El Sistema Egr en Common Rail

Diunggah oleh

pepeladazoDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

El Sistema Egr en Common Rail

Diunggah oleh

pepeladazoHak Cipta:

Format Tersedia

SERVICE TECH Vol.

484 06-6

9

"Fundamentals of the Common Rail System"

12th Session: CONTROL SYSTEM, E-EGR AND DPF (FINAL SESSION)

In the previous session, fuel injection control, which is the portion of the control system most

closely related to engine performance, was explained.

In this, the final session, Electronic Exhaust Gas Recirculation (E-EGR) and the Diesel

Particulate Filter (DPF), which are the components in the control system aimed at purifying

exhaust gas, will be explained.

1-1 Outline

The E-EGR system is an electronically controlled exhaust gas recirculation system. E-EGR recirculates a

portion of the exhaust gas to the intake manifold, minimizing NOx by lowering combustion temperature.

However, there are cases when EGR system operation is connected to a reduction in engine power output,

affecting drivability. To resolve this issue, in the E-EGR system, the engine ECU controls the optimum EGR

quantity in accordance with driving conditions.

Operating Conditions Example

The chart below shows operation in the region fulfilling starting conditions (one example.)

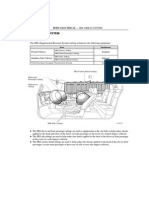

1-2 Operation

Vacuum pressure created by the vacuum pump is controlled by the Electric-Vacuum Regulation Valve (E-

VRV) and then directed to the EGR valve diaphragm chamber. The diaphragm compresses the spring

according to the amount of vacuum, determining the amount the EGR valve opens and controlling the

volume of EGR. (Refer to "System Example 1" on the following page.)

The EGR cooler, which is installed in the EGR passage between the cylinder head and intake passage,

maximizes EGR volume by cooling the exhaust gas.

The EGR Cut Vacuum Switching Valve (VSV) opens the diaphragm interior to atmospheric pressure when

the EGR valve is closed to increase system responsiveness.

As shown in "System Example 2" on the following page, an EGR valve sensor is also employed to perform

optimized EGR control by providing feedback on EGR valve position to the engine ECU.

1 ELECTRONIC EXHAUST GAS RECIRCULATION (E-EGR)

Injection

Quantity

Engine Speed

Operation

Initialization Conditions... Warm engine, vehicle already

started, no overheating, etc.

EGR Operating Range... Engine under low to medium load

SERVICE TECH Vol.484 06-6

10

"Fundamentals of the Common Rail System"

System Example 1

System Example 2

EGR Cooler

Exhaust Gas Recirculation

(EGR) Valve

Coolant

Diaphragm

Vacuum Damper

Spring

EGR Cut VSV

Vacuum Pump

Electric Vacuum Regulating

Valve (E-VRV)

Engine

ECU

Engine Rotational Speed

Accelerator Position

Boost Pressure

Atmospheric Pressure

Coolant Temperature

Intake Air

Relationship Between Diaphragm Vacuum and EGR Valve Opening

Low

Small

High

Large

Vacuum

EGR Valve Opening

Engine

Exhaust

Manifold

Gas Flow

EGR Valve Lift Sensor

Double Seat

Valve

EGR Gas

Inlet

EGR Gas

Outlet

Electronically Controlled EGR Valve

Linear Solenoid Type

Actuator

Coolant

EGR Cooler

Oxidation Catalyst

Engine

Exhaust

Manifold

Electronically Controlled

EGR Valve

EGR Valve

Lift Sensor

Linear Solenoid Type

Actuator

Engine

ECU

Engine Rotational Speed

Accelerator Position

Boost Pressure

Atmospheric Pressure

Coolant Temperature

Intake Air Volume

SERVICE TECH Vol.484 06-6

11

"Fundamentals of the Common Rail System"

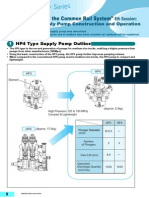

2-1 Outline

The DPF system reduces the emission of Particulate Matter (PM). In order to trap PM, a DPF with a built-in

catalytic filter is mounted on the muffler center pipe. During vehicle operation, the trapped PM is incinerated,

transformed to carbonate and then discharged.

2-2 Various Sensors

1. Exhaust Gas Temperature Sensor

Exhaust gas temperature sensors are installed to the front and rear of the DPF to detect the temperature

both before and after the filter. The engine ECU controls the exhaust temperature for PM combustion based

on signals from these sensors. The sensor element utilizes a thermistor, which displays resistance values

inverse to temperature (as shown in the diagram below). The sensor sends electrical signals proportionate

to the resistance value to the engine ECU.

2 DIESEL PARTICULATE FILTER (DPF)

Rail

Injector

Boost Pressure Sensor

Exhaust Gas Recirculation

(EGR) Valve

Supply Pump

EGR Cooler

Intercooler

Variable Turbo

Actuator

Exhaust

Brake

Actuator

Differential Pressure Sensor

Center Pipe

Exhaust Gas Temperature Sensor

Exhaust Gas Temperature Sensor

Engine

ECU

DPF

Resistance Value ( )

Exhaust Gas Temperature (C)

Cover

Thermistor Element

SERVICE TECH Vol.484 06-6

12

"Fundamentals of the Common Rail System"

2. Differential Pressure Sensor

The differential pressure sensor detects the difference in pressure across the DPF and outputs signals to

the engine ECU. The sensor portion, which is a semiconductor-type silicon element, is a pressure sensor

that utilizes the piezoelectric effect to amplify and output voltage in the IC circuit.

As PM is trapped and accumulates in the DPF, the filter becomes clogged, increasing the differential

pressure across the filter. The differential pressure sensor sends a voltage signal to the engine ECU

corresponding to the differential pressure. Therefore, the engine ECU interprets a large differential

pressure across the DPF as an accumulation of PM and issues a decision for PM combustion processing.

PM is trapped, oxidized, and self-combusted through injection pattern optimization and exhaust gas

temperature control based on exhaust gas temperature and differential pressure across the DPF. When

exhaust gas temperature is low, adding after-injection to the main injection raises the exhaust gas

temperature to approximately 250 C and promotes PM oxidation.

When trapping and accumulating PM, the addition of a post-injection supplements the catalyst with

hydrocarbons (HC), raising catalyst temperature to 600 C, which is the self-combustion temperature for

the PM. This decreases the combustion time for the accumulated PM.

The engine ECU controls times A, B, and C as well as the injection quantity (injection duration) for each

individual injection.

3 OPERATION

GND

VP

VC

Pressure (kPa)

Output

Voltage

VP (V)

TDC

A

B C

After-Injection

Main Injection

Post-Injection

Anda mungkin juga menyukai

- Engine Managment System PDFDokumen9 halamanEngine Managment System PDFDilanWijerathnaBelum ada peringkat

- WML 213Dokumen6 halamanWML 21308088338Belum ada peringkat

- FF EcuDokumen9 halamanFF EcuEduardo J CondeBelum ada peringkat

- Y290 WML 206Dokumen12 halamanY290 WML 206alex generalBelum ada peringkat

- Exhaust Gas RecirculationDokumen15 halamanExhaust Gas RecirculationJesus FloresBelum ada peringkat

- DENSO SystemsDokumen34 halamanDENSO Systemsthailan100% (3)

- Fuel Injection System Bosch AfcDokumen28 halamanFuel Injection System Bosch AfcShivam TandonBelum ada peringkat

- Em MissionsDokumen3 halamanEm Missionsภูเก็ต เป็นเกาะBelum ada peringkat

- On Board DiagnosticsDokumen52 halamanOn Board Diagnosticsjayasundar100% (1)

- Denso Engine Management SystemsDokumen184 halamanDenso Engine Management SystemsNiculae Noica100% (1)

- Sfi SystemDokumen96 halamanSfi SystemWawan SatiawanBelum ada peringkat

- Toyota Avensis DPFDokumen22 halamanToyota Avensis DPFCarl Anthony Chamberlain100% (3)

- Chevrolet Blazer - Engine Performance Theory - OperationDokumen30 halamanChevrolet Blazer - Engine Performance Theory - Operationprovajuv100% (1)

- Weber Injection-Ignition SystemDokumen27 halamanWeber Injection-Ignition SystemjohnvandurenBelum ada peringkat

- Phases of Operation - Injection System Magneti Marelli 6LPDokumen16 halamanPhases of Operation - Injection System Magneti Marelli 6LPGrizono MassimoBelum ada peringkat

- Influence of EGR (Exhaust Gas Recirculation) On Engine Components Durability & Lubricating Oil ConditionDokumen6 halamanInfluence of EGR (Exhaust Gas Recirculation) On Engine Components Durability & Lubricating Oil ConditionIJERDBelum ada peringkat

- Recent Advances in Ic Engine UNIT-5: SinghDokumen54 halamanRecent Advances in Ic Engine UNIT-5: SinghAshutosh RaiBelum ada peringkat

- Hybrid 12Dokumen22 halamanHybrid 12squishbug100% (1)

- Isuzu EngineDokumen53 halamanIsuzu EngineSmaileRun78% (18)

- Automotive Electronics - Vol 2Dokumen40 halamanAutomotive Electronics - Vol 2Victor Balas100% (14)

- Fuel InjectionDokumen4 halamanFuel InjectionWeyih ReganBelum ada peringkat

- AssignmentDokumen5 halamanAssignmentSai DivakarBelum ada peringkat

- Lect 1-Efi Petrol 3HRSDokumen50 halamanLect 1-Efi Petrol 3HRSHodge LorneBelum ada peringkat

- Diesel Engine ManagementDokumen56 halamanDiesel Engine Managementbravo6dBelum ada peringkat

- G17 Emission ControlDokumen30 halamanG17 Emission ControlMarjorye ZapataBelum ada peringkat

- Multi Port Fuel Injection SystemDokumen4 halamanMulti Port Fuel Injection SystemVarsha SreekumarBelum ada peringkat

- 2024-ISB/ISC/ISL CM2150 Crankcase BreatherDokumen7 halaman2024-ISB/ISC/ISL CM2150 Crankcase Breatherralph arisBelum ada peringkat

- Technical Service Bulletin: Exhaust Gas Recirculation (Egr) System DiagnosisDokumen13 halamanTechnical Service Bulletin: Exhaust Gas Recirculation (Egr) System DiagnosisWilliam J. BurnoreBelum ada peringkat

- SheronDokumen20 halamanSheronSheron ThomasBelum ada peringkat

- C200 - E-Egr SystemDokumen9 halamanC200 - E-Egr SystemKada Ben youcefBelum ada peringkat

- E - Theory/Operation - Efi: 1991 Mitsubishi MonteroDokumen7 halamanE - Theory/Operation - Efi: 1991 Mitsubishi MonteroAnimemanuel MuñozBelum ada peringkat

- E-Erg SystemDokumen20 halamanE-Erg SystemRiver OzBelum ada peringkat

- 1026-Fuel System Electrical ProblemsDokumen4 halaman1026-Fuel System Electrical Problemsralph arisBelum ada peringkat

- Operation Stages HDI SIEMENSDokumen9 halamanOperation Stages HDI SIEMENSSergio SambuelliBelum ada peringkat

- 4.1 Engine Management System-R1-1 MINYI EFFADokumen24 halaman4.1 Engine Management System-R1-1 MINYI EFFARusonegroBelum ada peringkat

- 1020-HPI-TP Unit Injector SystemsDokumen4 halaman1020-HPI-TP Unit Injector Systemsralph arisBelum ada peringkat

- Krrishna 341Dokumen30 halamanKrrishna 341Murali MaramreddyBelum ada peringkat

- Egine Control System: GeneralDokumen18 halamanEgine Control System: GeneralAnh Tu NguyenBelum ada peringkat

- 2.5l Cec SystemDokumen37 halaman2.5l Cec Systemdaniel lacerdaBelum ada peringkat

- Gas Turbine NotesDokumen21 halamanGas Turbine NotesJohn BlackburnBelum ada peringkat

- 1025-Fuel Sub-System Component MalfuntionsDokumen4 halaman1025-Fuel Sub-System Component Malfuntionsralph arisBelum ada peringkat

- Function 4 OralsDokumen24 halamanFunction 4 OralsSiva PrakasamBelum ada peringkat

- Electronic Engine ManagementDokumen27 halamanElectronic Engine Managementmkandan_263058Belum ada peringkat

- Automotive ElectronicsDokumen44 halamanAutomotive ElectronicsRohit Kumar100% (1)

- Engine Management System SAAB TRIONIC T5.5, Rev 102Dokumen9 halamanEngine Management System SAAB TRIONIC T5.5, Rev 102RxHughesBelum ada peringkat

- 2019-ISB CM2150 IntroductionDokumen7 halaman2019-ISB CM2150 Introductionralph arisBelum ada peringkat

- Understanding Exhaust Gas Recirculation SystemsDokumen4 halamanUnderstanding Exhaust Gas Recirculation SystemsPrasanna HasyagarBelum ada peringkat

- 2020-ISB CM2150 Shop TalkDokumen7 halaman2020-ISB CM2150 Shop Talkralph arisBelum ada peringkat

- ASE 2010 L2 Composite VehicleDokumen20 halamanASE 2010 L2 Composite VehicleSeven See67% (3)

- Tier III EGR For Large 2-Stroke MAN B&W Diesel EnginesDokumen6 halamanTier III EGR For Large 2-Stroke MAN B&W Diesel EnginesWon-young Seo100% (1)

- 2022-ISC/ISL CM2150 Shop TalkDokumen7 halaman2022-ISC/ISL CM2150 Shop Talkralph arisBelum ada peringkat

- 2025-ISB/ISC/ISL CM2150 Control SystemDokumen7 halaman2025-ISB/ISC/ISL CM2150 Control Systemralph arisBelum ada peringkat

- Tata Bs IV Final CircularDokumen19 halamanTata Bs IV Final CircularD. Nanda KishoreBelum ada peringkat

- Diesel Common Rail Injection Electronic Components ExplainedDari EverandDiesel Common Rail Injection Electronic Components ExplainedPenilaian: 3.5 dari 5 bintang3.5/5 (7)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDari EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SBelum ada peringkat

- Introduction to the simulation of power plants for EBSILON®Professional Version 15Dari EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Belum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- ECU Software/Firmware/USB Driver InformationDokumen2 halamanECU Software/Firmware/USB Driver InformationpepeladazoBelum ada peringkat

- Optical RPM Sensor ManualDokumen4 halamanOptical RPM Sensor ManualpepeladazoBelum ada peringkat

- VOLVO SRS AirbagsDokumen21 halamanVOLVO SRS AirbagsFlorentin ManeaBelum ada peringkat

- Sensor RPM PruebasDokumen1 halamanSensor RPM PruebaspepeladazoBelum ada peringkat

- Bomba de Alta Predion Denso Hp4Dokumen4 halamanBomba de Alta Predion Denso Hp4pepeladazoBelum ada peringkat

- Componentes Del Motor 3uz-Fe LexusDokumen4 halamanComponentes Del Motor 3uz-Fe Lexuspepeladazo0% (1)

- Principio y Funcion Inyector CRDokumen4 halamanPrincipio y Funcion Inyector CRElias Tito Avalos Apaza100% (1)

- Reparacion de Sensor de Cigueñal en ToyotaDokumen2 halamanReparacion de Sensor de Cigueñal en ToyotapepeladazoBelum ada peringkat

- Marelli MF4 Toyota 101 EngDokumen6 halamanMarelli MF4 Toyota 101 EngpepeladazoBelum ada peringkat

- Techstream Ecu Flash Reprogramming Procedure Ts-ss002-07Dokumen23 halamanTechstream Ecu Flash Reprogramming Procedure Ts-ss002-07pepeladazo100% (1)

- Ecu Flash Reprogramming Process T-ss002-01Dokumen19 halamanEcu Flash Reprogramming Process T-ss002-01pepeladazo100% (1)

- Computadora Toyota Manual de Pin OutDokumen11 halamanComputadora Toyota Manual de Pin OutAllvaro Torrico100% (2)

- Reparacion de Sensor Mass Air FlowDokumen2 halamanReparacion de Sensor Mass Air FlowpepeladazoBelum ada peringkat

- Luchtmassameter StoringDokumen4 halamanLuchtmassameter StoringpepeladazoBelum ada peringkat

- Umi MS8 1500aDokumen2 halamanUmi MS8 1500aIT AccountBelum ada peringkat

- UG40 ActuatorDokumen5 halamanUG40 ActuatorSaasiBelum ada peringkat

- Distributor CalibrationDokumen61 halamanDistributor CalibrationFranklinBelum ada peringkat

- Cooling System MR479QDokumen7 halamanCooling System MR479QAdi WidiantoBelum ada peringkat

- Construction Mechanic Basic Vol 2 PDFDokumen441 halamanConstruction Mechanic Basic Vol 2 PDFnuncafalha100% (1)

- Simba 1354Dokumen4 halamanSimba 1354Manuel Uturunco AguilarBelum ada peringkat

- (SB0A001) Measurement Products and Systems For The Oil and Gas IndustryDokumen62 halaman(SB0A001) Measurement Products and Systems For The Oil and Gas IndustryRoberto Carlos Teixeira100% (1)

- Astm D1500.18129Dokumen5 halamanAstm D1500.18129Cristian MedinaBelum ada peringkat

- Venturi Scrubber DesignDokumen2 halamanVenturi Scrubber Designankur2061Belum ada peringkat

- SSP 409 Audi A4 08Dokumen76 halamanSSP 409 Audi A4 08whistle-blower50% (2)

- Manual VN93 - Ver.2.0Dokumen62 halamanManual VN93 - Ver.2.0Ranko AmortizerBelum ada peringkat

- Qty Req'D 1 C0100ABG0005 Mark No.: Saudi Arabian Oil CompanyDokumen1 halamanQty Req'D 1 C0100ABG0005 Mark No.: Saudi Arabian Oil Company4romi89Belum ada peringkat

- Implementing Sustainable Bio-Fuels in Africa - Arrigo Della GherardescaDokumen61 halamanImplementing Sustainable Bio-Fuels in Africa - Arrigo Della GherardescaArrigo della GherardescaBelum ada peringkat

- Bustion Equipments and Firing Methods For FuelsDokumen62 halamanBustion Equipments and Firing Methods For FuelsTarvesh KumarBelum ada peringkat

- Les Photos de Matérieles de ForagesDokumen18 halamanLes Photos de Matérieles de Foragesعبد العزيز مروى100% (1)

- Astm D396Dokumen6 halamanAstm D396dennise8100% (2)

- Purevent 2.0 AlfalavalDokumen6 halamanPurevent 2.0 AlfalavalSmart LauBelum ada peringkat

- Powermate Pm0103002 User Manual and Parts List (Pramac)Dokumen36 halamanPowermate Pm0103002 User Manual and Parts List (Pramac)Adrian Fraga FernandezBelum ada peringkat

- Wet Shotcreting Machine Gives Nozzleman Total Control: Concrete Counterweight Repair Shows Machine's AdvantagesDokumen2 halamanWet Shotcreting Machine Gives Nozzleman Total Control: Concrete Counterweight Repair Shows Machine's AdvantagesLouie PascuaBelum ada peringkat

- Parts Manual DQGANDokumen244 halamanParts Manual DQGANAlexBelum ada peringkat

- JCR Vol. 10 No. 02: Symposium On Christianity and BusinessDokumen294 halamanJCR Vol. 10 No. 02: Symposium On Christianity and BusinessChalcedon Foundation100% (1)

- U 151eDokumen155 halamanU 151emauricio_ch_91100% (5)

- N67280 P3d04n003eDokumen4 halamanN67280 P3d04n003eToni PusicBelum ada peringkat

- How To Be A Good SvsTech HandbookDokumen18 halamanHow To Be A Good SvsTech HandbookMiguel NavarreteBelum ada peringkat

- 5 - Volumes & MaaspDokumen111 halaman5 - Volumes & Maaspsouthernor100% (2)

- Installation Manual: BECIN - 2000 BECIN - 3000 BEC - 1500 BEC - 2500Dokumen41 halamanInstallation Manual: BECIN - 2000 BECIN - 3000 BEC - 1500 BEC - 2500Marcus Miller100% (1)

- Supercharger BasicsDokumen9 halamanSupercharger BasicsAbhinand RaoBelum ada peringkat

- Audi A8 - A8 L - A8 L W12 Audi S8: Vorsprung Durch TechnikDokumen114 halamanAudi A8 - A8 L - A8 L W12 Audi S8: Vorsprung Durch TechnikMadaMadutsaBelum ada peringkat

- EDC 16 Fundamental FunctionDokumen70 halamanEDC 16 Fundamental FunctionFlorin Cososchi100% (5)

- Js Insight Gas Form CDokumen64 halamanJs Insight Gas Form CSomayajula SuryaramBelum ada peringkat