Pac Ahu SZ 005

Diunggah oleh

Hoàng TềDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pac Ahu SZ 005

Diunggah oleh

Hoàng TềHak Cipta:

Format Tersedia

CP-Open Global Libraries Documentation

Document1 1 of 15

Comfort Point Open - Global Library Documentation

APPLICATION DOCUMENTATION

PAC-AHU-SZ-005 (Pacific Application)

Table of Contents

1. System Synopsis ................................................................................................................................................. 2

2. Schematic .......................................................................................................................................................... 2

3. Theory of Operation ............................................................................................................................................ 3

4. Sequence of Operation ........................................................................................................................................ 3

5. Zone Temperature Control ................................................................................................................................... 9

6. Zone Temperature Alarm ................................................................................................................................... 14

7. Version History ................................................................................................................................................. 15

CP-Open Global Libraries Documentation

Document1 2 of 15

1. System Synopsis

This is a single zone air cooled heat pump fan coil unit with four stages of cooling and four stages of reverse cycle

heating.

Temperature control is from a zone temperature sensor.

Manual day extension of the air handling unit is included as a standard feature.

The control strategy also includes separate fire override facilities for general and zone fire alarms.

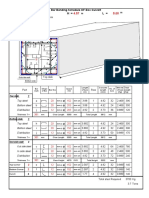

2. Schematic

CP-Open Global Libraries Documentation

Document1 3 of 15

3. Theory of Operation

This application uses heating & cooling P + I control loops to stage the fan coil unit air cooled heat pump

compressor stages On and Off from a temperature sensor located in the area or zone served by the unit.

4. Sequence of Operation

Time Schedule Control

The unit is activated from a dedicated time schedule within the Honeywell DDC Controller, as detailed in the

following table.

Day Of Week Occupied Time Unoccupied Time

Monday 0800 1800

Tuesday 0800 1800

Wednesday 0800 1800

Thursday 0800 1800

Friday 0800 1800

Saturday - -

Sunday - -

Day Extension Control (After Hours)

A dedicated push button is provided to allow the plant to be activated outside of occupied times.

When pressed, the button will activate the unit for an operator adjustable period of 2 hours.

Once activated the day extension may be cancelled by the operator by pressing the button a second time.

The day extension function will not operate during normal occupied times.

An output is provided which will activate during day extension mode and drive an indicator to inform the operator

that the plant is running in day extension mode.

CP-Open Global Libraries Documentation

Document1 4 of 15

Fire Mode Override Control

The signals for the Fire Mode Control System are derived from the main fire indicator panel and are wired to the

DDC panel.

General Fire Alarm (Supply Air Fan Stop)

A general fire alarm typically represents a shutdown scenario!

When the fire indicator panel initiates a general fire alarm condition the following control action will occur:-

a) The supply air fan will be commanded Off.

b) The unit heat pump compressor outputs are de-energised.

Zone Fire Requiring Smoke Exhaust (Supply Air Fan Start)

The fire indicator panel will discriminate between fire conditions in each area served by individual AHUs, these

areas are referred to as Fire Zones.

The fire indicator panel may place the plant (Fire Zone) in to a smoke exhaust condition; a smoke exhaust

condition will take precedent over a general fire alarm condition.

When the fire indicator panel initiates a smoke exhaust condition the following control action will occur:

a) The supply air fan will be commanded On.

b) The unit heat pump compressor outputs are de-energised.

CP-Open Global Libraries Documentation

Document1 5 of 15

Plant Mode

The operating mode for the fan coil unit plant is displayed in a Multistage Value point called xxxxPlantMode

(where xxxx refers to the actual plant name). All of the main operating functions for the plant are controlled by

xxxxPlantMode.

There are up to 32 possible values for xxxxPlantMode however not all modes are used in this application.

The modes used in this application are displayed in the following table.

Nr Mode Comment

03 UnOccupied Time Scheduled Control Unoccupied Mode

05 Occupied Time Scheduled Control Occupied Mode

06 Day Extension After Hours Mode

18 User Defined 6 (Delayed start) Power Fail Delayed Restart Mode

29 Fire_Off General Fire Alarm

30 Smoke_Exh Zone Fire Alarm

CP-Open Global Libraries Documentation

Document1 6 of 15

Temperature Control Mode

The temperature control mode for the air handling plant is displayed in a Multistage Value point called

xxxxTempCtlMd (where xxxx refers to the actual plant name). The operating functions for the temperature

control plant are interlocked with xxxxTempCtlMd.

There are up to 5 possible values for xxxxTempCtlMd however not all modes are used in this application.

The modes used in this application are displayed in the following table.

Nr Mode Comment Enable Condition

01 Disabled Heating and Cooling Disabled All remaining plant modes and low ambient lockout

03 Clg Cooling only enabled

Plant Mode 02,05,06 and 07 (Optimise start in

cooling, Occupied, Day extension and Optimise start

in heating) with HtgSP/ClgSP switching reference

and depending on the low ambient lockout status

04 Htg Heating only enabled

The heating and cooling mode change operation is detailed in the following diagram:

HtgSP ClgSP

Zone temperature

Deg C

Temp

Control

Mode

Clg Mode

Htg Mode

CP-Open Global Libraries Documentation

Document1 7 of 15

Low Ambient Lockout Control

If the temperature control mode is in Cooling Mode and the ambient temperature is less than the low ambient lock

out setpoint, the temperature control mode will be overridden and will be switched to Disabled. In this mode the

heat pump will not be available for cooling.

The low ambient lockout control will take priority over the zone temperature override for cooling mode.

The low ambient lockout mode change to Disabled operation is detailed in the following diagram:

The low ambient lockout control of the temperature control mode will initially be set up with the following default

values:-

Set Points

a) Low limit 8.0 C

b) Hysteresis 2.0 K

Low OaTemp

Limit SP

Outside Air temperature

Deg C

Clg Mode Disabled

Clg Mode Available

+Hyst

Temp

Control

Mode

CP-Open Global Libraries Documentation

Document1 8 of 15

Fan Fail Alarm

A fan failed alarm is generated whenever there is a mismatch between the fan start-stop signal and the fan status

input. An adjustable delay will prevent nuisance alarms from occurring.

Blocked Filter Alarm

A differential pressure switch is connected across the supply air filter assembly. The switch must be calibrated

(when air flow is present) to detect a pressure drop which corresponds to a blocked filter condition. The switch

provides a digital input to the DDC which will be used to generate the blocked filter alarm.

A blocked filter alarm will be raised at any time if the differential pressure switch has been activated continually

for a period of 300 seconds.

Once activated, the alarm will be latched until manually reset using the dedicated blocked filter alarm reset point.

FCU Start-up

Whenever the unit is called to run the supply air fan will start and the fan coil unit will operate under full

automatic control.

FCU Shutdown

Whenever the unit is turned off the following control action will occur:-

a) The unit heat pump compressor outputs are de-energised.

b) The air handling unit supply air fan will be commanded Off.

c) The unit heat pump reversing valve is switch to the Cooling position.

CP-Open Global Libraries Documentation

Document1 9 of 15

5. Zone Temperature Control

Whenever the supply air fan is commanded On, and the correct status input has been received, the unit thermal

control system is Enabled.

The air handling unit is provided with separate Cooling and Heating setpoints.

The unit heat pump compressors are controlled in sequence to maintain the required zone temperature set point

value.

When the zone temperature falls below the heating set point the heat pump reversing valve will be switched to

the heating position and the compressor stages will be sequentially enabled. When the zone temperature rises

above the heating set point the compressor stages will be commanded off.

When the zone temperature rises above the cooling set point the heat pump reversing valve will be switched to

the cooling position and the compressor stages will be sequentially enabled. When the zone temperature falls

below the cooling set point the compressor stages will be commanded off.

CP-Open Global Libraries Documentation

Document1 10 of 15

The operation of the heat pump compressors and the reversing valve is detailed in the following sequence

diagram, the PI function will be configured with default tuning parameters as detailed in the sequence diagram

which will require adjustment (tuning) for specific conditions at the time of commissioning.

The sequence diagram below shows only the proportional component of the PI control to detail the relative stage

positions.

-2.0 -1.5 -1.0 -0.5 HtgSP ClgSP +0.5 +1.0 +1.5 +2.0

Zone temperature

Deg C

Reversing

Valve

Compressor

stages in

Cooling

St 1

St 2

St 3

St 4

St 1

St 2

St 3

St 4

Compressor

stages in

Heating

CP-Open Global Libraries Documentation

Document1 11 of 15

The fan coil unit temperature control module will initially be set up with the following default values:-

Cooling Mode

a) Set Point 22.5 C

Heating Mode

a) Set Point 21.5 C

Time delays

a) Heat Pump Stage delay On 60.0 s

b) Heat Pump Stage delay Off 60.0 s

c) Heat Pump Mode change delay 120.0 s

CP-Open Global Libraries Documentation

Document1 12 of 15

Discharge Air Temperature Override Control

A discharge air temperature sensor is located in the fan coil unit supply air duct work downstream of the heat

pump evaporator coil. The sensor is located at a position within the duct work to ensure that the true mixed

discharge air temperature is measured at all times.

The discharge air temperature from the fan coil unit is monitored whenever the heat pump unit is enabled to

operate.

Should the heat pump unit be operating in reverse cycle heating mode and the discharge air temperature rises

above the high limit setpoint then the maximum stage output will be reduced from four to two. The override

condition will remain active until the discharge air temperature falls to below the setpoint minus the hysteresis

value. To prevent cycling, the lockout will remain active for at least the duration of the lockout delay time

If the heat pump unit is operating in cooling mode and the discharge air temperature falls to less than the low

limit setpoint then the maximum stage output will be reduced from four to two. The override condition will remain

active until the discharge air temperature rises above the setpoint plus the hysteresis value. To prevent cycling,

the lockout will remain active for at least the duration of the lockout delay time

Hyst

Hyst

Low SP High SP

Discharge Air Temperature

Deg C

Lockout Activated

Lockout Deactivated

CP-Open Global Libraries Documentation

Document1 13 of 15

The override control will initially be set up with the following default values:-

Setpoints

a) High limit Set Point 28.0 C

b) High limit Hysteresis 1.0 K

c) Low limit Set Point 15.0 C

d) High limit Hysteresis 1.0 K

e) Lockout time period delay 300.0 s

CP-Open Global Libraries Documentation

Document1 14 of 15

6. Zone Temperature Alarm

The zone temperature sensor will have alarming capability to indicate high and or low temperature alarms.

An alarm inhibit feature is provided which will allow the alarm to be active during specific times which correspond

to the following plant mode values.

Nr Mode Comment

05 Occupied Time Scheduled Control Occupied Mode

06 Day Extension After Hours Mode

When the plant mode changes to a value which enables the alarm, a time delay will be invoked which must expire

before the alarm will become un-inhibited, this delay will give the plant the necessary running time to stabilise the

zone temperature and thus prevent nuisance alarming.

The air handling unit temperature alarm module will initially be set up with the following default values:-

a) High temperature alarm set point Zone cooling mode set point +2.0 Deg K

b) Low temperature alarm set point Zone heating mode set point -2.0 Deg K

c) Delay time to un-inhibit the alarm 1800 Seconds

CP-Open Global Libraries Documentation

Document1 15 of 15

7. Version History

Doc

Version

Date

(dd/mm/yyyy)

Changes Made

Author

1.0 17/04/2013 Original version Pacific Library Group

1.1 15/10/2013 Remove R100 references Update control sequence diagram references Pacific Library Group

Honeywell Confidential

This document contains information that is confidential and proprietary to Honeywell International Inc. No part of this document may be

reproduced, copied, or transmitted in any form or for any purpose without express written permission of Honeywell. Any such

reproduction is expressly prohibited by law and violators will be prosecuted to maximum extent possible.

Copyright 2011 Honeywell International Inc.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- ㄹ 것Dokumen1 halamanㄹ 것Hoàng TềBelum ada peringkat

- 00 Guide PDFDokumen60 halaman00 Guide PDFLe Trong TanBelum ada peringkat

- BT CoolMasterDokumen33 halamanBT CoolMasterHoàng TềBelum ada peringkat

- 신혜성 - Take Me To Your HeartDokumen4 halaman신혜성 - Take Me To Your HeartHoàng TềBelum ada peringkat

- IM 1133-1 Jan 2014Dokumen39 halamanIM 1133-1 Jan 2014Hoàng TềBelum ada peringkat

- XS824Dokumen3 halamanXS824Hoàng TềBelum ada peringkat

- B - LIGHTING MANAGEMENTIntro-gen Characteristics (PPTminimizer)Dokumen24 halamanB - LIGHTING MANAGEMENTIntro-gen Characteristics (PPTminimizer)Hoàng TềBelum ada peringkat

- 6700 Series NVR 32 ChannelDokumen2 halaman6700 Series NVR 32 ChannelHoàng TềBelum ada peringkat

- 6700 Series NVR 4 ChannelDokumen2 halaman6700 Series NVR 4 ChannelHoàng TềBelum ada peringkat

- 6400 Hybrid NVRDokumen2 halaman6400 Hybrid NVRHoàng TềBelum ada peringkat

- 6700 Series NVR 16 ChannelDokumen2 halaman6700 Series NVR 16 ChannelHoàng TềBelum ada peringkat

- 6700 Series NVR 8 ChannelDokumen2 halaman6700 Series NVR 8 ChannelHoàng TềBelum ada peringkat

- Talk About English Academic 01 Au BBDokumen7 halamanTalk About English Academic 01 Au BBgachikBelum ada peringkat

- 10 - Software and ServicesDokumen7 halaman10 - Software and ServicesHoàng TềBelum ada peringkat

- WG20 enDokumen2 halamanWG20 enHoàng TềBelum ada peringkat

- Recording 32 Analog Cameras Using The 2316 Encoder With 8x32Dokumen1 halamanRecording 32 Analog Cameras Using The 2316 Encoder With 8x32Hoàng TềBelum ada peringkat

- 2013-14 DSC NA English InteractiveDokumen52 halaman2013-14 DSC NA English InteractivefabianalexiBelum ada peringkat

- Daikin Controls (BACNET) Product CatalogDokumen4 halamanDaikin Controls (BACNET) Product CatalogHoàng TềBelum ada peringkat

- HSH Fall2011Dokumen27 halamanHSH Fall2011Hoàng TềBelum ada peringkat

- DMS502A51 BACnet Interface Technical DataDokumen15 halamanDMS502A51 BACnet Interface Technical DataHoàng TềBelum ada peringkat

- Daikin (BACNET) Technical Data BookDokumen14 halamanDaikin (BACNET) Technical Data BookHoàng Tề100% (2)

- BT Digital SolutionsDokumen68 halamanBT Digital SolutionsHoàng TềBelum ada peringkat

- LG00050 B UKDokumen6 halamanLG00050 B UKHoàng TềBelum ada peringkat

- Control4® Access Agent: Control What People Can Access On Your Touch ScreensDokumen3 halamanControl4® Access Agent: Control What People Can Access On Your Touch ScreensHoàng TềBelum ada peringkat

- (Onbai - VN) BaiTap (Coloigiaichitiet) SongCo SongDungDokumen18 halaman(Onbai - VN) BaiTap (Coloigiaichitiet) SongCo SongDungNinja267Belum ada peringkat

- Freelance 800F System DescriptionDokumen44 halamanFreelance 800F System DescriptionHoàng TềBelum ada peringkat

- Home Smart Home Fall 2012 Free MagazineDokumen31 halamanHome Smart Home Fall 2012 Free MagazineFlorida Smart Homes100% (1)

- JP For Structural WorksDokumen4 halamanJP For Structural WorksRajeev KumarBelum ada peringkat

- Bar Bending Schedule OF Box CulvertDokumen1 halamanBar Bending Schedule OF Box CulvertAntonioNicala100% (1)

- E10 Rod Extensometer: Precisely MeasuredDokumen4 halamanE10 Rod Extensometer: Precisely MeasuredAlberto MartinezBelum ada peringkat

- ASTM A350/A350M-07 Standard Specification For Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsDokumen9 halamanASTM A350/A350M-07 Standard Specification For Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsAtul Anand SrivastavaBelum ada peringkat

- Dme Unit I Mech 30.6.12Dokumen22 halamanDme Unit I Mech 30.6.12PN MohankumarBelum ada peringkat

- Part RQ Qualification RequirementsDokumen8 halamanPart RQ Qualification RequirementsMARCIOBelum ada peringkat

- SFA Framing Guide Final 2Dokumen12 halamanSFA Framing Guide Final 2SevrinBelum ada peringkat

- Assignment01 PPT57Dokumen15 halamanAssignment01 PPT57Usman AhmedBelum ada peringkat

- Otbl 0608l8aohdkDokumen2 halamanOtbl 0608l8aohdkJhonathan075Belum ada peringkat

- Pec Report KP2488 PDFDokumen11 halamanPec Report KP2488 PDFMarcus AntoniusBelum ada peringkat

- FXSQ-A EEDEN20 Data Books EnglishDokumen37 halamanFXSQ-A EEDEN20 Data Books EnglishommfcBelum ada peringkat

- Mechanical Properties of High-Strength Lightweight ConcreteDokumen8 halamanMechanical Properties of High-Strength Lightweight ConcreteAdán Cogley CantoBelum ada peringkat

- Vortex Shear Mixer Product Leaflet enDokumen4 halamanVortex Shear Mixer Product Leaflet enJARABA - Jean Luis ReyesBelum ada peringkat

- Cavitation DamageDokumen18 halamanCavitation Damagescata1117Belum ada peringkat

- INST. INST. 844-TZ For Item 40Dokumen4 halamanINST. INST. 844-TZ For Item 40Zubab Panni100% (1)

- Lubrication and LubricantsDokumen17 halamanLubrication and LubricantsSamatha Farai ZviuyaBelum ada peringkat

- Electrical Works - Transformer and HT LineDokumen3 halamanElectrical Works - Transformer and HT LineSyed Abdul RawoofBelum ada peringkat

- NDT PDFDokumen4 halamanNDT PDFBHARANIBelum ada peringkat

- Eaton 7.2 KV Motor Control Ampgard Medium Voltage Design Guide Dg020001enDokumen46 halamanEaton 7.2 KV Motor Control Ampgard Medium Voltage Design Guide Dg020001enAlvaro Seguel SanhuezaBelum ada peringkat

- DOYMA Delivery Programme PDFDokumen72 halamanDOYMA Delivery Programme PDFTEIUSANUBelum ada peringkat

- Construction Methods and EquipmentsDokumen2 halamanConstruction Methods and EquipmentsAngel Lyn BagonBelum ada peringkat

- Civil: ANSYS, Inc. Proprietary © 2004 ANSYS, Inc. © 2004 ANSYS, IncDokumen62 halamanCivil: ANSYS, Inc. Proprietary © 2004 ANSYS, Inc. © 2004 ANSYS, IncSalam FaithBelum ada peringkat

- Heater & Air Conditioning Control System: SectionDokumen51 halamanHeater & Air Conditioning Control System: SectionIvan SauretBelum ada peringkat

- Epic For Upgrade of Port Control Tower and Systems at RlicDokumen8 halamanEpic For Upgrade of Port Control Tower and Systems at RlicsreeBelum ada peringkat

- REHAU 20UFH InstallationDokumen84 halamanREHAU 20UFH InstallationngrigoreBelum ada peringkat

- Dams FoundationDokumen8 halamanDams FoundationharikotoBelum ada peringkat

- Stair CaseDokumen10 halamanStair CaseUmar AbidBelum ada peringkat

- Part List - 69NT40-511-300 To 399Dokumen92 halamanPart List - 69NT40-511-300 To 399cloviskrelling100% (1)

- Kps Product Catalog 2013 en WebDokumen40 halamanKps Product Catalog 2013 en WebAsima Nezirevic100% (1)

- Building Drifts in ETABSDokumen16 halamanBuilding Drifts in ETABSJaime Manalili Landingin100% (1)