Email Brochure 1

Diunggah oleh

vsrikala680 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

85 tayangan4 halamanInstrument

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniInstrument

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

85 tayangan4 halamanEmail Brochure 1

Diunggah oleh

vsrikala68Instrument

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

HIGH TECHNOLOGY SOLUTIONS FOR THE INDIAN CEMENT INDUSTRY

Kiln Shell Scanning and 3D Kiln Shell Visualisation

High Temperature Kiln and Cooler Cameras

Expert Refractory Software System

Exclusive Agents for Thermoteknix

Cement Products in India

Trending

Designed to give reliability you can depend

on in the harshest plant environment, the

Centurion TK30 model is specifcally designed

for rotary kiln shell scanning. Centurion TK30

is a smart sensor with powerful embedded

microprocessor and internal temperature

references for long term accurate temperature

measurement and self calibration. With its 100

degree confgurable feld of view and 1120

linear temperature measurements per scan at

20 to 30 Hz, the Centurion covers every brick in

every ring to ensure the coating and brick performance are continually checked

from light up to shut down with temperature measurement resolution of 2mRad.

WinCem 3D Kiln Shell Visualisation

3D Coating / Brick thickness display WinCem

3D software technology peels away the kiln

in layers to show what you really need to see:

Shell and refractory temperatures, brick wear

and coating thickness...

Thermoteknix coating thickness software

provides high resolution rendering of refractory

thickness and location of brick thinning or coating

build-up.

Take a walk inside your kiln from the comfort of your own desk! With the Centurion and

WinCem continual history tracking system, every single measured point on the kiln is checked

on every revolution of the kiln to ensure you never miss a problem. All User preferences and

settings are saved automatically to ensure Operator familiarity and ease of use.

WinCem 3D Kiln Shell Visualisation System

WinCem incorporates the latest in 3D graphical image processing techniques to show

Operators real time kiln data from any angle or viewpoint. Operators can even view the

internal kiln conditions using the Thermoteknix proprietary modelling algorithms which display

refractory thickness and coating wear.

WinCem Graphic 3D software is compatible with all

Thermoteknix Centurion-based line scanning systems in

line with Company policy to supply future-proof value added

protection for your valuable kiln shell scanning investment.

Based on Client-Server technology, WinCem 3D provides

unrivalled fexibility in the display of multiple kiln data on any

PC monitor within your plant network.

User confgured Windows interface

WinCem 3D software gives the Operator a very fexible user interface. Users can display real time temperature trending at any

point or points on the kiln shell to see live or historical evolution of hotspot or coating formation. 8 digital outputs for fan control

are supplied as standard while as options 4-20 mA and OPC communications are available.

Single click selection of display modes enable subtraction

displays of reference temperature charts, shift or day to

day changes to display effects of different kiln operating

conditions at a glance. Plant wide display of Alarm status

or Tyre slip values keep engineers fully in the picture at all

times. With the Centurion and WinCem continual history

tracking system, every single measured point on the kiln is

checked on every revolution of the kiln to ensure you never

miss a problem. All User preferences and settings are saved

automatically to ensure Operator familiarity and ease of use.

1120 linear measurements per scan

100 Scanning

Sector

Kiln

Cent ur i on

infrared linescan camera

Wi nCem 3D

kiln shell visualisation system

&

Centurion Installation

VCR Style Historical Playback

2D and 3D views available

Client-Server Based System

more than just an image...

Tyre Slip Monitoring

WinCem 3D Kiln Display and WinCem Kiln Shell

Scanner by Thermoteknix Systems Ltd

HIGH TECHNOLOGY SOLUTIONS

FOR THE INDIAN CEMENT INDUSTRY

ThermaScope

SLK High Temperature Infrared Kiln and Cooler Camera

improves effciency, increases combustion control and reduces pollution.

Solid state infrared technology, superior image quality,

temperature measurement, accuracy and outputs for

pyro-processing control.

Unmatched reliability, ease of use and service

Powerful software with unlimited spot and area real time

measurement

Temperature versus Time and Alarm functions

ThermaScope SLK displays bright clear real time thermal images of high

temperature processes and measures temperature at every point in the

feld of view. A key factor in effcient

and safe kiln operation is the ability to

accurately monitor the combustion process.

ThermaScope SLK is a unique rugged instrument that sends real time thermal images and

unlimited temperature data of the kiln or clinker bed to its control room PC processor and

monitor. As fuel fow, operating conditions or fuel quality changes, ThermaScope gives

operators and control engineers a clear image and instantaneous temperatures at any spot

or within any area of interest.

Alarming will warn of unwanted temperature extremes and process variation whilst direct

external outputs enable interfacing and automated control.

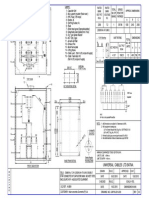

ThermaScope SLK Infrared Kiln Camera:

- Focal plane array imaging and temperature sensor

- Water cooled stainless steel protective camera housing

- Automatic, fail-safe pneumatic camera insert/retract

mechanism

- Camera interface, signal processing circuitry and services

control unit.

- Real time infrared digital thermal imaging and temperature

measurement

- High Resolution focal plane array IR detector

- Remote controlled, fail safe pneumatic insertion/retraction

- Patented calibration for accuracy even in dusty kilns

- Solid state - long term reliability you can depend on

- Direct view with no alignment inaccuracies

- Simple feld maintenance

ThermaScope software gives the process engineer or control room operator advanced

analysis tools with control interface signals for advanced closed loop control. User

friendly operator interface with unlimited number of simultaneous spot and area of interest

measurements, thermal profles, image storage, differential temperatures, live and historic

data trending, highlights and much more. ThermaScope HTV displays bright clear real time

images of high temperature processes.

ThermaScope

HTV Cooler Camera

A unique rugged instrument that sends real time CCTV

images of the kiln or clinker bed to the control room.

ThermaScope HTV has the following principle camera components:

- High resolution focal plane array imaging and temperature sensor

- Water cooled stainless steel protective camera housing

- Direct view with no alignment inaccuracies - simple feld maintenance

- Automatic, fail-safe pneumatic camera insert/retract mechanism with camera interface,

signal processing circuitry and services control unit

- Solid state for long term reliablity you can depend on

Ther maScope

HTV Kiln and Cooler Cameras

Radiometric ThermaScope SLK

ThermaScope HTV Cooler Camera

ThermaScope Kiln Installation

Diagram showing typical ThermaScope SLK Setup

Communication Cables

Fibre optic communication

Air and water

services control unit

Process control interface

4-20 mAoutputs

Alarms

Local network

PCwith

ThermaScope

software

ThermaScope

Control Unit

Ther maScope

Failsafe Retraction System

Air Purge

Water cooling

HIGH TECHNOLOGY SOLUTIONS

FOR THE INDIAN CEMENT INDUSTRY

more than just an image...

In India, Contact:

SB Engineers

404, Ornet Arcade, Opp. Simandhar Tower, Bodakdev,

Ahmedabad - 380 054, Gujarat, India

Ph: 079 26854375, Fax: 079 26854345,

Cell: (0) 98250 84769,

Email: keyurshah@sbgroupindia.com

Web: www.sbgroupindia.com

Until now, refractory management

software simply recorded brick

installed in a kiln.

WinBrix

Refractory Expert is a new

concept. It works with you, in the way you work planning, buying, stocking,

installing and documenting every aspect of refractory brick and castable used

in your plant pre-heater, risers, cyclones, kilns and coolers. WinBrix helps

you to make decisions based on what works best for you, in your kiln, with your

process, with your budget.

WinBrix Refractory Expert is designed to

help you increase clinker production, save

engineering mantime, reduce costs and

increase effciency. WinBrix Refractory Expert guides you

step by step to help make the best decisions and manage

your materials for the maximum campaign length and

optimum effciency. WinBrix can be installed on a single PC

in the production or maintenance offce or networked through

the plant to put the information you need at your fngertips.

WinBrix Refractory Expert sets the industry standard and is

suitable for the smallest to the largest plants. WinBrix is a

stand alone, dedicated package, ready to use without any

additional third party spreadsheets or database software.

So easy to use WinBrix has a picture based, user friendly interface incorporating Point and

Click data entry to get you up and running fast. Fuel changes, stoppages, clinker production,

drilling or lining thickness are entered in minutes. On-line Tip and Context sensitive Help are

there to assist you at every step and to see the results you can choose from tables, 2D or 3D

graphs at the click of your mouse. Refractory charting at a glance WinBrix Refractory Expert

creates installation charts instantly with materials and their performance shown at a glance.

No more laborious hours entering data or drawing paper installation records. Lining charts,

performance charts, refractory service, production, predicted brick life and much more!

SB Engineers - Exclusive Agents for Thermoteknix Systems Ltd Cement Products

The SB Group was founded in 1989 by Mr. Subodh Bhatt, a Mechanical Engineer with background of industrial marketing of

more than 20 years. It was set up with a clear objective of providing Engineering Solutions. The group includes companies

from both India and abroad, for their world class Products and Services.

SB Engineers is based in Gujarat and has been installing and supporting Thermoteknix high technology products

since 1989 and are the exclusive agents for Thermoteknix Cement Products in India.

WinBrix

refractory expert

In Europe, Contact:

Thermoteknix Systems Ltd

Teknix House

2 Pembroke Avenue

Waterbeach

Cambridge CB25 9QR - United Kingdom

www.thermoteknix.com

Drilling Records

Centralised Database

Consumption

HIGH TECHNOLOGY SOLUTIONS

FOR THE INDIAN CEMENT INDUSTRY

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- POAF (Employer)Dokumen1 halamanPOAF (Employer)Youka MainBelum ada peringkat

- Arunachala Aksharamanamalai - TamilDokumen10 halamanArunachala Aksharamanamalai - Tamildeepaksubsmani@yahoo.com95% (19)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- R Cheat Sheet PDFDokumen38 halamanR Cheat Sheet PDFMadhavi JBelum ada peringkat

- GD&T WikipediaDokumen4 halamanGD&T WikipediaJayesh PatilBelum ada peringkat

- Zero Speed Switch Data Sheet NO:ELAC020002: Application DetailsDokumen1 halamanZero Speed Switch Data Sheet NO:ELAC020002: Application Detailsvsrikala68Belum ada peringkat

- Technical Specs Lab EquipmentsDokumen8 halamanTechnical Specs Lab Equipmentsvsrikala68Belum ada peringkat

- Amavasya TharpanamDokumen5 halamanAmavasya TharpanamK KwaranBelum ada peringkat

- Elac030003 1 1Dokumen1 halamanElac030003 1 1vsrikala68Belum ada peringkat

- ACL - EP - GU - Part VI B4 Design Criteria ForTechnical Specification For C& I CableDokumen6 halamanACL - EP - GU - Part VI B4 Design Criteria ForTechnical Specification For C& I Cablevsrikala68Belum ada peringkat

- PR-131 (C) Q-U36-2010-256 (Item-1)Dokumen1 halamanPR-131 (C) Q-U36-2010-256 (Item-1)vsrikala68Belum ada peringkat

- Diff. Pressure Switch Data Sheet NO. ELAC010001: Application DetailsDokumen1 halamanDiff. Pressure Switch Data Sheet NO. ELAC010001: Application Detailsvsrikala68Belum ada peringkat

- Pressure Switch Data Sheet NO:ELAC000001: Application DetailsDokumen1 halamanPressure Switch Data Sheet NO:ELAC000001: Application Detailsvsrikala68Belum ada peringkat

- Diff. Pressure Switch Data Sheet NO. ELAC010001: Application DetailsDokumen1 halamanDiff. Pressure Switch Data Sheet NO. ELAC010001: Application Detailsvsrikala68Belum ada peringkat

- Flow Sheet - Cement SiloDokumen1 halamanFlow Sheet - Cement Silovsrikala68Belum ada peringkat

- M/S Asian Concretes & Cement PVT - LTD.: 1.5 Mtpa Grinding Unit-Ii at Solan (As Built - Electrical)Dokumen1 halamanM/S Asian Concretes & Cement PVT - LTD.: 1.5 Mtpa Grinding Unit-Ii at Solan (As Built - Electrical)vsrikala68Belum ada peringkat

- ACL - EP - GU - Part VI B1 Design Criteria and Technical Specification For Control & InstrumentationDokumen101 halamanACL - EP - GU - Part VI B1 Design Criteria and Technical Specification For Control & Instrumentationvsrikala68Belum ada peringkat

- 2356KVAr, 7.2KV - 12 UNIT (DRG. NO.10-203)Dokumen1 halaman2356KVAr, 7.2KV - 12 UNIT (DRG. NO.10-203)vsrikala68Belum ada peringkat

- Cover Sheet PDFDokumen1 halamanCover Sheet PDFvsrikala68Belum ada peringkat

- Flyash Storage & Transport - SheetDokumen2 halamanFlyash Storage & Transport - Sheetvsrikala68Belum ada peringkat

- Flow Sheet - Packing PlantDokumen1 halamanFlow Sheet - Packing Plantvsrikala68Belum ada peringkat

- Siemens PTDokumen71 halamanSiemens PTvsrikala68Belum ada peringkat

- Flow SheetDokumen4 halamanFlow Sheetvsrikala68Belum ada peringkat

- LT XLPE Aerial BunchedDokumen13 halamanLT XLPE Aerial BuncheddthotagamuwaBelum ada peringkat

- Brochure - Loading Spout - Pubc-0499-AulDokumen2 halamanBrochure - Loading Spout - Pubc-0499-Aulm_verma21Belum ada peringkat

- Vasa Mari Yat Hamal ArgalDokumen60 halamanVasa Mari Yat Hamal ArgalArockiaruby RubyBelum ada peringkat

- Satya TamilDokumen64 halamanSatya Tamilsrinivas3usBelum ada peringkat

- Corrig1 Eng 3889 TPT 828Dokumen37 halamanCorrig1 Eng 3889 TPT 828vsrikala68Belum ada peringkat

- Ameritrade 1099 2010Dokumen3 halamanAmeritrade 1099 2010vsrikala68Belum ada peringkat

- Best of Talacauvery - Indian Travel Guide to Karnataka's Holy River Origin SiteDokumen4 halamanBest of Talacauvery - Indian Travel Guide to Karnataka's Holy River Origin Sitevsrikala68Belum ada peringkat

- What Shirdi Saibaba Expects from Devotees During Their TripDokumen37 halamanWhat Shirdi Saibaba Expects from Devotees During Their Tripvsrikala68Belum ada peringkat

- CCTV Specification BCASDokumen8 halamanCCTV Specification BCASPraveen MohanBelum ada peringkat

- GanasktDokumen30 halamanGanasktvsrikala68Belum ada peringkat

- G InstrumentationDokumen4 halamanG Instrumentationvsrikala68Belum ada peringkat

- Daa Lab Term Work - Pcs 409Dokumen13 halamanDaa Lab Term Work - Pcs 409Tem PBelum ada peringkat

- All mIRC CommandsDokumen4 halamanAll mIRC CommandsAbhishek KunalBelum ada peringkat

- Install Ansible On Mac OSXDokumen5 halamanInstall Ansible On Mac OSXNagendraBelum ada peringkat

- IT0007-Laboratory-Exercise-6 - Creating CodesDokumen6 halamanIT0007-Laboratory-Exercise-6 - Creating CodesDenise JaoBelum ada peringkat

- Yamaha NU1 MIDI Control CodesDokumen6 halamanYamaha NU1 MIDI Control CodesisothermBelum ada peringkat

- Types of NumbersDokumen4 halamanTypes of NumbersSha MercsBelum ada peringkat

- 3 RD Party LicensesDokumen5 halaman3 RD Party LicensesReynaldo SanabiaBelum ada peringkat

- Generator Auto Start Mod Rolando Mod 8 ChokeDokumen3 halamanGenerator Auto Start Mod Rolando Mod 8 Chokeali mohammedBelum ada peringkat

- A Teen Trader FTR Indicator: DisclosureDokumen14 halamanA Teen Trader FTR Indicator: DisclosureMohamad ehteshamBelum ada peringkat

- 54 Channel EEG Digital SystemDokumen2 halaman54 Channel EEG Digital SystemDavit SoesantoBelum ada peringkat

- MPM2DZ CoursePack (2019)Dokumen254 halamanMPM2DZ CoursePack (2019)Hope ZhangBelum ada peringkat

- Ergonomic Analysis of Motor VehiclesDokumen14 halamanErgonomic Analysis of Motor VehiclesdeyeBelum ada peringkat

- Create Table PlayerDokumen8 halamanCreate Table PlayerMr MittalBelum ada peringkat

- Digital Public SpaceDokumen42 halamanDigital Public SpacesunnekoBelum ada peringkat

- SLHT Grade 7 CSS Week 2Dokumen6 halamanSLHT Grade 7 CSS Week 2princeyahweBelum ada peringkat

- ReadmasterdataDokumen3 halamanReadmasterdatagilles777Belum ada peringkat

- 1794 FLEX I/O Analog, TC and RTD Modules Specifications: Technical DataDokumen28 halaman1794 FLEX I/O Analog, TC and RTD Modules Specifications: Technical DataKelly Johana Moreno MendozaBelum ada peringkat

- (Hons,) SyllabusDokumen13 halaman(Hons,) SyllabusDhawal RajBelum ada peringkat

- Cs Lesson PlanDokumen3 halamanCs Lesson Planapi-426721162Belum ada peringkat

- All About Data Transfer Process (DTP) - SAP BW 7 - SCNDokumen6 halamanAll About Data Transfer Process (DTP) - SAP BW 7 - SCNloknathtanikantiBelum ada peringkat

- Splunk 4.2.3 AdminDokumen426 halamanSplunk 4.2.3 AdminjazzymoonBelum ada peringkat

- Komatsu Engine 155 4 Shop Manual Sebe6120a05Dokumen20 halamanKomatsu Engine 155 4 Shop Manual Sebe6120a05charles100% (27)

- Computer Engineering Department: Gtu Important Questions Bank Subject Name: Information Ecurity Subject Code SemesterDokumen5 halamanComputer Engineering Department: Gtu Important Questions Bank Subject Name: Information Ecurity Subject Code SemesterKaushal PardasaniBelum ada peringkat

- Difficulties in Learning Basic Concepts in Probability and Statistics: Implications For ResearchDokumen21 halamanDifficulties in Learning Basic Concepts in Probability and Statistics: Implications For ResearchRoy Umaña CarrilloBelum ada peringkat

- Introduction To Computing Fundamentals of ICT Week 1-2Dokumen21 halamanIntroduction To Computing Fundamentals of ICT Week 1-2Ronald Cambil Jr.Belum ada peringkat

- GIS Hydrology ToolsDokumen32 halamanGIS Hydrology ToolsNawanjana MaheepalaBelum ada peringkat

- UpdatepasswordDokumen4 halamanUpdatepasswordsaadouli nouhaBelum ada peringkat