Corrosion in HotGas Plants

Diunggah oleh

Anonymous yQ7SQrHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Corrosion in HotGas Plants

Diunggah oleh

Anonymous yQ7SQrHak Cipta:

Format Tersedia

Volume 6 Paper C042

Corrosion in Hot Gas Converters of Sulphuric Acid Plant

M.B. Ives, K.S. Coley and J. Rodda

Walter W. Smeltzer Corrosion Laboratory, McMaster University, Hamilton, Ont. L8S 4L7

Abstract

Weight loss measurements on a range of austenitic stainless steels exposed for up to three years in

the hotter sections of SO

2

/SO

3

converters of sulphuric acid plants are compared with the behaviour

of similar steels in laboratory-controlled gravimetric experiments in simulated sulphur-containing

atmospheres. The plant data indicate that the alloy currently in common use, S30409, exhibits

accelerated corrosion above 630C. However, the microstructure is quite stable, with only some

sensitization evident in the periods under study. High silicon stainless steels are shown to have

superior corrosion resistance at all operating temperatures, but microstructural variations, such as

the precipitation of silicon-rich phases, suggest the need for additional mechanical property analysis

on the exposed alloys.

Microstructural examination of the scales formed on the alloys after plant exposure indicate that

S30409 corrodes by the formation of a sulphate phase which is not protective. The high-silicon

alloys demonstrate superior corrosion resistance which is attributed to a silicon-rich phase at the

oxide-metal interface.

Keywords

Sulphuric acid production, hot gas converter, sulphur dioxide, stainless steels, silicon effects

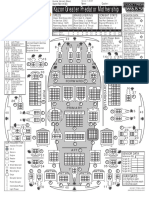

Figure 1. Schematic of a Converter

and Hot Heat Exchanger

Figure 2

Introduction

Many sulphuric acid plants in Canada

use the off-gas from metal smelting

operations. Corrosion of the hot gas

converter heat exchangers, main body

and catalyst support systems has been

found to produce significant quantity of

scale in the gas stream, requiring regular

screening of the catalyst beds,

sometimes at higher frequencies than

regular scheduled maintenance.

Converter and Heat Exchanger

Configuration

The hot gas converter system is

designed to optimize the reaction

whereby SO

2

is converted to SO

3

. It is a

system of vessels which consists of the

converter, usually containing four beds

of V

2

O

5

catalysts, with heat exchangers

located after each catalyst bed, which utilise the heat of the reaction to preheat the incoming gas to

the reaction temperature, and cool the reacted gas.

A schematic is shown in Figure 1. For simplicity only the one of the heat exchangers is

shown. This heat exchanger is located in the gas stream directly after the 1

st

bed, where the majority

of the conversion takes place, the majority of heat is generated, and thus is called the hot heat

exchanger. It is the only process vessel between the 1

st

and 2

nd

catalyst beds, and therefore the tubes

of this heat exchanger, along with the 1

st

bed support structure and the associated gas ducts,

represent the sources of the scale which foul the catalyst bed.

The photograph in Figure 2 shows the bottom vestibule

of the hot exchanger with some loose scale clearly

visible in the tubes.

In the plant where the 2

nd

and 3

rd

bed fouling is the most

serious, the materials of construction are AISI 304H for

the converter vessel walls, ducting and heat exchanger,

while AISI 321 was used as the support screen for the

catalyst bed.

The Alloy Coupon Programme

Over the last few years, a series of (stainless steel) alloys were mounted on racks and

mounted within the hot gas converters. The programme called for two coupon racks of alloys to be

Figure 3, Coupon rack exposure program.

inserted into each of five Canadian acid plants. One coupon rack would be placed at the exit of the

first catalyst bed (the hottest region of the converter), and one in the gas stream before it enters the

second catalyst bed. It was supposed that the gas content would be the same at these two locations,

with gas temperature the only variable. Additionally, in one plant a coupon rack was placed below

the 2

nd

pass to obtain an intermediate temperature.

The access to the converter is limited to the normal operating cycle of the plant. The

converter is only opened for catalyst screening, which is scheduled to coincide with the maintenance

shut-down of the smelter. These shut-downs are not always scheduled annually, but are taken when

required. This meant that the coupons would be installed at one shutdown and removed at the next,

and the duration of the exposure was fixed by the plant operations. A summary of the actual

exposure periods is provided in Figure 3.

Stainless Steels Studied

Table 1 lists the alloys used in this project, along with the detailed compositions for each

alloy from the mill specifications provided by the steel supplier.

TABLE 1, Composition of Alloys

AISI - Trade &

Heat No.

UNS

No. Cr Ni Mn Si Mo C N Cu Other

304H-32562-4A S30409 18.27 8.24 1.57 0.37 0.36 0.050 0.060 0.41

304H-576370 S30409 18.43 8.53 1.35 0.45 0.058 0.057

321H-461740 S32109 17.14 9.05 1.25 0.43 0.34 0.044 0.010

0.3-0.5 Ti

321H-383153 S32109 17.23 9.12 1.43 0.62 0.043 0.013

0.4 Ti

309-82451-4D S30900 22.41 12.23 1.67 0.44 0.34 0.060 0.080 0.22

310-84062-2A S31000 25.32 19.26 1.50 0.53 0.32 0.040 0.030 0.24

33-55027 R20033 32.75 31.35 0.63 0.3 1.49 0.012 0.4 0.54

KHR 35H.HiSi 25.00 35.00 1.50 1.75 1.5 0.450

253MA S31254 21.00 11.00 0.80 1.75 0.080 0.180

45TM-31854 27.50 46.75 0.31 2.70 0.100 0.05

0.08Ce

RA85H- 045908LL1 18.53 14.73 0.31 3.61 0.01 0.204 0.006 0.01

0.8 Al, 0.0005B, 0.01 Nb

1815LCSI- 20919 S30600 18.25 15.40 1.39 4.35 <0.01 0.005 0.011

A611-R32916 S30601 17.30 17.33 0.61 5.26 0.010 0.017

A611-R31670 S30601 17.25 17.21 0.70 5.17 0.004 0.017

2509- 66009 9.25 24.55 1.40 7.05 0.007

In addition some experimental surface-alloyed samples were produced using a pack cementation

technique, which diffused aluminum and silicon into the surfaces of 304H samples.

Plant Operating Data

Operating data was collected from the plants in hourly averages for the full exposure periods.

This included the temperatures, above and below the catalyst beds where the racks were exposed,

and the %SO

2

and %O

2

gas contents entering the plant.

This data provided information on the number of shutdowns and temperature excursions

occurring during each exposure period. Histograms of the data were prepared to obtain averages for

the temperatures and observe the spread in temperature.

Since the exposure durations were quite long, much of the scale had spalled by the time of

sample removal. Therefore the samples were cleaned of all retained scale using a glass bead blast,

and the corrosion rate was calculated from the weight loss data.

Corrosion Rates Measured

The 1 year corrosion rates as a function of temperature are summarized below for all the

samples in all the plants, for S30409 (Figure 4a), alloys with higher chromium and nickel content

(Figure 4b), and for the high silicon alloys (Figure 5).

0

1

2

3

4

5

6

7

400 450 500 550 600 650

Temperature, C

C

o

r

r

o

s

i

o

n

R

a

t

e

,

m

p

y

S30900 S31000 R20033

Figure 4b. Corrosion of tested alloys high in chromium and nickel.

0

1

2

3

4

5

6

7

400 450 500 550 600 650

Temperature, C

C

o

r

r

o

s

i

o

n

R

a

t

e

,

m

p

y

Figure 4a, Corrosion of S30409 as a function of temperature, 1 year exposures

I t is clear

that all t h e

a l l o y s included

in Figures 4A a nd

4b exhibit increase

d corrosio

n rat es a b o v e

6 0 0 C , and that

increasin g t h e

chromium a n d

n i c k e l contents

i s n o t effective

at these higher operating temperatures.

The corrosion rates of the alloys containing more than 1% silicon are substantially better at

the higher temperatures, as seen in Figure 5. The influence of the amount of alloyed silicon in the

alloys is shown in Figure 6.

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

0.0 1.0 2.0 3.0 4.0 5.0 6.0

% (wt) Si

C

o

r

r

o

s

i

o

n

R

a

t

e

,

m

p

y

Ni Base Alloy

High C Alloy,

Sensitized

Figure 6. Effect of alloyed silicon on corrosion rates at 635C,

(2-year exposures)

0

1

2

3

4

5

6

7

400 450 500 550 600 650

Temperature, C

C

o

r

r

o

s

i

o

n

R

a

t

e

,

m

p

y

253MA RA85H A610 A611 2509

Figure 5,

Corrosion of high Silicon alloys, 1 year exposures.

It is clear that increasing silicon increases the corrosion resistance. However, for effective

application it is important to appreciate the mechanical behaviour of the Si-containing alloys, since

silicon is frequently considered an embrittling species in iron-base alloys.

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0 5000 10000 15000 20000 25000 30000

Elapsed Time, hours

W

e

i

g

h

t

L

o

s

s

/

A

r

e

a

,

g

/

c

m

2

304H year 1 304H year 2 304H year 3

304H 2 years 304H 3 years Add year 1 + 2

Add year 1+ 2+ 3

Figure 8, Multiple years analysis for S30409 at 620

o

C, below bed 1

0.00

0.02

0.04

0.06

0.08

0.10

0 5000 10000 15000 20000 25000 30000

Elapsed Time, hours

W

e

i

g

h

t

L

o

s

s

/

A

r

e

a

,

g

/

c

m

2

304H year 1 304H year 2 304H year 3

304H 2 years 304H 3 years Add year 1 + 2

Add year 1+ 2+ 3

Figure 7, multiple years exposure for S30409 at 420

C, above bed 2

In order to clarify the time dependence of corrosion rates, it is instructive to superimpose the

rate measurements from 1, 2, and 3 year exposures in a given plant. These are shown graphically

in Figures 7 (for samples placed at the lower temperature, 420C) and Figure 8 (for samples at

620C).

Figure 9. S30409 not exposed in plant Figure 10. S30409, 1 year at 635C

Conclusions from the Coupon Exposure Measurements

The results summarized above indicate that the corrosion rate of the alloy currently the most

commonly used in converters, S30409, and other stainless steels with higher content of chromium

and nickel, experience significant corrosion above about 625C (Figure 4), suggesting a prime cause

of bed fouling when converters are operated above this temperature. The silicon-containing alloys

exhibit much lower corrosion rates at these temperatures (Figure 5), with even better performance

as the Si alloy level is increased (Figure 6), suggesting good alloy candidates for future plant,

assuming their mechanical properties are acceptable. In this regard the creep strength of S30600

alloy, containing over 4% Si, has been determined

1

to be quite similar to S30409.

The multiple-year comparisons suggest that at the lower temperatures, corrosion rates

decrease with time over a 3-year period such that superpositioning the rates for the individual years

sum to much less than the measured rate of the 2- and 3-year samples (Figure 7). However, at the

higher temperature (Figure 8) the superpositions indicate a better correlation among the multi-year

samples. One conclusion

2

from this observation is that spalling of the scales occurs within one year

at the higher temperature so that each sample is regularly reduced back to bare metal, whereas at

the lower temperature, the scale is more adherent. The topic of scale spalling will be discussed

further below.

Scale Microstructure

Samples removed from the exposed racks, after cleaning of the scale, were

metallographically prepared to determine microstructural modification occurring during exposure.

The stainless steel samples were etched by swabbing with a modified Glyceregia etchant

3

. The

following micrographs were originally obtained at 320X magnification. Figures 9-12 suggest some

grain boundary sensitization over the 3-year period, but no changes which might suggest

significant degradation of mechanical performance.

Figure 11. S30409, 2 years at 635C

Figure 12. S30409, 3 years exposure at 635C

Figure 13. S30601, unexposed

Figure 14. S30601, 1 year at 635C

Similar micrographs for the 5% Si alloy S30601 after shown in Figures 13 to 16. The high

silicon content appears to modify the microstructure significantly after 3-years exposure on the same

racks as the S31609 coupons shown above. Figure 16 indicates a profound change in the alloy,

presumably by the precipitation of a Si-rich phase which is readily etched. This alloy also exhibits

a distinctive subscale below the exposed surface.

Figure 15. S 30601, 2 years at 635C

Figure 16. S30601, 3 year at 635C

Figure 18. S30600, 3 year exposure at 625C,

(lower magnification)

Figure 17. S30600, 1 year exposure at 625C.

The development of new phases in the high Si alloys is also demonstrated in Figures 17 and

18, for the 4% alloy S30600. A distinct Widmansttten structure has developed in this alloy, in

addition to the subscale.

Figure 19. Rack of metallographic samples after exposure for

1 year above Bed 2 (high temperature) in Plant A

Figure 20. Scale structure on S30409 after 1

year at 625C (marker is 200 m)

Figure 21. Scale structure on S30601 after 1 year

at 625C (marker is 200 m)

Pottable samples for scale metallography

In an effort to retain the scale on the alloys at the end of a campaign, a set of small samples

were installed on the rack shown in Figure 19. Immediately on removal from the converter the

samples were potted in curable resin to permit sectioning and metallographic examination back in

the laboratory. As is seen from the Figure, significant scaling still occurred, although some of the

scale seen above originated from the holder plate.

Despite difficulties in retaining the scale, conditions within the wet acidic atmosphere within

the potting, and in moisture pickup on transfer to the scanning electron microscope, some complete

scale structures were observable. Typical scales are seen in Figure 20, for S30409 and Figure 21,

for S30601.

0

0.5

1

1.5

2

0 50 100 150 200

Time (Hours)

(

W

e

i

g

h

t

g

a

i

n

)

2

,

(

m

g

2

/

c

m

4

)

Linear (620C) Linear (720C)

Linear (420C) Linear (520C)

620

720

520

420

Figure 22,

Parabolic plot of the weight gain for S30409 at four temperatures in 7% SO

2

Recalling the significant difference in corrosion rate for these two alloys at this temperature,

the scale on the high silicon alloy (Figure 21) is compact, probably with an unresolved barrier layer

close to the metal. The scale on the low alloy sample (Figure 20) is much thicker and shows a clear

gap at the scale/alloy interface, suggesting spalling probably during the cool-down period.

X-ray diffraction analysis of these scales suggested they comprise both oxides and sulphates,

but no sulfides. Table 2 provides a simple breakdown of the phases detected in the two alloys. after

plant exposure to a gas containing 11% SO

3

at 635C for 26,000h.

Table 2: X-ray diffraction analysis of scales on S30409 and S30601

M

2

O

3

M

2

(SO4)

3

sulphides

S30409 major major absent

S30601 minor major absent

Scaling Kinetics Determined in the Laboratory

In order to better understand the oxidation processes occurring in the converters, a parallel

study has been made in the laboratory, using a gravimetric balance to continuously monitor sample

mass, and thereby determine corrosion kinetics. SO

2

was added to the gas stream and a gold wire

was installed near the sample in order to aid the conversion to SO

3

.

Figure 22 summarizes the weight gain data for S30409 at four temperatures, plotted on scales

to demonstrate parabolic kinetics. The largest oxidation was observed at 620C. At 720C the rate

has been reduced.

0

2

4

6

8

10

12

0 100 200 300 400 500 600

Time (hours)

W

e

i

g

h

t

g

a

i

n

(

m

g

2

/

c

m

4

)

S30409 S30601 Linear (150 hrs)

Figure 23

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

0 100 200 300 400 500 600

Exposure Time (hrs)

W

e

i

g

h

t

G

a

i

n

(

m

g

/

c

m

2

)

Cyclic Oxidation (24hrs)

Isothermal Oxidation

Figure 24

Figure 23 shows the kinetic data

2

in 7%

SO

2

at 620C for the two alloys of interest.

The S30409 alloy shows an initially linear

rate followed by an increase (breakaway)

after 150h. The S30601 alloy exhibits a

significantly lower reaction rate, consistent

with the observations of scale structure.

Because of the large difference in time

scale, direct comparison of the short

laboratory runs with the much longer field

exposures is not possible. However, the

trends of the two observations are

consistent.

It is also probable that thermal

cycling in the plants, caused by both routine and unexpected shutdowns, exacerbates the corrosion

situation by producing additional opportunities for spalling at the relatively weak scale/metal

interfaces. The detailed frequency of major temperature changes has been recorded for all plants,

and there is some relationship between these events and larger corrosion rates. Such temperature

cycling is probably more significant than plant to plant variations in gas stream SO

2

contents. This

has recently been demonstrated in the laboratory

4

.

Figure 24 shows oxidation kinetics

obtained from three samples of S30409

alloy placed in a tube furnace with 7% SO

2

and a gold catalyst. One sample was

removed and weighed after 120h, and

another after a total exposure time of 520h.

The third sample was removed from the

furnace every 24h, cooled to room

temperature and mass determined before

being replaced into the furnace. The first

two samples provide the isothermal

oxidation kinetics, and the other (eight)

measurements provide the cyclic

oxidation curve after successive removals

and reheats.

It is clear that temperature interruptions significantly increase the weight changes,

supporting the importance of plant down times on the corrosion behaviour of S30409.

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

0 50 100 150 200 250 300

Exposure Time (hrs)

W

e

i

g

h

t

g

a

i

n

(

m

g

/

c

m

2

)

7%SO2

Air

Figure 25

The observations from another

cycling experiment is shown in Figure 25.

All weight changes in this plot are the

result of 24h thermal cycling between

620C and ambient. This data show that

SO

2

is necessary for the spalling effect.

Cycling in air for 200h without sulphur-

containing species causes less than 2% of

the weight gain when SO

2

is present.

Discussion

The plant and laboratory data show that in conditions typical of sulphuric acid converters the

corrosion of alloy S30406 (or 304H) proceeds by the formation of a duplex scale, the outer layer

consisting of a mixed iron-chromium-sulphate and the inner layer mainly iron chromium oxide with

either sulphide or sulphate dispersed through the scale. The X-ray diffraction data suggests that the

sulphur in the inner scale arises from sulphate. Clearly, the experimental evidence of a sudden drop

in reaction rate above 620C, when the temperature exceeds that for the stability of iron and

chromium sulphate, emphasizes the importance of sulphate in the corrosion mechanism. This

importance has also been demonstrated by others

5,6

, but it was also found that the kinetics were only

rapid if a mixed oxide-sulphide layer existed below the outer sulphate. There was no direct evidence

for such a layer in the current work. However the presence of sulphide was indicated by the

evolution of hydrogen sulphide when the scale was dissolved in nitric acid.

The reaction kinetics follow an essentially linear relationship in the plant and are

approximately parabolic in short term laboratory experiments. There is some consistency between

the laboratory and plant data if one considers that breakaway corrosion occurs after about 500h at

620C. This would lead to approximately linear behaviour over 26,000h. If we assume that the onset

of breakaway is much later at 420C, probably after one year, we would expect to observe an

increase in rate over a three year period at this temperature. Also if the corrosion is on the cusp

between breakaway and protectiveness at 420C, we would expect to find a certain amount of scatter

in the plant data depending on minor plant to plant variations. Indeed this scatter is observed in

Figure 4.

Conclusions

1. In sulphuric acid converters, the stainless steel S30409 corrodes via iron-chromium-sulphate

formation. The kinetics are parabolic in the early stages but undergo breakaway to a linear

rate law over longer periods. Operating hot gas converters at temperatures constantly in

excess of 620C will require higher alloys to reduce the corrosion rates.

2. Alloyed silicon is shown to decrease the corrosion rate by up to an order of magnitude.

1. J. Magnan, Kubota Metal Corporation, unpublished research.

2. K. Draou et al. in Proceedings, 15

th

International Symposium on Corrosion, p.

3. Modified Glyceregia: Mixed in order: 3 drops of glycerol, 10 mls Acetic Acid, 15 mls HCl,

10 mls HNO

3

4. Weiguo Yang, M.Eng., unpublished research, McMaster University, 2002.

5. K.P. Lilerud, B. Haflan and P. Kofstad, Oxidation of Metals, 21, p.119 (1984)

6. A. Andersen and P. Kofstad, Corros. Sci. 24, p.731 (1984)

Examination of the scales on the high-silicon alloy, S30601, indicate that this decrease in

rate may be due to a thin silicon rich oxide formed at the scale/alloy interface.

Acknowledgments

This research was funded by the Natural Sciences and Engineering Research Council of

Canada under a Cooperative Research and Development Grant, and contributed to by a consortium

comprising Cecebe Technologies Inc, Teck-Cominco Ltd, Falconbridge Ltd, Inco Ltd, Kubota

Metal Corporation, NORAM Engineering and Constructors Ltd, and Noranda Inc.

The authors also wish to thank Avesta Polarit and Thyssen Marathon for supplying the alloy

samples; Sladjana Zdero for much of the sample preparation and metallography; Khaled Draou and

Weiguo Yang for the laboratory kinetic data.

References

Anda mungkin juga menyukai

- Foamglas Data Sheet EngDokumen2 halamanFoamglas Data Sheet EngAnonymous yQ7SQrBelum ada peringkat

- MSDS Eng FoamglasDokumen4 halamanMSDS Eng FoamglasAnonymous yQ7SQrBelum ada peringkat

- Caged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Dokumen1 halamanCaged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Anonymous yQ7SQrBelum ada peringkat

- GSL Actuator Sizing Calculation PDFDokumen1 halamanGSL Actuator Sizing Calculation PDFAnonymous yQ7SQrBelum ada peringkat

- UG-37 F FactorDokumen7 halamanUG-37 F FactorjamesBelum ada peringkat

- EMCO Floating Suctions enDokumen2 halamanEMCO Floating Suctions enAnonymous yQ7SQrBelum ada peringkat

- Comparison of Recent Us Seismic CodesDokumen8 halamanComparison of Recent Us Seismic CodesAnonymous yQ7SQrBelum ada peringkat

- GSL Actuator Sizing CalculationDokumen0 halamanGSL Actuator Sizing CalculationAnonymous yQ7SQrBelum ada peringkat

- Lincoln Stainless Welding GuideDokumen40 halamanLincoln Stainless Welding GuideAnonymous yQ7SQr100% (1)

- Sandvick Stainless Welding Products (S 236 Eng 2006)Dokumen27 halamanSandvick Stainless Welding Products (S 236 Eng 2006)Anonymous yQ7SQrBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Congenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementDokumen87 halamanCongenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementJZBelum ada peringkat

- Delonghi Esam Series Service Info ItalyDokumen10 halamanDelonghi Esam Series Service Info ItalyBrko BrkoskiBelum ada peringkat

- Produktkatalog SmitsvonkDokumen20 halamanProduktkatalog Smitsvonkomar alnasserBelum ada peringkat

- Food ResourcesDokumen20 halamanFood ResourceshiranBelum ada peringkat

- National Anthems of Selected Countries: Country: United States of America Country: CanadaDokumen6 halamanNational Anthems of Selected Countries: Country: United States of America Country: CanadaHappyBelum ada peringkat

- Fds-Ofite Edta 0,1MDokumen7 halamanFds-Ofite Edta 0,1MVeinte Años Sin VosBelum ada peringkat

- SLA in PEGA How To Configue Service Level Agreement - HKRDokumen7 halamanSLA in PEGA How To Configue Service Level Agreement - HKRsridhar varmaBelum ada peringkat

- Cable To Metal Surface, Cathodic - CAHAAW3Dokumen2 halamanCable To Metal Surface, Cathodic - CAHAAW3lhanx2Belum ada peringkat

- Nanolithography - Processing Methods PDFDokumen10 halamanNanolithography - Processing Methods PDFNilesh BhardwajBelum ada peringkat

- YIC Chapter 1 (2) MKTDokumen63 halamanYIC Chapter 1 (2) MKTMebre WelduBelum ada peringkat

- UntitledDokumen216 halamanUntitledMONICA SIERRA VICENTEBelum ada peringkat

- PresentationDokumen27 halamanPresentationMenuka WatankachhiBelum ada peringkat

- Kazon Greater Predator MothershipDokumen1 halamanKazon Greater Predator MothershipknavealphaBelum ada peringkat

- SASS Prelims 2017 4E5N ADokumen9 halamanSASS Prelims 2017 4E5N ADamien SeowBelum ada peringkat

- Bolt Grade Markings and Strength ChartDokumen2 halamanBolt Grade Markings and Strength ChartGregory GaschteffBelum ada peringkat

- What's New in CAESAR II: Piping and Equipment CodesDokumen1 halamanWhat's New in CAESAR II: Piping and Equipment CodeslnacerBelum ada peringkat

- Fertilization Guide For CoconutsDokumen2 halamanFertilization Guide For CoconutsTrade goalBelum ada peringkat

- The RBG Blueprint For Black Power Study Cell GuidebookDokumen8 halamanThe RBG Blueprint For Black Power Study Cell GuidebookAra SparkmanBelum ada peringkat

- Obligatoire: Connectez-Vous Pour ContinuerDokumen2 halamanObligatoire: Connectez-Vous Pour ContinuerRaja Shekhar ChinnaBelum ada peringkat

- Workbook Group TheoryDokumen62 halamanWorkbook Group TheoryLi NguyenBelum ada peringkat

- Reported SpeechDokumen6 halamanReported SpeechRizal rindawunaBelum ada peringkat

- 1 - 2020-CAP Surveys CatalogDokumen356 halaman1 - 2020-CAP Surveys CatalogCristiane AokiBelum ada peringkat

- Lieh TzuDokumen203 halamanLieh TzuBrent Cullen100% (2)

- Hidrl1 PDFDokumen7 halamanHidrl1 PDFRajesh Kumar100% (1)

- Export Management EconomicsDokumen30 halamanExport Management EconomicsYash SampatBelum ada peringkat

- FIRST SUMMATIVE EXAMINATION IN ORAL COMMUNICATION IN CONTEXT EditedDokumen3 halamanFIRST SUMMATIVE EXAMINATION IN ORAL COMMUNICATION IN CONTEXT EditedRodylie C. CalimlimBelum ada peringkat

- 2014 - A - Levels Actual Grade A Essay by Harvey LeeDokumen3 halaman2014 - A - Levels Actual Grade A Essay by Harvey Leecherylhzy100% (1)

- Where We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Dokumen1 halamanWhere We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Safia-umm Suhaim- FareedBelum ada peringkat

- Desktop 9 QA Prep Guide PDFDokumen15 halamanDesktop 9 QA Prep Guide PDFPikine LebelgeBelum ada peringkat

- Government College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniqueDokumen11 halamanGovernment College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniquepriyankaBelum ada peringkat