Steel Mech Properties

Diunggah oleh

anil4u29Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Steel Mech Properties

Diunggah oleh

anil4u29Hak Cipta:

Format Tersedia

USER'S GUIDE

CONTENTS

1 Introduction 2

2 Product Range : Hot Rolled Products 4

Carbon Steel : Standard Product Tolerance 4

Carbon Steel : Chemical Composition 5

Carbon Steel : Mechanical Properties 6

HR Stainless Steels : Standard Product Tolerance 7

3 Stainless Steels 8

Product Range : CR Stainless Steels 9

SurIace Finishes : Stainless Steels 10

Dimensional Tolerances : CR Stainless Steels 11

Stainless Steels : Chemical Composition 13

Stainless Steels : Mechanical Properties 14

Stainless Steels : Physical Properties 14

Stainless Steels : Equivalent SpeciIication 15

Stainless Steels : Theoretical Mass 16

4 Gauge Conversion Table 17

5 Hardness Conversion 19

6 Unit Coil Weight Diagram 20

7 Applications : Hot Rolled Carbon Steels 21

8 Applications : Stainless Steels 22

9 SS SurIace Finishes & Applications 26

10 Stainless Steel : Fabrication Guidelines 30

11 Blanking Line : 40

12 Value Added Products : 41

13 Process Flow : Hot Rolling Mill 43

: Cold Rolling Mill 44

14 Ordering InIormation 45

Our technical advisory service is always Ireely available.

For Iurther details, please contact our Marketing Head Quarters at Salem

Tel: 0427-2382236 / 2383836, Fax: 238 3249 / 2383063

The inIormation in this booklet is Ior guidance only.

SpeciIications are subject to change.

1

Introduction

Salem Steel Plant, a special steels unit oI Steel Authority oI India Ltd.,

pioneered the supply oI wider width stainless steel sheets / coils in India.

The plant can produce Austenitic, Ierritic, Martensitic and Low-nickel

stainless steel in the Iorm oI coils and sheets with an installed capacity oI

70,000 tonnes / year oI cold rolled stainless steel and 1,86,000 / year

tonnes oI hot rolled stainless steel / carbon steel Ilat products. In addition,

the country`s Iirst top-oI-the-line stainless steel Blanking Iacility with a

capacity oI 3600 t / year oI coin blanks and utility blanks / circles adds to

the credit oI the plant.

The products oI Salem Steel plant are popularly called as 'SALEM

STAINLESS` and well received in both national and international

markets Ior its renowned quality standards. The plant is certiIied with

ISO 9001:2000 Ior its Quality Management System, ISO14001:2004 Ior

its Environmental Management System and OHSAS 18001:1999 Ior

Occupational Health and SaIety system.

The plant is Iacilitated with hot rolling mill which can roll both stainless

& carbon steels and the mill caters mainly to the input needs oI stainless

steel coils Ior the cold rolling mills. Special grades oI carbon steels other

than Structural steels are also rolled Irom the Iacility includes Weathering

steels, High strength low alloy steels etc., which are extensively used in

industrial sectors.

Hot rolling mill complex is equipped with walking beam re-heating

Iurnace, primary descaler, 4-hi reversing roughing mill, 4-high reversing

steckel mill, down coiler, laminar cooling and roll grinding machines,

procured Irom world renowned suppliers. The steckel mill, the mother

unit oI hot rolling with level - 2 automation is provided with hydraulic

gauge setting and automatic gauge control. The continuously variable

crown(CVC) controls the proIile and Ilatness by roll shiIting and Work

roll bending system provide additional Iine control oI Ilatness oI the strip.

2

Cold rolling mill complex is equipped with the most modern stainless

steel production lines, sourced Irom leading manuIacturers oI the world.

Coil build up line, Bell anneal Iurnaces Continuous annealing and

pickling lines, Sendzimer Mills, Skinpass Mill, Strip grinding line,

Slitting and shearing lines to produce coils /sheets with precise

dimensional tolerance and Ilatness with superior metallurgical

characteristics.

Ferritic and Martensitic stainless steel are annealed/soItened at bell

annealing Iurnaces and austenitic stainless steel is annealed/soItened and

descaled in continuous annealing & pickling lines using Ruthner neutral

electrolytic pickling process and mixed acid pickling Ior superior surIace

Iinish. The coils are rolled in 20-High computerized sendzimer mills to

required dimensional tolerances. A 2-high skin pass mill with elongation

control and constant hydraulic roll Iorce system ensures a product oI

bright Iinish and high Ilatness. A shearing line with precision roller

levelers, electronic Ilying shear and vacuum piler Iacilitates deIect-Iree

piling oI the leveled cut sheets. Coils oI narrow width and smaller weight

are produced by a precision slitting line equipped with latest Ieatures like

in Ieed car, grip Ieed device, tension pad and interchangeable slitters.

The shearing and slitting lines have online continuous marking system to

make the products customer-Iriendly. Salem Steel Plant`s cold rolling

mill complex also includes a resquaring shear, a recoiling line, a packing

line Ior slit products and wider coils.

In addition to the common No1, 2D and 2B Iinishes, a wide range oI

Iinishes including No.3, No.4, No.8 (mirror)and special Iinishes like

Moon Rock, Chequered, Honeykom, Macromatt, Aqualine, Frondz,

Mystique, Linen, Fabrique Iinishes are also produced as per

requirement.

3

PRODUCT RANGE : Hot Rolled Products

The hot rolled products include austenitic ,Ierritic and low nickel grades

oI stainless steels and carbon steels oI drawing quality, structural quality,

high strength-low alloy steels and weathering steels.

Type of Product : Hot rolled Coil `

Carbon Steel Stainless Steel

Thickness 1.6 - 12.70 mm 2.0 - 8.0 mm

Width 1000 - 1275 mm 1000 - 1275 mm

Coil ID 762/610 mm 762/610 mm

Condition As rolled As rolled

Edge Mill Edge Mill Edge

*Cut to size/plate and higher thickness available by mutual discussion.

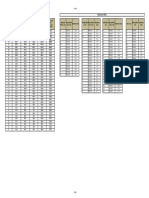

Carbon Steel : Standard product tolerance

Width Tolerance 30 mm, -0 mm (For all width ranges)

Thickness Tolerances ` (mm)

Width (mm) Thickness Range (mm)

1.6 -2.0 ~2.0-3.0 ~3.0-5.0 ~5.0-8.0 ~8.0-10.00 ~10.0-12.7

1000-1250 +0.18 +0.20 +0.25 +0.30 +0.35 +0.50

~1250-1275 +0.20 +0.25 +0.30 +0.35 +0.40 +0.50

*Thickness measurements are taken at 20 mm Irom the edge.

4

Carbon SteeIs: ChemicaI Composition

Grades

Chemical Composition

Deoxidation

C Mn Si S P Al Cr Ni Cu Nb V Ti N

IS 1079 Gr O

0.15

max

0.6

max

-

0.055

max

0.055

max

- - - - - - - -

Semi Killed /

Killed

IS 1079 Gr D

0.12

max

0.5

max

-

0.04

max

0.04

max

- - - - - - - -

Semi Killed /

Killed

IS 1079 Gr DD

0.1

max

0.4

max

-

0.035

max

0.035

max

0.02

min

- - - - - - - Al Killed

IS 1079 Gr EDD

0.08

max

0.4

max

-

0.03

max

0.03

max

0.02

min

- - - - - - - Al Killed

IS 2062 E250 A

0.23

max

1.5

max

0.40

max

0.045

max

0.045

max

- - - - - - - -

Semi Killed /

Killed

IS 2062 E250 B

0.22

max

1.5

max

0.40

max

0.045

max

0.045

max

- - - - - - - - Killed

IS 2062 E250 C

0.2

max

1.5

max

0.40

max

0.04

max

0.04

max

- - - - - - - - Killed

IS 2062 E250Cu

C

0.2

max

1.5

max

0.40

max

0.04

max

0.04

max

- - -

0.2-

0.35

- - - - Killed

IS 2062 E410

0.20

max

1.6

max

0.45

max

0.045

max

0.045

max

- - - - - - - - Killed

IS 2062 E450 D

0.22

max

1.6

max

0.45

max

0.045

max

0.045

max

- - - - - - - - Killed

IS 2062 E450 E

0.22

max

1.80

max

0.45

max

0.045

max

0.045

max

- - - - - - - - Killed

IS 5986 Fe410

0.20

max

1.20

max

-

0.040

max

0.040

max

- - - - - - - - Killed

IS 10748 Gr 1

0.10

max

0.50

max

-

0.040

max

0.040

max

- - - - - - - - killed

IRS M 41-97/

SAILCOR

0.1

max

0.25-

0.45

0.28-

0.72

0.03

max

0.075-

0.14

0.08

max

0.35-

0.60

0.20-

0.47

0.3-

0.6

- - - - Killed

SS 4012A-E34

0.1

max

0.7

max

0.2

max

0.03

max

0.03

max

0.02-

0.05

- - -

0.055

max

0.095

max

0.045

max

- Al Killed

SS 4012A-E38

0.1

max

1.0

max

0.4

max

0.03

max

0.03

max

0.02-

0.05

- - -

0.055

max

0.095

max

0.045

max

- Al Killed

SAILMA

350/350 Hi

0.25 1.50 0.40 0.055 0.055

0.01

min

- - - - - - - Killed

SAILMA

410/410Hi

0.25 1.50 0.40 0.055 0.055

0.01

min

- - - - - - - Killed

SAILMA

450/450 Hi

0.25 1.50 0.40 0.055 0.055

0.01

min

- - - - - - - Killed

Micro Alloying elements like Nb, V, Ti may be present simply or in combination, the

limits are given below:

Grade Nb, V, Ti (max)

IS 2062 E250 A, B, C, Cu C

IS 2062 E410

IS 2062 E450 D, IS 2062 E 450 E

0.25

SAILMA350

SAILMA 350 Hi

0.20

SAILMA410

SAILMA 410 Hi

0.20

SAILMA450

SAILMA 450 Hi

0.20

Incidental element limit in grade IRSM-41/97/SAILCOR is as Iollows

5

Element Limit

Mo 0.05 max

V 0.05 max

Al 0.08 max

Nb 0.04 max

Mo V Al Nb 0.15 max

Maximum carbon equivalent Ior grades is as Iollows:

Grade Carbon Equivalent (max)

IS 2062 E250 A 0.42

IS 2062 E250 B 0.41

IS 2062 E250 C 0.39

IS 2062 E410 0.44

IS 2062 E450 D 0.46

IS 2062 E450 E 0.48

IS 5986 Fe410 0.42

MECHANICAL PROPERTIES OF STANDARD GRADES

Grades

YS

N/mm

2

UTS

N/mm

2

E| (V|r)

0L= 5.53o

Bend Test

(t)

Hard

R

B

Charpy V-Notch Impact

Energy (min)

IS 1079 Gr O - - - 2 t - -

IS 1079 Gr D

- 240- 400 25 1 t - -

IS 1079 Gr DD - 260-390 28 Close - -

IS 1079 Gr EDD - 260-380 32 Close - -

IS 2062 E250 A 250 min 410 min 23 3 t - -

IS 2062 E250 B

250 min 410 min 23 2 t - 2Z J al Roor lerp 3ee Nole

IS 2062 E250 C 250 min 410 min 23 2 t - 2Z J al Roor lerp 3ee Nole

IS2062E250Cu C 250 min 410 min 23 2 t - 2Z J al Roor lerp 3ee Nole

IS 2062 E410 410 min 540 min 23 2 t - 50 J al Roor lerp 3ee Nole

IS 2062 E450 D 450 min 570 min 20 2 t - 15 J al Roor lerp 3ee Nole

IS 2062 E450 E 450 min 590 min 20 2 t - 15 J al Roor lerp 3ee Nole

IS 5986 Fe410 255 min 410-520

21 lor l >3/0 rr

2t - -

IS 10748 Grade I 170 min 290 min 30 T - -

SS 4012A E-34 334-412 392-490 27

C|ose

(For 'l'<Z.0 rr)

0.5 l(For 'l'=Z.0)

- -

SS4012A E-38 373-461 442-559 25 0.5 t - -

IRS M 41-97/

SAILCOR

340 min 480 min 22 1 t - -

t` : Nominal thickness oI test piece, * : Elongation 15 min N in 80 mm GL Ior t _ 3.0 mm

Note: For grade IS 2062 E250 B,IS 2062 E250 C,E410,E450 D,E450 E Impact Test shall be certiIied

Ior product thickness oI 12 mm or more. The testing temperature will be room temperature unless

otherwise speciIied in the order.

Standard Product Tolerance: Hot Rolled Stainless Steel

6

Thickness Tolerance

(For all width ranges)

Thickness (mm) Tolerance (mm)

2.00 0.18

2.25 0.20

2.50 0.23

3.00 0.25

3.50 0.30

4.00 0.36

5.00 - 0.25, + 0.47

6.00 - 0.25, + 0.51

8.00 & above - 0.25, + 0.75

For speciIied thickness other than those shown, the tolerance Ior the next

higher thickness shall apply.

Thickness measurements are taken at least 15 mm Irom the edge Ior

Trimmed Edge (TE) and 25 mm Irom the edge Ior Mill Edge (ME)

products.

7

Stainless Steels

Stainless Steel is a group oI heat and corrosion resisting steels. They

have in general a higher resistance to corrosion in some deIinite

environment, as well as a higher resistance to scaling at high temperature.

Stainless Steel are iron-based alloys containing a minimum oI 10.5

Chromium with or without other alloying elements. Based on the alloy

content and the micro structure, stainless steels are classiIied into three

major categories viz, Austenitic, Ferritic, and Martensitic.

Austenitic

This category oI stainless steel contains 16 to 26 Chromium and 6

to22 Nickel. They are non- magnetic in annealed condition and have

excellent corrosion resistance. They are not hardenable by heat

treatment. However, they can develop high strength on cold working.

They have excellent weldability, Iormability, hygiene Iactor and

cryogenic properties. . On cold working they exhibit diIIerent degrees oI

magnetism. They are identiIied in the AISI 300 series

Ferritic

This category oI stainless steel contains 10.5 to 30 chromium without

any Nickel. They are Ferro magnetic in nature and generally not

hardenable by heat treatment. These steels possess good resistance to

stress corrosion cracking and moderate weldability &Iormability. They

are identiIied in the AISI 400 series.

Martensitic

This group contains 11 to 14 chromium without any nickel, but with a

higher carbon content compared to the Austenitic and Ierritic stainless

steels. They are Ierro-magnetic in nature and are hardenable by heat

treatment. They possess moderate corrosion resistance and are identiIied

in the AISI 400 series.

8

PRODUCT RANGE : Cold Rolled Stainless Steels

Salem Steel Plant produces a wide range oI cold rolled coils and cut

lengths (sheets) in austenitic, Ierritic and martensitic grades oI stainless

steel conIorming to ASTM and various other speciIications in a variety oI

sizes and Iinishes.

Product Specifications

Coil Sizes (mm)

Dimension Range (mm) Standard sizes (mm)

Thickness 0.3 to 6.00 0.30, 0.40, 0.50, 0.55, 0.63, 0.70,

0.80,0.90,1.00,1.25,1.50,1.60,

2.00,2.50,2.80, 3.00, 3.15, 3.60,

4.00,5.00 6.00

Width (mm) 50 to 1250 1000, 1250

Inner Diameter 406, 508 or 610

Sheet / Plate

Dimension Range (mm) Standard sizes (mm)

Thickness 0.5 to 6.00 0.50, 0.55, 0.63, 0.70, 0.80,

0.90, 1.00, 1.25, 1.50, 1.60

2.00, 2.50, 2.80, 3.00, 3.15

3.60, 4.00, 5.00, 6.00

Width (mm) 600 to 1250, 1000, 1250

Length (mm) 500 to 4000 1500, 2000, 2500, 3000, 3500,

4000

- Supply oI 0.1 and 0.2 mm thickness by mutual discussion.

- Supply oI Non-standard and higher thickness by mutual discussion.

- Hot rolled, annealed, shot blasted and pickled stainless steel (No.1

Iinish) coils sheets/ plates are available in thicknesses oI 2.00- 8.00

mm.

9

S

u

r

f

a

c

e

F

i

n

i

s

h

e

s

-

S

t

a

i

n

l

e

s

s

S

t

e

e

l

s

F

i

n

i

s

h

D

e

s

c

r

i

p

t

i

o

n

R

e

m

a

r

k

s

N

o

:

1

H

o

t

r

o

l

l

e

d

,

a

n

n

e

a

l

e

d

,

s

h

o

t

b

l

a

s

t

e

d

a

n

d

p

i

c

k

l

e

d

U

s

e

d

w

h

e

r

e

s

u

r

I

a

c

e

I

i

n

i

s

h

i

s

n

o

t

a

c

r

i

t

i

c

a

l

C

R

W

o

r

k

h

a

r

d

e

n

e

d

u

s

e

d

w

h

e

r

e

h

i

g

h

e

r

h

a

r

d

n

e

s

s

&

s

t

r

e

n

g

t

h

i

s

r

e

q

u

i

r

e

d

2

D

C

o

l

d

r

o

l

l

e

d

,

a

n

n

e

a

l

e

d

a

n

d

p

i

c

k

l

e

d

U

n

i

I

o

r

m

d

u

l

l

I

i

n

i

s

h

I

o

r

a

p

p

l

i

c

a

t

i

o

n

s

2

B

C

o

l

d

r

o

l

l

e

d

,

a

n

n

e

a

l

e

d

,

p

i

c

k

l

e

d

&

s

k

i

n

p

a

s

s

e

d

B

r

i

g

h

t

s

m

o

o

t

h

I

i

n

i

s

h

I

o

r

g

e

n

e

r

a

l

a

p

p

l

i

c

a

t

i

o

n

s

N

o

.

3

.

C

o

l

d

r

o

l

l

e

d

,

a

n

n

e

a

l

e

d

,

p

i

c

k

l

e

d

&

p

o

l

i

s

h

e

d

w

i

t

h

1

0

0

t

o

1

2

0

g

r

i

t

a

b

r

a

s

i

v

e

F

o

r

d

e

c

o

r

a

t

i

v

e

a

p

p

l

i

c

a

t

i

o

n

s

N

o

.

4

.

C

o

l

d

r

o

l

l

e

d

,

a

n

n

e

a

l

e

d

,

p

i

c

k

l

e

d

&

p

o

l

i

s

h

e

d

w

i

t

h

1

2

0

t

o

1

5

0

g

r

i

t

a

b

r

a

s

i

v

e

F

o

r

d

e

c

o

r

a

t

i

v

e

a

p

p

l

i

c

a

t

i

o

n

s

N

o

.

8

.

C

o

l

d

r

o

l

l

e

d

,

a

n

n

e

a

l

e

d

,

p

i

c

k

l

e

d

,

s

k

i

n

p

a

s

s

e

d

&

p

o

l

i

s

h

e

d

A

s

p

r

e

s

s

p

l

a

t

e

s

,

e

l

e

c

t

r

o

n

i

c

e

q

u

i

p

m

e

n

t

I

r

a

m

e

s

a

n

d

d

e

c

o

r

a

t

i

v

e

a

p

p

l

i

c

a

t

i

o

n

s

S

p

e

c

i

a

l

F

i

n

i

s

h

e

s

C

o

l

d

r

o

l

l

e

d

w

i

t

h

s

p

e

c

i

a

l

r

o

l

l

s

,

a

n

n

e

a

l

e

d

,

p

i

c

k

l

e

d

a

n

d

s

k

i

n

p

a

s

s

e

d

.

F

o

r

d

e

c

o

r

a

t

i

v

e

a

p

p

l

i

c

a

t

i

o

n

s

.

D

u

l

l

F

i

n

i

s

h

C

o

l

d

r

o

l

l

e

d

,

a

n

n

e

a

l

e

d

a

n

d

s

k

i

n

p

a

s

s

e

d

w

i

t

h

2

4

g

r

i

t

a

b

r

a

s

i

v

e

.

F

o

r

d

e

c

o

r

a

t

i

v

e

a

p

p

l

i

c

a

t

i

o

n

s

.

C

o

i

l

s

a

n

d

s

h

e

e

t

s

c

a

n

b

e

s

u

p

p

l

i

e

d

w

i

t

h

s

u

r

I

a

c

e

p

r

o

t

e

c

t

i

o

n

I

i

l

m

.

P

l

e

a

s

e

c

o

n

t

a

c

t

I

o

r

m

o

r

e

i

n

I

o

r

m

a

t

i

o

n

.

1

0

D

i

m

e

n

s

i

o

n

a

l

T

o

l

e

r

a

n

c

e

s

(

U

n

i

t

:

m

m

`

)

T

o

l

e

r

a

n

c

e

s

o

n

T

h

i

c

k

n

e

s

s

-

(

U

n

i

t

:

m

m

`

)

N

o

r

m

a

l

T

o

l

e

r

a

n

c

e

{

C

o

d

e

N

"

}

-

C

R

8

8

P

r

e

c

i

s

i

o

n

T

o

l

e

r

a

n

c

e

{

C

o

d

e

P

'

}

T

h

i

c

k

n

e

s

s

T

o

l

e

r

a

n

c

e

f

o

r

N

o

.

1

T

h

i

c

k

n

e

s

s

R

a

n

g

e

P

e

r

m

i

t

t

e

d

T

o

l

.

o

n

T

h

i

c

k

f

o

r

s

p

e

c

i

f

i

e

d

w

i

d

t

h

T

h

i

c

k

n

e

s

s

r

a

n

g

e

P

e

r

m

i

t

t

e

d

T

o

l

.

o

n

t

h

i

c

k

(

T

o

t

a

l

)

T

h

i

c

k

n

e

s

s

P

e

r

m

i

t

t

e

d

T

o

l

.

(

)

o

n

t

h

i

c

k

_

1

0

0

0

~

1

0

0

0

t

o

_

1

2

7

5

0

.

3

0

0

.

0

4

0

2

.

0

0

0

.

1

8

_

0

.

3

0

+

0

.

0

3

0

-

~

0

.

3

0

t

o

0

.

5

0

0

.

0

6

0

2

.

2

5

0

.

2

0

~

0

.

3

0

t

o

_

0

.

4

0

+

0

.

0

4

0

+

0

.

0

4

~

0

.

5

0

t

o

0

.

8

0

0

.

0

8

0

2

.

5

0

0

.

2

3

~

0

.

4

0

t

o

_

0

.

5

0

+

0

.

0

4

5

+

0

.

0

5

0

~

0

.

8

0

t

o

1

.

0

0

0

.

0

9

0

3

.

0

0

0

.

2

5

~

0

.

5

0

t

o

_

0

.

8

0

+

0

.

0

5

0

+

0

.

0

5

0

~

1

.

0

0

t

o

1

.

5

0

0

.

1

0

0

3

.

5

0

0

.

3

0

~

0

.

8

0

t

o

_

1

.

0

0

+

0

.

0

5

5

+

0

.

0

6

0

~

1

.

5

0

t

o

2

.

0

0

0

.

1

2

0

5

.

0

0

-

0

.

2

5

,

0

.

4

7

~

1

.

0

0

t

o

_

1

.

5

0

+

0

.

0

8

0

+

0

.

0

8

0

~

2

.

0

0

t

o

2

.

5

0

0

.

1

6

0

6

.

0

0

-

0

.

2

5

,

0

.

5

1

~

1

.

5

0

t

o

_

2

.

0

0

+

0

.

1

0

+

0

.

1

0

~

2

.

5

0

t

o

3

.

0

0

0

.

2

0

0

8

.

0

0

-

0

.

2

5

,

0

.

7

5

~

2

.

0

0

t

o

_

2

.

5

+

0

.

1

0

+

0

.

1

1

~

3

.

0

0

t

o

4

.

0

0

0

.

2

4

0

~

2

.

5

0

t

o

_

3

.

0

0

+

0

.

1

3

+

0

.

1

3

C

l

o

s

e

T

o

l

e

r

a

n

c

e

{

C

o

d

e

C

'

}

~

3

.

0

0

t

o

_

4

.

0

0

+

0

.

1

7

+

0

.

1

7

A

n

y

t

h

i

c

k

n

e

s

s

c

l

o

s

e

r

t

h

a

n

p

r

e

c

i

s

i

o

n

t

o

l

e

r

a

n

c

e

a

g

r

e

e

d

b

y

m

u

t

u

a

l

d

i

s

c

u

s

s

i

o

n

~

4

.

0

0

t

o

_

5

.

0

0

+

0

.

1

7

+

0

.

1

7

~

5

.

0

0

t

o

_

6

.

0

0

+

0

.

1

7

+

0

.

2

0

N

o

r

m

a

l

T

o

l

.

f

o

r

M

E

-

1

0

0

0

:

-

0

,

+

3

0

/

<

1

0

0

0

:

-

0

,

+

2

5

T

o

l

e

r

a

n

c

e

s

o

n

W

i

d

t

h

-

(

U

n

i

t

:

m

m

`

)

1

1

N

o

r

m

a

l

T

o

l

e

r

a

n

c

e

I

o

r

s

h

e

e

t

s

a

n

d

c

o

i

l

s

(

C

o

d

e

N

`

)

-

C

R

S

S

T

r

i

m

m

e

d

E

d

g

e

T

H

I

C

N

E

S

S

P

e

r

m

|

t

t

e

d

T

o

|

e

r

a

n

c

e

o

n

w

|

d

t

h

f

o

r

s

p

e

c

|

f

|

e

d

w

|

d

t

h

2

5

0

>

2

5

0

t

o

6

0

0

>

6

0

0

t

o

1

0

0

0

>

1

0

0

0

t

o

1

2

5

0

_

1

.

0

0

0

.

5

0

,

-

0

0

.

7

0

,

-

0

1

.

5

0

,

-

0

2

.

0

0

,

-

0

~

1

.

0

t

o

_

1

.

5

0

0

.

7

0

,

-

0

1

.

0

0

,

-

0

1

.

5

0

,

-

0

2

.

0

0

,

-

0

~

1

.

5

t

o

_

2

.

5

0

1

.

0

0

,

-

0

1

.

2

0

,

-

0

2

.

0

0

,

-

0

2

.

5

0

,

-

0

~

2

.

5

0

t

o

_

3

.

5

0

1

.

2

0

,

-

0

1

.

5

0

,

-

0

3

.

0

0

,

-

0

3

.

0

0

,

-

0

~

3

.

5

0

t

o

_

6

.

0

0

2

.

0

0

,

-

0

2

.

0

0

,

-

0

4

.

0

0

,

-

0

4

.

0

0

,

-

0

P

r

e

c

i

s

i

o

n

T

o

l

e

r

a

n

c

e

o

n

w

i

d

t

h

(

T

r

i

m

m

e

d

E

d

g

e

)

C

R

S

S

c

o

i

l

s

(

C

o

d

e

P

`

)

.

A

n

y

w

i

d

t

h

s

t

r

i

c

t

e

r

t

h

a

n

n

o

r

m

a

l

t

o

l

e

r

a

n

c

e

a

g

r

e

e

d

b

y

m

u

t

u

a

l

d

i

s

c

u

s

s

i

o

n

.

N

o

r

m

a

l

T

o

l

e

r

a

n

c

e

I

o

r

s

h

e

e

t

s

a

n

d

c

o

i

l

s

(

C

o

d

e

N

`

)

-

N

o

.

1

T

r

i

m

m

e

d

E

d

g

e

T

o

l

e

r

a

n

c

e

o

n

l

e

n

g

t

h

-

(

U

n

i

t

:

m

m

`

)

T

h

i

c

k

W

i

d

t

h

P

e

r

m

i

t

t

e

d

T

o

l

.

w

i

d

t

h

N

o

r

m

a

l

T

o

l

e

r

a

n

c

e

(

C

o

d

e

N

`

)

-

C

R

S

S

N

o

r

m

a

l

T

o

l

e

r

a

n

c

e

(

C

o

d

e

N

`

)

-

N

o

.

1

_

5

.

0

0

1

2

0

0

2

,

-

0

S

p

e

c

i

f

i

e

d

L

e

n

g

t

h

P

e

r

m

i

t

t

e

d

T

o

l

.

o

n

l

e

n

g

t

h

S

p

e

c

i

f

i

e

d

L

e

n

g

t

h

P

e

r

m

i

t

t

e

d

T

o

l

.

o

n

l

e

n

g

t

h

_

5

.

0

0

_

1

2

0

0

6

,

-

0

~

5

.

0

0

t

o

_

6

.

0

0

1

2

0

0

4

,

-

0

_

2

0

0

0

5

,

-

0

3

0

0

0

1

2

,

-

0

~

5

.

0

0

t

o

_

6

.

0

0

_

1

2

0

0

9

,

-

0

~

2

0

0

0

0

.

0

0

2

5

x

L

,

-

0

3

0

0

0

0

.

0

0

5

x

L

,

-

0

T

o

l

e

r

a

n

c

e

o

n

F

l

a

t

n

e

s

s

-

(

U

n

i

t

:

m

m

`

)

T

o

l

e

r

a

n

c

e

I

o

r

C

R

S

S

1

0

m

m

m

a

x

I

o

r

a

l

l

t

h

i

c

k

n

e

s

s

e

s

a

n

d

w

i

d

t

h

s

T

o

l

e

r

a

n

c

e

I

o

r

N

o

.

1

S

p

e

c

i

f

i

e

d

T

h

i

c

k

n

e

s

s

(

m

m

)

S

p

e

c

i

f

i

e

d

w

i

d

t

h

(

m

m

)

P

e

r

m

i

t

t

e

d

T

o

l

e

r

a

n

c

e

(

m

m

)

o

n

f

l

a

t

n

e

s

s

5

.

0

9

0

0

1

3

5

.

0

9

0

0

-

1

2

7

5

1

9

_

5

.

0

1

2

7

5

2

3

1

2

S

t

a

n

d

a

r

d

G

r

a

d

e

s

a

n

d

C

h

e

m

i

c

a

l

C

o

m

p

o

s

i

t

i

o

n

G

r

a

d

e

C

h

e

m

i

c

a

l

C

o

m

p

o

s

i

t

i

o

n

(

L

a

d

l

e

)

C

(

m

a

x

)

S

i

(

m

a

x

)

M

n

C

r

N

i

P

(

m

a

x

)

S

(

m

a

x

)

N

(

m

a

x

)

O

t

h

e

r

E

l

e

m

e

n

t

s

3

0

1

0

.

1

5

1

.

0

0

2

.

0

0

m

a

x

1

6

.

0

0

1

8

.

0

0

6

.

0

0

-

8

.

0

0

0

.

0

4

5

0

.

0

3

0

0

.

1

-

3

0

1

L

0

.

0

3

1

.

0

0

2

.

0

0

m

a

x

1

6

.

0

0

1

8

.

0

0

6

.

0

0

-

8

.

0

0

0

.

0

4

5

0

.

0

3

0

0

.

2

-

3

0

4

0

.

0

7

0

.

7

0

2

.

0

0

m

a

x

1

7

.

5

-

1

9

.

5

8

.

0

0

-

1

0

.

5

0

0

.

0

4

5

0

.

0

3

0

0

.

1

-

3

0

4

L

0

.

0

3

0

.

7

5

2

.

0

0

m

a

x

1

7

.

5

-

1

9

.

5

8

.

0

0

-

1

2

.

0

0

0

.

0

4

5

0

.

0

3

0

0

.

1

-

3

1

0

S

0

.

0

8

1

.

5

0

2

.

0

0

m

a

x

2

4

.

0

0

2

6

.

0

0

1

9

.

0

0

-

2

2

.

0

0

.

0

4

5

0

.

0

3

0

-

-

3

1

6

0

.

0

8

0

.

7

5

2

.

0

0

m

a

x

1

6

.

0

0

1

8

.

0

0

1

0

.

0

0

-

1

4

.

0

0

0

.

0

4

5

0

.

0

3

0

0

.

1

M

o

2

.

0

-

3

.

0

3

1

6

L

0

.

0

3

0

.

7

5

2

.

0

0

m

a

x

1

6

.

0

0

1

8

.

0

0

1

0

.

0

0

-

1

4

.

0

0

0

.

0

4

5

0

.

0

3

0

0

.

1

M

o

2

.

0

-

3

.

0

3

2

1

0

.

0

8

0

.

7

5

2

.

0

0

m

a

x

1

7

.

0

0

1

9

.

0

0

9

.

0

0

-

1

2

.

0

0

0

.

0

4

5

0

.

0

3

0

0

.

1

T

i

5

x

(

C

N

)

M

i

n

/

0

.

7

0

m

a

x

S

S

L

N

Q

0

.

1

2

0

.

7

5

1

0

.

5

m

a

x

1

4

.

5

-

1

5

.

5

0

.

3

0

-

1

.

0

0

0

.

0

7

5

0

.

0

1

5

0

.

2

0

C

u

2

.

0

m

a

x

.

S

S

L

N

1

0

.

1

2

0

.

7

5

1

0

.

0

m

a

x

1

4

.

0

0

1

6

.

0

0

0

.

9

0

-

1

.

7

0

0

.

0

7

5

0

.

0

3

0

0

.

2

0

C

u

2

.

2

m

a

x

S

S

L

N

4

0

.

1

0

.

7

5

8

.

0

m

a

x

1

4

.

0

0

1

7

.

0

0

3

.

8

0

-

4

.

7

0

0

.

0

7

0

0

.

0

3

0

0

.

1

5

C

u

2

.

2

m

a

x

2

0

4

C

u

0

.

1

5

1

.

0

0

6

.

5

0

-

9

.

0

0

1

5

.

5

1

7

.

5

1

.

5

3

.

5

0

.

0

6

0

0

.

0

3

0

0

.

2

5

C

u

2

.

0

4

.

0

4

0

9

0

.

0

3

1

.

0

0

1

.

0

0

m

a

x

1

0

.

5

0

1

1

.

7

0

0

.

5

0

m

a

x

0

.

0

4

0

.

0

2

0

.

0

3

T

|

=

x

(

C

N

)

r

|

r

/

0

.

5

0

r

a

x

N

o

0

.

1

Z

r

a

x

S

S

4

0

9

M

0

.

0

3

1

.

0

0

0

.

5

-

1

.

5

1

0

.

8

0

-

1

2

.

5

0

1

.

5

m

a

x

0

.

0

4

0

0

.

0

3

0

0

.

0

3

-

4

1

0

S

0

.

0

8

1

.

0

0

1

.

0

0

m

a

x

1

1

.

5

0

1

3

.

5

0

0

.

6

m

a

x

0

.

0

4

0

0

.

0

3

0

-

-

4

2

0

0

.

1

5

m

i

n

1

.

0

0

1

.

0

0

m

a

x

1

2

.

0

0

1

4

.

0

0

0

.

7

5

m

a

x

0

.

0

4

0

0

.

0

3

0

-

M

o

0

.

5

m

a

x

4

3

0

0

.

1

2

1

.

0

0

1

.

0

0

m

a

x

1

6

.

0

0

1

8

.

0

0

0

.

7

5

m

a

x

0

.

0

4

0

0

.

0

3

0

-

-

4

3

9

0

.

0

3

1

.

0

0

1

.

0

0

m

a

x

1

7

.

0

0

-

1

9

.

0

0

0

.

5

m

a

x

0

.

0

4

0

0

.

0

3

0

0

.

0

3

T

|

[

0

.

2

1

(

C

N

)

|

V

|

r

/

1

.

1

r

a

x

A

|

0

.

1

5

r

a

x

1

3

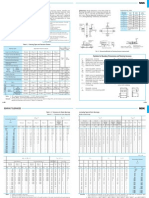

Mechanical Properties of Standard Grades in annealed condition

Grade U.T.S.

N/mm

2

Min

0.2 ProoI

Stress / YS

N/mm

2

Min

El

(GL 50 mm)

Min

Hardness

HR

B

max

Cold Bend

301 515 205 40 95 Not required

301L 550 220 45 100 Not required

304 515 205 40 92 Not required

304L 485 170 40 92 Not required

310S 515 205 40 95 Not required

316 515 205 40 95 Not required

316L 485 170 40 95 Not required

321 515 205 40 95 Not required

204 Cu 650 310 40 - Not required

SSLN4 600 275 40 96 Not required

409 380 170 20 88 180 1 t

SS409M 450 275 22 92 180 1 t

410S 415 205 22* 89 180 1 t

420 690 max - 15 96 Not required

430 450 205 22 * 89 180 1 t

439 415 205 22 89 180 1 t

* 20 Min Ior Thickness less than 1.27 mm

Physical Properties` (Annealed Conditions) CRSS

Details 301 304/304L 316/316L 310S 430 409

Density (gm/cm

3

) 7.9 7.9 8.0 7.9 7.7 7.7

Modules oI Elasticity

(kg /mm

2

)

19700 19700 19700 20300 20300 20300

SpeciIic Heat

Capacity Cal/gm/

0

C

0.12 0.12 0.12 0.12 0.11 0.11

Thermal conductivity

(Cal/cm

2

/Sec/

0

C/cm at

100

0

c

0.039 0.039 0.037 0.033 0.0625 0.0595

SpeciIic Electrical

Resistance (u.cm3)

72 72 74 80 60 57

Coell|c|erl ol lrerra|

expars|or (

0

Cx10-, 0-500

0

C)

19.8 18.4 16.0 16.9 11.34 11.52

Melting Range (

0

C) 1400-

1420

1400-

1455

1370-

1400

1400-

1455

1430-

1510

1430-

1510

* For Guidance Only

14

E

q

u

i

v

a

l

e

n

t

S

p

e

c

i

f

i

c

a

t

i

o

n

s

:

S

t

a

i

n

l

e

s

s

s

t

e

e

l

s

G

R

A

D

E

I

S

I

N

D

I

A

A

I

S

I

U

S

A

D

I

N

G

E

R

M

A

N

Y

A

F

N

O

R

F

R

A

N

C

E

1

I

S

1

A

P

A

N

B

S

B

R

I

T

I

A

N

S

I

S

S

W

E

D

E

N

U

N

S

U

N

I

I

T

A

L

Y

S

S

3

0

1

X

1

0

C

r

1

7

N

i

7

3

0

1

1

.

4

3

1

0

Z

1

2

C

N

1

7

-

0

8

S

U

S

3

0

1

3

0

1

S

2

1

1

4

2

3

3

1

S

3

0

1

0

0

X

1

2

C

r

N

i

1

7

0

7

S

S

3

0

4

X

0

2

C

r

1

9

N

i

1

0

3

0

4

1

.

4

3

0

1

Z

6

C

N

1

8

-

1

9

S

U

S

3

0

4

3

0

4

S

1

5

1

4

2

3

3

3

S

3

0

4

0

0

X

5

C

r

N

i

1

8

1

0

S

S

3

0

4

L

-

3

0

4

L

1

.

4

3

0

6

Z

2

C

N

1

8

-

1

0

S

U

S

3

0

4

L

3

0

4

S

1

1

1

4

2

3

5

2

S

3

0

3

0

3

X

2

C

r

N

i

1

8

1

1

S

S

3

1

0

S

-

3

1

0

S

1

.

4

8

4

5

-

S

U

S

3

1

0

S

-

1

4

2

3

6

1

S

3

1

0

0

8

X

6

C

r

N

i

2

5

2

0

S

S

3

1

6

X

0

1

C

r

1

Z

N

|

1

2

V

o

2

3

1

6

1

.

4

4

0

1

Z

6

C

N

D

1

7

-

1

1

S

U

S

3

1

6

3

1

6

S

3

1

1

4

2

3

4

7

S

3

1

6

0

0

X

8

C

r

N

i

M

o

1

7

1

3

S

S

3

1

6

L

X

0

2

C

r

1

Z

N

|

1

2

V

o

2

3

1

6

L

1

.

4

4

0

4

Z

2

C

N

D

1

7

-

1

2

S

U

S

3

1

6

L

3

1

6

S

3

1

1

4

2

3

3

8

S

3

1

6

0

3

X

2

C

r

N

i

M

o

1

7

1

2

S

S

3

2

1

X

0

1

C

r

1

8

N

|

1

0

T

|

2

0

3

2

1

1

.

4

8

7

8

Z

6

C

N

T

1

8

-

1

2

S

U

S

3

2

1

3

2

1

S

3

1

1

4

2

3

3

7

S

3

2

1

0

0

X

6

C

r

N

i

T

i

1

8

1

1

S

S

4

0

9

-

4

0

9

1

.

4

5

1

2

Z

5

C

T

1

2

S

U

S

4

0

9

4

0

9

S

1

7

-

S

4

0

9

0

0

-

S

S

4

1

0

S

-

4

1

0

S

-

-

-

-

-

-

-

S

S

4

3

0

X

1

0

C

r

1

7

4

3

0

1

.

4

0

1

6

Z

8

C

1

7

S

U

S

4

3

0

4

3

0

S

1

7

1

4

2

3

2

0

S

4

3

0

0

0

X

1

2

C

r

1

7

C

S

S

4

0

9

M

-

-

-

-

-

H

Y

F

A

B

3

/

1

2

-

-

-

1

5

Theoretical Mass : Stainless Steel

Size (1000 x 1000) MM Unit : Kg

Thick (mm) 300 series (Density: 8g/cc) 400 series (Density: 7.7 g/cc)

0.30 2.40 2.31

0.40 3.20 3.08

0.50 4.00 3.85

0.63 4.00 3.85

0.70 5.04 4.85

0.80 5.60 5.39

0.90 6.4 6.16

1.00 8.00 7.70

1.25 10.00 9.63

1.60 12.80 12.32

2.00 16.00 15.40

2.50 20.00 19.25

3.00 24.00 23.10

4.00 32.00 30.80

5.00 40.00 38.50

6.00 48.00 46.20

8.00 64.00 61.60

* These weights are theoretical, Ior guidance only and are not to be used Ior

commercial purpose, as there is a tolerance on thickness, width and length.

16

1

7

1

8

19

20

A pplication: Hot Rolled Carbon Steels

Drawing Quality Steels - IS 1079D, DD, EDD

Drawing quality steels are low Carbon steels, meant Ior applications requiring

ductility superior to that oI general structural steel Ior cold Iorming, drawing

and general engineering purposes.

DD and EDD quality has superior press Iormability.

Typical applications include transport and hoisting equipment, masts and

towers, tubes etc,

Weathering Steels - SAILCOR

These steels are characterized by good atmospheric corrosion resistance and

high yield strength. In as rolled` condition, weathering steels can be used in

normal outdoor applications where the surIace oI the steel remains exposed to

the atmosphere, becoming alternating wet and dry. In course oI time, a

protective layer is Iormed on the surIace oI the weathering steel. These are also

well suited Ior steel structures which are to be painted. The weathering property

prolongs liIe oI paint, requiring minimum repainting. The resistance oI

weathering steels to combustion gases is better compared to general structural

steels as also is their resistance to scaling at high temperature.

The hot rolled steel Iinds applications in railway wagons, coaches, Ireight

containers, truck and bus bodies, material handling equipment, earth moving

equipment and agricultural implements.

High Strength Low Alloys Steels

SAILMA-300/300HI, 350/350HI, 410/410HI, 450/450HI,

E34, E38, IS2062-E410, E450-D, E450-E

These are high strength micro alloyed steels having a combination oI desirable

properties not attainable in conventional mild steel. These steels have higher

yield strength, higher notch toughness, good Iatigue properties, excellent weld

ability and good Iormability.

These steels can be used Ior general structural applications, including ships,

railway wagons and carriages, pressure vessels, pipes, heavy duty transport

vehicles, earth moving equipment and storage tanks.

Structural Steel - IS 2062 / IS 5986.

These steels Ior general structural purpose are unalloyed and are characterized

by their tensile strength and yield strength.

21

Welded tubes and pipes - IS 10748

22

Applications: Stainless Steels

Listed below are some typical uses oI various grades oI Stainless Steels.

However, this is not an exhaustive list. Salem Steel Plant provides technical

assistance in the selection oI proper grade oI stainless steel Ior your speciIic end

uses.

SS 301

An austenitic stainless steel, it has the ability to attain high strength with some

sacriIice oI ductility through moderate or severe cold working. It can be used

where high strength to weight ratio is required with good general corrosion

resistance. By varying chemical composition within ASTM limits and temper

rolling broad range oI magnetic & mechanical properties can be achieved Ior a

variety oI applications. The susceptibility to carbide precipitation during

welding restricts its use in many applications in Iavour oI 304 grade.

Transportation cars such as railway coaches, wagons, subway cars, electrical

equipment and endless belts are some oI the major applications where SS 301 is

preIerred.

SS 301 L

A Cr-Ni austenitic stainless steel, similar to SS301 with lower carbon (0.03)

and higher Nitrogen (0.20), it has the ability to attain high strength without

much sacriIice oI ductility through moderate or severe cold working. It can be

used where high strength to weight ratio is required with good general corrosion

resistance & weldability. Broad range oI mechanical properties with good

Weldability can be achieved by temper rolling. Transportation cars such as

railway coaches, wagons, Iixtures Ior construction purposes, electrical

equipment and endless belts are some oI the major applications.

SS 304

The most widely used austenitic stainless steel with a nominal composition oI

18 Chromium & 8 Nickel It has excellent general corrosion resistance and

Iorming characteristics. It Iinds application in transport, chemical,

petrochemical and Iertilizers industries, dairy, Iood processing, pharmaceutical

industries, hospital equipment, cryogenic vessels, households as utensils &

appliances , heat exchangers, machinery in paper, pulp, textile and beverage

industries. In architectural applications it is used Ior panels, curtain walls,

23

rooIing etc. The weld ability oI this grade is very good; it can be used in work

hardened condition Ior uses requiring high strength.

24

SS 304L

An austenitic stainless steel similar to SS 304 with lower carbon level (0.03

max). Used in place oI SS 304 Ior improved resistance to Intergranular

corrosion and excellent Weldability. It is used Ior parts and structures which

cannot be heat treated aIter welding. It has less tendency to work hardened by

cold working.

SS 310S

This is an austenitic stainless steel with a higher Chromium and Nickel content.

The restricted Carbon helps in better welding and Iormability. Because oI their

relatively high creep strength and mechanical properties at higher temperatures,

these grades Iind applications where higher temperature and severe service

conditions exist. They have high temperature scaling resistance but not good Ior

high sulphur environments. Used Ior air heaters, annealing boxes, ovens,

carburizing boxes, Iire box sheets, Iurnace linings, Iurnace stacks and dampers,

gas turbine parts, heat exchangers, kiln linings, nozzle diaphragm assemblies Ior

turbo jet engines, oil burner parts, paper mill equipment, oil reIinery equipment

and recuperater.

SS 316

An austenitic stainless steel with 2 to 3 Molybdenum to have improved

corrosion resistance, particularly apparent Ior pitting and crevice corrosion

resistance in chloride environment. This grade has good oxidation resistance.

Continuous use at 425-860 degree C is not recommended due to carbide

precipitation. Typical applications include architectural trims, marine exteriors,

chemical processing equipment, Iood processing equipment, petroleum reIining

equipment, pharmaceuticals equipment, photographic equipment, pulp & paper

processing equipment and textile Iinishing equipment.

SS 316L

An austenitic stainless steel similar to SS 316 with lower carbon level (0.03 )

to have better corrosion resistance and Weldability. Low carbon content also

reduces work hardening and improves ductility Ior cold Iorging, drawing etc.,

Low hot strength than SS316.Typical applications include Iood processing,

chemical and petrochemical equipment, brewery equipment, coastal

architectural paneling ,laboratory equipments, heat exchangers, mining screens,

chemical transportation containers etc.,.

25

SS 321

An austenitic stainless steel similar to SS 304 but stabilised with Titanium to

avoid inter-granular corrosion. It has a good Weldability and is used Ior exhaust

stacks and maniIolds, pressure vessels, large muIIlers Ior engines, expansion

bellows, stack liners, thin wall tubes etc where no post heat treatment oI welds

is desired.

SS 409

It is a low alloyed straight Chromium Ferro-magnetic stainless steel. It replaces

carbon steels and low alloy steels where elevated temperature corrosion

resistance , medium strength & good Iormability are required. Titanium is

added to improve the weldability. Typical application are Iins in heater tubes,

transIormer and capacitor cases, dry Iertilizer spreaders, automotive exhaust

systems including muIIlers, pipes and emission control units, shipping

containers and Iarm equipment.

SS 409M

Type SS 409 M is a modiIied version oI SS 409 with lower carbon content

(0.03). It replaces carbon steels and low alloy steels where higher strength,

abrasion resistance, weld-ability and slide-ability are required. It posses good

scaling &oxidation resistance at elevated temperature including sulphur bearing

atmospheres. It Iinds application in bulk solids handling areas/bunkers,

transport(wagons), petrochemical, sugar, agriculture, Iishing, mining

&quarrying, sewage plants and general engineering industries.

SS 410S

SS 410S is a Ierritic stainless steel having 11 chromium minimum. It is

mainly used Ior its high strength and wear resistance and in mild corrosive

environment. Typical applications are Iurnace parts and burners operating at

lower temperatures, tray supports, bubbles caps and internals in petroleum

Iractionating towers. It has moderate weldability and Iormability.

SS 420

SS 420 is a Martensitic Stainless Steel contains Carbon 0.15 min. and around

12 Chromium. It has good ductility in annealed condition and capable oI

being hardened to high hardness(~50HRC) by heat treatment. Weldability is

poor. Typical applications are cutlery, kniIe blades, surgical equipments, needle

valves, shear blades, scissors, hand tools.

26

SS 430

SS 430, is a Ierritic, non-hardenable plain chromium stainless steel with 16-

18 Chromium content. It has good corrosion resistance & Iormability but less

than that oI SS304. Typical applications are decorative trims, reIrigerators,

cookers, stove elements, Iasteners, Ilue linings, scientiIic apparatus storage

vessels, solar water heaters, kitchenware, tableware, washing machine parts,

building and construction hardware, automobile components etc.

Low-Nickel stainless steels ( SSLNQ, SSLN1, 204Cu, SSLN4)

All grades belong to low nickel Chrome Manganese stainless steels commonly

reIerred to 200 series. The Nickel content is replaced with Manganese, Nitrogen

& Copper. These alloys are non magnetic in annealed condition and like SS 304

becomes mildly magnetic aIter cold working. It is recommended Ior

applications oI stainless steels exposed to normal atmospheric conditions and

moderate drawing requirement. Typical applications are utensils , appliances,

consumable durables, transport, Iood processing, building &constructions etc.

PerIormance with respect to Iormability, Weldability and general corrosion

resistance, these grades can be rated in common scale as depicted below

(indicative, not to the scale):

204 Cu

SSLN4

Low

SSLNQ

SSLN1

304

High

27

S tainless Steels Surface Finishes & Applications

SurIace Iinish is an important element in any speciIication Ior stainless steel.

For those applications in which appearance is important, Iinish is a design

element and must be speciIied to avoid receiving a Iinish that is not appropriate

Ior the application.

Finish - A Design Element

There are several good reasons Ior paying close attention to the Iinish

designation. In architecture or other highly visible applications, the appearance

oI stainless steel is a critical design element and a misunderstanding or the

wrong Iinish can alter the desired eIIect.

On the other hand, some Iabrication operations in manuIacturing stainless steel

products such as deep drawing, rough surIace/texture yield better results by

holding lubricants Ior better lubrication.

The surIace on stainless steel Irom the mill or steel warehouse is either the

result oI processes used in producing the basic mill Iorm or it is the result oI

subsequent operations perIormed speciIically to alter the surIace condition or

appearance.

Mill processes include hot rolling, cold rolling, annealing and pickling. These

operations are intended to bring the steel product to a speciIic dimension and

metallurgical condition and the resulting Iinish is generally reIerred to as a

rolled (or unpolished) Iinish.

Subsequent mechanical operations, however, which include grinding, polishing

and buIIing are intended primarily to enhance the brightness oI the surIace.

Rolled Iinishes serve a very broad and practical use because they are usually the

simplest to produce and they are generally the lowest in cost.

Standard Finishes

Stainless steel Ilat products are usually produced Irom cast slabs by hot rolling

at steckel mill as hot rolled coils. Hot Rolled Coils are Iurther processed at

annealing& descaling line Ior soItening and then cold rolled at Z-mill to

speciIied thickness. The cold rolled coil is Iurther annealed & descaled to get

required surIace Iinish.

28

Rolled product Iinishes are designated by a system oI numbers No: 1,2D & 2B

and mechanically polished Iinishes by No: 3, No: 4 & No: 8.Various other

speciIic rolled pattern Iinishes are also in vogue. They are produced by rolling

with special rolls in which designs are engraved / etched.

Surface Finish

No: 1 Finish/HRAP (Hot rolled, annealed and descaled/pickled)

Hot rolled coils are annealed ,shot blasted and pickled which results in a dull,

slightly rough surIace, quite suitable Ior industrial applications which generally

involve a range oI thicknesses.

Typical uses : Air heaters, annealing boxes, boiler baIIles, ducts, carburizing

boxes, coal & ore handling systems, crystallizing pans, Iire box sheets, Iurnace

supports, conveyors, lining, damper, stacks, gas turbine parts, heat exchanger

tubing supports and baIIles, incinerators, industrial over liners, kiln liners, oil

burner parts, pipes, rail coach / wagon components, recuperators, reIinery

equipment, tube hangers etc.

Cold Rolled Finishes

The starting material Ior cold rolling is a No. 1 Iinish coil. Cold rolled material

is supplied with the Iollowing standard mill Iinishes.

2D Finish (Cold rolled, annealed and descaled/pickled)

Cold rolled, annealed and pickled No.1 Iinish material results in a uniIorm dull

Iinish, superior to No.1 Iinish suitable Ior industrial application and deep

drawing .The dull surIace (which may be polished aIter Iabrication) retains the

lubricant during the drawing operation.

Typical uses: Utensils & appliances,Automotive exhaust systems, builders`

hardware, chemicals & petrochemical equipment, electric appliance parts,

Iurnace parts, household ware, kitchen equipment, rail coach parts, trays & pans

Ior chemical equipment etc.

29

2B Finish (Cold rolled, annealed, descaled/pickled and skinpassed)

2D Iinish material is given a light skin pass operation between polished rolls to

get 2B Iinish, which is the most common Iinish Ior sheet material. It is brighter

than 2DIinish and is semi reIlective which in turn depends on the grade oI

stainless steel. It is commonly used Ior most deep drawing operations and is

more easily polished to the Iinal Iinishes required than in a 2D Iinish.

Typical uses : Bake ware, chemical plant equipment, cookware, dairy & Iood

processing machinery, drums, dryers, dye house equipment, Ilatware, laundry

equipment, paper mill equipment, pharmaceutical equipment, plumbing

Iixtures, reIrigeration equipment, steel metal products, small tanks, solar

collector panels, washing machine parts, welded tubing & pipe Ior general

service etc.

Mechanically Polished Finishes

The Iollowing are mechanically produced polished Iinishes, as well as standard

mill Iinishes. They are also used to produce stainless steel articles and

components that require aesthetics. It should be appreciated that Iactors such as

hand polishing vs mechanical polishing, polishing a Ilat product as against a

component oI complex shape and thickness and composition oI material can

aIIect the visual appearance oI the Iinal surIace.

No:3 Finish (Ground-100,120 abrasive)

This is a ground unidirectional uniIorm Iinish obtained with 100, 120 grit

abrasive. It is a good intermediate or starting surIace Iinish Ior use in such

instances where the surIace will require Iurther polishing operations to a Iiner

Iinish aIter subsequent Iabrication or Iorming. It can also be used as a Iinal

Iinish in certain applications.

Typical uses: Architectural components, brewery equipment, Iood processing,

institutional kitchen equipment.

No: 4 Finish (Ground-120,150 abrasive)

This is a ground unidirectional Iinish obtained with 120-150 grit abrasive. It is

not highly reIlective, but is a good general purpose Iinish on components which

will suIIer Irom Iairly rough handling in service (e.g. restaurant equipment).

30

Typical uses : Appliances, architectural wall panels, beverage equipment,

column cladding, dairy equipment, elevator door & interiors, escalator trim,

Iurniture, hospital equipment, instrument or control panels, kitchen equipment,

luggage handling equipment, mass transit equipment, restaurant equipment,

sinks, sterilizers, store Ironts, tankers, etc.

No: 8 Finish (Mirror finish)

A highly reIlective Iinish that is commonly produced on sheet. It is obtained by

polishing with rotating cloth mops and polishing soaps / paste containing Iine

abrasives. The directionality oI polishing may be seen in the sheets. They have a

high degree oI reIlectivity.

Typical uses: Architectural parts, press plates, reIlectors etc.

Special Finishes

Moon Rock, Chequered, Striped, Hammer Tone, Pearl Plus, Honeykom,

Macromatt, Aqualine, Frondz, Mystique, Linen, Epiderma, Fabrique Iinishes

* Special Iinishes are produced as per Iollowing route:

- Hard route Work hardened condition

- SoIt route Cold rolled, annealed & pickled and skinpassed

(either ground or un-ground)

Typical uses: Architectural panels, Ilooring, interior decoration, transport

industry etc.