Simulation Energy Consumption

Diunggah oleh

Hannah BeachJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Simulation Energy Consumption

Diunggah oleh

Hannah BeachHak Cipta:

Format Tersedia

Journal of Thermal Science Vol.23, No.

3 (2014) 285289

Received: September 2013 HAO Xuejun, Associate Professor

This paper was supported by a Grant-in-Aid for Scientific Research through grant number KM200610016003 from the Beijing Mu-

nicipal Commission of Education.

www.springerlink.com

DOI: 10.1007/s11630-014-0708-4 Article ID: 1003-2169(2014)03-0285-05

Simulation Analysis of Factors Influencing Chiller EER

HAO Xuejun, WANG Tong

Beijing University of Civil Engineering and Architecture, Beijing 100044, PR China

Science Press and Institute of Engineering Thermophysics, CAS and Springer-Verlag Berlin Heidelberg 2014

This study constructed a mathematic model of a variable frequency centrifugal chiller using Simulink software.

By running the simulation, it was discovered that when the other factors are constant, the EEREnergy Efficiency

Ratio of the chiller increases with decreases in the temperature of the cooling water and increases in the tem-

perature of the chilled water. The effect of changes in the cooling water temperature on the EER of the chiller is

stronger than that of changes in the chilled water temperature. In addition, as the chiller load decreases, the EER

increases until reaching a maximum, after which it decreases. Furthermore, the EER of chillers working under a

constant flow rate is slightly higher than that of those working under varying flow rates.

Keywords: Chiller, Simulation, EER

Introduction

The EER of a chiller is an important index, reflecting

its efficiency and therefore energy consumption. Many

factors directly affect the EER, such as the temperature

of the cooling water, the chiller load, the flow rate, and

the temperature of the chilled water. However, the change

in the EER for a given change in these parameters has

not been quantified. In this paper, using a simulation, a

model of variable-frequency centrifugal chiller was con-

structed (variable-frequency centrifugal chillers are com-

mon). In this paper, the EER was analyzed as a function

of three different parameters: cooling water temperature,

chilled water flow, and chilled water temperature.

Description of the mathematical model of a vari-

able-frequency centrifugal chiller

There are two important hypotheses for the mathe-

matical modeling of a variable-frequency centrifugal

chiller in this paper.

Because chillers can maintain the chilled water tem-

perature near the value set by the automatic control

equipment, this paper assumes that the temperature of the

chilled water is constant.

This paper neglects the heat transferred through the

wall of the pipe and compressor. Specifically, this paper

considered the load of the condenser to be equal to the

sum of the refrigerating capacity and compressor power.

Mathematical model of the evaporator

In a centrifugal chiller, the evaporator is generally a

full liquid evaporator. To keep the evaporator liquid level

constant, it is generally equipped with a float ball valve,

which controls the flow rate of the refrigerant according

to the liquid level of the evaporator. Thus, in this paper,

the liquid level of the evaporator is considered constant.

Applying energy conservation, the amount of heat lost

be the chilled water is equal to the amount of heat trans-

ferred from the chilled water side to the refrigerant side.

That is,

286 J. Therm. Sci., Vol.23, No.3, 2014

1 2

0 Z1 2

1

2

C M (T T ) K A

ln

z z

z

z z

z z

T T

Q

T T

T T

= =

| |

|

\ .

(1)

where T

z1

, T

z2

inlet and outlet chilled water tem-

perature, respectively, C;

Q

0

refrigerating capacity of the evaporator, W;

Cspecific heat capacity of water, J/(kgC);

Mflow rate of water, kg/s;

Aeffective heat transfer area of the evaporator,

m

2

;

Kheat transfer coefficient of the evaporator,

W/(m

2

K).

Formula (1) can be rewritten as

1 2

1

K A

C M

z

K A

C M

T T e

T

e

(2)

where T

z

evaporation temperature of the refrig-

erant, C.

Furthermore, the boiling heat transfer coefficient of

the refrigerant side is

[2]

0.5 0.25 0.45

0

0

16.4 p ( )

b z

s

h

d

= (3)

where h

bz

boiling heat transfer coefficient of the

refrigerant side;

heat flux, W/m

2

;

p

0

evaporation pressure, kPa;

sdistance between tubes, m;

d

0

pipe outer diameter, m.

The following formula was used to calculate the con-

vective heat transfer coefficient of the chilled water side

[3]

:

When Re2100 (laminar region),

1/3 0.14

1.86 ( ) [Re Pr ( )]

i i

i i

i i

h

d d

= u (4)

When 2100<Re10

4

(transitional flow region),

2/3

2/3 1/3 0.14

0.116 ( ) [Re 125]

[1 ( ) ] Pr

i

i

i

i

i

i

h

d

d

=

+ u

(5)

When 10

4

<Re (turbulent region),

0.8 1/3 0.14

0.027 ( ) Re Pr

i

i i

i

h

d

= u (6)

where h

i

convective heat transfer coefficient of the

chilled water side;

i

correction factor of the wall temperature;

PrPrandtl number;

ReReynolds number;

i

thermal conductivity of chilled water, W/(mK);

d

i

pipe inner diameter, m.

The heat transfer coefficient between the chilled water

and refrigerant sides can be calculated by the following

formula

[2]

:

1

1 1

[( ) ( ) ]

o o

oil p fou

b z i i

A A

K R R R

h A h A

= + + + +

(7)

where Kheat transfer coefficient between the

chilled water and refrigerant sides;

R

oil

thermal resistance of film, m

2

K/W;

R

fou

thermal resistance of dirt, m

2

K/W;

R

p

thermal resistance of the pipe wall, m

2

K/W;

A

o

pipe external surface area, m

2

;

A

i

pipe internal surface area, m

2

;

Aaverage value of external pipe area and internal

pipe area, m

2

.

Applying energy conservation, the following relation

can be obtained:

i

z

o

dM d

V M M

dt dt

= = (8)

where M

z

quality of vapor within the evaporator,

kg;

M

i

refrigerant evaporation rate, kg/s;

M

o

flow rate of vapor discharged at the outlet,

kg/s;

Vvolume of vapor at the evaporator, m

3

.

Rearranging formula (8), the following formula can be

obtained:

i o

d

M M V

dt

= (9)

The evaporation rate can be calculated as

0

o

Q

M

r

= (10)

where rlatent heat of the refrigerant, J/kg.

Mathematical model of variable-frequency centrifu-

gal compressor

Based on the parameters of the centrifugal compressor

samples and the compressor similarity law, the fitting

curves for the different speeds of the centrifugal com-

pressor can be obtained. These curves can be expressed

as follows:

2

2

w w w

m m

n n

W A Q B Q C

n n

| |

= + +

|

\ .

(11)

2

2

m m

n n

A Q B Q

n n

q q

q

| |

= +

|

\ .

(12)

2 3

2

N N N

m m m

n n n

N A Q B Q C

n n n

| | | |

= + +

| |

\ . \ .

(13)

where Wenergy provided by the compressor, J/kg;

Qflow rate of discharged vapor, kg/s;

Npower of compressor, W;

n

m

rated speed of the compressor, r/s;

nactual speed of the compressor, r/s;

HAO Xuejun et al. Simulation Analysis of Factors Influencing Chiller EER 287

efficiency of the compressor.

In formulas (11) - (13), each coefficient associated

with the actual compressor models can be fitted by the

related parameters in the compressor sample. Further-

more, according to mass conservation, the flow rate of

the compressor is approximately equal to the flow rate of

the evaporator M

o

.

Because the actual compression process is not isen-

tropic, the actual energy provided is greater than the the-

oretical energy provided:

,

2 1

( )

c th

ad

W

W h h

q

= = (14)

where Wactual energy provided, J/kg;

W

c, th

theoretical energy provided, J/kg;

ad

adiabatic efficiency of the compressor, set as

0.8;

h

2

enthalpy of the refrigerant at the compressor

outlet, J/kg;

h

1

enthalpy of the refrigerant at the compressor

inlet, J/kg.

Mathematical model of the condenser

The condenser of the centrifugal chiller is generally

comprised of a horizontal shell and tube condensers. The

flow rate of cooling water is constant. In addition, the

assumption at the beginning of this section shows that the

heat dissipation of condenser is

0 e

Q Q N = + (15)

where Q

e

heat dissipation of the condenser, w.

According to energy conservation, the heat gain from

the cooling water is equal to the heat transferring from

the chilled water to the refrigerant sides.

( )

( )

2 1

2 1

2

1

ln

e e

e e e

e e

e e

K A T T

Q C M T T

T T

T T

= =

| |

|

\ .

(16)

where T

e1

, T

e2

inlet and outlet water temperature of

the condenser, respectively, C.

The condensation heat transfer coefficient of the re-

frigerant side[2] is

1

3 2

3

0.65

C

g r

h

l

| |

=

|

|

\ .

(17)

where h

c

condensation heat transfer coefficient of the

refrigerant side;

heat flux, w/m

2

;

thermal conductivity of the refrigerant, w/(mK);

density of the refrigerant, kg/m

3

;

lstereotype size, m;

kinetic viscosity of the refrigerant, m/s

2

.

Furthermore, the cooling water side convective heat

transfer coefficient h

i

can be obtained from equations (4)

- (6), and the water side heat transfer coefficient of re-

frigerant side can be obtained from equation (7).

Solving the mathematical model using Simulink

The simulation software used in this paper is Simulink.

By creating the corresponding block diagram with Simu-

link software, the mathematical model can be solved.

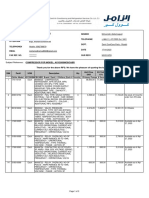

Figure 1 shows the block diagram of the centrifugal

Fig. 1 Highest-level block diagram of the centrifugal chiller model

288 J. Therm. Sci., Vol.23, No.3, 2014

chillers model created in this paper. As observed in the

diagram, the block diagram mainly includes four modules:

the condenser sub-module, the evaporator sub-module, the

compressor sub-module, and a load sub module to calcu-

late the hourly return water temperature and the flow rate

of chilled water according to the refrigerating load. Be-

cause the model must iteratively solve numerous equa-

tions at each time step, a do-while module and memory

module are used in the block diagram. First, according to

the hourly load values and the conditions (variable or

constant flow conditions), the program uses the load sub-

module to calculate the hourly return water temperature

T

z1

and chilled water flow M of the chiller and sends the

data to the sub-module of the evaporator. Furthermore,

the sub-module of the evaporator can calculate the re-

frigerating capacity Q

0

, the flow rate of the vapor dis-

charged from the evaporator M

0

, the evaporation tem-

perature T

e

, and the evaporation pressure P

1

based on

these two values and sends the flow rate of the vapor

discharged from evaporator M

0

and the evaporating

pressure P

1

to the centrifugal compressor sub-module.

First, the compressor sub-module calculates the power of

the compressor according to these values as well as the

assumptive initial rotational speed and sends it out. Next,

the condensing load of the condenser Q

e

is calculated by

adding the power value W to the refrigerating capacity of

the evaporator Q

0

in this program, which is then sent to

the sub-module of the condenser. The sub-module of the

condenser can calculate the condensing temperature T

d

and condensing pressure P

2

according these values. The

sub-module of the condenser then sends this pressure

information to the sub-module of the compressor. Next,

the sub-module of the compressor can calculate the theo-

retical energy head W

c, th

in accordance with the ideal

constant entropy process using the internally stored data

of the pressure-enthalpy diagram according to the con-

densing pressure P

2

and the evaporating pressure P

1

. The

actual energy head W can then be calculated using equa-

tion (14). Substituting this value into equation (11), the

program can calculate a new value of rotational speed N

and send it out. There is an iterative loop structure in the

outermost layer of the model. If the relative error be-

tween the speed value N in the previous iteration step and

the speed value in this step is greater than 1%, then the

iterative loop structure will send the new speed value N

to the compressor sub-module and perform a new inter-

action. In addition, the memory sub-module can provide

an initial rotational speed for the compressor sub-module.

Above is the general working process of the model.

Performance analysis of variable-frequency cen-

trifugal chillers

Effect of cooling water temperature on the chiller EER

For chillers, the temperature of the cooling water

changes throughout the air-conditioning season. To ana-

lyze how the cooling water temperature affects the chiller

EER, the supply and return water temperature of chilled

water and the flow of the chilled water are taken as con-

stant. By running the simulation, the curve of the chiller

EER with the cooling water temperature can be obtained,

as shown in Figure 2. As observed in the figure, when the

temperature of the cooling water decreases, the EER of

the chiller increases. The relationship between these pa-

rameters is nearly linear. This linear relationship is

mainly due to the fact that when the supply and return

water temperature of chilled water and the flow of the

chilled water are constant, the refrigerating capacity of

the chiller and the evaporating pressure is constant;

however, a decrease in the temperature of the cooling

water will lead to a decrease in the condensing pressure.

Thus, the compressor energy head will decrease, as will

the total power.

Fig. 2 EER as a function of cooling water temperature

Effect of flow rate of chilled water on the chiller EER

As seen in Figure 3, whether the chilled water is under

constant or variable flow conditions, the EER of the

chiller increase and then decrease as the chiller load de-

creases. As the load decreases, the chiller EER decreases

more rapidly. The figure shows that the maximum EER

does not occur under the full load condition. In addition,

the chiller EER is lower for the variable flow conditions

than the constant flow conditions. When the chiller ap

proaches the full load condition, the EER is very close

for both flow conditions; however, as the load continues

to decrease, the difference between them increases.

However, overall, both conditions are still very close to

each other. Thus, for the variable-flow primary pump

system, the total energy consumption is not much higher

than that for the constant flow system.

Effect of chilled water temperature on the chiller EER

When the chilled water temperature changes, the EER

also changes. To analyze how a change in the chilled

water temperature will affect the chiller EER, the differ-

ence between the supply and return temperature of the

chilled water is set to 5C, and the flow of the chilled

HAO Xuejun et al. Simulation Analysis of Factors Influencing Chiller EER 289

Fig. 3 EER as a function of relative chiller load

Fig. 4 EER as a function of chilled water temperature

water as well as the chilled water temperature are as-

sumed to be constant. The simulation provides the chiller

EER as a function of the chilled water temperature, as

shown in Figure 4. As the chilled water temperature in-

creases, the chiller EER will also increase in a nearly

linear fashion. Furthermore, Figures 2 and 4 show that

the effect of the cooling water temperature on the EER is

greater than that of the chilled water temperature.

Conclusions

Through the analysis of chillers simulation, the fol-

lowing conclusions can be obtained:

(1) With the other parameters held constant, as the

cooling water temperature decreases, the chiller EER

increases in a nearly linear fashion.

(2) With the other factors held constant, as the chiller

load decreases, the chiller EER first increases and sub-

sequently decreases. Moreover, as the load continues to

decrease, the EER will decrease more rapidly. In addition,

the EER of the chiller running under variable flow condi-

tions is slightly lower than that of the chiller running un-

der constant flow conditions.

(3) With the other factors held constant, as the chilled

water temperature increases, the chiller EER also in-

creases in a nearly linear fashion. In addition, the effect

of the cooling water temperature on the EER is greater

than that of the chilled water temperature.

Acknowledgment

This paper was supported by a Grant-in-Aid for Scien-

tific Research through grant number KM200610016003

from the Beijing Municipal Commission of Education.

References

[1] Li Ying, Xue Haibin Zhu Boli, Liu Chunhui: Simulink

dynamic system modeling and simulation, [M] 2nd Edi-

tion, Xi'an: Xidian University Press, pp.1390, 2009

[2] Zhang Qisen, Shi Wenxing, Tian Changqing: Air condi-

tioning refrigeration technology, [M] 4th Edition, Beijing:

China Building Industry Press, pp.74118, 2007

[3] PING Laizhou, ZHANG Rongke: Air cooler, [M] Version

1, Beijing: China Petrochemical Press, pp. 2530, 2010

[4] CAI Zengji, LONG Tianyu: Fluid mechanics with pumps

and fans, [M] 4th Edition, Beijing: China Building Indus-

try Press, pp. 287326, 2006

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Product Catalog: Koolman Air-Cooled Chiller and Heat PumpDokumen16 halamanProduct Catalog: Koolman Air-Cooled Chiller and Heat PumpLEYSER ALBERTO ALVAREZ BETRUSBelum ada peringkat

- KBR Ammonia PDFDokumen10 halamanKBR Ammonia PDFsadsnd-1100% (1)

- Absorption Chiller: Operation ManualDokumen56 halamanAbsorption Chiller: Operation ManualkorayBelum ada peringkat

- Report ONGCDokumen47 halamanReport ONGCMehul SutariyaBelum ada peringkat

- Catalogue Carrier 2021 enDokumen1.072 halamanCatalogue Carrier 2021 enKeren QiBelum ada peringkat

- 30rba Broucher PDFDokumen3 halaman30rba Broucher PDFMohammedIrfanAhmedBelum ada peringkat

- BMS Chiller Plant Management SystemDokumen100 halamanBMS Chiller Plant Management SystemNadeem khanBelum ada peringkat

- High Performance Chilled Water Systems: Earthwise HvacDokumen18 halamanHigh Performance Chilled Water Systems: Earthwise HvacPietBelum ada peringkat

- General Chiller Catalogue EPCEN07-400 - Catalogues - EnglishDokumen48 halamanGeneral Chiller Catalogue EPCEN07-400 - Catalogues - EnglishMutiara Puspahati CripstyaniBelum ada peringkat

- CG Svx17h en IomDokumen140 halamanCG Svx17h en IomHECTOR CRUZBelum ada peringkat

- Liebert-HPC S 006 022-TS-EN-EMEA-273571Dokumen54 halamanLiebert-HPC S 006 022-TS-EN-EMEA-273571Breno ETCENGENHARIABelum ada peringkat

- 2164 MCW Chiller DDC Manual Web 15337Dokumen48 halaman2164 MCW Chiller DDC Manual Web 15337Radu-Gabriel Gherghe100% (2)

- Environmental Sustainability of Buildings: Code ForDokumen175 halamanEnvironmental Sustainability of Buildings: Code ForWei Meng SimBelum ada peringkat

- Max e3-ENGDokumen16 halamanMax e3-ENGDamVent DamVentBelum ada peringkat

- Ari 550-590Dokumen36 halamanAri 550-590AshwinBelum ada peringkat

- Compressor For Model: Asy295Bmcbcabr: Engr. Mohamed HammadDokumen3 halamanCompressor For Model: Asy295Bmcbcabr: Engr. Mohamed HammadMohamed HamadBelum ada peringkat

- Tier IV Specs - TIA-942Dokumen6 halamanTier IV Specs - TIA-942netlinkinBelum ada peringkat

- M&E Works Risk MGMTDokumen8 halamanM&E Works Risk MGMTSyaFiq MansoorBelum ada peringkat

- Power ThermDokumen17 halamanPower ThermFah RoziBelum ada peringkat

- Draft Question Bank Module-3Dokumen164 halamanDraft Question Bank Module-3pallavishraddhaBelum ada peringkat

- Unisab III Industrial Refrigeration Package Controller: Ultimate FlexibilityDokumen7 halamanUnisab III Industrial Refrigeration Package Controller: Ultimate Flexibilityandrew.golovanBelum ada peringkat

- Company ProfileDokumen20 halamanCompany ProfileChristian Banzuela PadillaBelum ada peringkat

- LG Centrifugal Chiller Manual.Dokumen36 halamanLG Centrifugal Chiller Manual.Umar Majeed100% (2)

- Improve Chiller Efficiency - The Engineering MindsetDokumen10 halamanImprove Chiller Efficiency - The Engineering Mindsetjeevitha jeeviBelum ada peringkat

- TT 400, Turbocor TIMDokumen68 halamanTT 400, Turbocor TIManil kumarBelum ada peringkat

- Advantages and Disadvantages of Using Absorption Chillers ToDokumen4 halamanAdvantages and Disadvantages of Using Absorption Chillers Toأحمد صلاحBelum ada peringkat

- Brochure Model RHSDWDokumen4 halamanBrochure Model RHSDWcnbminhBelum ada peringkat

- Model YK (Style H) Centrifugal Liquid ChillersDokumen56 halamanModel YK (Style H) Centrifugal Liquid ChillersAbdulSattarBelum ada peringkat

- Chiller Tripping Points (AutoRecovered)Dokumen34 halamanChiller Tripping Points (AutoRecovered)Saurabh RuhellaBelum ada peringkat

- R-100 Data Sheet en A 0Dokumen8 halamanR-100 Data Sheet en A 0Shah12Belum ada peringkat