Ucm03 081936

Diunggah oleh

namduong368Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ucm03 081936

Diunggah oleh

namduong368Hak Cipta:

Format Tersedia

TECHNICAL TRAINING

CUSTOMER TRAINING PROGRAM TEREX PORT SOLUTIONS

2 Terex Port Solutions 2014

Customer training program Terex Port Solutions

Please contact us!

In this brochure, you will fnd details of the courses available within the Terex Port Solu-

tions (TPS) customer training program.

Should you have any further questions about this TPS Customer Training Program or do

you want to order one of our trainings, please do not hesitate to contact us.

Alexander Bongart

Manager Training Operation

Training (PSS 26)

Forststrae 16

40597 Dsseldorf, Germany

T +49 211 7102-3546

M +49 173 29 27 361

F +49 211 7102-53546

E alexander.bongart@terex.com

Deborah Schriegel

Training Administration & Coordination

Training (PSS 26)

Forststrae 16

40597 Dsseldorf, Germany

T +49 211 7102-3792

M +49 162 25 96 648

F +49 211 7102-53792

E deborah.schriegel@terex.com

Foreword

3 Terex Port Solutions 2014

Customer training program Terex Port Solutions

Making skills work

develop your staff through our training courses

Making skills work true to this motto we support you with high quality training solu-

tions to exploit the full potential of your TPS products and to boost your productivity.

We offer you a comprehensive range of training courses that qualify your staff in the safe

and effcient operation and maintenance of TPS products and their components. You ben-

eft from our many years of experience. We continuously develop our training courses on

the basis of intensive customer interaction and local expertise. With practical work carried

out on the products, we ensure that your staff acquires the relevant know-how. We docu-

ment the participants successful completion of the course with our training certifcates,

which are recognised by the industry.

The most important highlights

Modular, practice-oriented training program

German-educated technical trainers

Operator trainers with more than 20 years experience in Port of Antwerp

State-of-the-art equipment used in training

Comprehensive training documentation for each course

Training courses held at our training centers in

Dsseldorf (Germany)

Wrzburg/Hamburg (Germany)

Antwerp (Belgium)

Montceau les Mines (France)

Training courses held onsite at your port

Renowned Terex Port Solutions training certifcate

Foreword

4 Terex Port Solutions 2014

Customer training program Terex Port Solutions

Training centre in Dsseldorf, Germany

Highlights:

Highly experienced trainers

State-of-the-art training workplaces with

their own PC and the Simatic Manager

Simulators to represent the overall

crane control system

Comprehensive training documentation

for each course

Renowned Terex Port Solutions training

certifcate

Training centre in Antwerp, Belgium

Highlights:

Trainers from experience

Two state-of-the-art simulators featuring many

operating scenarios that are adapted to Terex

Gottwald mobile harbour cranes

HMK 260 E mobile harbour crane for hands-on

training

Renowned Terex Port Solutions training certifcate

Foreword

5 Terex Port Solutions 2014

Customer training program Terex Port Solutions

Training centre in Montceau les Mines, France

Highlights:

Terex Port Solutions certifed trainers

TPS training quality workplace

Terex reach stacker for hands-on training

Technical documentation for training

Renowned Terex Port Solutions training

certifcate

Training centre in Wrzburg/Hamburg, Germany

Highlights:

Well-educated trainers

Terex straddle carrier for hands-on training

Detailed training documentation

Renowned Terex Port Solutions training certifcate

Foreword

6 Terex Port Solutions 2014

Customer training program Terex Port Solutions

Content

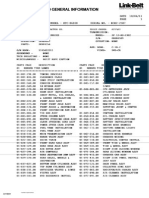

1 Mobile harbour crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Technical training 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Technical training 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Hydraulic training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Troubleshooting training (onsite & hands-on) . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Automated guided vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1 Technical training 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Technical training 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Battery exchange station & battery training . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Straddle carrier & sprinter carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1 Technical training 1 for Noell NSC E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 Technical training 2 for Noell NSC E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Technical training 1 for Noell NSC H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4 Technical training 2 for Noell NSC H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Reach stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1 Technical training for Terex TFC 45H/TFC 45HC . . . . . . . . . . . . . . . . . . . . . . 30

5 General products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1 Basic training Simatic S7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Contents

7 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

1 Mobile harbour crane

Safe operation and

maximum handling rates

Concept:

Basic training hydraulics

Basic training Simatic S7

Troubleshooting training

(on-site)

Technical training 1 & 2

Target groups

Maintenance staff and

service technicians

Maintenance staff and

service technicians

Experienced service

technicians

Targets

Acquiring and

improving the

necessary skills

Application of

skills gained from

classroom training

course to practical

use

Improved productivity

through minimum

downtimes and well

trained staff

8 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

1.1 Technical training 1

Number of participants:

Min. 3 and max. 8 participants

Duration:

5 days

Location:

Dsseldorf, Germany

On site

In this course, fundamental knowledge about Terex

Gottwald cranes is conveyed to the

trainees. Trainees will frst learn about the general set-up of their crane(s) and become

familiar with the product documentation. To be able to perform the maintenance work and

fault diagnosis, trainees are introduced to the fundamentals of the electrics and hydraulics

of their Terex

Gottwald products. The training also includes learning to read the circuit

diagrams and hydraulic drawings. Trainees also receive instruction on the functions and

settings of drive units and assemblies such as the hoists, slewing gears and luffng gear

as well as on the brakes, steering and stabilisers.

The technical training 1 is designed for electricians and mechanics involved in work or

maintenance work on mechanical, hydraulic or electric components of a Terex

Gottwald

product.

Seminar contents:

Mobile harbour cranes

General diagram G HxK/HxK

Superstructure/chassis/etc. G HxK/HxK

Documentation

Training manual

Operating and maintenance manuals

Spare parts catalogue (CD ROM)

Electrics

Designation system for control systems and auxiliary units

Functional groups, function designations, etc.

Circuit diagram booklet

Hydraulics

Introduction to hydraulics

Illustration of hydraulic symbols

Hydraulics circuit diagrams

Continued on next page

9 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

Continued from course program technical training 1

Functions and design

Crane control system

Superstructure and tower setup

Hoist function and setup

Slewing gear function and setup

Luffng gear function and setup

Chassis setup

Travel gear function and setup

Steering function and setup

Brake function and setup

Stabilizer function and setup

for G HMK/HMK

10 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

1.2 Technical training 2

Number of participants:

Min. 3 and max. 8 participants

Duration:

5 days

Location:

Dsseldorf, Germany

On site

Trainees are communicated the relevant knowledge to diagnose and remedy faults oc-

curring on Terex

Gottwald cranes. After fundamental explanations of the way the control

system, consisting of hardware and software components, is made up, key aspects of

the bus systems are examined in detail. Additional insights into programming and the

programming language used make subsequent troubleshooting that much easier. Train-

ees will become familiar with one of the tried-and-tested aids for diagnosing faults the

Visumatic

control and visualisation system. Hands-on training enables the trainees to

learn practical fault diagnosis skills and remedies.

The technical training 2 is designed for electricians involved in more complex mainte-

nance work or tougher troubleshooting.

Seminar contents:

Programmable logic control (PLC)

PLC on mobile harbour cranes

Industrial PC/hardware/software/ethernet

Controller S7 300/S7 400 setup/displays

PROFIBUS DP

PROFIBUS DP components and interface

S7 hardware confguration

ET 200S

IM 151 interface module setup and displays

ET 200S input and output modules

ASI bus

Setup/function

Master and slave module setup/function

CAN bus (G HxK only)

Setup/function

Master and slave module setup/function

Continued on next page

11 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

Continued from course program technical training 2

STEP 7 programming environment

Organisation blocks (OB)

Function blocks (FB)

Function (FC)

Data blocks (DB)

Programming languages

Structured text (STL)

Function block diagram (FBD)

Ladder diagram (LAD)

Online functions

Main window

Menu and toolbar

Object organiser

Variable table (VAT)

User program

Components

User program blocks

Block types

Functions

12 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

1.3 Hydraulic training

Number of participants:

Min. 3 and max. 6 participants

Duration:

5 days

Location:

Dsseldorf, Germany

In this course, fundamental knowledge about Terex

Gottwald cranes is conveyed to the

trainees. Trainees will frst learn about the general set-up of their crane(s) and become

familiar with the product documentation. To be able to perform the maintenance work

and fault diagnosis, trainees are introduced to the fundamentals of the hydraulics of their

Terex

Gottwald products. The training also includes learning to read the hydraulic draw-

ings. Trainees also receive instruction on the functions and settings of hydraulic units and

assemblies such as the travel gears and luffng gear as well as on the brakes, steering

and stabilisers.

The hydraulic training is designed for electricians and mechanics involved in work or

maintenance work on hydraulic components.

Seminar contents:

What is hydraulic fuid technology?

Generation of force using hydraulics

Illustration of hydraulic symbols

Layout of hydraulic drawings

Hydraulic systems in the 4

th

or 5

th

generation of mobile harbour cranes

Hydraulic system on HMK or G HMK platforms

Four-rope grab crane superstructure hydraulic system

Hydraulic power generation and distribution

HMK or G HMK pump system on platforms

A11VO hydraulic pump

Control block

Distributor block

Pressure stages

Set-up and function of hydraulic drives in the superstructure

Luffng gear hydraulic system

Design of rexroth and tries block

Luffng-in or raising the boom

Luffng-out or setting down the boom

Description of the hoist and slewing gear brakes

Continued on next page

13 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

Continued from course program hydraulic training

Set-up and function of the hydraulic drives in the chassis

HMK or G HMK chassis hydraulic system on platforms

Description of travel gear, steering, travel gear brake, stabiliser system

Valve lists

HMK or G HMK platforms

14 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

1.4 Troubleshooting training (onsite & hands-on)

Number of participants:

Min. 3 and max. 4 participants

Duration:

5 days

Location:

On site

Requirements:

Mobile harbour crane must be available

Trainees are communicated the relevant knowledge to diagnose and remedy faults oc-

curring on Terex

Gottwald cranes. After fundamental explanations of the way the control

system, consisting of hardware and software components, is made up, key aspects of

the bus systems are examined in detail. Additional insights into programming and the

programming language used make subsequent troubleshooting that much easier. Train-

ees will become familiar with one of the tried-and-tested aids for diagnosing faults the

Visumatic

control and visualisation system. Hands-on training enables the trainees to

learn practical fault diagnosis skills and remedies.

The troubleshooting training is designed for electricians involved in more complex mainte-

nance work or tougher troubleshooting.

Seminar contents:

Electrics

Fault fnding with visumatic

Fault fnding with electrical booklet and multimeter

Hydraulics

Fault fnding with visumatic and hydraulic diagram

Programmable logic control (PLC)

Introduction of the user program

Pinpoint faults in the program

Error logging

Error recovery

Profbus DP

Review connections at components and interfaces

Bypass faulty components

ET 200S

Evaluate status LEDs

Check input and output modules

Continued on next page

15 Terex Port Solutions 2014

Customer training program Terex Port Solutions

1 Mobile harbour crane

Continued from course program troubleshooting training

ASI Bus

Evaluate status LEDs

Replace faulty components

Readdress connected slaves

Display digital and analogue values

Online functions

Diagnose online status of the crane

Display variable in VAT

Compare online/offine user program

Download user program

16 Terex Port Solutions 2014

Customer training program Terex Port Solutions

2 Automated guided vehicle

2 Automated guided vehicle

2.1 Technical training 1

Number of participants:

Min. 3 and max. 6 participants

Duration:

2,5 days

Location:

On site

Requirements:

AGV must be available

In this course, fundamental knowledge about AGVs is conveyed to the trainees. Train-

ees will frst learn about the general set-up of their AGVs and become familiar with the

product documentation. To be able to perform the maintenance work and fault diagnosis,

trainees are introduced to the fundamentals of the electrics and hydraulics of their Terex

Gottwald products. The training also includes learning to read the circuit diagrams and

hydraulic drawings.

The technical training 1 is designed for electricians and mechanics involved in work or

maintenance work on mechanical, hydraulic or electric components of a Terex

Gottwald

product.

Seminar contents:

Automated guided vehicle

General view of the components

Technical data

Documentation

Training manual

Operating and maintenance manuals

Spare parts catalogue (CD ROM)

Electrics

Designation system for control systems and auxiliary units

Functional groups, function designations, etc.

Circuit diagram booklet

Hydraulics

Introduction to hydraulics

Illustration of hydraulic symbols

Continued on next page

17 Terex Port Solutions 2014

Customer training program Terex Port Solutions

2 Automated guided vehicle

Continued from course program technical training 1

Hydraulics circuit diagrams

Functions and design

Control system

Sensors

Chassis setup

Travel gear function and setup

Steering function and setup

Brake function and setup

18 Terex Port Solutions 2014

Customer training program Terex Port Solutions

2 Automated guided vehicle

2.2 Technical training 2

Number of participants:

Min. 3 and max. 6 participants

Duration:

2,5 days

Location:

On site

Requirements:

AGV must be available

Trainees are communicated the relevant knowledge to diagnose and remedy faults occur-

ring on AGVs. After fundamental explanations of the way the control system, consisting

of hardware and software components, is made up, key aspects of the bus systems are

examined in detail. Additional insights into programming and the programming language

used make subsequent troubleshooting that much easier. Hands-on training enables the

trainees to learn practical fault diagnosis skills and remedies.

The technical training 2 is designed for electricians involved in more complex mainte-

nance work or tougher troubleshooting.

Seminar contents:

Basics of programmable logic control (PLC)

PLC on automated guided vehicles

User program

Software update

Troubleshooting

CAN bus

CAN bus components and interface

Hardware confguration

Introductions to TEAMS, FMDS, BMS, FCS

Inverters

Basics

Manufacturers documentation

User-specifc parameters

Change parameters

Firmware update

Trace function

Continued on next page

19 Terex Port Solutions 2014

Customer training program Terex Port Solutions

2 Automated guided vehicle

Continued from course program technical training 2

Steering controller

Basics

User program

Trace function

Software update

IO Box

Ltze locc box

Display

Sensors used on the AGV

Software

AGV-monitor

FMDS

20 Terex Port Solutions 2014

Customer training program Terex Port Solutions

2 Automated guided vehicle

2.3 Battery exchange station & battery training

Number of participants:

Min. 3 and max. 6 participants

Duration:

1,5 days

Location:

On site

Requirements:

Battery-AGV and battery exchange station must be available

In this course, fundamental knowledge about the AGVs battery and the battery changing

station is conveyed to the trainees. Trainees will frst learn about the general set-up of the

battery and the battery changing station and become familiar with the product documen-

tation to perform the maintenance work. Hands-on training enables the trainees to learn

practical fault diagnosis skills and remedies.

The battery & battery changing station training is designed for electricians involved in

work or maintenance work on electric components or involved in troubleshooting.

Seminar contents:

Safety

Electrical hazards

Safe handling of batteries

Documentation

Training manual

Operating and maintenance manuals

Batteries

Design

Charge manually

Maintenance

Water refll

Measure acid density

Measurement of cell voltage

Manual remove of the batteries

Function of WI-IQ

Battery charger

Functions

Status lamps

Fault messages

Continued on next page

21 Terex Port Solutions 2014

Customer training program Terex Port Solutions

2 Automated guided vehicle

Continued from course program battery & battery changing station training

Battery changing station

Automatic mode

Manual operation

Maintenance

Calibration

Fault messages

Troubleshooting

22 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

3 Straddle carrier & sprinter carrier

3.1 Technical training 1 for Noell NSC E

Number of participants:

Min. 3 and max. 8 participants

Duration:

5 days

Location:

Wrzburg, Germany

On site

Requirements:

For onsite training, a straddle carrier and/or a sprinter carrier must be available

In this course, fundamental knowledge about straddle carrier & sprinter carrier is con-

veyed to the trainees. Trainees will frst learn about the general set-up of their straddle

carrier & sprinter carrier and become familiar with the product documentation. To be able

to perform the maintenance work and fault diagnosis, trainees are introduced to the fun-

damentals of the electrics and hydraulics. The training also includes learning to read the

circuit diagrams and hydraulic drawings.

The technical training 1 is designed for electricians and mechanics involved in work or

maintenance work on mechanical, hydraulic or electric components of a straddle carrier &

sprinter carrier.

Seminar contents:

Straddle carrier & sprinter carrier

Inspection of the main straddle carrier components

Explanation and location of the safety features

Introduction of the operational controls of the straddle & sprinter carrier

Documentation

Training manual

Operating and maintenance manual

Spare parts catalogue (CD ROM)

Electrics

Designation systems for control systems and auxiliary units

Functional groups, function designations, etc.

Circuit diagrams

Basic description of individual electric systems (hoist system, drive system)

Continued on next page

23 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

Continued from course program technical training 1 for Noell NSC E

Hydraulics

Introduction to hydraulics

Illustration of hydraulic symbols

Hydraulics circuit diagrams

Basic description of individual hydraulic systems

Steering system

Brake system

Spreader

PLC System

Description and function of the CAN-bus

Basic description of the PLC system

PLC Software update with a USB memory stick

Generator

Basic description of the generator

Generator/frequency converters

Basic description of the converters

Diagnostic using the frequency converter/CAN fault list

Basic description of the emergency recovery procedure

Diesel engine

Overview of the main diesel engine components

Straddle carrier & sprinter carrier maintenance

Maintenance schedule

24 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

3.2 Technical training 2 for Noell NSC E

Number of participants:

Min. 3 and max. 8 participants

Duration:

5 days

Location:

Wrzburg, Germany

On site

Requirements:

For onsite training, a straddle carrier and/or a sprinter carrier must be available

Trainees are communicated the relevant knowledge to diagnose and remedy faults oc-

curring on straddle carrier & sprinter carrier. After fundamental explanations of the way

the control system, consisting of hardware and software components, is made up, key

aspects of the bus systems are examined in detail. Additional insights into programming

and the programming language used make subsequent troubleshooting that much easier.

Hands-on training enables the trainees to learn practical fault diagnosis skills and rem-

edies.

The technical training 2 is designed for electricians involved in more complex mainte-

nance work or tougher troubleshooting.

Seminar contents:

Straddle carrier & sprinter carrier

Explanation and location of the safety features

Electrics

Overview of the electrical system

Electrical components (e.g. absolute encoder, keyboard etc.)

Description and function of the individual electric systems

Hoist system

Drive system

Troubleshooting the electrical system

PLC System

Description and function of the CAN-bus

Working with PCanView to diagnose the CAN-bus

Working with CoDeSys (monitoring the program and creating HEX fles)

Working with WinFlash (downloading HEX fles to ESX controller)

Working with the Mvision software to setup and programming the display

PLC software update with a USB memory stick

PLC data upload with a USB memory stick

Continued on next page

25 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

Continued from course Program technical training 2 for Noell NSC E

Description and changing of important PLC parameters

Troubleshooting the PLC system

Generator

Description and function of the generator

Troubleshooting the generator

Frequency converters

Description and function of converters

Diagnostic using the frequency converter/CAN fault list

Downloading and changing parameters

Troubleshooting the frequency converter

Description and function of the emergency recovery procedure

Hydraulics

Steering system

Diagnostic software (only for electrical steering system)

Brake system

Spreader

Troubleshooting the hydraulic systems

Diesel engine

Diagnose the diesel engine

26 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

3.3 Technical training 1 for Noell NSC H

Number of participants:

Min. 3 and max. 8 participants

Duration:

5 days

Location:

Wrzburg, Germany

On site

Requirements:

For onsite training, a straddle carrier and/or a sprinter carrier must be available

In this course, fundamental knowledge about straddle carrier & sprinter carrier is con-

veyed to the trainees. Trainees will frst learn about the general set-up of their straddle

carrier & sprinter carrier and become familiar with the product documentation. To be able

to perform the maintenance work and fault diagnosis, trainees are introduced to the fun-

damentals of the electrics and hydraulics. The training also includes learning to read the

circuit diagrams and hydraulic drawings.

The technical training 1 is designed for electricians and mechanics involved in work or

maintenance work on mechanical, hydraulic or electric components of a straddle carrier &

sprinter carrier.

Seminar contents:

Straddle carrier & sprinter carrier

Inspection of the main straddle carrier & sprinter carrier components

Explanation and location of the safety features

Introduction of the operational controls of the straddle carrier & sprinter carrier

Documentation

Training manual

Operating and maintenance manual

Spare parts catalogue (CD ROM)

Electrics

Designation systems for control systems and auxiliary units

Functional groups, function designations, etc.

Circuit diagrams

Hydraulics

Introduction to hydraulics

Hydraulic principles

Illustration of hydraulic symbols

Hydraulics circuit diagrams

Continued on next page

27 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

Continued from course program technical training 1 for Noell NSC H

Basic description of individual hydraulic systems

Steering system, brake system, spreader, hoist system and drive system

Basic description of the emergency recovery procedure

PLC system

Description and function of the CAN-bus

Basic description of the PLC system

PLC software update with a USB memory stick

Diesel engine

Overview of the main diesel engine components

Straddle carrier & sprinter carrier maintenance

Maintenance schedule

28 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

3.4 Technical training 2 for Noell NSC H

Number of participants:

Min. 3 and max. 8 participants

Duration:

5 days

Location:

Wrzburg, Germany

On site

Requirements:

For onsite training, a straddle carrier and/or a sprinter carrier must be available

Trainees are communicated the relevant knowledge to diagnose and remedy faults oc-

curring on straddle carrier & sprinter carrier. After fundamental explanations of the way

the control system, consisting of hardware and software components, is made up, key

aspects of the bus systems are examined in detail. Additional insights into programming

and the programming language used make subsequent troubleshooting that much easier.

Hands-on training enables the trainees to learn practical fault diagnosis skills and rem-

edies.

The technical training 2 is designed for electricians involved in more complex mainte-

nance work or tougher troubleshooting.

Seminar contents:

Straddle carrier & sprinter carrier

Explanation and location of the safety features

Electrics

Overview of the electrical system

Electrical components (e.g. absolute encoder, keyboard etc.)

Description and function of the individual electric systems

Troubleshooting the electrical system

PLC System

Description and function of the CAN-bus

Working with PCanView to diagnose the CAN-bus

Working with CoDeSys (monitoring the program and creating HEX fles)

Working with WinFlash (downloading HEX fles to ESX controller)

Working with the Mvision software to setup and programming the display

PLC software update with a USB memory stick

PLC data upload with a USB memory stick

Description and changing of important PLC parameters

Troubleshooting the PLC system

Continued on next page

29 Terex Port Solutions 2014

Customer training program Terex Port Solutions

3 Straddle carrier & sprinter carrier

Continued from course program technical training 2 for Noell NSC H

Hydraulics

Description and function of the individual hydraulic systems

Steering system

Diagnostic software (only for electrical steering system)

Brake system

Spreader

Hoist system

Drive system

Troubleshooting the hydraulic systems

Description and function of the emergency recovery procedure

Diesel engine

Diagnose the diesel engine

30 Terex Port Solutions 2014

Customer training program Terex Port Solutions

4 Reach stacker

4 Reach stacker

4.1 Technical training for Terex TFC 45H/TFC 45HC

Number of participants:

Min. 3 and max. 8 participants

Duration:

5 days

Location:

Montceau les mines, France

On site

Requirements:

For onsite training, a reach stacker must be available

This course will introduce the TFC 45 reach stackers to the service engineers. Treating

the main differences between the two version TFC 45 H and TFC 45 HC.

After presentation of the all pilots control unit, we analyse the two different transmission

and all functions through the hydraulic and electric system.

This will give useful basics in order to approach the different methods for trouble shooting

and repair.

During the training the student will get a training manual and the standard CD containing

manual of conduct, spare parts and schematics.

Course activities

Theoretical lessons on training room and practical lessons on the reach stacker

Completion of benefts

Machine working and systems understanding

Acquiring and improving hydraulic, electric and pneumatic knowledge for troubleshoot-

ing

Operation knowledge

LMI use and adjustments procedure.

Duration

Courses started monday 2.00 pm till friday 12.00 am.

Seminar contents:

Historic of the reach stacker

Summary of the pilot unit

Control panel

Maintenance schedule

Continued on next page

31 Terex Port Solutions 2014

Customer training program Terex Port Solutions

4 Reach stacker

Continued from course program technical training for Terex TFC 45H/TFC 45HC

Transmission analyse

Dana TE 27000 vfs-booster (APC 200)

Dana TE 27418 full fow ( APC 216)

Gear box calibration

Load sensing pump

Cooling circuit

Parker control valve (M400LS-L90LS)

Pilot pressure regulation

Steering function

Brake system

Spreader functions

Logic module reading (practice on millennium type)

Telescope and boom hoist functions

MD3 Display

Description of the menu

Diagnostic mode

Adjustments (angle, pressure, boom length)

32 Terex Port Solutions 2014

Customer training program Terex Port Solutions

5 General products

5 General products

5.1 Basic training Simatic S7

Number of participants:

Min. 3 and max. 6 participants

Duration:

5 days

Location:

Dsseldorf, Germany

Trainees are communicated the relevant knowledge Siemens S7 PLC Systems, the Hard-

ware setup and the programming languages. Trainees will work with the belt model and

start to develop their own programming solutions. Hands-on training enables the trainees

to learn practical fault diagnosis skills and remedies.

Seminar contents:

Programmable logic controller (PLC)

Fundamental programmable logic controller (PLC)

Memory areas

Program cycle

Block types

Data types

Addressing

Programming of the PLC

Programming languages

Structured text (STL)

Function block diagram (FBD)

Ladder diagram (LAD)

Digital and analog instructions

PLC hardware

Central device S7 300/S7 400 (CPU)

Decentralised periphery (ET 200 station)

Hardware confguration

Profbus connection

Simatic manager

General set up

Continued on next page

33 Terex Port Solutions 2014

Customer training program Terex Port Solutions

5 General products

Continued from course program basic training Simatic S7

User interface and operation

Applications

Creating logic blocks

Multiple instances in the variable declaration

Entering and editing addresses and parameters

Editing FBD and STL elements

Establishing online connections

Download/upload

Deleting on the programmable controller

Compressing the user memory

Managing multilingual texts

Simulation tool

SIMATIC S/-PLCSIM

Belt model (hands-on)

34 Terex Port Solutions 2014

Customer training program Terex Port Solutions

5 General products

Notes

35 Terex Port Solutions 2014

Customer training program Terex Port Solutions

5 General products

Notes

www.terexportsolutions.com

Effective date: August, 2013. Product specications and prices are subject to change without notice or obligation. The photographs and/or drawings

in this document are for illustrative purposes only. Refer to the appropriate Operators Manual for instructions on the proper use of this equipment.

Failure to follow the appropriate Operators Manual when using our equipment or otherwise failure to act responsibly may result in serious injury or death.

The only warranty applicable to our equipment is the standard written warranty applicable to the particular product and sale and Terex Port Solutions makes

no other warranty, express or implied. Products and services listed may be trademarks, service marks or trade-names of Terex Corporation and/or its subsidiaries

in the USA and other countries. All rights are reserved. Terex is a registered trademark of Terex Corporation in the USA and many other countries.

2014 Terex Corporation.

S

u

b

j

e

c

t

t

o

c

h

a

n

g

e

w

i

t

h

o

u

t

n

o

t

i

c

e

C

u

s

t

o

m

e

r

t

r

a

i

n

i

n

g

p

r

o

g

r

a

m

T

e

r

e

x

P

o

r

t

S

o

l

u

t

i

o

n

s

-

V

e

r

s

i

o

n

0

7

.

1

4

Hier in die Zeile Thema des Handbuches eintragen, Texfeld wird nicht gedruckt!!!

Customer training program Terex Port Solutions

Anda mungkin juga menyukai

- 2013 Manitowoc Course CatalogDokumen16 halaman2013 Manitowoc Course CatalogjairseguraBelum ada peringkat

- Energy Efficiency of Industrial Trucks - Test Methods - Container Straddle CarriersDokumen13 halamanEnergy Efficiency of Industrial Trucks - Test Methods - Container Straddle CarriersHamouda EL Sayed Safan100% (1)

- Powering The Port of The Future With Eco-Efficient SolutionsDokumen28 halamanPowering The Port of The Future With Eco-Efficient Solutionsbobbyhardian100% (1)

- Technical Deviation List - Cable Reel RTG CargotecDokumen6 halamanTechnical Deviation List - Cable Reel RTG CargotectuanvupnBelum ada peringkat

- Converting A Manual RTG Terminal To An AutoRTG TerminalDokumen16 halamanConverting A Manual RTG Terminal To An AutoRTG Terminalacanbasri1980Belum ada peringkat

- KC Technical Customer enDokumen48 halamanKC Technical Customer enAri YandokoBelum ada peringkat

- RTG Konecranes Booklet RTG Retrofits 2015 enDokumen28 halamanRTG Konecranes Booklet RTG Retrofits 2015 enFendy KurniadiBelum ada peringkat

- Linde c4026-4535 en SiDokumen8 halamanLinde c4026-4535 en Sigus100% (1)

- QC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprDokumen160 halamanQC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprCarlos Luis Esquerdo MarcanoBelum ada peringkat

- PSA Crane Spreader Cable Reel Data ProjeDokumen72 halamanPSA Crane Spreader Cable Reel Data ProjeCristel Rodríguez BarríaBelum ada peringkat

- Technical Description of an RTG Rubber Tyre Gantry CraneDokumen4 halamanTechnical Description of an RTG Rubber Tyre Gantry CraneZuhal ZaeemBelum ada peringkat

- Weight Reduction of Reach Stacker (Konecrane)Dokumen111 halamanWeight Reduction of Reach Stacker (Konecrane)Bruno SantosBelum ada peringkat

- H16 22 00 12EC PDF 4Dokumen24 halamanH16 22 00 12EC PDF 4Ing FermínBelum ada peringkat

- Kalmar Maintenance Cost CompareDokumen17 halamanKalmar Maintenance Cost CompareAnonymous kVxE6a100% (1)

- Kalmar Services Course Catalogue 0405Dokumen20 halamanKalmar Services Course Catalogue 0405Muhammad rizki100% (1)

- Optimize CAN Network StructureDokumen14 halamanOptimize CAN Network StructureyousufBelum ada peringkat

- DRD420Dokumen15 halamanDRD420neper14100% (2)

- 7 55T GT550e TadanoDokumen12 halaman7 55T GT550e Tadanoa1435Belum ada peringkat

- 8 Rope Reeving 3 PDFDokumen4 halaman8 Rope Reeving 3 PDFsanjay aBelum ada peringkat

- B-Repair Ad Maintenance Manual - Rev0Dokumen82 halamanB-Repair Ad Maintenance Manual - Rev0Carlos Alberto Cortes OlivanBelum ada peringkat

- PSC Reachstackers & Heavy Lift TrucksDokumen8 halamanPSC Reachstackers & Heavy Lift TrucksPinki SahayBelum ada peringkat

- Adjust slewing gear valve block and motor speedsDokumen3 halamanAdjust slewing gear valve block and motor speedsHERNANDO A BECERRABelum ada peringkat

- Section 3 - Maintenance Instruction - ZPMCDokumen38 halamanSection 3 - Maintenance Instruction - ZPMCGer Bos100% (1)

- D3549 2Dokumen14 halamanD3549 2Minh Canh100% (1)

- Kalmar DRF 450 Drive AxleDokumen8 halamanKalmar DRF 450 Drive Axletuấn anh nguyễnBelum ada peringkat

- RTGMekEN PDFDokumen163 halamanRTGMekEN PDFsudaryanto100% (1)

- Demag 20 DH20 HoistDokumen4 halamanDemag 20 DH20 HoistnikkoBelum ada peringkat

- Dispotif Suplementaires LHM SpreaderDokumen853 halamanDispotif Suplementaires LHM Spreaderأيوب نعيوة100% (1)

- TPS-Services en PDFDokumen17 halamanTPS-Services en PDFJack CorreiaBelum ada peringkat

- Apm Terminals Hopper Manual: Port of CallaoDokumen34 halamanApm Terminals Hopper Manual: Port of CallaoSaray Fernández SaavedraBelum ada peringkat

- Cargotec Lashing Systems Items FALDokumen41 halamanCargotec Lashing Systems Items FALstopless_dalian685Belum ada peringkat

- RAM Spreaders Customer Information Pack PDFDokumen26 halamanRAM Spreaders Customer Information Pack PDFMantenimiento TPP0% (1)

- 2632-1266-9900 StinisDokumen302 halaman2632-1266-9900 StinisJugaro OscarBelum ada peringkat

- Cooling SystemDokumen28 halamanCooling SystemQuyết HữuBelum ada peringkat

- Automated RTG: The Yard RevolutionDokumen12 halamanAutomated RTG: The Yard Revolutionjppn33Belum ada peringkat

- Straddle CarriersDokumen13 halamanStraddle Carriersyousuf79Belum ada peringkat

- R-GAGE Radar SensorDokumen6 halamanR-GAGE Radar Sensors_alishBelum ada peringkat

- Hyd. Plan Luffing TrainningDokumen4 halamanHyd. Plan Luffing TrainningMIGUEL PEÑABelum ada peringkat

- BOOMDokumen28 halamanBOOMDatBelum ada peringkat

- SIMATIC Catalog ST80 HMI 2011 PDFDokumen892 halamanSIMATIC Catalog ST80 HMI 2011 PDFFlorinBelum ada peringkat

- TMEIC Container Crane Modernization 2011 Low-Res 1317751432Dokumen8 halamanTMEIC Container Crane Modernization 2011 Low-Res 1317751432escupabloBelum ada peringkat

- TMEIC Container Crane Modernization 2011 Low Res 1317751432Dokumen8 halamanTMEIC Container Crane Modernization 2011 Low Res 1317751432alkazumBelum ada peringkat

- Udrf06 01GBDokumen374 halamanUdrf06 01GBJuanjo Garcia JimenezBelum ada peringkat

- Quay Crane Productivity Paper PDFDokumen12 halamanQuay Crane Productivity Paper PDFAdnan BhuttoBelum ada peringkat

- Electric Reach Trucks Capacity 1400-2000 kg Technical SpecsDokumen6 halamanElectric Reach Trucks Capacity 1400-2000 kg Technical Specsingenioso23Belum ada peringkat

- Wciagniki - Lancuchowe - Angielski STAHL CRANE SYSTEM GRUAS PUENTE PDFDokumen32 halamanWciagniki - Lancuchowe - Angielski STAHL CRANE SYSTEM GRUAS PUENTE PDFJose QuiroaBelum ada peringkat

- KC SC Spreader en 01Dokumen7 halamanKC SC Spreader en 01Mohammed Muzzammil100% (1)

- ASC SpecificationsDokumen6 halamanASC SpecificationsChan Sek YeongBelum ada peringkat

- Rope Guide: Service PartsDokumen2 halamanRope Guide: Service PartsDumebiBelum ada peringkat

- Kalmar DCF80-100 Empty Container Handler Standard and Optional EquipmentDokumen4 halamanKalmar DCF80-100 Empty Container Handler Standard and Optional Equipmentphamvanmanh1989Belum ada peringkat

- 01 - General InformationDokumen27 halaman01 - General InformationFarah Omar Farah100% (1)

- Hyster Electronic Diagram - (09-2012) - UK-ENDokumen44 halamanHyster Electronic Diagram - (09-2012) - UK-ENMarlon Villano100% (2)

- Reachstacker Performance & SpecsDokumen8 halamanReachstacker Performance & SpecsHugo Julian Sanchez MayorgaBelum ada peringkat

- Training For KOJA RTGDokumen211 halamanTraining For KOJA RTGAntonio100% (1)

- Service-Products TPS PDFDokumen39 halamanService-Products TPS PDFJack CorreiaBelum ada peringkat

- Cargotec - Kalmar RT240 Handler 6pp WebDokumen6 halamanCargotec - Kalmar RT240 Handler 6pp WebThinkDefenceBelum ada peringkat

- Kalmar OPERATOR TRAININGDokumen40 halamanKalmar OPERATOR TRAININGWhite Tiger100% (7)

- Seminarbrochure 2023 EnglishDokumen13 halamanSeminarbrochure 2023 EnglishShadab AmeenBelum ada peringkat

- Training Course OverviewDokumen29 halamanTraining Course OverviewKing B&GBelum ada peringkat

- Energies 10 00666 PDFDokumen46 halamanEnergies 10 00666 PDFnamduong368Belum ada peringkat

- ZF - 3HP12 For BMW Workshop ManualDokumen36 halamanZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- TEREX AC1000 - Load Chart PDFDokumen116 halamanTEREX AC1000 - Load Chart PDFduongpnBelum ada peringkat

- CBE 25, MN PDFDokumen95 halamanCBE 25, MN PDFnamduong368Belum ada peringkat

- CBE 25, MN PDFDokumen95 halamanCBE 25, MN PDFnamduong368Belum ada peringkat

- AutoCAD 2013Dokumen264 halamanAutoCAD 2013panosscribd100% (1)

- AutoCAD 3D Course ManualDokumen166 halamanAutoCAD 3D Course ManualJed Tedor98% (47)

- CBE 25, MN PDFDokumen95 halamanCBE 25, MN PDFnamduong368Belum ada peringkat

- AutoCAD 2014 Tutorial 3DDokumen26 halamanAutoCAD 2014 Tutorial 3DseleneletoBelum ada peringkat

- CBD&CBG 25manual PDFDokumen120 halamanCBD&CBG 25manual PDFnamduong368Belum ada peringkat

- CBE 25, MN PDFDokumen95 halamanCBE 25, MN PDFnamduong368Belum ada peringkat

- CBE 25, MN PDFDokumen95 halamanCBE 25, MN PDFnamduong368Belum ada peringkat

- Link Belt RTC80130 Parts Manual PDFDokumen453 halamanLink Belt RTC80130 Parts Manual PDFnamduong368100% (1)

- 3 - Electrical System PDFDokumen39 halaman3 - Electrical System PDFnamduong3680% (1)

- CBE 25, MN PDFDokumen95 halamanCBE 25, MN PDFnamduong368Belum ada peringkat

- LTM 1130-5.1 - PN - Technical Specification PDFDokumen18 halamanLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Belum ada peringkat

- SM-751 - 67 To 88 PDFDokumen22 halamanSM-751 - 67 To 88 PDFnamduong368100% (1)

- Manitowoc Parts ManualDokumen1.040 halamanManitowoc Parts Manualnamduong368100% (2)

- Manitowoc SC70 Lubrication Guide PDFDokumen32 halamanManitowoc SC70 Lubrication Guide PDFnamduong368Belum ada peringkat

- Manitowoc 4600 S4 Parts Manual PDFDokumen108 halamanManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- Link Belt HTC86100 Parts Manual PDFDokumen423 halamanLink Belt HTC86100 Parts Manual PDFnamduong368Belum ada peringkat

- Manitowoc 8500-1 Parts Manual PDFDokumen1.046 halamanManitowoc 8500-1 Parts Manual PDFnamduong368100% (1)

- SM-751 - 1 To 22 PDFDokumen22 halamanSM-751 - 1 To 22 PDFnamduong368Belum ada peringkat

- Workshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Dokumen140 halamanWorkshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Courtney French91% (23)

- Manitowoc 4600 S4 Lubrication Guide PDFDokumen40 halamanManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- LTM 1130-5.1 - PN - Technical Specification PDFDokumen18 halamanLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Belum ada peringkat

- Manitowoc 4600 S4 Parts Manual PDFDokumen108 halamanManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- LTM 1130-5.1 - PN - Technical Specification PDFDokumen18 halamanLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Belum ada peringkat

- LTM 1130-5.1 - PN - Technical Specification PDFDokumen18 halamanLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Belum ada peringkat

- Hypac C766C, C778B - Om PDFDokumen122 halamanHypac C766C, C778B - Om PDFnamduong368100% (2)