GM 9

Diunggah oleh

cubillosnelsonDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GM 9

Diunggah oleh

cubillosnelsonHak Cipta:

Format Tersedia

GM9 - 1 of 7 Rev.

1: 1/10/13

adopted 1995

Revision 1 (editorial): January 10, 2013

GRI Test Method GM9

*

Standard Practice for

Cold Weather Seaming of Geomembranes

This specification was developed by the Geosynthetic Research Institute (GRI) with the

cooperation of the member organizations for general use by the public. It is completely optional

in this regard and can be superseded by other existing or new specifications on the subject matter

in whole or in part. Neither GRI, the Geosynthetic Institute, nor any of its related institutes,

warrant or indemnifies any materials produced according to this specification either at this time

or in the future.

1. Scope

1.1 This standard provides guidelines for the field seaming of geomembranes in cold weather.

The applicable temperature range of the geomembrane sheet is from 0 to -15C (32 to 5F).

This practice, however, is not to be considered as all-encompassing since each material and site

specific condition presents its own challenges and special conditions.

1.2 This practice is focused on thermal fusion and extrusion fillet seaming methods for the

seaming of thermoplastic geomembranes.

1.3 This practice is intended to be a guide for those monitoring geomembrane installations as

well as an aid to installers for the seaming of geomembranes in cold climates and conditions.

1.4 This standard may involve hazardous operations, equipment and climates. This standard does

not purport to address all of the safety problems associated with its use. It is the responsibility of

the user of this standard to establish appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use.

*

This GRI standard is developed by the Geosynthetic Research Institute through consultation and review by the

member organizations. This specification will be reviewed at least every 2-years, or on an as-required basis. In this

regard it is subject to change at any time. The most recent revision date is the effective version.

Copyright 1995, 2013 Geosynthetic Institute

All rights reserved

Geosynthetic I nstitute

475 Kedron Avenue

Folsom, PA 19033-1208 USA

TEL (610) 522-8440

FAX (610) 522-8441

GSI

GRI

GII

GAI

GEI

GCI

GM9 - 2 of 7 Rev. 1: 1/10/13

2. Reference Documents

2.1 ASTM Standards:

2.2 EPA Documents:

EPA/530/SW-91/051, "Inspection Techniques for Fabrication of Geomembrane Field Seams"

EPA/600/R-93/182, "Quality Assurance and Quality Control for Waste Containment Facilities"

3. Terminology

3.1 Definitions of Generic Terms

3.1.1 geomembrane - An essentially impermeable geosynthetic composed of one or more

synthetic sheets. (ASTM definition)

3.1.2 destructive tests - Tests performed on geomembrane samples cut from a field

installation or test strip to verify specification performance requirements, e.g., shear and

peel tests of geomembrane seams during which the specimens are tested to failure.

3.1.3 seam shear test - A destructive test in which two seamed sheets on opposite sides of

the seam are pulled in tension placing the seam in a shear mode of stress.

3.1.4 seam peel test - A destructive test in which two seamed sheets on the same side of

the seam are pulled in tension placing the seam in a tensile mode of stress.

3.1.5 Construction Quality Control (CQC) - A planned system of inspections that is used

to directly monitor and control the quality of a construction project. Construction quality

control is normally performed by the geosynthetics installer and is necessary to achieve

quality in the constructed or installed system. Construction quality control (CQC) refers

to measures taken by the installer or contractor to determine compliance with the

requirements for materials and workmanship as stated in the plans and specifications for

the project.

3.1.6 Construction Quality Assurance (CQA) - A planned system of activities that

provides the owner and permitting agency assurance that the facility was constructed as

specified in the design. Construction quality assurance includes inspections, verifications,

audits, and evaluations of materials and workmanship necessary to determine and

document the quality of the constructed facility. Construction quality assurance (CQA)

refers to measures taken by the CQA organization to determine if the installer or

contractor is in compliance with the plans and specifications of the project.

3.2 Description of Terms Specific to This Standard

3.2.1 field seams - The seaming of geomembrane rolls or panels together in the field

making a continuous liner system. Synonymous with production seams.

GM9 - 3 of 7 Rev. 1: 1/10/13

3.2.2 trial seams - Trial sections of seamed geomembranes used to establish machine

settings of temperature, pressure and travel rate for a specific geomembrane under a

specific set of atmospheric conditions for machine-assisted seaming as well as

establishing procedures to be correctly used by the installation personnel.

3.2.3 test strips - Synonymous with "trial seams".

3.2.4 test welds - Synonymous with "trial seams".

3.2.5 thermal fusion seams - A seam which involves the temporary, thermally-induced

reorganization in the polymer structure at the surface of two opposing geomembrane

sheets which, after the application of pressure and the passage of a certain amount of

time, results in the two geomembranes being permanently joined together.

3.2.6 mouse - Synonymous term for hot wedge, or hot shoe, seaming device.

3.2.7 extrusion fillet seams - A seam between two geomembrane sheets achieved by heat-

extruding a ribbon of molten polymer over the overlap areas followed by the application

of a nominal amount of pressure which results in the two geomembrane sheets being

permanently joined together.

3.2.8 gun - Synonymous term for hand held extrusion fillet seaming device.

4. Significance and Use

4.1 Most federal and state environmental regulations call for special procedures for field seaming

of geomembranes when sheet temperatures are less than 0C (32F). This standard practice is

meant to give procedural guidance for seaming of geomembranes at sheet temperatures down to -

15C (5F). Geomembrane seaming at temperatures below -15C (5F) is not generally

recommended from both material and personnel perspectives.

4.2 The standard is focused on the two main types of thermal seaming methods, thermal fusion

and extrusion fillet methods, where trial seam tests and production seam tests can be conducted

within minutes after the seam is fabricated.

5. Procedure

5.1 Preparation of the geomembrane surfaces to be seamed:

5.1.1 Seaming is not to take place when it is snowing, sleeting or hailing on the

geomembrane in the area to be seamed.

5.1.2 In the area to be seamed, all frost must be removed from the opposing surfaces of

the geomembrane sheets in the regions where the actual seaming is to be performed.

5.1.3 The residual moisture left after removing frost must be wiped dry.

GM9 - 4 of 7 Rev. 1: 1/10/13

Note 1: Perhaps the most difficult surfaces to prepare in this regard are textured

geomembranes where the texturing extends to the roll edges or roll ends.

5.1.4 The application of heat to remove moisture using a hand held hot air device can be

used providing care against excessive heat application is taken. An assessment using trial

seams is recommended.

5.1.5 The specific area to be seamed must be free of soil particles and other foreign

matter.

5.1.6 For thermal fusion welding, such as the hot wedge method, the under side of the

lower sheet should be free of frost so that the lower drive wheels of the device can move

evenly and do not slip.

Note 2: It may be necessary to use a rub sheet beneath the area being seamed to

separate the geomembrane from frozen soil subgrade. Various materials have

been used for rub sheets including smooth membranes, smooth films and even

certain types of geotextiles.

5.1.7 For fillet extrusion welding the thermal tacking of the sheets together should

proceed as with similar welding at temperatures above freezing.

5.1.8 Preheating of the geomembrane area to be seamed is common but the amount of

preheat and its timing preceding the actual production seaming is at the option of the

installer based upon past practice and experience. An assessment using trial seams is

recommended.

5.2 Thermal fusion seaming (e.g., using a hot wedge welding device):

5.2.1 In general, the rate of seaming, i.e., the speed of the hot wedge device, is usually

slower than when seaming at temperatures above 0C (32F). Furthermore, the rate

should decrease with decreasing sheet temperature.

5.2.2 Cold temperature seaming requires more frequent trial seams than when welding at

temperatures above freezing. For example, if the CQA plan calls for two trial seams a day

at temperatures above freezing, the number should be increased by one per day for each

7.5C (13.5F) less than freezing. Trial seams should be made at the discretion of the

CQA Engineer.

5.2.3 Cold temperature seaming may also require more destructive tests on production

seams than when welding above freezing. For example, in addition to the CQA plan

written around above freezing temperatures, additional destructive seam samples may be

taken at the end(s) of each continuous production seams.

Note 3: The actual schedule for destructive test samples is at the discretion of the

CQA Engineer.

GM9 - 5 of 7 Rev. 1: 1/10/13

5.2.4 Movable enclosures (i.e., tents) traveling along with the welding device and

personnel are particularly effective at sites with high wind. Cold temperature, per se, will

not demand the use of protective tents. The decision to use tents is that of the installer and

CQC personnel.

5.3 Extrusion fillet seaming:

5.3.1 The necessary grinding of the geomembrane surfaces in preparation of placing

extrudate should be no further ahead of the extrusion gun than 10 m (30 ft.), or as stated

in the CQA plan.

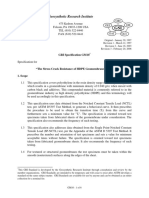

5.3.2 At the discretion of the parties involved, the profile of the base of the extrusion gun

barrel is often shaped more rectangularly than when seaming at temperatures above

freezing. The reason for this is to minimize the cooling rate in the thinner extrudate

regions, see Figure 1.

"flashing"

contoured

extrudate

"flashing"

rectangular

extrudate

(a) Typical Cross Section for (b) Alternative Cross Section for

Temperatures > 0C Temperatures < 0C

Figure 1 - Extrusion Fillet Patterns

5.3.3 In general, the rate of seaming, i.e., the speed of travel, is slower than when

seaming at temperatures above 0 (32F). Furthermore, the rate should decrease with

decreasing sheet temperatures.

5.3.4 Cold temperature seaming requires more frequent trial seams than when welding at

temperatures above freezing. For example, if the CQA plan calls for two trial seams a day

at temperatures above freezing, the number should be increased by one per day for each

7.5C (13.5F) less than freezing. Trial seams should be made at the discretion of the

CQA Engineer.

5.3.5 Cold temperature seaming may also require more destructive tests on production

seams than when welding above freezing. For example, in addition to the CQA plan

written around above freezing temperatures, additional destructive seam samples may be

taken at the end(s) of each continuous production seam.

Note 4: The actual schedule for destructive test samples is at the discretion of the

CQA Engineer.

GM9 - 6 of 7 Rev. 1: 1/10/13

5.3.6 Movable enclosures (i.e., tents) traveling along with the welding device and

personnel are particularly effective at sites with high wind. Cold temperature, per se, will

not demand the use of protective tents. The decision to use tents is that of the installer and

CQC personnel.

5.4 Seam Testing

5.4.1 In general, destructive testing of seams (both shear and peel) made in cold

temperatures should follow the same protocol and test methods as for temperatures above

freezing.

5.4.2 Destructive seam samples for CQA purposes should be taken as described

previously and sent to the laboratory for testing at the designated test method conditions

for above freezing temperatures.

5.4.3 Seam tests from trial seams can be taken to a field trailer, allowed to equilibrate to

the designated test temperature and tested accordingly. However, seam tests from trial

seams which are tested with a tensiometer on-site at temperatures less than freezing

cannot be compared to geomembrane sheet strengths at room temperature. Numerous

invalid results will occur if this procedure is practiced. Instead, the field tensiometer must

be used to determine the strength of the unseamed geomembrane sheets at the same

temperature as the seam test. The apparent strength will be higher as the temperature of

the test specimen decreases. Acceptance of the trial seam is then based on the percentages

of sheet strength as prescribed in the CQA plan, e.g., 90% in shear and 62% in peel for

HDPE geomembranes.

Note 5: This type of testing whereby the seam test specimen results are compared

to a single value of sheet strength is contentious since the value of sheet strength

is not statistically reliable. Agreement by the parties involved is necessary.

6. CQA Report

6.1 The report should include hourly temperatures during cold weather seaming which includes

the actual temperature of the surface of the geomembrane (using a pyrometer) and the ambient

air temperature measured approximately 1 m (3 ft.) above the geomembrane.

6.2 The method of removing frost from the area to be seamed (if any is present), as well as

drying and cleaning of the surfaces involved, should be described.

6.3 The condition of the subgrade beneath the area being seamed should be assessed. If a rub

sheet is used during the seam process it should be noted.

6.4 Complete identification of the field seaming system used, including material, methods,

preheat, seaming rate, use of tents or enclosures and other details of the procedure should be

documented.

GM9 - 7 of 7 Rev. 1: 1/10/13

6.5 The type, nature, number, condition and details of trial seams, as well as the results of such

tests, should be detailed.

6.6 The type, nature, number and details of destructive samples and disposition of sections of the

sample should be described. Proper identification is required to identify results of CQA

laboratory testing in the final as-built plans of the project.

6.7 Any unusual condition with respect to personnel, equipment, sampling and/or testing that

may be attributable to the cold weather should be described and documented.

Anda mungkin juga menyukai

- GM19 Geosynthetic PDFDokumen13 halamanGM19 Geosynthetic PDFRicardo RodriguezBelum ada peringkat

- Geosynthetic Institute: GRI Test Method GM19Dokumen13 halamanGeosynthetic Institute: GRI Test Method GM19piterdiaBelum ada peringkat

- GRI GM19aDokumen13 halamanGRI GM19aAllen EstelaBelum ada peringkat

- gm19 - GEOMEMBRANASDokumen13 halamangm19 - GEOMEMBRANASIsaias Quispe RuizBelum ada peringkat

- Astm D6392 23Dokumen2 halamanAstm D6392 23ailennoraliBelum ada peringkat

- ASTM-D7408-12-2020-Shear Test and Peel TestDokumen2 halamanASTM-D7408-12-2020-Shear Test and Peel Testoktarama rifaiBelum ada peringkat

- GRI-GM19a Standard SpecificationDokumen13 halamanGRI-GM19a Standard Specificationwati moeljonoBelum ada peringkat

- gm19b PDFDokumen11 halamangm19b PDFJuan MansillaBelum ada peringkat

- Geosynthetic Institute: GRI Test Method GM29Dokumen17 halamanGeosynthetic Institute: GRI Test Method GM29mBelum ada peringkat

- Iagi - May07 - Hdpeinstallfinal EnglishDokumen22 halamanIagi - May07 - Hdpeinstallfinal EnglishLuciano SalituriBelum ada peringkat

- Testing of Factory Thermo-Fusion Seams For Fabricated Geomembrane PanelsDokumen3 halamanTesting of Factory Thermo-Fusion Seams For Fabricated Geomembrane PanelsasmaBelum ada peringkat

- Gri GT 12Dokumen14 halamanGri GT 12gadBelum ada peringkat

- MOS HDPE Lining General Rev.8 - 1-4-2019 DG PDFDokumen13 halamanMOS HDPE Lining General Rev.8 - 1-4-2019 DG PDFahmadBelum ada peringkat

- Astm D 7408 - 12Dokumen5 halamanAstm D 7408 - 12darthluissBelum ada peringkat

- Astm D7747 D7747M 11Dokumen3 halamanAstm D7747 D7747M 11Samer MohamedBelum ada peringkat

- Astm D 6214 D6214M-98Dokumen4 halamanAstm D 6214 D6214M-98darthluiss100% (1)

- Determining The Integrity of Factory Seams Used in Joining Manufactured Flexible Sheet GeomembranesDokumen3 halamanDetermining The Integrity of Factory Seams Used in Joining Manufactured Flexible Sheet GeomembranesEdmundo Jaita CuellarBelum ada peringkat

- Non Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForDokumen5 halamanNon Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForLupita RamirezBelum ada peringkat

- Installation Guideline: Technical InformationDokumen40 halamanInstallation Guideline: Technical InformationMohsen HalweniBelum ada peringkat

- ASTM D 4545-86 Standard Practice For Determining The Integrity of Factory Seams Used in Joining Manufactured Flexible Sheet GeomembranesDokumen3 halamanASTM D 4545-86 Standard Practice For Determining The Integrity of Factory Seams Used in Joining Manufactured Flexible Sheet GeomembranesPablo Antonio Valcárcel VargasBelum ada peringkat

- D7982 15 (Reapproved 2021)Dokumen2 halamanD7982 15 (Reapproved 2021)Samer MohamedBelum ada peringkat

- Astm D6392 12 2018Dokumen3 halamanAstm D6392 12 2018ailennoraliBelum ada peringkat

- GT 7Dokumen13 halamanGT 7Mostafa AbdellaBelum ada peringkat

- Determining The Integrity of Field Seams Used in Joining Flexible Polymeric Sheet GeomembranesDokumen3 halamanDetermining The Integrity of Field Seams Used in Joining Flexible Polymeric Sheet GeomembranesEdmundo Jaita CuellarBelum ada peringkat

- Geosynthetic Institute: GRI Test Method GT10Dokumen9 halamanGeosynthetic Institute: GRI Test Method GT10Григорий ЛевашовBelum ada peringkat

- ASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsDokumen6 halamanASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsMoeketsi KhubeluBelum ada peringkat

- Determining The Tensile Shear Strength of Pre-Fabricated Bituminous Geomembrane SeamsDokumen3 halamanDetermining The Tensile Shear Strength of Pre-Fabricated Bituminous Geomembrane SeamsDanZel DanBelum ada peringkat

- Astm d6392Dokumen6 halamanAstm d6392Danilo Rojas MartinezBelum ada peringkat

- D5820-95 (Reapproved 2011)Dokumen3 halamanD5820-95 (Reapproved 2011)mithileshBelum ada peringkat

- ASTM D6392 2012 Rev 2018 PDFDokumen6 halamanASTM D6392 2012 Rev 2018 PDFWard BentBelum ada peringkat

- GM 13Dokumen11 halamanGM 13cubillosnelsonBelum ada peringkat

- Test Methods, Test Properties and Testing Frequency For High Density Polyethylene (HDPE) Smooth and Textured GeomembranesDokumen11 halamanTest Methods, Test Properties and Testing Frequency For High Density Polyethylene (HDPE) Smooth and Textured Geomembranesgeo_unoBelum ada peringkat

- D 1970 - 00 Rde5nzatukveDokumen7 halamanD 1970 - 00 Rde5nzatukvedaovandongpktBelum ada peringkat

- Gri GM13Dokumen11 halamanGri GM13Mauricio PerezBelum ada peringkat

- IAGI Hdpe Installation SpecDokumen18 halamanIAGI Hdpe Installation Speccorrundum_vBelum ada peringkat

- Gri GM 13Dokumen14 halamanGri GM 13dadang2121Belum ada peringkat

- Astm D 6392 - 12Dokumen6 halamanAstm D 6392 - 12darthluissBelum ada peringkat

- Astm D 5397Dokumen7 halamanAstm D 5397yuBelum ada peringkat

- Geosynthetic Institute: GRI Test Method GM13Dokumen11 halamanGeosynthetic Institute: GRI Test Method GM13Nolo Araya GaeteBelum ada peringkat

- Hydrostatic Pressure Resistance of Waterproofing Membranes: Standard Test Method ForDokumen3 halamanHydrostatic Pressure Resistance of Waterproofing Membranes: Standard Test Method ForSiddesh VinchurkarBelum ada peringkat

- Astm d7272Dokumen6 halamanAstm d7272Manuel ContrerasBelum ada peringkat

- Gs 11Dokumen7 halamanGs 11Dimas NugrahaBelum ada peringkat

- Astm d6392Dokumen6 halamanAstm d6392Talca CalderónBelum ada peringkat

- D 3903 - 00 - Rdm5mdmtukveDokumen5 halamanD 3903 - 00 - Rdm5mdmtukvePrakash MakadiaBelum ada peringkat

- F 1921 PDFDokumen9 halamanF 1921 PDFjai soniBelum ada peringkat

- 10-C1262 10 Standard Test Method ForDokumen5 halaman10-C1262 10 Standard Test Method ForAlireza AzarioonBelum ada peringkat

- D 3771 - 00 - Rdm3nzetukveDokumen5 halamanD 3771 - 00 - Rdm3nzetukvePrakash MakadiaBelum ada peringkat

- GM 10Dokumen6 halamanGM 10Dimas NugrahaBelum ada peringkat

- Geosynthetic Institute: GRI Standard Practice GG4 (B)Dokumen13 halamanGeosynthetic Institute: GRI Standard Practice GG4 (B)irsanBelum ada peringkat

- ASTM D 6392-99 Thermo-FusionDokumen6 halamanASTM D 6392-99 Thermo-FusionSantiago MiguesBelum ada peringkat

- Effects of Temperature On Stability of Geotextiles: Standard Test Method ForDokumen3 halamanEffects of Temperature On Stability of Geotextiles: Standard Test Method ForAlabbas FadhelBelum ada peringkat

- Test Method For Determining The Flammability of Interior Trim MaterialsDokumen18 halamanTest Method For Determining The Flammability of Interior Trim MaterialsJefferson CruzBelum ada peringkat

- D 6214 - 98 - RdyymtqtotgDokumen4 halamanD 6214 - 98 - RdyymtqtotgCasey RybackBelum ada peringkat

- IAGI HDPE-LLDPE Geomembrane Installation Spec - May07 - SpanishDokumen19 halamanIAGI HDPE-LLDPE Geomembrane Installation Spec - May07 - SpanishCesar SoncoBelum ada peringkat

- Air Channel Evaluation of Polyvinyl Chloride (PVC) Dual Track Seamed GeomembranesDokumen3 halamanAir Channel Evaluation of Polyvinyl Chloride (PVC) Dual Track Seamed GeomembranesdarthluissBelum ada peringkat

- Hail Impact Resistance of Aerospace Transparent Enclosures: Standard Test Method ForDokumen8 halamanHail Impact Resistance of Aerospace Transparent Enclosures: Standard Test Method Forjun floresBelum ada peringkat

- Gri GM 20Dokumen6 halamanGri GM 20darthluissBelum ada peringkat

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorDari EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorBelum ada peringkat

- GM 13Dokumen11 halamanGM 13cubillosnelsonBelum ada peringkat

- Chemical Resistance ChartDokumen2 halamanChemical Resistance ChartcubillosnelsonBelum ada peringkat

- 2.3 Configuration Management PlanDokumen9 halaman2.3 Configuration Management PlancubillosnelsonBelum ada peringkat

- 2.7 Procurement Management PlanDokumen11 halaman2.7 Procurement Management PlancubillosnelsonBelum ada peringkat

- 1.3 Project Charter LongDokumen8 halaman1.3 Project Charter LongcubillosnelsonBelum ada peringkat

- Green Roofs EpaDokumen29 halamanGreen Roofs EpaFabian CubillosBelum ada peringkat

- Genetically Engineered MicroorganismsDokumen6 halamanGenetically Engineered Microorganismsaishwarya joshiBelum ada peringkat

- 10059-DC-K-01-A Design BasisDokumen34 halaman10059-DC-K-01-A Design BasisAnonymous RvIgDUBelum ada peringkat

- FinalsDokumen8 halamanFinalsDumpBelum ada peringkat

- Chemical and Physical Properties of Refined Petroleum ProductsDokumen36 halamanChemical and Physical Properties of Refined Petroleum Productskanakarao1Belum ada peringkat

- Owners Manual Water Mist PDFDokumen6 halamanOwners Manual Water Mist PDFZeeBelum ada peringkat

- RHS NCRPO COVID FormDokumen1 halamanRHS NCRPO COVID Formspd pgsBelum ada peringkat

- English III Module 2 Simple Present Job and Job VerbsDokumen4 halamanEnglish III Module 2 Simple Present Job and Job VerbsAdrian CortesBelum ada peringkat

- Ucg200 12Dokumen3 halamanUcg200 12ArielBelum ada peringkat

- TDS Versimax HD4 15W40Dokumen1 halamanTDS Versimax HD4 15W40Amaraa DBelum ada peringkat

- MAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFDokumen2 halamanMAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFXavi AnpiBelum ada peringkat

- Kertas Trial English Smka & Sabk K1 Set 2 2021Dokumen17 halamanKertas Trial English Smka & Sabk K1 Set 2 2021Genius UnikBelum ada peringkat

- Clinical Case Report No 2Dokumen11 halamanClinical Case Report No 2ملک محمد صابرشہزاد50% (2)

- MLS 321 Aubf M6u2 Other Metabolic Diseases V2122Dokumen7 halamanMLS 321 Aubf M6u2 Other Metabolic Diseases V2122proximusBelum ada peringkat

- Alok ResumeDokumen3 halamanAlok Resumealok choudharyBelum ada peringkat

- Practical Examination Marking Guideline Grade 12 Physical Science 2019 PDFDokumen5 halamanPractical Examination Marking Guideline Grade 12 Physical Science 2019 PDFWonder Bee Nzama100% (1)

- Position paper-MUNUCCLE 2022: Refugees) Des États !Dokumen2 halamanPosition paper-MUNUCCLE 2022: Refugees) Des États !matBelum ada peringkat

- 7 Surprising Cyberbullying StatisticsDokumen4 halaman7 Surprising Cyberbullying StatisticsJuby Ann Enconado100% (1)

- 559 Fault CodeDokumen4 halaman559 Fault Codeabdelbagi ibrahim100% (1)

- Jounce Therapeutics Company Events and Start DatesDokumen48 halamanJounce Therapeutics Company Events and Start DatesEquity NestBelum ada peringkat

- Social Studies SbaDokumen12 halamanSocial Studies SbaSupreme KingBelum ada peringkat

- Carpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesDokumen105 halamanCarpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesVinod KumarBelum ada peringkat

- OC - PlumberDokumen6 halamanOC - Plumbertakuva03Belum ada peringkat

- Gate Installation ReportDokumen3 halamanGate Installation ReportKumar AbhishekBelum ada peringkat

- Arp0108 2018Dokumen75 halamanArp0108 2018justin.kochBelum ada peringkat

- Past The Shallows EssayDokumen2 halamanPast The Shallows EssaycaitlinBelum ada peringkat

- VIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhDokumen3 halamanVIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhÝ Nguyễn NhưBelum ada peringkat

- 1 Colmac DX Ammonia Piping Handbook 4th EdDokumen64 halaman1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoBelum ada peringkat

- Base para Detectores de Humo y Temperatura KIDDE KI-SBDokumen2 halamanBase para Detectores de Humo y Temperatura KIDDE KI-SBAnderson CastañedaBelum ada peringkat

- Construction and Operation 1. Air Conditioning Control PanelDokumen18 halamanConstruction and Operation 1. Air Conditioning Control PanelRoma KuzmychBelum ada peringkat

- Q1 Tle 4 (Ict)Dokumen34 halamanQ1 Tle 4 (Ict)Jake Role GusiBelum ada peringkat