Single-Pass Heat Exchangers

Diunggah oleh

Brando_BalagonJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Single-Pass Heat Exchangers

Diunggah oleh

Brando_BalagonHak Cipta:

Format Tersedia

What is a heat exchanger?

Classification of heat exchangers

Regenerators

Open-type heat exchangers

Closed-type heat exchangers

Classification of recuperators

Single-pass vs multi-pass

Parallel flow, counterflow, and crossflow

Temperature profiles for single-pass heat

exchangers

LMTD and AMTD

Sample problems

Exercises

RB Astillero 1

A heat exchanger is a device whose

primary purpose is the transfer of

energy between two fluids.

Examples:

- Radiator

- Evaporator

- Condenser

- boiler

RB Astillero 2

1. regenerators

2. open-type heat exchangers

3. closed-type heat exchangers

or recuperators

RB Astillero 3

Regenerators are exchangers in

which hot and cold fluids flow

alternately through the same

space with as little physical

mixing between the two streams

as possible.

RB Astillero 4

RB Astillero 5

Open-type heat exchangers are

devices wherein physical

mixing of the two fluid streams

actually occurs.

RB Astillero 6

RB Astillero 7

Recuperators are devices wherein

the hot and cold fluid streams do

not come into direct contact with

each other but are separated by a

tube wall or a surface that may

be flat or curved in some manner.

RB Astillero 8

RB Astillero 9

1. single-pass heat exchanger

- parallel flow

- counterflow

- crossflow

2. multi-pass heat exchanger

RB Astillero 10

Single-pass heat exchanger is one

in which each fluid flows through

the exchanger only once.

RB Astillero 11

Parallel low heat exchangers is one in which

the fluids flow in the same direction.

RB Astillero 12

Counterflow heat exchanger is one in which the

fluids flow in opposite direction.

RB Astillero 13

Crossflow heat exchanger is one in which the fluids

flow at right angles to one another.

RB Astillero 14

In order to accomplish as much transfer of

energy in as little space as possible, it is

desirable to utilize multiple passes of one or

both fluids. A common configuration is the

shell-and-tube heat exchanger.

RB Astillero 15

RB Astillero 16

RB Astillero 17

Where LMTD = Log Mean Temperature Difference

1

= maximum temperature difference

2

= minimum temperature difference

NOTE: If

1

and

1

are nearly the same use the Arithmetic-

Mean Temperature Difference (AMTD)

AMTD =

1

+

2

2

RB Astillero 18

q = UA (LMTD)

Where q = the heat tranfer between fluids, kJ or kW

U = the overall heat transfer coefficient, kJ (or kW)/m

2

K

A = surface area of the tube

LMTD = Log Mean Temperature Difference

RB Astillero 19

A hot process stream being cooled from 100

o

C to 60

o

C by a cooling

water stream that is heated from 15

o

C to 30

o

C. What temperature

driving force (LMTD) should be used to calculate the required area?

Solution:

1

= 100 15 = 85C

2

= 60 30 = 30C

=

1

2

=

8530

85

30

= 52. 81 (ans)

RB Astillero 20

RB Astillero 21

RB Astillero 22

RB Astillero 23

1. A liquid to liquid counterflow heat exchanger is used to heat a cold

fluid from 120F to 310F. Assuming that the hot fluid enters at 500F

and leaves at 400F, calculate the log-mean temperature difference of

the heat exchanger.

Ans. LMTD = 232F

2. A turbo-generator, 16 cylinder, V type Diesel engine has an air

consumption of 3000 kg/hr per cylinder at rated load and speed. This

air is drawn in through a filter by a centrifugal compressor directly

connected to the exhaust gas turbine. The temperature of the air from

the compressor is 145C and a counterflow air cooler reduces the air

temperature to 45C before it goes to the engine suction header.

Cooling water enters air cooler at 30C and leaves at 38C. Calculate

the arithmetic-mean temperature difference.

Ans. 61C

RB Astillero 24

3. Exhaust steam at 7 kPa at the rate of 75 kg/s enters a single pass

condenser containing 5,780 pieces of copper tubes with a total surface

area of 2950 m

2

. The steam has a moisture content of 10% and the

condensate leaves saturated liquid at a steam temperature. The

cooling water flow rate is 4,413 liters per second entering at 20C. Size

of tubes, 25 mm O.D. by 3 mm thick wall. Find the overall heat-

transfer coefficient.

Ans. U = 4275 W/m

2

K

4. An oil having a specific heat of 1880 J/kg K enters a single-pass

counterflow heat exchanger at a rate of 2 kg/s and a temperature of

400 K. It is to be cooled to 350 K. Water is available to cool the oil at a

rate of 2 kg/s and a temperature of 280 K. Determine the surface area

required if the overall heattransfer coefficient is 230W/m

2

K.

[Note: specific heat of water is 4.80 J/kgK]

Ans. A = 9.85 m

2

RB Astillero 25

5. Onehundred thousand pounds per hour ofwater are to pass

through a heat exchanger, which is to raise the water

temperature from 140 to 200F. Combustion products having a

specific heat of 0.24 Btu/lbmF are available at 800F. The

overall heat-transfer coefficient is 12 Btu/h ft

2

F. If 100,000

lbm/h of the combustion products are available, determine

a. the exit temperature of the flue gas;

b. the required heat-transfer area for a counterflow

exchanger.

RB Astillero 26

Anda mungkin juga menyukai

- Heat Exchangers LectureDokumen37 halamanHeat Exchangers LectureTerna Orlanda100% (2)

- Shell and Tube Heat ExchangersDokumen11 halamanShell and Tube Heat ExchangersSuresh SjBelum ada peringkat

- Design of Shell and Tube Heat ExchangerDokumen4 halamanDesign of Shell and Tube Heat ExchangerIqra Safdar100% (1)

- 8-2. Heat Ex ChangersDokumen6 halaman8-2. Heat Ex ChangersBambang HermawanBelum ada peringkat

- Shell and Tube Condenser DesignDokumen5 halamanShell and Tube Condenser DesignAli DandamunBelum ada peringkat

- Heat Exchanger Glossary of TermsDokumen3 halamanHeat Exchanger Glossary of Termsusman_hafeez86Belum ada peringkat

- Glycol De-Hydrator DesignDokumen30 halamanGlycol De-Hydrator DesignNana TwumBelum ada peringkat

- FLR - Performance of A Tubular CondenserDokumen12 halamanFLR - Performance of A Tubular CondenserNazario Emil LintagBelum ada peringkat

- HW 4 3.12Dokumen33 halamanHW 4 3.12Anonymous U3DpVvqVWx0% (3)

- Basic Ref PipingDokumen28 halamanBasic Ref PipingMohammed Jassim50% (2)

- Internal Combustion Engines Syllabus & ChaptersDokumen92 halamanInternal Combustion Engines Syllabus & ChaptersRupinder Rp100% (1)

- Surface Condensers PDFDokumen7 halamanSurface Condensers PDFing_julio_siviraBelum ada peringkat

- Pump Principles I Course IntroductionDokumen6 halamanPump Principles I Course IntroductionMuhammad ArslaanBelum ada peringkat

- Heat ExchangerDokumen4 halamanHeat ExchangerIzwanaRahimiBelum ada peringkat

- <ITER 機構から参加極へのレタ ーよ り > 以下に、外部委託の概要と要求事項が示されています。参加極には、提案された業務に要求される能力 を有し、入札すべきと考える企業及び研究機関の連絡先の情報を ITER 機構へ伝えることが求められていま す。このため、本研究・業務に関心を持たれる企業及び研究機関におかれましては、応募書類の提出要領 にしたがって連絡先情報をご提出下さい。Dokumen8 halaman<ITER 機構から参加極へのレタ ーよ り > 以下に、外部委託の概要と要求事項が示されています。参加極には、提案された業務に要求される能力 を有し、入札すべきと考える企業及び研究機関の連絡先の情報を ITER 機構へ伝えることが求められていま す。このため、本研究・業務に関心を持たれる企業及び研究機関におかれましては、応募書類の提出要領 にしたがって連絡先情報をご提出下さい。kanchanabalajiBelum ada peringkat

- Refrigeration Paper in IJSER FormatDokumen14 halamanRefrigeration Paper in IJSER Formattitto84886Belum ada peringkat

- Formulas in Cooling TowerDokumen6 halamanFormulas in Cooling TowerGringoBelum ada peringkat

- Glossary of Heat Exchanger TerminologyDokumen2 halamanGlossary of Heat Exchanger Terminologypvwander100% (1)

- Multi-Pressure Refrigeration SystemsDokumen12 halamanMulti-Pressure Refrigeration Systemsciko_kacrut75% (4)

- Reynolds ExperimentDokumen3 halamanReynolds ExperimentShary MosqueraBelum ada peringkat

- Isentropic Efficiencies of Turbines, Compressors and NozzlesDokumen24 halamanIsentropic Efficiencies of Turbines, Compressors and NozzlesgrandecaciqueBelum ada peringkat

- Book - 9. Sample CalculationsDokumen29 halamanBook - 9. Sample CalculationsTri Sesilia100% (1)

- Engineering Unit Conversion PDFDokumen5 halamanEngineering Unit Conversion PDFBarcepandoBelum ada peringkat

- Thermal Energy Multiple Choice QuizDokumen3 halamanThermal Energy Multiple Choice QuizAlexia VargasBelum ada peringkat

- Lecture-5: Typical Air-Conditioning ProcessesDokumen10 halamanLecture-5: Typical Air-Conditioning Processesabrar alhadadBelum ada peringkat

- Heat Exchanger Design OptimizationDokumen27 halamanHeat Exchanger Design OptimizationUsama AkramBelum ada peringkat

- Sample Problem - NPSHA Calculation For PumpsDokumen6 halamanSample Problem - NPSHA Calculation For Pumpsanayo100% (1)

- Thermal Performance Assessment of Steam Surface CondenserDokumen8 halamanThermal Performance Assessment of Steam Surface CondenserJeeEianYannBelum ada peringkat

- Shell and Tube Heat Exchanger Cost EstimationDokumen5 halamanShell and Tube Heat Exchanger Cost EstimationFebry AhmadBelum ada peringkat

- Heat Exchanger Types and CalculationsDokumen16 halamanHeat Exchanger Types and CalculationsAudrey Patrick KallaBelum ada peringkat

- Expackcolumn PDFDokumen9 halamanExpackcolumn PDFfatamorgganaBelum ada peringkat

- Practice Problems (METE 40 2018)Dokumen2 halamanPractice Problems (METE 40 2018)Sky FallBelum ada peringkat

- Industrial Plant EngineeringDokumen4 halamanIndustrial Plant EngineeringKarl Luis CansinoBelum ada peringkat

- Thermodynamics Pure Substances Phase ChangesDokumen30 halamanThermodynamics Pure Substances Phase Changesleelamech36Belum ada peringkat

- Gas Compressor: 1.types of CompressorsDokumen9 halamanGas Compressor: 1.types of CompressorsSimona Gheorghe100% (1)

- ADVANCED THERMODYNAMICS COURSEDokumen2 halamanADVANCED THERMODYNAMICS COURSEVivek VenugopalBelum ada peringkat

- Axial Compressor - Wikipedia, The Free EncyclopediaDokumen11 halamanAxial Compressor - Wikipedia, The Free EncyclopediaSurendra ReddyBelum ada peringkat

- 01 - Heat Loss in Bare, Finned, & Lagged PipesDokumen17 halaman01 - Heat Loss in Bare, Finned, & Lagged PipesAllen Jerry AriesBelum ada peringkat

- Triangle Velocity For Centrifugal PumpDokumen27 halamanTriangle Velocity For Centrifugal PumpWinter NaiBelum ada peringkat

- Lecture 5Dokumen28 halamanLecture 5Mesbahose SalekeenBelum ada peringkat

- Rac NotesDokumen16 halamanRac NotesJohnRay LominoqueBelum ada peringkat

- Heat Exhanger Individual ReportDokumen16 halamanHeat Exhanger Individual ReportMusa OtoBelum ada peringkat

- Practice Set 19 (Fins)Dokumen2 halamanPractice Set 19 (Fins)Nibir SahaBelum ada peringkat

- 5-Thermodynamics For CryogenicsDokumen52 halaman5-Thermodynamics For CryogenicsBhuvanaBelum ada peringkat

- Design Shell TubeDokumen3 halamanDesign Shell TubeAKSHEYMEHTABelum ada peringkat

- Material Handling Ch-1&2Dokumen98 halamanMaterial Handling Ch-1&2Shuguta LatiBelum ada peringkat

- Steam Turbines: PartaDokumen52 halamanSteam Turbines: PartaSheetal JadhavBelum ada peringkat

- 125452033-Thermodynamics D.J.Dunn PDFDokumen185 halaman125452033-Thermodynamics D.J.Dunn PDFkalite123Belum ada peringkat

- Pressure Vessel Topic ES9Dokumen11 halamanPressure Vessel Topic ES9killuaBelum ada peringkat

- Boiler:: Working Principle of A BoilerDokumen22 halamanBoiler:: Working Principle of A BoilerZeshan AbdullahBelum ada peringkat

- Technical Specifications BoilerDokumen3 halamanTechnical Specifications Boilerbeymar_5631Belum ada peringkat

- Chapter 5Dokumen34 halamanChapter 5Jayshon Montemayor100% (1)

- CH 7 PowerCyclesDokumen12 halamanCH 7 PowerCyclescarleston thurgoodBelum ada peringkat

- Multipass Heat ExchangersDokumen21 halamanMultipass Heat ExchangersBrando_BalagonBelum ada peringkat

- TUTORIAL 6 Heat ExchangerDokumen4 halamanTUTORIAL 6 Heat ExchangerFikri Rahim50% (2)

- Tutorial Questions On Heat Ex ChangersDokumen3 halamanTutorial Questions On Heat Ex ChangersPuneet Garg100% (1)

- Heat Exchanger Tutorial Sheet 5Dokumen4 halamanHeat Exchanger Tutorial Sheet 5Charlotte BBelum ada peringkat

- Heat Exchanger Tutorial Sheet 5Dokumen4 halamanHeat Exchanger Tutorial Sheet 5Charlotte BBelum ada peringkat

- LMDTDokumen6 halamanLMDThassnainiqbal11Belum ada peringkat

- Practice Problems For Heat ExchangerDokumen2 halamanPractice Problems For Heat ExchangerFour AyesBelum ada peringkat

- CombinatoricsDokumen30 halamanCombinatoricsBrando_BalagonBelum ada peringkat

- Heat Transfer Modes in 40 CharactersDokumen50 halamanHeat Transfer Modes in 40 CharactersJacob Onjwaya MbegoBelum ada peringkat

- Isobaric ProcessDokumen24 halamanIsobaric ProcessBrando_Balagon75% (4)

- Multipass Heat ExchangersDokumen21 halamanMultipass Heat ExchangersBrando_BalagonBelum ada peringkat

- NBC540 - Fourth TrancheDokumen12 halamanNBC540 - Fourth Tranchereseljan100% (1)

- Refrigeration Unit: Muhammad Tarmizi Bin Abdul Murad (2019883632)Dokumen18 halamanRefrigeration Unit: Muhammad Tarmizi Bin Abdul Murad (2019883632)Lehbron JemsBelum ada peringkat

- RED DOT AC Aftermarket Catalog 2015Dokumen784 halamanRED DOT AC Aftermarket Catalog 2015cascade10% (1)

- Chapter 5Dokumen59 halamanChapter 5Nur Ain ZainuddinBelum ada peringkat

- Fujitsu General Ash7asc-W - 9710k1222Dokumen16 halamanFujitsu General Ash7asc-W - 9710k1222Liuda Scutaru Zarisneac100% (2)

- HVAC Simplified PDFDokumen250 halamanHVAC Simplified PDFمحمداحمدحسنالفنجرى86% (7)

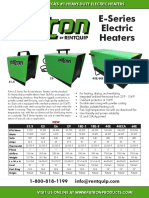

- E-Series Electric Heaters: E1.5 E9 40E/60EDokumen2 halamanE-Series Electric Heaters: E1.5 E9 40E/60ERahim BuxBelum ada peringkat

- TRANE - HVAC Resource Guide For LEED PDFDokumen36 halamanTRANE - HVAC Resource Guide For LEED PDFjupoc100% (1)

- Technical & Service ManualDokumen90 halamanTechnical & Service ManualStefano FerrariBelum ada peringkat

- Master List of Instrument For ISO (Version 1)Dokumen76 halamanMaster List of Instrument For ISO (Version 1)Eng Ali Al-MarzohBelum ada peringkat

- Coolingsystem 141121065724 Conversion Gate02Dokumen30 halamanCoolingsystem 141121065724 Conversion Gate02rinku sainiBelum ada peringkat

- Chiller Plant Control - Io Summary: Chilled Water SystemDokumen2 halamanChiller Plant Control - Io Summary: Chilled Water SystemMohammed AminuddinBelum ada peringkat

- Mounting details for wall-mounted cooling unitsDokumen4 halamanMounting details for wall-mounted cooling unitsalmedinBelum ada peringkat

- Cooling Tower CalculationeditedDokumen3 halamanCooling Tower CalculationeditedMark LouieBelum ada peringkat

- Split System Air Conditioner Model and Accessory ID GuideDokumen1 halamanSplit System Air Conditioner Model and Accessory ID GuidebluemojoBelum ada peringkat

- Guentner Flyer Commercial Refrigeration enDokumen2 halamanGuentner Flyer Commercial Refrigeration enAnonymous 5moojwBelum ada peringkat

- X Line Product Catalog en Us 4972704Dokumen48 halamanX Line Product Catalog en Us 4972704Nelson Ariel Sierra SierraBelum ada peringkat

- 20.2 2009 ASHRAE Handbook-Fundamentals: Fig. 1 Classification of Air Distribution StrategiesDokumen13 halaman20.2 2009 ASHRAE Handbook-Fundamentals: Fig. 1 Classification of Air Distribution StrategiesImran AzizBelum ada peringkat

- ASHRAE Terminology - Complete ListDokumen298 halamanASHRAE Terminology - Complete Listwado11Belum ada peringkat

- AC CaterpillarDokumen17 halamanAC CaterpillarGerald BoyBelum ada peringkat

- Cooling Coil SelectionDokumen5 halamanCooling Coil Selectionabmopalhvac100% (3)

- High Performance Data Centers: A Design Guidelines SourcebookDokumen63 halamanHigh Performance Data Centers: A Design Guidelines SourcebookRich Hintz100% (20)

- Update on Maintenance Costs of Commercial Ground-Source Heat Pump SystemsDokumen9 halamanUpdate on Maintenance Costs of Commercial Ground-Source Heat Pump Systemssdio06Belum ada peringkat

- May Jun 2017Dokumen4 halamanMay Jun 2017Nilesh LavandBelum ada peringkat

- fa4c-2pd-FAN COIL UNITDokumen15 halamanfa4c-2pd-FAN COIL UNITAhmed KhattabBelum ada peringkat

- Testing Adjusting and BalancingDokumen16 halamanTesting Adjusting and BalancingmasoodaeBelum ada peringkat

- Dimplex Pool Heat PumpDokumen2 halamanDimplex Pool Heat PumpahoirebaBelum ada peringkat

- HM61/AM61V: Home Comfort SystemsDokumen4 halamanHM61/AM61V: Home Comfort SystemsJames LoewenBelum ada peringkat

- VRV Condensing UnitDokumen24 halamanVRV Condensing UnitLeo NgBelum ada peringkat

- Cold Pump Air Conditioner: Condizionatori A Ciclo Chiuso Per Quadri ElettriciDokumen4 halamanCold Pump Air Conditioner: Condizionatori A Ciclo Chiuso Per Quadri ElettriciNilesh PatelBelum ada peringkat

- Chapter 5: Preheat: 5.1. Theory and ApplicationsDokumen7 halamanChapter 5: Preheat: 5.1. Theory and Applicationslang74Belum ada peringkat