Product Data

Diunggah oleh

khalid764Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Product Data

Diunggah oleh

khalid764Hak Cipta:

Format Tersedia

Product Data

Product Data

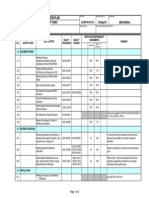

Product Data Sheet

HEMPEL

HEMPALINENAMEL 52140

Description: HEMPALIN ENAMEL 52140 is a glossy alkyd enamel which forms a weather resistant

coating. It is flexible and resistant to salt water and spillage of mineral oil and other

aliphatic hydrocarbons.

Recommended use: As a general purpose finishing coat in alkyd systems on exterior and interior steel

and woodwork in mildly to moderately corrosive environment.

As a finishing coat in engine rooms including tanktops, main engines and auxiliary

machinery.

Service temperatures: Maximum, dry exposure only:

120C/248F (these temperatures may cause yellowing/discoloration).

Certificates/Approvals: Approved as a low flame spread material by Danish, French , Spanish and Singaporian

authorities according to IMO resolution MSC 61 (67).

Has a Danish, French, Spanish, Singaporian and Malaysian EC-type Examination

Certificate.

Please see REMARKS overleaf.

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Colours/Shade nos: White/10000* Black/19990*

Finish: Glossy Glossy

Volume solids, %: 46 1 43 1

Theoretical spreading rate: 15.3 m/litre - 30 micron 14.3 m/litre - 30 micron

615 sq.ft./US gallon - 1.2 mils 575 sq.ft./US gallon - 1.2 mils

Flash point: 38C/100F 38C/100F

Specific gravity: 1.1 kg/litre - 9.2 lbs/US gallon 0.9 kg/litre - 7.5 lbs/US gallon

Surface dry: 2 (approx) hrs at 20C/68F (ISO 1517) 2 (approx) hrs at 20C/68F (ISO 1517)

Dry to touch: 6-8 hours at 20C/68F 6-8 hours at 20C/68F

V.O.C.: 430 g/litre - 3.6 lbs/US gallon 455 g/litre - 3.8 lbs/US gallon

*Other shades according to assortment list.

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas. They are

subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.

APPLICATION DETAILS:

Application method: Airless spray Air spray Brush/Roller

Thinner (max. vol.): 08230 (5%) 08230 (15%) 08230 (5%) (See REMARKS

overleaf)

Nozzle orifice: .018"

Nozzle pressure: 150 bar/2200 psi

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: THINNER 08230

Indicated film thickness, dry: 30 micron/1.2 mils

Indicated film thickness, wet: 75 micron/3 mils

Recoat interval, min: 8 hours (20C/68F)

Recoat interval, max: See REMARKS overleaf

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well ventilated areas.

1/2

Issued: November 2004 Page 1 of 2

Product Data Sheet

APPLICATION As dictated by normal good painting practice.

CONDITIONS: In confined spaces provide adequate ventilation during application and drying.

PREDEDING HEMPALIN PRIMER 12050, HEMPALIN PRIMER HI-BUILD 13200, HEMPALIN UNDERCOAT 42460

COAT: according to specification.

SUBSEQUENT None.

COAT:

REMARKS: Certificates have been issued under the former quality number 5214.

Colours: Certain lead-free red and yellow colours may discolour when exposed to chlorine- containing

atmosphere.

Leaded colours may become discoloured when exposed to sulphide-containing atmosphere.

To obtain full opacity, an extra coat may be necessary, especially for certain lead-free colours in

eg red, orange, yellow and green.

Film thicknesses: May be specified in other filmthicknesses than indicated depending on purpose and area of use.

This will alter spreading rate and may influence drying time and recoat interval. Normal range

30-40 micron/1.2-1.6 mils.

Thinning: THINNER 08080 may be used for spray application, however, with a certain risk of wrinkling of the

preceding fresh coat of HEMPALIN.

Recoating: Recoat intervals related to later conditions of exposure:

(30 micron/1.2 mils dry film thickness of HEMPALIN ENAMEL 52140)

5 days None 8 hours 8 hours 52140

Medium Mild Medium Mild

Atmospheric Atmospheric Recoated with

(quality numbers only)

20C/68F 20C/68F Surface temperature

Maximum Minimum

If the maximum recoat interval is exceeded, roughening of the surface is recommended to ensure

intercoat adhesion.

Before recoating after exposure in contaminated environment, clean the surface thoroughly by

(high pressure) fresh water hosing and allow to dry.

Note: HEMPALIN ENAMEL 52140 is for professional use only.

ISSUED BY: HEMPEL A/S - 5214010000CO017

Issued: November 2004 Page 2 of 2

2/2

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see Explanatory Notes in the HEMPEL Book.

Data, specifications, directions and recommendations given in this data sheet represent only test results or

experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appro-

priateness under the actual conditions of any intended use of the Products herein must be determined exclusively

by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF

SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing. The Manufacturer and Seller

disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence,

except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or

damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

HEMPALIN ENAMEL 52140

Anda mungkin juga menyukai

- Understanding Photography-Master Your Digital Camera and Capture That Perfect Photo by Sean T. McHugh 2019Dokumen319 halamanUnderstanding Photography-Master Your Digital Camera and Capture That Perfect Photo by Sean T. McHugh 2019powergraphics100% (3)

- 355 SaDokumen2 halaman355 Sakhalid764100% (1)

- 355 SaDokumen2 halaman355 Sakhalid764100% (1)

- Gossip Girl - The CarlylesDokumen146 halamanGossip Girl - The CarlylesAlice Jang100% (1)

- Marie ClaireUSA-February 2017Dokumen166 halamanMarie ClaireUSA-February 2017Viktoria Hosszu100% (1)

- Brower, Harriette - Piano Mastery - Talks With Master Pianists and Teachers - Second Series (1917)Dokumen330 halamanBrower, Harriette - Piano Mastery - Talks With Master Pianists and Teachers - Second Series (1917)lazer84100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDari EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsPenilaian: 5 dari 5 bintang5/5 (1)

- Art MovementDokumen39 halamanArt MovementCeejay FrillarteBelum ada peringkat

- RLM 83 GreenDokumen4 halamanRLM 83 GreenMuazBelum ada peringkat

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Dokumen4 halaman1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764Belum ada peringkat

- Gas Sweetening and Processing Field ManualDari EverandGas Sweetening and Processing Field ManualPenilaian: 4 dari 5 bintang4/5 (7)

- Geotextiles and Geomembranes HandbookDari EverandGeotextiles and Geomembranes HandbookT.S. IngoldPenilaian: 5 dari 5 bintang5/5 (1)

- Pressure Test ProceduresDokumen5 halamanPressure Test Procedureszaxader100% (1)

- Copyright InfringementDokumen43 halamanCopyright InfringementAsHervea AbanteBelum ada peringkat

- Arts Throughout HistoryDokumen8 halamanArts Throughout Historyapi-264373083100% (4)

- UntitledDokumen380 halamanUntitledDiana PetreBelum ada peringkat

- Dip Viscosity Cups, Zahn TypeDokumen2 halamanDip Viscosity Cups, Zahn Typedaniela0% (1)

- Method Statement For Surface Preparation Prtective CoatingDokumen10 halamanMethod Statement For Surface Preparation Prtective CoatingJaved MABelum ada peringkat

- Merleau Ponty Cezanne's DoubtDokumen9 halamanMerleau Ponty Cezanne's DoubtFernanda_Pitta_502186% (7)

- Free Paris Walking Tour: Street ArtDokumen17 halamanFree Paris Walking Tour: Street ArtInvisibleParis75% (8)

- TOPOGRAPHICAL BIBLIOGRAPHY OFANCIENT EGYPTIAN HIEROGLYPHIC TEXTS RELIEFS AND PAINTINGS -V-UPPER EGYPT : SITES DEIR RiFA TO ASWAN, EXCLUDING THEBES AND THE TEMPLES OF ABYDOS -DENDERA,ESNA,EDFU,-KOMOMBO AND PHILAE)Dokumen314 halamanTOPOGRAPHICAL BIBLIOGRAPHY OFANCIENT EGYPTIAN HIEROGLYPHIC TEXTS RELIEFS AND PAINTINGS -V-UPPER EGYPT : SITES DEIR RiFA TO ASWAN, EXCLUDING THEBES AND THE TEMPLES OF ABYDOS -DENDERA,ESNA,EDFU,-KOMOMBO AND PHILAE)cravelandBelum ada peringkat

- Pds Hempadur Glass Flake 35851 En-GbDokumen2 halamanPds Hempadur Glass Flake 35851 En-Gbkalpesh parmarBelum ada peringkat

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDari EverandModeling, Control, and Optimization of Natural Gas Processing PlantsPenilaian: 5 dari 5 bintang5/5 (1)

- Hempel Colour ChartDokumen2 halamanHempel Colour Chartkhalid76467% (6)

- PDS Hempathane Topcoat 55210 en-GBDokumen2 halamanPDS Hempathane Topcoat 55210 en-GBJames PittsBelum ada peringkat

- Efal Panofsky e AuerbachDokumen30 halamanEfal Panofsky e AuerbachmatteobensiBelum ada peringkat

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- HEMPALIN ENAMEL 52140 Product Data SheetDokumen2 halamanHEMPALIN ENAMEL 52140 Product Data SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣBelum ada peringkat

- Product DataDokumen2 halamanProduct Dataabdulgafoor54Belum ada peringkat

- Hempalin Enamel 52140Dokumen2 halamanHempalin Enamel 52140ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣ100% (1)

- Protective Coating for Steel StructuresDokumen2 halamanProtective Coating for Steel StructuresJj OredinaBelum ada peringkat

- Hempalin Primer Option-1Dokumen2 halamanHempalin Primer Option-1syammcBelum ada peringkat

- Product DataDokumen2 halamanProduct DataMuhammad AsifBelum ada peringkat

- Hempel's ZP Alkyd Primer 12090Dokumen2 halamanHempel's ZP Alkyd Primer 12090EngTamerBelum ada peringkat

- Hempadur 15130Dokumen2 halamanHempadur 15130MuthuKumarBelum ada peringkat

- HEMPADUR 47140: DescriptionDokumen2 halamanHEMPADUR 47140: DescriptionMashudi FikriBelum ada peringkat

- Pds Hempathane Topcoat 55210 En-GbDokumen2 halamanPds Hempathane Topcoat 55210 En-GbDoni HardiBelum ada peringkat

- 55210Dokumen2 halaman55210whah11Belum ada peringkat

- Pds Hempathane Topcoat 55210 En-GbDokumen2 halamanPds Hempathane Topcoat 55210 En-Gblara_rajkumar667Belum ada peringkat

- Galvocoat 16380Dokumen2 halamanGalvocoat 16380MuhammedHafisBelum ada peringkat

- Pds Hempel's Silicone Acrylic 56940 En-GbDokumen2 halamanPds Hempel's Silicone Acrylic 56940 En-GbsenthilkumarBelum ada peringkat

- PDS HEMPATHANE ENAMEL 55100 en-GBDokumen2 halamanPDS HEMPATHANE ENAMEL 55100 en-GBMohamed NouzerBelum ada peringkat

- Pds Hempathane Topcoat 55210 En-GbDokumen2 halamanPds Hempathane Topcoat 55210 En-GbSachin NambiarBelum ada peringkat

- Product DataDokumen2 halamanProduct DataVentas SA TabBelum ada peringkat

- Glide Speed Product Data SheetDokumen2 halamanGlide Speed Product Data Sheetapi-266933400Belum ada peringkat

- Hempadur 15590Dokumen2 halamanHempadur 15590Yosses Sang NahkodaBelum ada peringkat

- Hempel's Silicone Acrylic 56940Dokumen2 halamanHempel's Silicone Acrylic 56940jeya vasanthBelum ada peringkat

- Tiger Xtra Product Data SheetDokumen2 halamanTiger Xtra Product Data Sheetapi-266933400Belum ada peringkat

- PDS HEMPALIN PRIMER 12050 en-GBDokumen2 halamanPDS HEMPALIN PRIMER 12050 en-GBAsongwe HansBelum ada peringkat

- Pds Hempel's Silicone Aluminium 56910 En-GbDokumen2 halamanPds Hempel's Silicone Aluminium 56910 En-GbjakelowBelum ada peringkat

- DSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetDokumen2 halamanDSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetMehedi HasanBelum ada peringkat

- Hempathane HS 55610Dokumen2 halamanHempathane HS 55610prabha221Belum ada peringkat

- PDS 55910Dokumen2 halamanPDS 55910daimaheshBelum ada peringkat

- PDS Hempadur Hi-Build 45200 en-GBDokumen2 halamanPDS Hempadur Hi-Build 45200 en-GBvitharvanBelum ada peringkat

- 353 SaDokumen2 halaman353 Sakhalid764Belum ada peringkat

- Product Data: Hempacore One FD 43601Dokumen2 halamanProduct Data: Hempacore One FD 43601Khurshid ImamBelum ada peringkat

- PDFDokumen2 halamanPDFMuhammad AsifBelum ada peringkat

- Hempadur 85530Dokumen2 halamanHempadur 85530kumarnowabuBelum ada peringkat

- Hempathane Topcoat Product DataDokumen2 halamanHempathane Topcoat Product DataQA QCBelum ada peringkat

- Hempathane Topcoat Product DataDokumen2 halamanHempathane Topcoat Product DataSanjay TekriwalBelum ada peringkat

- Product DataDokumen2 halamanProduct Dataabdulgafoor54Belum ada peringkat

- Hard Racing Product Data SheetDokumen2 halamanHard Racing Product Data Sheetapi-266933400Belum ada peringkat

- Pds Hempadur Obm 47150 En-GbDokumen2 halamanPds Hempadur Obm 47150 En-GbHuascar Rafael Robles CaceresBelum ada peringkat

- Pds Hempel's Silicone Aluminium 56914 En-GbDokumen2 halamanPds Hempel's Silicone Aluminium 56914 En-GbMatej ZirdumBelum ada peringkat

- Hempadur 15570 15570 En-GbDokumen2 halamanHempadur 15570 15570 En-GbgabyorBelum ada peringkat

- Hempel's Epoxy Resin 05500 Product Data SheetDokumen2 halamanHempel's Epoxy Resin 05500 Product Data SheetaymannasserBelum ada peringkat

- Pds Hempathane Hs 55610 En-GbDokumen2 halamanPds Hempathane Hs 55610 En-GbThines KumarBelum ada peringkat

- Product Data: Hempel'S Silicone Zinc 16900Dokumen2 halamanProduct Data: Hempel'S Silicone Zinc 16900Anuar SalehBelum ada peringkat

- Fast-Drying Epoxy Primer DataDokumen2 halamanFast-Drying Epoxy Primer Datadkdkdkdkdkdk_Belum ada peringkat

- Hempathane Hs 55610 55610 En-GbDokumen2 halamanHempathane Hs 55610 55610 En-GbfaizalBelum ada peringkat

- Pds Hempadur 15130 - 2014Dokumen3 halamanPds Hempadur 15130 - 2014walesh_vx5Belum ada peringkat

- HEMPEL'S PHENOLIC EPOXY 163US Product Data SheetDokumen2 halamanHEMPEL'S PHENOLIC EPOXY 163US Product Data SheetRyan DuhonBelum ada peringkat

- HEMPALIN DANREX 52360 Alkyd Economy PaintDokumen2 halamanHEMPALIN DANREX 52360 Alkyd Economy PaintasxceBelum ada peringkat

- Hempel Product Data SheetDokumen6 halamanHempel Product Data SheetHendri Arief SetyawanBelum ada peringkat

- Hempels Galvosil 15780Dokumen7 halamanHempels Galvosil 15780Yosses Sang NahkodaBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Dari EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Belum ada peringkat

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDari EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryBelum ada peringkat

- Hempadur 4714911150 En-UsDokumen11 halamanHempadur 4714911150 En-Uskhalid764Belum ada peringkat

- HEMPADUR 47140: DescriptionDokumen2 halamanHEMPADUR 47140: DescriptionMashudi FikriBelum ada peringkat

- Surface PrepDokumen7 halamanSurface Prepkhalid764Belum ada peringkat

- 15550Dokumen2 halaman15550khalid764Belum ada peringkat

- Explanatory NotesDokumen10 halamanExplanatory Noteskhalid764Belum ada peringkat

- 81970Dokumen2 halaman81970khalid764Belum ada peringkat

- HEMPEL'S GLASSFIBRE MAT 690SA Product Data SheetDokumen1 halamanHEMPEL'S GLASSFIBRE MAT 690SA Product Data Sheetkhalid764Belum ada peringkat

- Hempel: Hempadur "No Slide" 369saDokumen2 halamanHempel: Hempadur "No Slide" 369sakhalid764Belum ada peringkat

- 15780Dokumen7 halaman15780khalid764Belum ada peringkat

- 06520Dokumen2 halaman06520khalid764Belum ada peringkat

- 568 SaDokumen2 halaman568 Sakhalid764Belum ada peringkat

- 05500Dokumen6 halaman05500khalid764Belum ada peringkat

- Hempel: Hempadur "No Slide" 369saDokumen2 halamanHempel: Hempadur "No Slide" 369sakhalid764Belum ada peringkat

- 12050Dokumen2 halaman12050khalid764Belum ada peringkat

- 528MEDokumen1 halaman528MEkhalid764Belum ada peringkat

- 05990Dokumen2 halaman05990khalid764Belum ada peringkat

- 353 SaDokumen2 halaman353 Sakhalid764Belum ada peringkat

- HEMPEL'S GLASS BEADS Product Data SheetDokumen1 halamanHEMPEL'S GLASS BEADS Product Data Sheetkhalid764100% (1)

- HEMPADUR 47140: DescriptionDokumen2 halamanHEMPADUR 47140: DescriptionMashudi FikriBelum ada peringkat

- HEMPADUR 47140: DescriptionDokumen2 halamanHEMPADUR 47140: DescriptionMashudi FikriBelum ada peringkat

- 691 SaDokumen1 halaman691 Sakhalid764Belum ada peringkat

- HEMPEL'S THINNERS 08 Product Data SheetDokumen2 halamanHEMPEL'S THINNERS 08 Product Data Sheetkhalid764Belum ada peringkat

- 133 SaDokumen2 halaman133 Sakhalid764Belum ada peringkat

- 951GBSDokumen4 halaman951GBSkhalid764Belum ada peringkat

- Hempel Group Health, Safety and Environmental PolicyDokumen1 halamanHempel Group Health, Safety and Environmental Policykhalid764Belum ada peringkat

- Art Appreciation Chapter 4 SummaryDokumen4 halamanArt Appreciation Chapter 4 SummaryDiego A. Odchimar IIIBelum ada peringkat

- Contemporary Art Practices and ProductionDokumen8 halamanContemporary Art Practices and ProductionJuliet DianneBelum ada peringkat

- Create Greeting Card and Calendar in PublisherDokumen3 halamanCreate Greeting Card and Calendar in PublisherAmmar MutuBelum ada peringkat

- DATE:21-12-2018 Refurbishment of Palladium Washroom - Material ListDokumen6 halamanDATE:21-12-2018 Refurbishment of Palladium Washroom - Material ListVishal KediaBelum ada peringkat

- Latinos in The Arts (A To Z of Latino Americans)Dokumen289 halamanLatinos in The Arts (A To Z of Latino Americans)Bruxaria BrasileiraBelum ada peringkat

- LCP LYCORPANEL SpecificationDokumen2 halamanLCP LYCORPANEL SpecificationGarfieldBelum ada peringkat

- Sport On The Barcoo: Governor's Visit A Great SuccessDokumen12 halamanSport On The Barcoo: Governor's Visit A Great SuccessbarcooindependentBelum ada peringkat

- CivilDokumen153 halamanCivilhbuyhbuyBelum ada peringkat

- Eva Respini On The Work of Walid RaadDokumen21 halamanEva Respini On The Work of Walid RaadJP MapleBelum ada peringkat

- Explore the significance of artworks from different periods and culturesDokumen5 halamanExplore the significance of artworks from different periods and culturesRoselyn Relacion LucidoBelum ada peringkat

- 2023 Scouting Month ActivitiesDokumen3 halaman2023 Scouting Month ActivitiesREYNOLD LIBATO100% (1)

- Identity Unit Plan 5th and 6thDokumen3 halamanIdentity Unit Plan 5th and 6thapi-292318834Belum ada peringkat

- Module 1 - Lesson 3 - Contemporary ArtsDokumen17 halamanModule 1 - Lesson 3 - Contemporary ArtsCressia Mhay BaroteaBelum ada peringkat

- Americans Before Columbus Elizabeth Chesley Baity 280 1951Dokumen280 halamanAmericans Before Columbus Elizabeth Chesley Baity 280 1951Jonas BarbosaBelum ada peringkat

- Victaulic DimensionsDokumen2 halamanVictaulic DimensionsSH1961Belum ada peringkat