Caterpillar

Diunggah oleh

Carlos MartinezDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Caterpillar

Diunggah oleh

Carlos MartinezHak Cipta:

Format Tersedia

Oilfield

Mechanical

Rig Power

3306

3406

3408

3412

The outstanding performance of Caterpillar

engines is the result of fifty years experience in

diesel power, plus a multi-million dollar research

and development program. For the user this means

continual improvement and refinement in engine

performance.

The diesel engines and attachments described

here are offered by Caterpillar for use as prime

power on mechanical drilling rigs.

The typical package contains the attachments

normally specified on engines powering mechanical

rigs. These Cat

engines, when equipped with the

users choice of torque converter or clutch, result in

a unit that specifically meets the application

requirements of the drilling contractor.

SPECIFICATIONS

CAT

3306

Bore mm (in) . . . . . . . . . . . . . . . . . . . . . . . . 121 (4.75)

Strokemm (in). . . . . . . . . . . . . . . . . . . . . . . . . 152 (6.0)

Displacement L (cu in) . . . . . . . . . . . . . . . . 10.5 (638)

Weight kg (lb). . . . . . . . . . . . . . . . . . . . . . 1,007 (2,220)

Low idlerpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

CAT

3406

Boremm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . 137 (5.4)

Strokemm (in). . . . . . . . . . . . . . . . . . . . . . . . . 165 (6.5)

DisplacementL (cu in) . . . . . . . . . . . . . . . . . 14.6 (893)

Weight kg (lb). . . . . . . . . . . . . . . . . . . . . . 1,356 (2,990)

Low idlerpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

CAT

3408

Boremm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . 137 (5.4)

Strokemm (in). . . . . . . . . . . . . . . . . . . . . . . . . 152 (6.0)

DisplacementL (cu in) . . . . . . . . . . . . . . . 18.0 (1,099)

Weight kg (lb). . . . . . . . . . . . . . . . . . . . . . 1,513 (3,335)

Low idlerpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650

CAT

3412

Boremm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . 137 (5.4)

Strokemm (in) . . . . . . . . . . . . . . . . . . . . . . . . . 152 (6.0)

DisplacementL (cu in) . . . . . . . . . . . . . . . 27.0 (1,649)

Weight kg (lb) . . . . . . . . . . . . . . . . . . . . . 2,141 (4,720)

Low idlerpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

OILFIELD MECHANICAL RIG POWER

TYPICAL EQUIPMENT

Air and exhaust

air cleaner service indicator, single stage dry air

cleaner, exhaust manifold

Cooling

jacket water pump, water connections, thermostat

and housing

Fuel

flexible fuel lines, fuel filter, priming and transfer

pumps

Instrument panel

fuel pressure, lubricating oil pressure, water

temperature gauges

Lubrication

oil cooler, filter, pan, oil level gauge

Protection devices

mechanical shutoffs oil pressure, water

temperature

Starting and control

air starting motor, manual shutoff control,

hydra-mechanical governor and air throttle

Miscellaneous

service hour meter, SAE #1 (3306,3406) SAE #0

(3406, 3408, 3412), flywheel and housing, SAE

standard rotation, vibration damper, industrial

engine supports

OPTIONAL EQUIPMENT

Air and exhaust

two-stage dry air cleaner, air cleaner adapters,

precleaner, flexible exhaust fitting, muffler, elbow

Cooling

corrosion resistant aftercooler core, radiators,

torque converter oil cooler

Tachometer

Transmission/torque converter adaptation

RATINGS (without fan)

Model kW (hp) rpm Aspiration

3306 186 (250) 2200 T

3306 242 (325) 2200 TA

3406 242 (325) 2100 T

3406 269 (360) 2100 T

3406 300 (402) 2100 TA

3406 343 (460) 2100 TA

3408 375 (503) 2100 TA

3412 429 (575) 2100 T

3412 485 (650) 2100 T

3412 600 (804) 2100 TA

Model kW (hp) rpm Aspiration

3306 167 (225) 2000 T

3306 220 (295) 2000 TA

3406 224 (300) 1800 T

3406 242 (325) 1800 T

3406 276 (370) 1800 TA

3406 321 (430) 1800 TA

3408 358 (480) 1800 TA

3412 384 (515) 1800 T

3412 410 (550) 1800 T

3412 541 (725) 1800 TA

Hoisting Pumping and Drilling

CAT

3306

OILFIELD MECHANICAL RIG POWER

CAT

3412

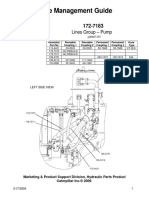

* Radiator dimensions

reflect radiator with

suction fan 125F

ambient temperature,

torque converter heat

load, and pumping

and drilling rating.

CAT

3408

W

WR

H

HR

LR

L

CL

CAT

3406

3306

3406

3408

3412

L LR* CL W WR* H HR*

mm in mm in mm in mm in mm in mm in mm in

1576 62.0 1634 64.3 318 12.5 833 32.8 797 31.4 1104 43.5 1118 44.0

1660 65.4 1930 76.0 432 17.0 906 35.7 1002 39.4 1335 52.6 1513 59.6

1383 62.6 1839 72.4 432 17.0 1232 48.5 1270 50.0 1377 54.2 1705 67.1

1995 78.6 2179 85.8 432 17.0 1496 58.9 1270 50.0 1483 58.4 1705 67.1

DIMENSIONS

OILFIELD MECHANICAL RIG POWER

RATING CONDITIONS AND DEFINITIONS

Ratings are based on SAE J1349 standard conditions

of 100 kPa (29.61 in Hg) and 25C (77F). These

ratings also apply at ISO3046/1, DIN6271, and

BS5514 standard conditions of 100 kPa

(29.61 in Hg), 27C (81F) and 60% relative

humidity.

Fuel rates are based on fuel oil having an LHV of

45 570 kJ/kg (19,590 Btu/lb) and weighing 848 g/liter

(7.076 lb/U.S. gal).

Hoisting: The power and speed capability of the

engine which can be used to power the drawworks

only of a drilling or workover rig through a mechanical

drive.

Pumping and drilling: The power and speed

capability of the engine which can be used to power

the mud pumps, rotary table, and drawworks through

a mechanical drive.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

LEHW4116 (5-94) 1994 Caterpillar Printed in U.S.A.

Supersedes LEHW4409

CATERPILLAR PARTS AND SERVICE

You will find Caterpillar parts and service outlets in

major oil producing areas worldwide. With the most

comprehensive parts distribution system in the

industry, most engine parts orders can be filled

immediately over a dealers counter. As a backup,

dealers can quickly convey their parts needs to the

nearest location in a network of Caterpillar parts

facilities around the world. The dealer places an

order with the Caterpillar parts depot and a

computerized inventory control system helps fill that

order, printing shipping instructions for any part in the

system wherever it might be.

While many oilfield contractors maintain a service

department adept at handling repairs, they have the

assurance that Caterpillar engine dependability is

backed by a force of factory qualified dealer

servicemen worldwide men who are specially

trained to keep Cat

engines operating at peak

efficiency. For all engine repairs, from minor work to

a major overhaul or rebuild, expert attention is as

near as your phone or radio. Work is fast and

accurate. Downtime is minimized.

Ask about installation and start-up procedures

offered by Caterpillar.

Anda mungkin juga menyukai

- 3516 516de4a 50HZ 6300Dokumen6 halaman3516 516de4a 50HZ 6300sinliongBelum ada peringkat

- 3406 Engine TroubleshootingDokumen3 halaman3406 Engine TroubleshootingB E BalaramenterpriseBelum ada peringkat

- Cornell BR Mine DewateringDokumen8 halamanCornell BR Mine Dewateringtan_dat2003Belum ada peringkat

- Valve Lash CheckingDokumen2 halamanValve Lash CheckingRajan MullappillyBelum ada peringkat

- Adobe Scan 04 Jul. 2022Dokumen7 halamanAdobe Scan 04 Jul. 2022Abel Alejandro Vera TriviñosBelum ada peringkat

- Engine Rating DefinitionsDokumen2 halamanEngine Rating Definitionsharikrishnanpd3327Belum ada peringkat

- Part (3) CAT EngineDokumen25 halamanPart (3) CAT EngineIslam ElsaeedBelum ada peringkat

- Manual Maintenance Intervals Caterpillar Ad40 Ae40 II Underground Articulated TrucksDokumen97 halamanManual Maintenance Intervals Caterpillar Ad40 Ae40 II Underground Articulated Truckssuwarjitechnic100% (2)

- d10r - Akt HosesDokumen43 halamand10r - Akt Hosesleaw81Belum ada peringkat

- 920 WHEEL LOADER 62K07095-UP (MACHINE) POWERED BY 3304 ENGINE (SEBP1054 - 00) - Systems & ComponentsDokumen56 halaman920 WHEEL LOADER 62K07095-UP (MACHINE) POWERED BY 3304 ENGINE (SEBP1054 - 00) - Systems & ComponentsTransportation MaintananceBelum ada peringkat

- General Fuel InformationDokumen5 halamanGeneral Fuel InformationElmer Tintaya MamaniBelum ada peringkat

- Cat 914G2Dokumen20 halamanCat 914G2t1me50% (2)

- Caterpillar AD55BDokumen20 halamanCaterpillar AD55BForomaquinas100% (1)

- Caterpillar Performance Handbook 49 62020 - Partie588Dokumen4 halamanCaterpillar Performance Handbook 49 62020 - Partie588ali alilouBelum ada peringkat

- Crankshaft Position For Fuel Injector Adjustment and Valve Lash SettingDokumen2 halamanCrankshaft Position For Fuel Injector Adjustment and Valve Lash SettingEva AprianaBelum ada peringkat

- SakaiDokumen2 halamanSakaiariBelum ada peringkat

- TIBU7664 - The Third Clutch Friction Disc May Fail On Certain 777 Off-Highway Trucks (PN 391-4047) PDFDokumen2 halamanTIBU7664 - The Third Clutch Friction Disc May Fail On Certain 777 Off-Highway Trucks (PN 391-4047) PDFCarlos LoboBelum ada peringkat

- Caterpillar C15 P1Z00331Dokumen3 halamanCaterpillar C15 P1Z00331Hendra MechanicBelum ada peringkat

- Turbine ProcedureDokumen77 halamanTurbine Procedureenzobv100% (1)

- Engine Speed/Timing Sensor Circuit - Test: TroubleshootingDokumen13 halamanEngine Speed/Timing Sensor Circuit - Test: TroubleshootingRodrigo Herrera GodosBelum ada peringkat

- Failure Modes of TurbochargersDokumen12 halamanFailure Modes of Turbochargersbetoven8437Belum ada peringkat

- Tool Catalog P 4Dokumen15 halamanTool Catalog P 4cav4444Belum ada peringkat

- Valvulas ICM 793Dokumen17 halamanValvulas ICM 793Pablo Cesar Poma ArrateaBelum ada peringkat

- Dozers: What Are These ? & What They Does ?Dokumen118 halamanDozers: What Are These ? & What They Does ?harirambo100% (1)

- Caterpillar 3406Dokumen6 halamanCaterpillar 3406api-224431410Belum ada peringkat

- Cat 3304b Disassimble BearingDokumen8 halamanCat 3304b Disassimble BearingMahmoud KhattabBelum ada peringkat

- CAT Engine Driving TipsDokumen2 halamanCAT Engine Driving Tipsjinxy5779Belum ada peringkat

- 3512C 1810 BHP A Rating SpecDokumen6 halaman3512C 1810 BHP A Rating SpecRodolfo Curci Puraca100% (1)

- Caterpillar: Guideline For Reusable Parts and Salvage OperationsDokumen59 halamanCaterpillar: Guideline For Reusable Parts and Salvage OperationsPaul Gustavo100% (1)

- Media Search - SEBF8059 - Inspection Procedures and Specifications For Pistons (1214, 1214)Dokumen22 halamanMedia Search - SEBF8059 - Inspection Procedures and Specifications For Pistons (1214, 1214)Muhammad AliBelum ada peringkat

- Smcs Codes: Adds / Changes / DeletesDokumen103 halamanSmcs Codes: Adds / Changes / DeletesvpurillaBelum ada peringkat

- Estimating Dozer Operating CostsDokumen14 halamanEstimating Dozer Operating CostsYacine BouBelum ada peringkat

- D399 Industrial EngineDokumen49 halamanD399 Industrial EngineMohamed SaiedBelum ada peringkat

- 3512C Oil Well Servicing EngineDokumen16 halaman3512C Oil Well Servicing EngineMaxiBelum ada peringkat

- Operation and Maintenance Manual: 3500B Series II and 3500C Marine Auxiliary EnginesDokumen136 halamanOperation and Maintenance Manual: 3500B Series II and 3500C Marine Auxiliary EnginesRuslanRumyantsev100% (1)

- Test Pressure Head PDFDokumen4 halamanTest Pressure Head PDFbabyBelum ada peringkat

- 7 - Moteur C18Dokumen34 halaman7 - Moteur C18Hafid BoumhaoudBelum ada peringkat

- QXR 1320 Specification Completed March 26 2010Dokumen3 halamanQXR 1320 Specification Completed March 26 2010death666dark100% (1)

- TA Steering 777DDokumen4 halamanTA Steering 777DBroCactus100% (1)

- 3512 IND-C 1119bkWDokumen5 halaman3512 IND-C 1119bkWuripssBelum ada peringkat

- C11 Troubleshooting High Coolant Temperature PDFDokumen3 halamanC11 Troubleshooting High Coolant Temperature PDFmanu luvungaBelum ada peringkat

- Track Tipe Tractors: Model Eng - Tip N Cil - Cil. B/S RPM Fly Power KW/ HP DSP L. LDokumen6 halamanTrack Tipe Tractors: Model Eng - Tip N Cil - Cil. B/S RPM Fly Power KW/ HP DSP L. Lkatakliztma100% (1)

- Testing and AdjustingDokumen10 halamanTesting and Adjustingale gamingBelum ada peringkat

- Cat 3306 Ta - Spec - 1Dokumen5 halamanCat 3306 Ta - Spec - 1Adrian CojocaruBelum ada peringkat

- Assignment On BANGLACATDokumen6 halamanAssignment On BANGLACATBaygas MithuBelum ada peringkat

- P086ti 1Dokumen2 halamanP086ti 1Serhan AysanBelum ada peringkat

- Reuse & Salvage Guidelines (Valve & Valve Spring Spec)Dokumen25 halamanReuse & Salvage Guidelines (Valve & Valve Spring Spec)carlos angelBelum ada peringkat

- Winches ChinosDokumen3 halamanWinches Chinosfelixriosl100% (1)

- UNIT1L1S Cat Fuel Systems PDFDokumen24 halamanUNIT1L1S Cat Fuel Systems PDFbejoythomasBelum ada peringkat

- Manufacturer of The Most Complete Line of Drilling Rigs in The IndustryDokumen2 halamanManufacturer of The Most Complete Line of Drilling Rigs in The IndustryCarlos Galvez100% (1)

- Starting Parts 777DDokumen4 halamanStarting Parts 777DGerald BoyBelum ada peringkat

- D399 Operation SystemDokumen64 halamanD399 Operation SystemNOUR ZAINBelum ada peringkat

- Desmontaje CAT 3612Dokumen114 halamanDesmontaje CAT 3612cachaco2009Belum ada peringkat

- CAT 769c Valvula de Control de Transmision 1Dokumen28 halamanCAT 769c Valvula de Control de Transmision 1Taller Pahr100% (1)

- Piston Ring Liner RodDokumen4 halamanPiston Ring Liner Rodmuhammad arif100% (1)

- Caterpilar 160m Motor GraderDokumen28 halamanCaterpilar 160m Motor GraderCitizen Kwadwo Ansong100% (1)

- Manuales de Camiones Off-Highway TrucksDokumen80 halamanManuales de Camiones Off-Highway Trucksyan100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDari EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementBelum ada peringkat

- Oilfield Mechanical Rig Power: SpecificationsDokumen4 halamanOilfield Mechanical Rig Power: Specificationslinkangjun0621Belum ada peringkat

- Cat 12Dokumen4 halamanCat 12Surya Chala PraveenBelum ada peringkat

- 2017 Alcon Catalogue NewDokumen131 halaman2017 Alcon Catalogue NewJai BhandariBelum ada peringkat

- Astm B695-04-2009Dokumen6 halamanAstm B695-04-2009Danny TriwibowoBelum ada peringkat

- TCL CommandsDokumen52 halamanTCL Commandssurya_gaddeBelum ada peringkat

- Back-to-Back Accelerometer CalibrationDokumen3 halamanBack-to-Back Accelerometer CalibrationAekDzLaiBelum ada peringkat

- PDPP - Presentation.3.Concurrent. Engineering - January.2021Dokumen17 halamanPDPP - Presentation.3.Concurrent. Engineering - January.2021Ashish KumarBelum ada peringkat

- Tesp12205pi R1Dokumen36 halamanTesp12205pi R1arabsniperBelum ada peringkat

- 1575 Tania SultanaDokumen10 halaman1575 Tania SultanaTania SultanaBelum ada peringkat

- Standarization of Volumetric SolutionsDokumen9 halamanStandarization of Volumetric SolutionsZahid IqbalBelum ada peringkat

- Optimum Policy ControlDokumen4 halamanOptimum Policy ControlKimberly VargasBelum ada peringkat

- Friction Stir Additive ReviewDokumen34 halamanFriction Stir Additive ReviewpeterBelum ada peringkat

- Sony SDM-N50R PDFDokumen76 halamanSony SDM-N50R PDFFöldi BélaBelum ada peringkat

- Test 4: GRE Real 19Dokumen6 halamanTest 4: GRE Real 19rdrprsdm2640Belum ada peringkat

- Solubility PDFDokumen36 halamanSolubility PDFAshwin Narayan100% (1)

- TELEMETRY TEMPERATURE MONITOR (Project)Dokumen34 halamanTELEMETRY TEMPERATURE MONITOR (Project)Judpraise AkumsBelum ada peringkat

- Astrophysics QuestionsDokumen19 halamanAstrophysics QuestionsMauzoom AliBelum ada peringkat

- Construction Cost EstimatesDokumen25 halamanConstruction Cost EstimatesAnonymous zwnFXURJBelum ada peringkat

- AdsorptionDokumen20 halamanAdsorptionNoreen Guiyab TannaganBelum ada peringkat

- Properties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistDokumen4 halamanProperties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistPaul Schumann50% (2)

- MicroDokumen13 halamanMicroArsalan KhanBelum ada peringkat

- BM2 24H+Installation+InstructionsDokumen7 halamanBM2 24H+Installation+InstructionsremediospereiraBelum ada peringkat

- PLCC-28: FeaturesDokumen5 halamanPLCC-28: Features肖磊Belum ada peringkat

- Hana Table PartitioningDokumen12 halamanHana Table PartitioningGowri Prasanth Chaduvula0% (1)

- Is 4031 Part 4 - ConsistencyDokumen4 halamanIs 4031 Part 4 - ConsistencyCrypto AbhishekBelum ada peringkat

- DREHMO Matic-C ENDokumen36 halamanDREHMO Matic-C ENsimbamikeBelum ada peringkat

- CHAPTER 69 Steering FundDokumen16 halamanCHAPTER 69 Steering FundÆxis QuevedoBelum ada peringkat

- HKV-8 Valve Catalog SPLRDokumen128 halamanHKV-8 Valve Catalog SPLRCabrera RodriguezBelum ada peringkat

- Magnetism: Teacher Notes and Answers 19 MagnetismDokumen3 halamanMagnetism: Teacher Notes and Answers 19 Magnetismmahsan abbas100% (1)

- Upflow Anaerobic Sludge Blanket-Hollow Centered Packed Bed (UASB-HCPB) Reactor For Thermophilic Palm Oil Mill Effluent (POME) TreatmentDokumen12 halamanUpflow Anaerobic Sludge Blanket-Hollow Centered Packed Bed (UASB-HCPB) Reactor For Thermophilic Palm Oil Mill Effluent (POME) TreatmentAgung Ariefat LubisBelum ada peringkat

- FAR21x7 28x7 Operator's Manual P 4-8-11Dokumen312 halamanFAR21x7 28x7 Operator's Manual P 4-8-11Miguel PerezBelum ada peringkat

- Lab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Dokumen4 halamanLab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Penelope MeloBelum ada peringkat