Removal of Impurities

Diunggah oleh

Abdullah ZaidDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Removal of Impurities

Diunggah oleh

Abdullah ZaidHak Cipta:

Format Tersedia

REMOVAL OF IMPURITIES

FROM WATER

engineering-resource.com

Removal of Impurities from water

Removal of suspended impurities (solids)

Removal of dissolved solids (salts)

engineering-resource.com

REMOVAL OF SUSPENDED

IMPURITIES

Screening

Sedimentation

Filteration

engineering-resource.com

SCREENING

Process of arresting large and

small floating matter by passing

rawwater through a screen with

large number of perforations

For removal of large things from

water

engineering-resource.com

FILTERATION

process of removing colloidal matter

and most of bacterial impurities by

passing water through a bed of proper

sized material

suspended matter, Colloidal matter,

Bacterias, Colours, and odour of water

are removed.

Two types of filters are commonly used

engineering-resource.com

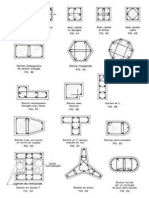

SEDIMENTATION

Process of removing suspended matter from

water, by keeping it quiescent (motionless) in

tanks so that suspended solids may settle

down at the bottom due to force of gravity.

Generally carried in continuous flow type

tanks

Three types of continuous flow type tanks

Horizontal flow rectangular tank

Radial flow circular tank

Vertical flow hopper bottom tank

engineering-resource.com

Sedimentation with Co-agulation

Process of removing fine size

suspended particles by addition of

requisite amount of suspended

chemicals called co-agulants to water

before sedimentation

Common co-agulants in use are

Alum K

2

SO

4

.Al

2

(SO

4

)

3

.24H

2

O

Ferrous Sulphate FeSO

4

7H

2

O

engineering-resource.com

Flocculation

Al

2

(SO

4

)

3

+ 3Ca(HCO

3

)

2

2Al(OH)

3

+3CaSO

4

+ 6CO

2

co-agulant calcium bicarbonate gelatinous floc

FeSO

4

+ Mg(HCO

3

)

2

Fe(OH)

2

+MgCO

3

+ CO

2

+ H

2

O

4Fe(OH)

2

+2H

2

O + O

2

4Fe(OH)

3

Dissolved oxygen Floc

o Coagulants are generally added in soln for precipitation

(flocculation) and for their proper mixing mixers are

employed

engineering-resource.com

REMOVAL OF DISSOLVED

SALTS/SOFTENING

Water used for steam generation

should be pure particularly w.r.t.

calcium and magnesium salts

which cause scale formation in

boilers

The process of removing

hardness producing salts from

water is known as water

softening

engineering-resource.com

WATER SOFTENING PROCESSES

1) Lime-Soda Process

Cold Lime-Soda Process

Hot Lime-Soda Process

2) Zeolite or Permutit Process

3) Demineralization / Deionization

Process

engineering-resource.com

Lime-Soda Process

Used for softening of boiler feed

Converts dissolved calcium and magnesium

salts in to insoluble salts , which settle down

and are filtered.

Lime Ca(OH)

2

precipitates temporary

hardness, permanent magnesium hardness,

iron and aluminium salts and free acids like

CO

2

, H

2

S

Added ingredient soda ash Na

2

CO

3

reacts

with soluble permanent calcium hardness.

Bicarbonate as NaHCO

3

.KHCO

3

also requires

lime.

engineering-resource.com

Lime-Soda Process

Ca(HCO

3

)

2

+ Ca(OH)

2

2CaCO

3

+2H

2

O

Mg(HCO

3

)

2

+ 2Ca(OH)

2

2CaCO

3

+Mg(OH)

2

+2H

2

O

MgCl

2

+ Ca(OH)

2

Mg(OH)

2

+ CaCl

2

MgSO

4

+ Ca(OH)

2

Mg(OH)

2

+ CaSO

4

FeSO

4

+ Ca(OH)

2

Fe(OH)

2

+ CaSO

4

2Fe(OH)

2

+ H

2

O + 0.5O

2

2Fe(OH)

3

Co

2

+ Ca(OH)

2

CaCO

3

+H

2

O

2HCl + Ca(OH)

2

CaCl

2

+ H

2

O

H

2

SO

4

+ Ca(OH)

2

CaSO

4

+ H

2

O

CaCl

2

+ Na

2

CO

3

CaCO

3

+ 2NaCl

CaSO

4

+ Na

2

CO

3

CaCO

3

+ Na

2

SO

4

2HCO

3

-

+ Ca(OH)

2

CaCO

3

+H

2

O +CO

3

2-

engineering-resource.com

Cold Lime-Soda Process

Lime and soda are added to raw water at room

temperature

Finely divided precipitates are formed at

room temperature.

Co-agulants are added like alum, aluminium

sulphate, sodium aluminate.

Co-agulants hydrolyse to flocculant

gelatinuous precipitate aluminium

hydrooxide.entraps fine precipitates formed

by the reactions of lime and soda.

Residual hardness 50 to 60 ppm.

engineering-resource.com

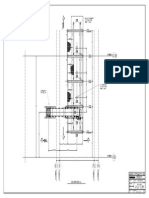

Hot Lime-Soda Process

Process carried out at 80 to 150C

Advantages:

Reaction proceeds faster

Softening capacity is increased

Precipitate and sludge formed settled rapidly.

Much of the dissolved gases are driven out

Viscosity lower, so easy filteration.

Residual hardness 15 to 30 ppm.

Plant consists of 3 parts

Reaction tank

Conical sedimentation vessel

Sand filter.

engineering-resource.com

Basic ion exchange softening

Whats an ion?

An ion is an atom or molecule that has a positive or

negative electrical charge

Remember: Opposites attract

engineering-resource.com

Basic ion exchange

softening

How does ion exchange work?

Hard water

Calcium ions

Resin

bed

Soft water

Sodium ions

Resin exchange site

(receptor)

exchanges salt

for hardness

Hardness washed away

during backwash

Sodium added during

regeneration from salt brine

engineering-resource.com

Zeolite or Permutit Process

Zeolite or Permutits are Complex silicates

consisting of macro molecules of several

metallic and non metallic oxides

Crystalline structure of chemical formula

Na

2

O.Al

2

O

3

.2SiO

2

.6H

2

O

Simply represented as Na

2

Ze

When treated with a solution, equilibrium is

formed between sodium ions held by Zeolite

and positive ions present in the solution. so

there's a tendency for the positive ions to be

exchanged with sodium ions of solution

decreases.

engineering-resource.com

Zeolite or Permutit Process

Na

2

Ze + Ca

2+

2Na

+

+ CaZe (Exhausted zeolite)

Na

2

Ze + Mg

2+

2Na

+

+ MgZe

Exhausted zeolite can be reclaimed by immersing it in

conc. brine soln

CaZe + 2NaCl Na

2

Ze +CaCl

2

MgZe + 2NaCl Na

2

Ze +MgCl

2

Reclaimed zeolite

Zeolite may be

Natural: mined, more durable

Synthetic: manufactured by heating felspar,china clay

and soda ash together and cooling and crushing the

resulting glass, greater exchange capacity per unit

weight, less durable

engineering-resource.com

Reactions in Zeolite or Permutit

Process

Na

2

Ze + Ca(HCO

3

)

2

CaZe + 2NaHCO

3

Na

2

Ze + Mg(HCO

3

)

2

MgZe + 2NaHCO

3

Na

2

Ze + CaCl

2

CaZe + 2NaCl

Na

2

Ze + MgCl

2

MgZe + 2NaCl

Na

2

Ze + CaSO

4

CaZe + Na

2

SO

4

Na

2

Ze + MgSO

4

MgZe + Na

2

SO

4

Exhausted zeolite bed can be regenerated by

treating it with conc Brine soln

CaZe + 2NaCl Na

2

Ze + CaCl

2

MgZe + 2NaCl Na

2

Ze + MgCl

2

Reclaimed zeolite

engineering-resource.com

Limitations

If supply water is turbid, remove suspended

matter otherwise pores of zeolite bed will

clog and restrict flow.

Pre-treatment required if water contains

colored ions like Fe

2+

or Mn

3+

because these

ions produce Iron or manganese zeolite which

cant be generated easily.

Mineral Acids must be neutralized with soda

before adding water to zeolite bed as they

destroy it.

engineering-resource.com

Advantages

Zero hardness

Compact equipment

No danger of sludge formation

Automatically adjustable process

for different hardness

Clean process

engineering-resource.com

Disadvantages

Treated water contains more sodium salts

than in soda lime process

Zeolite treatment replaces cat ions but not

the acidic ions in water, thus produce carbon

dioxide in steam boilers which is extremely

corrosive to its material

NaHCO

3

NaOH + CO

2

Na

2

CO

3

+ H

2

O 2NaOH + CO

2

Sometimes zeolite softener is placed in series

with a lime soda softener.

engineering-resource.com

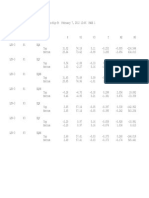

Comparison between permutit and Lime

Soda Process

Permutit Method Lime-Soda Method

1. Zero hardness

2. Treated water has larger

amount of sodium salts

3. Capital cost is higher

4. Operation expenses are lower

5. Cant treat acidic water

6. PlantLess space

7. Raw water must be free of

suspended matter

8. Can operate under pressure

9. No problem of settling and

sludge handling

1. 15-50ppm hardness

2. Treated water has lesser

amount of sodium salts

3. Capital cost is lower

4. Operation expenses are higher

5. No such limitation

6. Plant. More space

7. No such limitation

8. Cannot operate under pressure

9. Problem of difficulty in settling

and sludge handling

engineering-resource.com

Demineralization/ Deionization

Process

An ion exchange resin is an insoluble

acid or base which can also form

insoluble salts.

An ion exchange resin consists of cross

linked polymer network to which ionized

groups are attached.

Ion Exchangers are of two types:

Hydrogen or Cation Exchanger

Anion Exchangers

engineering-resource.com

Demineralization/ Deionization

Process

Cation Exchange Resins:

Main functional groups in them are -SO

3

H,-COOH,-OH

Most stable is -SO

3

H , exchanges H

+

rapidly

2RSO

3

H + Ca

2+

(RSO

3

)

2

Ca + 2H

+

2ROH + Mg

2+

(RO)

2

Mg + 2H

+

Hydrogen exchangers are generally represented as RH

2

RH

2

+ Ca

2+

RCa + 2H

+

RH

2

+ Mg

2+

RMg + 2H

+

Regeneration carries out by passing through an excess of

strong acid solution.

RCa + 2HCl RH

2

+ CaCl

2

RMg + 2HCl RH

2

+ MgCl

2

engineering-resource.com

Demineralization/ Deionization

Process

Anion Exchange Resins:

Capable of exchanging anions

Main functional groups are N(CH

3

)

2+

, -OH

-

, -NH

2

,

NHCH

3

N(CH

3

)

2+

, -OH

-

, are most stable and can operate in

acidic alkaline solution.

Represented as R(OH)

2

R(OH)

2

+ SO

4

2-

R SO

4

+ 2 OH

-

R(OH)

2

+ 2Cl

-

RCl

2

+ 2 OH

-

Regenrated by passing alkaline soln

RCl

2

+ 2 NaOH R(OH)

2

+ 2NaCl

R SO

4

+ 2 NaOH R(OH)

2

+ Na

2

SO

4

engineering-resource.com

Demineralization/ Deionization

Process

Consists in passing hard water first

through cation exchanger bed

Then anion exchanger bed

And then through a degasifier

engineering-resource.com

Anda mungkin juga menyukai

- Unit-I Water TechnologyDokumen22 halamanUnit-I Water TechnologyManivannanVenkatesan100% (1)

- CY6251 Engineering Chemistry II Lecture NotesDokumen55 halamanCY6251 Engineering Chemistry II Lecture NotesAravind Phoenix100% (1)

- 3Dokumen66 halaman3Nikhil AroraBelum ada peringkat

- Softening FinalDokumen23 halamanSoftening FinalSonali Jahagirdar100% (1)

- CHY1701 M2 - Dr. Krishnendu BiswasDokumen70 halamanCHY1701 M2 - Dr. Krishnendu Biswaslalithkumaran LBelum ada peringkat

- Water SofteningDokumen20 halamanWater SofteningHassan AliBelum ada peringkat

- Softening MethodsDokumen7 halamanSoftening MethodsPranay ChandrikapureBelum ada peringkat

- Module V LecDokumen21 halamanModule V LecAman John TuduBelum ada peringkat

- Water SofteningDokumen6 halamanWater SofteningHuda ShahBelum ada peringkat

- Water TreatmentDokumen37 halamanWater TreatmentAMAL MATHEWBelum ada peringkat

- Water SofteningDokumen6 halamanWater SofteningHuda ShahBelum ada peringkat

- Water Its Treatment Part2Dokumen43 halamanWater Its Treatment Part2netsanet mesfinBelum ada peringkat

- Handout BOILER FEED WATERDokumen9 halamanHandout BOILER FEED WATERMuhammad Omar AzadBelum ada peringkat

- Environmental Chemistry - Causes of Hardness in WaterDokumen87 halamanEnvironmental Chemistry - Causes of Hardness in WaterVikas KabburiBelum ada peringkat

- Unit 4-Water TreatmentDokumen11 halamanUnit 4-Water Treatmentgopi nath sahuBelum ada peringkat

- Water TreatmentDokumen66 halamanWater Treatment22cs103Belum ada peringkat

- Chemistry Materials - QuestionsDokumen11 halamanChemistry Materials - QuestionsSanthosh kannaBelum ada peringkat

- Module 2Dokumen85 halamanModule 2Suhil IrshadBelum ada peringkat

- Removal of Hardness 1Dokumen35 halamanRemoval of Hardness 1KISHAN PATELBelum ada peringkat

- Module 2Dokumen17 halamanModule 2PARTH SUNIL CHAVAN 20BCI0055Belum ada peringkat

- Water Softening: Removal of Hardness Hardness Is?..Dokumen38 halamanWater Softening: Removal of Hardness Hardness Is?..Pradhumna AdhikariBelum ada peringkat

- Watertreatmentandanalysis 2Dokumen19 halamanWatertreatmentandanalysis 2O MBelum ada peringkat

- Chem Mod1Dokumen10 halamanChem Mod1baritone.exhaustBelum ada peringkat

- Calculation BFWDokumen22 halamanCalculation BFWDavid Lambert100% (1)

- Boiler Feed WaterDokumen4 halamanBoiler Feed Wateranghel_florin82Belum ada peringkat

- 2 ADokumen45 halaman2 AShyam SundarBelum ada peringkat

- Basic Training WTCDokumen244 halamanBasic Training WTCsushant100% (2)

- Water Treatment Operation: The Object of Boiler Feed Water Treatment Is To AvoidDokumen27 halamanWater Treatment Operation: The Object of Boiler Feed Water Treatment Is To AvoidAmarendra Mani TiwariBelum ada peringkat

- Boiler Feed Water CalculationDokumen4 halamanBoiler Feed Water Calculationamit_kt1973Belum ada peringkat

- Water ChemistryDokumen19 halamanWater ChemistryNupur ChoudharyBelum ada peringkat

- Dr. M. Akhila Maheswari: CHY 1701 Engineering ChemistryDokumen51 halamanDr. M. Akhila Maheswari: CHY 1701 Engineering ChemistryShaunak bagadeBelum ada peringkat

- Reject PretreatmentDokumen2 halamanReject PretreatmentVisheasBelum ada peringkat

- Final (Water Fuel Polymer)Dokumen18 halamanFinal (Water Fuel Polymer)amanBelum ada peringkat

- DUREZA 1sssssDokumen14 halamanDUREZA 1sssssCarolina HerreraBelum ada peringkat

- Unit-2 Water ChemistryDokumen15 halamanUnit-2 Water ChemistryKunjal singhBelum ada peringkat

- FALLSEM2019-20 CHY1701 ETH VL2019201007061 Reference Material I 19-Jul-2019 FALLSEM2013-14 CP2530 31-Jul-2013 RM01 Presentation1Dokumen66 halamanFALLSEM2019-20 CHY1701 ETH VL2019201007061 Reference Material I 19-Jul-2019 FALLSEM2013-14 CP2530 31-Jul-2013 RM01 Presentation1jaswanth chowdary lankaBelum ada peringkat

- 2 - Water N TreatmentDokumen47 halaman2 - Water N TreatmentdarshanBelum ada peringkat

- Anthony M. Wachinski - Environmental Ion Exchange - Principles and Design-Taylor & Francis, Chapman and Hall - CRC (2016) (1) (032-042)Dokumen11 halamanAnthony M. Wachinski - Environmental Ion Exchange - Principles and Design-Taylor & Francis, Chapman and Hall - CRC (2016) (1) (032-042)HARDY EDDISONBelum ada peringkat

- Soft and Hard Water, Temporary and PermanentDokumen21 halamanSoft and Hard Water, Temporary and PermanentRaqib NomanBelum ada peringkat

- Water Chemistry & Applications in Water TreatmentDokumen32 halamanWater Chemistry & Applications in Water TreatmentmasoodismBelum ada peringkat

- Boiler WaterDokumen70 halamanBoiler WaterDarius DsouzaBelum ada peringkat

- Unit 4 Part 3 PPT (1) ChemDokumen16 halamanUnit 4 Part 3 PPT (1) Chemneha yarrapothuBelum ada peringkat

- Chemistry ExperimentDokumen15 halamanChemistry ExperimentvishalBelum ada peringkat

- UICP CH 1 HardnessDokumen42 halamanUICP CH 1 HardnessPatel JayBelum ada peringkat

- M1 L9 Zeolite Ion ExchangeDokumen21 halamanM1 L9 Zeolite Ion Exchangegaurav toppoBelum ada peringkat

- Chapter 7Dokumen21 halamanChapter 7Solomon DesalegnBelum ada peringkat

- Water TechnologyDokumen58 halamanWater TechnologyAdi Mantha اديتية منتة100% (3)

- Unit 1Dokumen11 halamanUnit 1softsen10Belum ada peringkat

- Water Softening MethodsDokumen34 halamanWater Softening MethodsAjitsingh Jagtap100% (1)

- Water Tratment Training For Engineer by Eng A.hussienDokumen35 halamanWater Tratment Training For Engineer by Eng A.hussienMohamed MoüsaBelum ada peringkat

- Chemistry (Water Tech-2-External Treatment)Dokumen21 halamanChemistry (Water Tech-2-External Treatment)Anjan PrasadBelum ada peringkat

- Unit - I: Water TreatmentDokumen127 halamanUnit - I: Water TreatmentAnu ShanthanBelum ada peringkat

- Thermal Power Plant Water ChemistryDokumen33 halamanThermal Power Plant Water ChemistryNAITIK100% (4)

- Chemistry Da 1Dokumen14 halamanChemistry Da 1Aditya GhoshBelum ada peringkat

- BV Water Lecturer 2Dokumen15 halamanBV Water Lecturer 2Prathamesh KumbharBelum ada peringkat

- Adobe Scan 22 Jan 2021Dokumen13 halamanAdobe Scan 22 Jan 2021safa babuBelum ada peringkat

- DM PlantDokumen9 halamanDM Plantsohag97Belum ada peringkat

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesDari EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesPenilaian: 5 dari 5 bintang5/5 (1)

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionDari EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionPenilaian: 5 dari 5 bintang5/5 (1)

- Gauge and Weight Chart: Process Supply, LLC / Phone 423 765 9991 / Fax 888 241 7573Dokumen1 halamanGauge and Weight Chart: Process Supply, LLC / Phone 423 765 9991 / Fax 888 241 7573Abdullah ZaidBelum ada peringkat

- Wall Forces For FFDokumen1 halamanWall Forces For FFAbdullah ZaidBelum ada peringkat

- Column SectionsDokumen1 halamanColumn SectionsAbdullah ZaidBelum ada peringkat

- Safe FootingDokumen1 halamanSafe FootingClifton EdwardsBelum ada peringkat

- J-Bolt Embedment DesignDokumen80 halamanJ-Bolt Embedment DesignZahid Iqbal100% (2)

- Proposal 2Dokumen1 halamanProposal 2Abdullah ZaidBelum ada peringkat

- TrussDokumen1 halamanTrussAbdullah ZaidBelum ada peringkat

- 07 01 - 0steelDokumen1 halaman07 01 - 0steelAbdullah ZaidBelum ada peringkat

- Pages From GB50009 2006 Design Building Structure1Dokumen1 halamanPages From GB50009 2006 Design Building Structure1Abdullah ZaidBelum ada peringkat

- 1Dokumen1 halaman1Abdullah ZaidBelum ada peringkat

- 111Dokumen1 halaman111Abdullah ZaidBelum ada peringkat

- Sign BoardDokumen1 halamanSign BoardAbdullah ZaidBelum ada peringkat

- Hanger BarsDokumen1 halamanHanger BarsAbdullah ZaidBelum ada peringkat

- Wall SectionDokumen1 halamanWall SectionAbdullah ZaidBelum ada peringkat

- Culvert Slab PDFDokumen1 halamanCulvert Slab PDFAbdullah ZaidBelum ada peringkat

- Shear LinksDokumen1 halamanShear LinksAbdullah ZaidBelum ada peringkat

- Culvert Slab PDFDokumen1 halamanCulvert Slab PDFAbdullah ZaidBelum ada peringkat

- 3 Dplan 1Dokumen1 halaman3 Dplan 1Abdullah ZaidBelum ada peringkat

- 3 Dplan 1Dokumen1 halaman3 Dplan 1Abdullah ZaidBelum ada peringkat

- Culvert Slab PDFDokumen1 halamanCulvert Slab PDFAbdullah ZaidBelum ada peringkat

- Reinforcement DetailingDokumen47 halamanReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Sign BoardDokumen1 halamanSign BoardAbdullah ZaidBelum ada peringkat

- Job Vacancy Kabil - Batam April 2017 RECARE PDFDokumen2 halamanJob Vacancy Kabil - Batam April 2017 RECARE PDFIlham AdeBelum ada peringkat

- Knopp2017 Article OnceACheaterAlwaysACheaterSeriDokumen11 halamanKnopp2017 Article OnceACheaterAlwaysACheaterSeriAnda F. CotoarăBelum ada peringkat

- I. Choose The Meaning of The Underlined Words Using Context CluesDokumen4 halamanI. Choose The Meaning of The Underlined Words Using Context CluesMikko GomezBelum ada peringkat

- ChartDokumen27 halamanChartFlorijan ŠafarBelum ada peringkat

- Separating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationDokumen4 halamanSeparating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationAndrea SobredillaBelum ada peringkat

- Facebow Tech Spec Gen LRDokumen1 halamanFacebow Tech Spec Gen LRrojBelum ada peringkat

- Reclaimer Inspection ReportDokumen51 halamanReclaimer Inspection ReportThiru Malpathi100% (1)

- Case Study MMDokumen3 halamanCase Study MMayam0% (1)

- Hemorrhagic Shock (Anestesi)Dokumen44 halamanHemorrhagic Shock (Anestesi)Dwi Meutia IndriatiBelum ada peringkat

- Seed PrimingDokumen4 halamanSeed PrimingbigbangBelum ada peringkat

- Technical Reference For Water Conservation in Cooling TowersDokumen41 halamanTechnical Reference For Water Conservation in Cooling TowersDorn GalamarBelum ada peringkat

- Extubation After Difficult IntubationDokumen3 halamanExtubation After Difficult Intubationramanrajesh83Belum ada peringkat

- 084 - ME8073, ME6004 Unconventional Machining Processes - NotesDokumen39 halaman084 - ME8073, ME6004 Unconventional Machining Processes - NotesA. AKASH 4001-UCE-TKBelum ada peringkat

- Exercise 3 ASC0304 - 2019-1Dokumen2 halamanExercise 3 ASC0304 - 2019-1Nuraina NabihahBelum ada peringkat

- Fan Adta-En-50hz-March-2018 - 20180315Dokumen52 halamanFan Adta-En-50hz-March-2018 - 20180315Andi JatmikoBelum ada peringkat

- Perdev - Module 9Dokumen9 halamanPerdev - Module 9April Rose CortesBelum ada peringkat

- Child DevelopmentDokumen12 halamanChild DevelopmentPija Mohamad100% (1)

- 50-Article Text-116-1-10-20191113Dokumen6 halaman50-Article Text-116-1-10-20191113Annisa FauziahBelum ada peringkat

- Resectoscopio 8677 Richard WolfDokumen25 halamanResectoscopio 8677 Richard WolfManuel FloresBelum ada peringkat

- Practice Questions Human Nutrition Part 1Dokumen4 halamanPractice Questions Human Nutrition Part 1PeiYi TanBelum ada peringkat

- Serbia Malta & Bermuda Medical Instructions PDFDokumen3 halamanSerbia Malta & Bermuda Medical Instructions PDFGISI KeyBOarD0% (1)

- Application of Different Fruit Peels FormulationsDokumen3 halamanApplication of Different Fruit Peels FormulationsYvette GarciaBelum ada peringkat

- Radfet DatasheetDokumen6 halamanRadfet DatasheetNicholas EspinozaBelum ada peringkat

- Genomics and Crop ImprovementDokumen56 halamanGenomics and Crop Improvementsenguvelan100% (6)

- Nursing Care of A Family With An InfantDokumen26 halamanNursing Care of A Family With An InfantJc GarciaBelum ada peringkat

- Location: Map of Naga CityDokumen2 halamanLocation: Map of Naga Citycatherine boragayBelum ada peringkat

- PU-133AB - 規格GMXa spc 2022Dokumen5 halamanPU-133AB - 規格GMXa spc 2022Ý TrầnBelum ada peringkat

- Tara FeminismDokumen3 halamanTara FeminismDushyant Nimavat100% (1)

- Streptococcus Pneumoniae Staphylococci Faculty: Dr. Alvin FoxDokumen32 halamanStreptococcus Pneumoniae Staphylococci Faculty: Dr. Alvin Foxdanish sultan100% (1)

- FF Recipe BookDokumen17 halamanFF Recipe BookElectrox3dBelum ada peringkat