0.53 0.47 0.41 0.40 0.38

Double Glazing, e=0.20

1

4" airspace 0.45 0.61 0.54 0.48 0.48 0.45

1

2" airspace 0.35 0.53 0.46 0.40 0.39 0.37

1

4" argon space 0.38 0.55 0.48 0.42 0.42 0.40

1

2" argon space 0.30 0.48 0.41 0.36 0.35 0.33

Double Glazing, e=0.10

1

4" airspace 0.42 0.59 0.52 0.46 0.45 0.43

1

2" airspace 0.32 0.50 0.43 0.37 0.37 0.35

1

4" argon space 0.35 0.53 0.46 0.40 0.39 0.37

1

2" argon space 0.27 0.46 0.39 0.33 0.33 0.31

Double Glazing, e=0.05

1

4" airspace 0.41 0.58 0.51 0.45 0.44 0.42

1

2" airspace 0.30 0.48 0.41 0.36 0.35 0.33

1

4" argon space 0.33 0.51 0.44 0.38 0.38 0.36

1

2" argon space 0.25 0.44 0.37 0.32 0.31 0.29

Other

Glass block 0.51

A

l

u

m

i

n

u

m

A

l

u

m

i

n

u

m

w

i

t

h

T

h

e

r

m

a

l

B

r

e

a

k

R

e

i

n

f

o

r

c

e

d

V

i

n

y

l

o

r

A

l

u

m

i

n

u

m

C

l

a

d

FRAME TYPE

GLAZING TYPE

C

e

n

t

e

r

o

f

G

l

a

s

s

(

f

o

r

r

e

f

e

r

e

n

c

e

o

n

l

y

)

W

o

o

d

o

r

V

i

n

y

l

I

n

s

u

l

a

t

e

d

F

i

b

e

r

g

l

a

s

s

/

V

i

n

y

l

Shaded values do not meet prescriptive path code requirement for

climate zone 1; i.e., they are greater than 0.54.

For climate zone 1 U-factor must be no greater than 0.54. For climate

zone 2 U-factor must be no greater than 0.50.

3-28 Tables (10/00)

E

n

v

e

l

o

p

e

SKYLIGHT U-FACTORS

U-Factors

The values in this

table are from the

1997 ASHRAE

Handbook of

Fundamentals,

Table 29-5 for

manufactured

skylights.

Table 3e (cont.)

Skylight

Conversion

Testing labs usually

test skylights in a

vertical position.

Manufacturers use

these numbers on

skylight labels and

in literature. If this is

the case, you may

use the equation

(right) to calculate

the actual skylight

U-factor.

The equation below provides an alternate approach for converting from vertical glazing to skylights:

Skylight U-Factor = 0.06 + 1.07 x U-Factor*

*Tested in vertical orientation and certified in accordance with NFRC procedures

Single Glazing

1

8" glass 1.19 1.98 1.89 1.75 1.47

1

4" acrylic/polycarb 1.03 1.82 1.73 1.60 1.31

1

8" acrylic/polycarb 1.11 1.90 1.81 1.68 1.39

Double Glazing

1

4" airspace 0.58 1.31 1.11 1.05 0.84

1

2" airspace 0.57 1.30 1.10 1.04 0.84

1

4" argon space 0.53 1.27 1.07 1.00 0.80

1

2" argon space 0.53 1.27 1.07 1.00 0.80

Double Glazing, e=0.40

1

4" airspace 0.51 1.25 1.05 0.99 0.78

1

2" airspace 0.50 1.24 1.04 0.98 0.77

1

4" argon space 0.44 1.18 0.99 0.92 0.72

1

2" argon space 0.46 1.20 1.00 0.94 0.74

Double Glazing, e=0.20

1

4" airspace 0.46 1.20 1.00 0.94 0.74

1

2" airspace 0.46 1.20 1.00 0.94 0.74

1

4" argon space 0.39 1.14 0.94 0.88 0.68

1

2" argon space 0.40 1.15 0.95 0.89 0.68

Double Glazing, e=0.10

1

4" airspace 0.44 1.18 0.99 0.92 0.72

1

2" airspace 0.44 1.18 0.99 0.92 0.72

1

4" argon space 0.36 1.11 0.91 0.85 0.65

1

2" argon space 0.38 1.13 0.93 0.87 0.67

Double Glazing, e=0.05

1

4" airspace 0.42 1.17 0.97 0.91 0.70

1

2" airspace 0.43 1.17 0.98 0.91 0.71

1

4" argon space 0.34 1.09 0.89 0.83 0.63

1

2" argon space 0.36 1.11 0.91 0.85 0.65

GLAZING TYPE

FRAME TYPE

C

e

n

t

e

r

o

f

G

l

a

s

s

(

f

o

r

r

e

f

e

r

e

n

c

e

o

n

l

y

)

A

l

u

m

i

n

u

m

A

l

u

m

i

n

u

m

w

i

t

h

T

h

e

r

m

a

l

B

r

e

a

k

R

e

i

n

f

o

r

c

e

d

V

i

n

y

l

o

r

A

l

u

m

i

n

u

m

C

l

a

d

W

o

o

d

o

r

V

i

n

y

l

Shaded values do not meet prescriptive path code requirement; i.e.,

they are greater than 1.23.

Tables 3-29 (10/00)

E

n

v

e

l

o

p

e

FENESTRATION SHADING COEFFICIENTS

Table 3f

Values are from the

1997 ASHRAE

Handbook of

Fundamentals,

Table 29-11. Unless

otherwise noted,

tinted glass and

reflective glass

coatings are on the

outer pane and low-

e coatings are

applied to inner

pane in double-

glazed systems.

Shading

Coefficient

Oregon code

requires that the

center-of-glass

shading coefficient

for non-merchan-

dise glazing be less

than or equal to

0.57.

SC

c

= Shading

Coefficient for the

glazing system

(center of glass)

SC

c

=

SHGC

c

= Solar

Heat Gain

Coefficient (center

of glass)

e = Infrared

emissivity of the

glazing layer

SHGC

c

0.87

Center-of-Glass

Shading Equivalent

Glazing Description Coefficient (SCc) SHGC

Single Glazing

1

8" clear 1.00 0.87

1

4" clear 0.94 0.82

Single acrylic or polycarbonate clear 0.98 0.85

Single acrylic, gray or bronze 0.90 0.78

Single

1

8" polycarbonate, gray or bronze 0.74 0.64

Glass Block

Clear 0.65 0.57

Frosted 0.50 0.44

Double Glazing

1

8" thick

clear 0.87 0.76

bronze 0.72 0.63

green or gray 0.70 0.61

bronze, low-e with e=0.2 0.66 0.57

green or gray, low-e with e=0.2 0.63 0.55

tinted, low-e with e=0.1 0.57 0.50

clear, low-e with e=0.05 0.48 0.42

Double Glazing

1

4" thick

clear 0.81 0.70

clear, low-e with e=0.2 0.75 0.65

clear, low-e on outer pane with e=0.2 0.70 0.61

clear, low-e with e=0.1 0.66 0.57

clear, low-e on outer pane with e=0.1 0.59 0.51

bronze 0.59 0.51

bluegreen 0.58 0.50

green 0.54 0.47

bronze, low-e with e=0.2 0.52 0.45

gray 0.51 0.44

green, low-e with e=0.2 0.48 0.42

gray, low-e with e=0.2 0.46 0.40

bronze or green, low-e with e=0.1 0.45 0.39

clear, low-e on outer pane with e=0.05 0.43 0.37

gray, low-e with e=0.1 0.40 0.35

green, low-e on outer pane with e=0.05 0.35 0.30

titanium reflective 0.33 0.29

blue, low-e on outer pane with e=0.05 0.32 0.28

gray, low-e on outer pane with e=0.05 0.27 0.23

stainless steel reflective 0.26 0.23

Shaded values do not meet prescriptive path code requirement;

i.e., the SCc is greater than 0.57.

Anda mungkin juga menyukai

- Shear Strength and Stiffness of Diaphragms From Test ResultsDokumen27 halamanShear Strength and Stiffness of Diaphragms From Test ResultsalbertoxinaBelum ada peringkat

- Braced Wall PanelsDokumen10 halamanBraced Wall PanelsMike LojoBelum ada peringkat

- SurvCE V4 Instrument Setup Manual PDFDokumen113 halamanSurvCE V4 Instrument Setup Manual PDFCadastru IntabulareBelum ada peringkat

- Teng Method On SANDDokumen2 halamanTeng Method On SANDOdspiBelum ada peringkat

- Manual Canadense Eifs PDFDokumen138 halamanManual Canadense Eifs PDFLuciano DodlBelum ada peringkat

- Timber Examples - TeddsDokumen19 halamanTimber Examples - TeddsTom KwoBelum ada peringkat

- Australia Triboard Construction Manual (Aug02)Dokumen112 halamanAustralia Triboard Construction Manual (Aug02)keithjonathan100% (1)

- 009 CarrilloDokumen27 halaman009 Carrilloqatarstructz30Belum ada peringkat

- CSA Spec HILTI HIT 100 Technical SupplementDokumen32 halamanCSA Spec HILTI HIT 100 Technical SupplementIsidro P. BuquironBelum ada peringkat

- R-Value and CR Value Spreadsheet (Ver11)Dokumen8 halamanR-Value and CR Value Spreadsheet (Ver11)Souvik Roy ChowdhuryBelum ada peringkat

- Chapter 5 Snow LoadsDokumen30 halamanChapter 5 Snow LoadsbranimirBelum ada peringkat

- Vulcraft Bar Joist CatalogDokumen129 halamanVulcraft Bar Joist CatalogKris MossBelum ada peringkat

- 4.2.1 HVA Capsule Adhesive Anchoring (151-166)Dokumen19 halaman4.2.1 HVA Capsule Adhesive Anchoring (151-166)Jonathan DouglasBelum ada peringkat

- SR-103 APA System Report 103 Use of Wood Structural Panels For Energy-Heel Trusses PDFDokumen12 halamanSR-103 APA System Report 103 Use of Wood Structural Panels For Energy-Heel Trusses PDFAbdurrahman CinarBelum ada peringkat

- GlulamDokumen8 halamanGlulamErnest JuniorBelum ada peringkat

- 400 Narrowline Technical Manual - 2013!07!31Dokumen87 halaman400 Narrowline Technical Manual - 2013!07!31lia_tr2656Belum ada peringkat

- CIVL 331 - Loads On StructuresDokumen27 halamanCIVL 331 - Loads On Structuresকাফী ওয়াহিদBelum ada peringkat

- Footing DesignDokumen35 halamanFooting DesignAngel MouriBelum ada peringkat

- Beam Truss AnalogyDokumen4 halamanBeam Truss AnalogyspamBelum ada peringkat

- Only / Underline Format: Chapter C16 Nonlinear Response History AnalysisDokumen53 halamanOnly / Underline Format: Chapter C16 Nonlinear Response History AnalysissharethefilesBelum ada peringkat

- AISI S230-12-E1Dokumen2 halamanAISI S230-12-E1Jon JacobsBelum ada peringkat

- Highter Anders 1985 PDFDokumen8 halamanHighter Anders 1985 PDFErnesto Fidel Mandujano CardenasBelum ada peringkat

- Nail Plates GuideDokumen14 halamanNail Plates Guidejohn.aboodBelum ada peringkat

- Aci 330r 92Dokumen1 halamanAci 330r 92Sue JinsueBelum ada peringkat

- Timber Frame Design 1Dokumen6 halamanTimber Frame Design 1Avery SanbornBelum ada peringkat

- NBC - 1970 - Climatic DataDokumen39 halamanNBC - 1970 - Climatic Dataelidstone@hotmail.comBelum ada peringkat

- Water StopsDokumen12 halamanWater Stopstss13723Belum ada peringkat

- Diaphragm Action and Design - SpringerDokumen3 halamanDiaphragm Action and Design - SpringerGuillermo Agustín Yáñez QuezadaBelum ada peringkat

- C11Dokumen6 halamanC11Fredy SierraBelum ada peringkat

- Helical Pile Design Per IBC PDFDokumen12 halamanHelical Pile Design Per IBC PDFJorge Rosero QuevedoBelum ada peringkat

- FM Global Property Loss Prevention Data Sheets: List of FiguresDokumen12 halamanFM Global Property Loss Prevention Data Sheets: List of FigureshhBelum ada peringkat

- ASTM E119 - 12aDokumen34 halamanASTM E119 - 12aOmer Taj-eldinBelum ada peringkat

- Notes On Design of Steel Parking Structures IncludDokumen42 halamanNotes On Design of Steel Parking Structures IncludSudhakar KrishnamurthyBelum ada peringkat

- FEMA P-361 2015r2 PDFDokumen189 halamanFEMA P-361 2015r2 PDFGanea Marius BogdanBelum ada peringkat

- Use of Expanded Polystyrene in Road EmbankmentsDokumen6 halamanUse of Expanded Polystyrene in Road EmbankmentsmikadituBelum ada peringkat

- Anchor Bolts in Light-Frame Construction at Small Edge Distances PDFDokumen8 halamanAnchor Bolts in Light-Frame Construction at Small Edge Distances PDFmlamourBelum ada peringkat

- PCI DH-Loss of PrestressDokumen5 halamanPCI DH-Loss of PrestressCarlisle Flores-GarayBelum ada peringkat

- Acs102v3 Floating FloorDokumen24 halamanAcs102v3 Floating FloorDaris SkaBelum ada peringkat

- Boxspan Residential Span TablesDokumen36 halamanBoxspan Residential Span TablesÁngel Raúl DipierroBelum ada peringkat

- Tips For Designers PDFDokumen5 halamanTips For Designers PDFSushil DhunganaBelum ada peringkat

- CARLISLE WATERPROOFING Internationalgeomanual 2002Dokumen91 halamanCARLISLE WATERPROOFING Internationalgeomanual 2002Ajna SalimBelum ada peringkat

- Gang Nail Trussed Rafter Manual-WoodDokumen49 halamanGang Nail Trussed Rafter Manual-Woodfacagaua100% (1)

- Wood Express ManualDokumen36 halamanWood Express ManualgertjaniBelum ada peringkat

- FEA of Radomes PDFDokumen7 halamanFEA of Radomes PDFudaykumar8995Belum ada peringkat

- Disclosure To Promote The Right To InformationDokumen17 halamanDisclosure To Promote The Right To InformationIndira MukherjeeBelum ada peringkat

- Iapmo Ues Er493Dokumen13 halamanIapmo Ues Er493jeffuangBelum ada peringkat

- Slope Stability ImprovementDokumen43 halamanSlope Stability Improvementomar cBelum ada peringkat

- Steel Buildings: Ferenc PappDokumen17 halamanSteel Buildings: Ferenc PappSandeep ShakyaBelum ada peringkat

- Emperical Design of Concrete MasonryDokumen8 halamanEmperical Design of Concrete MasonryKmrnKhnBelum ada peringkat

- Terramodel Faq & Frequent QuestionsDokumen9 halamanTerramodel Faq & Frequent QuestionsBrago AjpBelum ada peringkat

- Engineering Structures: SciencedirectDokumen8 halamanEngineering Structures: SciencedirectFeleki AttilaBelum ada peringkat

- Downspout & Gutter Sizing Reports: Rainfall Intensity Manually Entered by UserDokumen1 halamanDownspout & Gutter Sizing Reports: Rainfall Intensity Manually Entered by UserMarlouie Mitch ArangosoBelum ada peringkat

- 2015 IRC Revision History PDFDokumen1.301 halaman2015 IRC Revision History PDFviralisursBelum ada peringkat

- Weight of Building MaterialDokumen34 halamanWeight of Building MaterialJosilva MuniandyBelum ada peringkat

- U.P. KumarasingheDokumen2 halamanU.P. KumarasingheMSCETM22005 M.A.A. Lasantha De SoyzaBelum ada peringkat

- Sound Absorption DataDokumen4 halamanSound Absorption DataJeofrey Awingan CodiamatBelum ada peringkat

- Resistance Values of Structural and Finish Materials: Material R-Value Material R-ValueDokumen1 halamanResistance Values of Structural and Finish Materials: Material R-Value Material R-ValueRiyas UdheenBelum ada peringkat

- Daftar Harga Satuan BahanDokumen5 halamanDaftar Harga Satuan BahanvascodesBelum ada peringkat

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Dokumen6 halamanType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheBelum ada peringkat

- Rockewell Dynamix 1444-Um001 - En-P PDFDokumen458 halamanRockewell Dynamix 1444-Um001 - En-P PDFronfrendBelum ada peringkat

- EMT HVAC - 02A-r8-56-PschycrometryDokumen28 halamanEMT HVAC - 02A-r8-56-PschycrometryronfrendBelum ada peringkat

- Rockewell Dynamix 1444-Um001 - En-P PDFDokumen458 halamanRockewell Dynamix 1444-Um001 - En-P PDFronfrendBelum ada peringkat

- Fluxtech PDFDokumen2 halamanFluxtech PDFronfrendBelum ada peringkat

- CHTC - Tairyuu PDFDokumen9 halamanCHTC - Tairyuu PDFronfrendBelum ada peringkat

- Vibration Signature Analysis PROC - V18Dokumen2 halamanVibration Signature Analysis PROC - V18ronfrendBelum ada peringkat

- PROC - V19 PL302 DownloadDokumen2 halamanPROC - V19 PL302 DownloadronfrendBelum ada peringkat

- 450 A Oil Analysis 450 A Oil Analysis: Iron Copper Iron CopperDokumen1 halaman450 A Oil Analysis 450 A Oil Analysis: Iron Copper Iron CopperronfrendBelum ada peringkat

- 3906 Qep Dec11Dokumen88 halaman3906 Qep Dec11ronfrendBelum ada peringkat

- Rutina de Termografia - CarroceriasDokumen2 halamanRutina de Termografia - CarroceriasronfrendBelum ada peringkat

- Tribology: Evaluating Used EquipmentDokumen13 halamanTribology: Evaluating Used EquipmentronfrendBelum ada peringkat

- Level 3 NVQ Refinery Ops Control Room NOSDokumen42 halamanLevel 3 NVQ Refinery Ops Control Room NOSronfrendBelum ada peringkat

- Integration of Safety in Machine DesignDokumen13 halamanIntegration of Safety in Machine DesignronfrendBelum ada peringkat

- MV VFD SpecDokumen17 halamanMV VFD Specronfrend100% (1)

- Vibration Analysis Measurement ManualDokumen215 halamanVibration Analysis Measurement Manualronfrend100% (1)

- DC Motor Brush LifeDokumen13 halamanDC Motor Brush LiferonfrendBelum ada peringkat

- Risk Based Inspection Jacketed PlatformsDokumen19 halamanRisk Based Inspection Jacketed PlatformsronfrendBelum ada peringkat

- 2.4 Road Note 29 (RN-29)Dokumen33 halaman2.4 Road Note 29 (RN-29)Rajesh Khadka85% (13)

- Chhaya Center Case StudyDokumen7 halamanChhaya Center Case StudyPrashna Shrestha0% (1)

- Landscape+Urbanism - Ecological Urbanism - Introduction Part 1Dokumen6 halamanLandscape+Urbanism - Ecological Urbanism - Introduction Part 1Arnostca LopezBelum ada peringkat

- The Judge's HouseDokumen10 halamanThe Judge's HousearavindpunnaBelum ada peringkat

- The Loads Acting On BridgesDokumen21 halamanThe Loads Acting On BridgesdabalaBelum ada peringkat

- Portal Frame - Airport Hangar PDFDokumen12 halamanPortal Frame - Airport Hangar PDFShinjini BhattacharjeeBelum ada peringkat

- GCP Pricing Estimator 2021Dokumen7 halamanGCP Pricing Estimator 2021Marco RamirezBelum ada peringkat

- Design of Column SpliceDokumen13 halamanDesign of Column SplicemithunBelum ada peringkat

- Ian Batty Design Tables For Water Retaining Structures PDFDokumen209 halamanIan Batty Design Tables For Water Retaining Structures PDFLance Zhengling Yin100% (1)

- Usak Ceramic Price List UsdDokumen1 halamanUsak Ceramic Price List UsdTanvir Ahmed KhanBelum ada peringkat

- Waffle SlabDokumen22 halamanWaffle Slabnirvaang100% (2)

- Estimation 2 PDFDokumen2 halamanEstimation 2 PDFAppi Shrikanta AngadiBelum ada peringkat

- Art App Prefinal ExamDokumen14 halamanArt App Prefinal ExamAljohn ReyesBelum ada peringkat

- Asian Architecture PhilDokumen4 halamanAsian Architecture PhilRen MariBelum ada peringkat

- Proposed Residence House: © Marc Allen Building Pty LTDDokumen4 halamanProposed Residence House: © Marc Allen Building Pty LTDYorga JhohansyahBelum ada peringkat

- Hengzhu 2020 Version CatalogDokumen314 halamanHengzhu 2020 Version CatalogNhok Nho Suy TinkBelum ada peringkat

- 5 +factors+that+affect+design PDFDokumen2 halaman5 +factors+that+affect+design PDFarchitectfemil6663Belum ada peringkat

- Wa0000Dokumen35 halamanWa0000gauthami pjBelum ada peringkat

- BOQ For Steel Structure Processing FactoryDokumen4 halamanBOQ For Steel Structure Processing FactoryArshad SanBelum ada peringkat

- ' Classical Ottoman ' Art and ArchitectureDokumen95 halaman' Classical Ottoman ' Art and ArchitectureAbul QasimBelum ada peringkat

- CHUAN - Grade 1.1 - Listening-Reading & Writing 1st Term TestDokumen6 halamanCHUAN - Grade 1.1 - Listening-Reading & Writing 1st Term TestNgô TuấnBelum ada peringkat

- Logcat 1689770402587Dokumen9 halamanLogcat 1689770402587Ssanjnna Kavita GuptaBelum ada peringkat

- Moveis SorocabaDokumen16 halamanMoveis SorocabaThamires AlvesBelum ada peringkat

- SEHS4593 (201902) - Comment On A9Dokumen3 halamanSEHS4593 (201902) - Comment On A9Tik HonBelum ada peringkat

- G2 PlansDokumen2 halamanG2 PlansNicole EstanislaoBelum ada peringkat

- Identitas Barang Rehab R.kerja KH LT1 1Dokumen2 halamanIdentitas Barang Rehab R.kerja KH LT1 1Erwin Alcapone0707Belum ada peringkat

- Planned and Built Cities: Tel Aviv (Israel)Dokumen11 halamanPlanned and Built Cities: Tel Aviv (Israel)Amrutha Pavithran100% (1)

- Combined Gradation of Coarse Aggregate - Astm C33-Size 67-1Dokumen106 halamanCombined Gradation of Coarse Aggregate - Astm C33-Size 67-1Hasan al MahmudBelum ada peringkat

- Sears - Modern Home 132Dokumen1 halamanSears - Modern Home 132Eric MarchandBelum ada peringkat

- Comparison Study of Bioclimatic Strategies of Vernacular and Contemporary Architecture in The Dominican RepublicDokumen16 halamanComparison Study of Bioclimatic Strategies of Vernacular and Contemporary Architecture in The Dominican RepublicJudithBelum ada peringkat