Textile Reinforcement Concrete

Diunggah oleh

Dikshant HasbeDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Textile Reinforcement Concrete

Diunggah oleh

Dikshant HasbeHak Cipta:

Format Tersedia

TEXTILE REINFORCEMENT CONCRETE

Reinforced concrete (RC) is the most successful building material of the past century and

most likely of the current century too. Combining steel bar reinforcement and concrete produces

an almost ideal composite material. RC is extremely powerful, durable, and cost-effective. It fits

nearly into every form, is extremely versatile and is therefore widely used as a construction

material in buildings and bridges. There is just one problem: to achieve these features, RC

structures need to have a minimum thickness in order to protect the metal reinforcement. A

minimum concrete cover of 2070 mm per layer is necessary to protect steel bar reinforcements

from corrosion during a building's lifetime.

Textile reinforcement structures produced from carbon fibres represent an excellent

alternative and complement existing reinforcement materials made from steel. Textile-reinforced

concrete (TRC) has the same advantages as traditional RC, but also offers some new

opportunities.

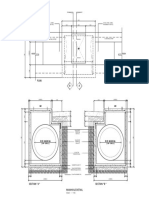

To produce textile reinforcements, continuous yarns or rovings are processed in a planar

structure by a textile technique to produce an optimal alignment and arrangement of fibres in

structural members (Figure 1). This in turn results in either a much higher load-bearing

performance than fibre-reinforced concrete (FRC) with equivalent fibre content, or in a reduced

amount of reinforcement fibres to reach an equal load capacity. TRC is the way to manufacture

thin concrete parts with an extremely high load capacity. Even now, it is a very promising

alternative for strengthening and repairing concrete structures, not least from a cost viewpoint.

TRCs are made from carbon fibre grid structures which are embedded in a fine-grained

concrete matrix & the result is a composite material with remarkable properties and advantages

in use:

No concrete cover is necessary to protect the reinforcement from corrosion since the

reinforcing materials used do not corrode under normal environmental conditions.

Considering that no concrete cover is needed, very thin strengthening layers can be

produced.

Carbon textile reinforcements have a much larger surface area than traditional steel-bar

reinforcements. Thus, very high bond forces can be introduced into the concrete.

TRCs produced from carbon possess distinctly higher strength than standard steel-bar

reinforcements. The current generation of textile reinforcements has reached strengths well

over 1,500 N/mm.

The use of additional TRC strengthening layers in RC structures has proved to have a

positive influence on subsequent concrete cracking. The number of cracks increases while

crack spacing decreases, and crack width is simultaneously reduced

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hawkers Survey - B Ward: SR No ID Date Name Profession Location Contact NoDokumen13 halamanHawkers Survey - B Ward: SR No ID Date Name Profession Location Contact NoDikshant HasbeBelum ada peringkat

- Historical Perspective: Fiber-Reinforced Concrete (FRC) IsDokumen3 halamanHistorical Perspective: Fiber-Reinforced Concrete (FRC) IsDikshant HasbeBelum ada peringkat

- Strengthening of Reinforced Concrete Columns Is Needed WhenDokumen6 halamanStrengthening of Reinforced Concrete Columns Is Needed WhenDikshant Hasbe100% (1)

- Re Alkalization 1Dokumen2 halamanRe Alkalization 1Dikshant Hasbe100% (1)

- Structures Seismic Activity Soil Earthquakes Modern Seismic CodesDokumen1 halamanStructures Seismic Activity Soil Earthquakes Modern Seismic CodesDikshant HasbeBelum ada peringkat

- Fibre Wrapping (Carbon, Aramid, Glass)Dokumen1 halamanFibre Wrapping (Carbon, Aramid, Glass)Dikshant HasbeBelum ada peringkat

- Fibre Reinforced CompositesDokumen2 halamanFibre Reinforced CompositesDikshant HasbeBelum ada peringkat

- Fibre Reinforced ConcreteDokumen21 halamanFibre Reinforced ConcreteSiddharth BeheraBelum ada peringkat

- Textile Reinforced ConcreteDokumen21 halamanTextile Reinforced ConcreteDikshant Hasbe50% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Castwise CookwareDokumen9 halamanCastwise CookwarePreet Inder SinghBelum ada peringkat

- Use of Geosynthetics in WR ProjectsDokumen3 halamanUse of Geosynthetics in WR Projectsashwaniv_6Belum ada peringkat

- Case 7 and 8Dokumen2 halamanCase 7 and 8Xyrille Jocson100% (1)

- Metric Structural Steel CatalogDokumen22 halamanMetric Structural Steel CatalogBeniamine SarmientoBelum ada peringkat

- K011en-Nippon Steel PilesDokumen25 halamanK011en-Nippon Steel PilesJustin CorbettBelum ada peringkat

- Ppop Bab Ii PDFDokumen44 halamanPpop Bab Ii PDFSabrinanur RamadhaniBelum ada peringkat

- r05220501 Software EngineeringDokumen4 halamanr05220501 Software EngineeringSRINIVASA RAO GANTABelum ada peringkat

- Local Case Study Arba Minch University D PDFDokumen16 halamanLocal Case Study Arba Minch University D PDFKayfi Akram Mawlan100% (1)

- Recycled Concrete AggregateDokumen28 halamanRecycled Concrete AggregatePrashant pande100% (1)

- ANSYS 2d PlaneDokumen13 halamanANSYS 2d Planeadnan100% (1)

- Labunets PHD ThesisDokumen162 halamanLabunets PHD ThesisNoman RazaBelum ada peringkat

- Master Thesis Biomedical Engineering ExampleDokumen5 halamanMaster Thesis Biomedical Engineering Exampleambervoisineanchorage100% (4)

- Drainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Dokumen1 halamanDrainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Jayson DaiganBelum ada peringkat

- Zain Jaber Saadoon New CV - 231019 - 215022Dokumen4 halamanZain Jaber Saadoon New CV - 231019 - 215022SudeepDPoojaryBelum ada peringkat

- Shahkar Azam Civil Engineer ResumeDokumen2 halamanShahkar Azam Civil Engineer ResumeazamshahkarBelum ada peringkat

- Preferences For TNAU UG Admission 2019: Registration Number: Name of CandidateDokumen3 halamanPreferences For TNAU UG Admission 2019: Registration Number: Name of CandidateRaja RajBelum ada peringkat

- Interior Designers List GurgaonDokumen53 halamanInterior Designers List GurgaonKevin HansonBelum ada peringkat

- Demag KBK Light Crane System: Overhead Transport, Exact Positioning, Ergonomic HandlingDokumen36 halamanDemag KBK Light Crane System: Overhead Transport, Exact Positioning, Ergonomic HandlingVijay PapriwalBelum ada peringkat

- Hyper Compressor CatalougeDokumen24 halamanHyper Compressor Catalougetatarey79Belum ada peringkat

- Bhoj Raj Pant Steel Sap ReportDokumen60 halamanBhoj Raj Pant Steel Sap ReportRooking Ewondo SfuutBelum ada peringkat

- Wayne County Jail ProposalDokumen204 halamanWayne County Jail ProposalClickon DetroitBelum ada peringkat

- 2 3 8 AresidentialwatersupplyDokumen5 halaman2 3 8 Aresidentialwatersupplyapi-348898646Belum ada peringkat

- Acc Report On RMC Industry in AhmedabadDokumen43 halamanAcc Report On RMC Industry in AhmedabadMaulik Padh100% (1)

- Software Validation: Errors - These Are Actual Coding Mistakes Made by Developers. in AdditionDokumen2 halamanSoftware Validation: Errors - These Are Actual Coding Mistakes Made by Developers. in Additionanon_723333426Belum ada peringkat

- Introduction To MechatronicsDokumen46 halamanIntroduction To MechatronicsChristian Breth Burgos100% (2)

- Manual CAEPipeDokumen47 halamanManual CAEPipeClaudio GimenezBelum ada peringkat

- Curriculum Vitae - Electrical EngineerDokumen3 halamanCurriculum Vitae - Electrical EngineerLingaraj Suresh LingaianBelum ada peringkat

- Engineering and Ethics SyllabusDokumen6 halamanEngineering and Ethics SyllabusSarah BurgenBelum ada peringkat