Series 90 IOM

Diunggah oleh

Anonymous 7xHNgoKE6e0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan6 halamanSeries 90 pump installation and operation manual

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniSeries 90 pump installation and operation manual

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan6 halamanSeries 90 IOM

Diunggah oleh

Anonymous 7xHNgoKE6eSeries 90 pump installation and operation manual

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNERS USE.

Series 90 In-Line Centrifugal Pump

Installation, Operation & Service Instructions

DESCRIPTION

The Series 90 In-Line Mounted Centrifugal Pump is a close

coupled, space saving, low maintenance pump capable of

performing a wide range of fluid applications. The Back Pull-

Out feature allows the pump to be serviced without disturbing

system piping. The Series 90 pumps are available for pipe

sizes from 1" to 2".

PUMP APPLICATION

Series90 Pumps may be used for hydronic heating and cool-

ing, domestic hot water, cooling towers, machinery cooling,

pressure boosting, industrial fluid transfer, refrigeration and

heater exchanger circulation. Bell & Gossett recommends that

bronze constructed pumps be used for pumping potable

water. For other applications contact your local Bell & Gossett

representative.

OPERATIONAL LIMITS

Bell & Gossett Series 90 Pumps are designed to pump liquids

compatible with their iron or bronze body construction.

Unless special provisions have been made by ITT Bell &

Gossett, the operational limits for Series 90 Pumps are listed

below.

Do not exceed these values.

Maximum Working Pressure: 175 psi

Mechanical Seal: BUNA PH Limitations 7-9;

Temperature Range 20 to +225F

EPT PH Limitations 7-11;

Temperature Range 20 to +250F

Bell & Gossett

Instruction Manual P81547

REVISION B

ADDITIONAL SAFETY REQUIREMENTS:

MECHANICAL SAFETY:

2

WARNING: ELECTRICAL OVERLOAD HAZARD

Three phase motors must have properly sized heaters

to provide overload and under voltage protection. Single

phase motors have built-in overload protections. Failure to

follow these instructions could result in serious personal

injury, death and/or property damage.

WARNING: ELECTRICAL SHOCK HAZARD

Electrical connections to be made by a qualified elec-

trician in accordance with all applicable codes, ordinances

and good practices. Failure to follow these instructions

could result in serious personal injury, death and/or property

damage.

WARNING: UNEXPECTED STARTUP HAZARD

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious per-

sonal injury, death and/or property damage.

WARNING: EXCESSIVE SYSTEM

PRESSURE HAZARD

The maximum working pressure of the pump is listed on the

nameplate DO NOT EXCEED THIS PRESSURE. Failure to

follow these instructions could result in serious personal

injury, death and/or property damage.

WARNING: EXCESSIVE PRESSURE HAZARD

VOLUMETRIC EXPANSION

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failure of sys-

tem components and release high temperature fluids. This

can be prevented by installing properly sized and located

compression tanks and pressure relief valves. Failure to fol-

low these instructions could result in serious personal injury,

death and/or property damage.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on

pump instruction decals to draw attention to safety related

instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

Your Series 90 Pump should have the following warning labels

affixed to the pump in the approximate positions shown. If

these warnings are missing or are illegible, contact your local

Bell & Gossett representative for a replacement.

SAFETY REQUIREMENTS

ELECTRICAL SAFETY:

WARNING: EXTREME TEMPERATURE HAZARD

If the pump, motor, or piping are operating at extremely

high or low temperature, guarding or insulation is required.

Failure to follow these instructions could result in serious

personal injury, death and/or property damage.

WARNING: HOT WATER HAZARD

When disassembling a gasketed joint, always use a

new gasket upon reassembly. NEVER RE-USE OLD GAS-

KETS. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

THERMAL SAFETY:

Install the suction and discharge flanges on the pipe ends

using teflon tape sealer or high quality thread sealant. Minimize

strain on the pump by supporting the suction and discharge

piping with pipe hangers near the pump. Line up the vertical

and horizontal piping so that the bolt-holes in both the pump

and pipe flanges are aligned. DO NOT ATTEMPT TO SPRING

THE SUCTION OR DISCHARGE LINES INTO POSITION. THIS

MAY RESULT IN UNWANTED STRESS IN THE PUMP BODY,

FLANGE CONNECTIONS AND/OR PIPING. The code for pres-

sure piping, ANSI B31.1, lists types of supports available for

various applications.

Ordinary wire or band hangers are not adequate to maintain

alignment. It is very important to provide strong, rigid support

for the suction and discharge lines.

New Bell & Gossett flange gaskets must be installed between

the flanges of the pump body and suction and discharge

pipes. The gaskets should be clean and grease-free; old gas-

kets should never be reused. Suitable fasteners for this con-

nection are supplied in the Bell & Gossett fastener pack. Apply

a torque of 8-11 ft. lbs. to each of the flange bolts. Both the

suction and discharge flanges must be torqued to the same

level.

PUMP LOCATION

PUMP SUPPORT AND LOCATION

The Bell & Gossett Series 90 Pump should be installed where

there will be sufficient room for future inspection, maintenance

and service. It is highly recommended that service valves

(shut-off) also be installed on each side of the pump to facili-

tate servicing or replacing without draining the system. Special

precautions should be taken to avoid sound and vibration

transmission. If the pump is to be located near a noise sensi-

tive area, consult a sound specialist.

If it is required to lift the entire pump, do so with slings placed

around the pump assembly as shown.

IMPORTANT: In closed systems, do not install and operate

Bell & Gossett pumps, 3D valves, suction diffusers, etc., with-

out properly sized safety and control devices. Such devices

include properly sized and located pressure relief valves, com-

pression tanks and pressure, temperature, and flow controls. If

the system is not equipped with these devices, consult the

responsible engineer or architect before operating.

MODE OF DISCHARGE

Bell & Gossett Series 90 In-Line Pumps may be installed to

discharge vertically or horizontally. THE ARROW ON THE

PUMP BODY MUST POINT IN THE DIRECTION OF THE

FLOW.

The pump may be installed with the motor vertical or horizon-

tal. Do not install with the motor below the pump body.

SYSTEMPIPING

Always install a section of straight pipe between the suction

side of the pump and the first elbow. The length of this pipe

should be equal to five times the diameter of the suction pipe

size. This reduces turbulence of the suction by straightening

the liquid flow path prior to pump entry.

Air must be kept out of the system. On an open system always

place the end of the suction pipe at least three feet (3') below

the surface of the water in the suction well to prevent air from

being drawn into the pump. Avoid air pockets in the suction

line and ensure that each section of the suction pipe is

absolutely air tight.

If high temperature variation is anticipated, expansion fittings

should be installed such that they reduce pump strain.

3

WARNING: HOT WATER LEAKAGE HAZARD

Make certain that the flange bolts have been ade-

quately torqued. Failure to follow these instructions could

result in serious personal injury and/or property damage.

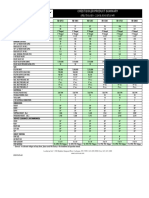

PIPING SCHEMATIC EXAMPLE

4

WIRING INSTRUCTIONS

Remove the screws securing the conduit box cover (wiring

compartment) and lift off the cover. Attach the appropriate size

connector to the hole in the side of the conduit box.

OPERATIONAL INSTRUCTIONS

SYSTEMPREPARATION

Prior to pump startup, closed heating and cooling systems

should be flushed and drained with clean water. The system

should then be filled with clean water have a PH between 7

and 9.

LUBRICATION

Series 90 Pumps with 5 HP and smaller motors are perma-

nently lubricated. Pumps with 7

1

/2, 10 and 15 HP motors are

furnished with grease fittings and should be lubricated in

accordance with the manufacturers nameplate instructions.

For future lubrication, Bell & Gossett supplies a high quality

lubricant specifically for this purpose which can be purchased

from and Bell & Gossett representative (Part No. L23401).

ROTATION

Pump rotation is clockwise when viewed from the back of the

motor. An arrow is provided to show rotational direction.

PRIMING AND STARTING

Before starting, the Series 90 Pump must first be filled with

water. Manual priming may be necessary if the system does

not fill the pump body automatically. Vent plugs are provided

on the pump body to vent the air.

The pump should be started with the discharge valve closed

and the suction valve fully open. After the pump is at operating

speed, the discharge valve should be opened gradually.

SERVICE INSTRUCTIONS

GENERAL INSTRUCTIONS

1. Keep motor properly lubricated if required.

2. If the pump is to be exposed to freezing temperatures, drain

the pump.

PERIODIC INSPECTION

Inspect the pump regularly for leaking seals, worn gaskets,

and loose or damaged components. Replace or repair as

required.

REPLACING THE SEAL

The electrical supply must be disconnected and locked out of

service. Loosen the conduit box cover screws and remove the

cover. Disconnect conduit and wiring.

Close the valves on the suction and discharge sides of the

pump (if no valves have been installed, it will be necessary to

drain the system).

Loosen the volute capscrews but do not remove them. Shift

the pump position slightly to allow the pressurized water to

escape.

Remove the volute capscrews and remove the pump assembly

from the volute.

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lockout the power before making

electrical connections. Failure to follow these instructions

could result in serious personal injury, death and/or property

damage.

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lockout the power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

WARNING: ELECTRICAL OVERLOAD HAZARD

Three phase motors must have properly sized heaters

to provide overload and under voltage protection. Single

phase motors have built-in overload protectors. Failure to

follow these instructions could result in serious personal

injury or death.

CAUTION: SEAL DAMAGE HAZARD

Do not run the pump dry seal damage may occur.

Failure to follow these instructions could result in moderate

personal injury and/or property damage.

WARNING: HOT WATER LEAKAGE HAZARD

Pressurize the pump body slowly while checking for

leaks at all joints with gaskets. Failure to follow these

instructions could result in serious personal injury and/or

property damage.

WARNING: UNEXPECTED STARTUP HAZARD

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious per-

sonal injury, death and/or property damage.

CAUTION: EXTREME TEMPERATURE HAZARD

Allow the pump temperature to reach acceptable

level before proceeding. Open drain valve and do not pro-

ceed until the liquid has completely drained. If the liquid

does not stop flowing from drain valve, then the isolation

valves are not sealing and should be repaired before con-

tinuing. After the liquid has stopped flowing, leave the drain

valve open and continue. Remove the drain plug located on

the bottom of the pump volute. Do not reinstall plug or close

drain valve until the reassembly is complete. Failure to follow

these instructions could result in moderate personal injury

and/or property damage.

WARNING: EXCESSIVE PRESSURE HAZARD

Make certain that the internal pressure is relieved

before continuing. Failure to follow these instructions could

result in serious personal injury and/or property damage.

WARNING: ELECTRICAL SHOCK HAZARD

Be certain that all connections are secure and the

conduit box cover is closed before electrical power is con-

nected. Failure to follow these instructions could result in

serious personal injury or death.

5

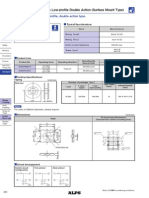

DETERMINE THE SEAL SIZE

Cut away diagrams have been provided to illustrate the com-

ponents of the Series 90 Pump assemblies. The primary fea-

ture distinguishing between the A and AA type pumps is size.

Measure the diameter of the shaft sleeve to determine nominal

seal size. Series 90 Pumps have three nominal seal sizes:

1

/2",

3

/4" and 1

1

/4". Most components of the A and AA pump seals

are similar (but not interchangeable). All Series 90 seals,

except the 1

1

/4", require a spring retainer as part of the seal

assembly. Refer to these diagrams whenever seal replacement

becomes necessary.

REPLACEMENT PROCEDURE

With the motor assembly removed from the system, use the

following instructions to facilitate the replacement.

1. Use a strap wrench or rag to prevent the impeller from turn-

ing with one hand and loosen the impeller nut with the other.

2. Lift the spring retainer (not found in the 1

1

/4" seal assem-

bly) and the seal spring from the shaft. Remove the com-

pression ring from the seal collar by inserting a small

screwdriver underneath the ring and carefully applying an

upward force.

NOTE: Bell & Gossett seal assemblies consist of a stationary

seal insert assembly and a rotating seal assembly. Each of

these components must be replaced when replacing the

mechanical seal. NEVER REPLACE INDIVIDUAL COMPO-

NENTS SEPARATELY.

3. Using a clean, lint free rag, remove any debris that may

have accumulated in the seal recess.

4. For the

1

/2" and

3

/4" seals, place the new retainer in the

face plate seal recess. Set the thin seat gasket in the

recess and set the seat insert atop the gasket. A ceramic

insert has a top side and bottom side. The bottom is identi-

fiable by its slightly recessed grooves. These grooves

should face downward toward the rubber gasket.

For the 1

1

/4" seals, set the seal insert into the elastomeric

seat cup. Lubricate the seat cup with soapy water and

set it into the face plate recess.

5. Lubricate the rubber seal collar with soapy water. The

entire rotating seal assembly, which includes a seal ring,

bellows and seal housing, is to be pushed onto the shaft

as one unit. Do not attempt to assemble the seal by plac-

ing the components on the shaft individually. The notches

in the collar should be aligned with the recesses found on

each side of the carbon ring.

6. Press the seal housing tightly against the upper end of

the rubber collar. A screwdriver can be used at several

points along its periphery to provide a tight and even fit.

Press with the screwdriver dot not tap. Tapping on the

seal may break the ceramic or carbon insert.

7. Place the seal spring on the shaft and then the spring

retainer (except for the 1

1

/4" seal). Next, place the

impeller and lock washer on the shaft. Thread the

impeller nut onto the shaft and tighten according to:

3

/8"

nut to 8-12 ft. lbs.,

7

/16" nut to 17-22 ft. lbs., and

3

/8" cap-

screws to 10-14 ft. lbs. Do not overtighten.

8. Clean the pump body of excess debris. Place a new gas-

ket in the recess of the pump body; ensure that it sits

flush against the gasket surface.

9. Replace the motor assembly by inserting the impeller in

the pump body and evenly tighten the eight cap screws.

Refer to the TORQUE CHART on the back page.

10. Refer to the WIRING INSTRUCTIONS section in this

manual to properly configure all electrical connections.

11. Follow the OPERATIONAL INSTRUCTIONS in this manual

to 1) check the PH of the system water, 2) to check the

rotation of the pump and 3) to pressurize the system prior

to starting.

PUMP BODY DIAGRAM A Size

PUMP BODY DIAGRAM AA Size

WARNING: HOT WATER HAZARD

When disassembling a gasketed joint, always use a

new gasket upon reassembly. NEVER RE-USE OLD GAS-

KETS. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

DEALER SERVICING

If your pump requires further repair, contact your local Bell &

Gossett representative. Having the following information at

hand will facilitate your representatives ability to assist you:

1. Complete data from nameplate.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pumping system (include pipes valves, etc).

YOUR BELL & GOSSETT REPRESENTATIVE IS

ITT

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Fax: (847) 966-9052

www.bellgossett.com

COPYRIGHT 2007 BY

ITT CORPORATION

PRINTED IN U.S.A. 6-07

THE ITT ENGINEERED BLOCKS SYMBOL AND

ENGINEERED FOR LIFE ARE REGISTERED

TRADEMARKS OF ITT CORPORATION

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Series 100Dokumen1 halamanSeries 100Anonymous 7xHNgoKE6eBelum ada peringkat

- Troubleshooting E00669 PDFDokumen20 halamanTroubleshooting E00669 PDFCarlosBelum ada peringkat

- Airtrol IOM 599 PDFDokumen6 halamanAirtrol IOM 599 PDFAnonymous 7xHNgoKE6eBelum ada peringkat

- A Mobile Application That Provides Boiler Control, From AnywhereDokumen1 halamanA Mobile Application That Provides Boiler Control, From AnywhereAnonymous 7xHNgoKE6eBelum ada peringkat

- 2001 - B&G Centrifugal PumpsDokumen6 halaman2001 - B&G Centrifugal PumpsAnonymous 7xHNgoKE6eBelum ada peringkat

- Power System Dynamics and Control, 1a. Ed. - Harry G. Kwatny, Karen Miu-MillerDokumen274 halamanPower System Dynamics and Control, 1a. Ed. - Harry G. Kwatny, Karen Miu-MillerAnonymous CqddyPpb100% (1)

- Bell & Gossett 1531 Pump Manual Circa 2007Dokumen8 halamanBell & Gossett 1531 Pump Manual Circa 2007Anonymous 7xHNgoKE6eBelum ada peringkat

- 1536 Subm 277Dokumen2 halaman1536 Subm 277Anonymous 7xHNgoKE6eBelum ada peringkat

- E-60 ECM - Subm-B-144-2-weaDokumen4 halamanE-60 ECM - Subm-B-144-2-weaAnonymous 7xHNgoKE6eBelum ada peringkat

- Guide Specification Index: DomesticDokumen6 halamanGuide Specification Index: DomesticAnonymous 7xHNgoKE6eBelum ada peringkat

- Domestic Pump: Series CM Boiler Feed UnitsDokumen4 halamanDomestic Pump: Series CM Boiler Feed UnitsAnonymous 7xHNgoKE6eBelum ada peringkat

- 751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT) PDFDokumen68 halaman751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT) PDFAnonymous 7xHNgoKE6eBelum ada peringkat

- Series 60 Inline Pump With Electronically Commutated Motor (ECM)Dokumen3 halamanSeries 60 Inline Pump With Electronically Commutated Motor (ECM)Anonymous 7xHNgoKE6eBelum ada peringkat

- Bell & Gossett: Submittal B-341BDokumen2 halamanBell & Gossett: Submittal B-341BAnonymous 7xHNgoKE6eBelum ada peringkat

- AWX2-I-O Rev G - High Altitude PDFDokumen68 halamanAWX2-I-O Rev G - High Altitude PDFAnonymous 7xHNgoKE6eBelum ada peringkat

- B&G E1510 Pump Technical InformationDokumen8 halamanB&G E1510 Pump Technical InformationAnonymous 7xHNgoKE6eBelum ada peringkat

- B&G E1510 Pump Technical InformationDokumen8 halamanB&G E1510 Pump Technical InformationAnonymous 7xHNgoKE6eBelum ada peringkat

- SYNC-PCP Rev BDokumen20 halamanSYNC-PCP Rev BAnonymous 7xHNgoKE6eBelum ada peringkat

- 60ECM Lit B 107D PDFDokumen4 halaman60ECM Lit B 107D PDFAnonymous 7xHNgoKE6eBelum ada peringkat

- Series 60 Inline Pump With Electronically Commutated Motor (ECM)Dokumen3 halamanSeries 60 Inline Pump With Electronically Commutated Motor (ECM)Anonymous 7xHNgoKE6eBelum ada peringkat

- Electric Iom PDFDokumen68 halamanElectric Iom PDFAnonymous 7xHNgoKE6eBelum ada peringkat

- Usg Iom PDFDokumen56 halamanUsg Iom PDFAnonymous 7xHNgoKE6eBelum ada peringkat

- 751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT)Dokumen4 halaman751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT)Anonymous 7xHNgoKE6eBelum ada peringkat

- E-90 ECM - Subm-142Dokumen3 halamanE-90 ECM - Subm-142Anonymous 7xHNgoKE6eBelum ada peringkat

- Modbus Communication Instructions: Models: 1.0 - 1.3 - 1.5Dokumen24 halamanModbus Communication Instructions: Models: 1.0 - 1.3 - 1.5Anonymous 7xHNgoKE6eBelum ada peringkat

- Condensing Commercial Gas Water HeatersDokumen4 halamanCondensing Commercial Gas Water HeatersAnonymous 7xHNgoKE6eBelum ada peringkat

- Crest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRDokumen1 halamanCrest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRAnonymous 7xHNgoKE6eBelum ada peringkat

- Usg Iom PDFDokumen56 halamanUsg Iom PDFAnonymous 7xHNgoKE6eBelum ada peringkat

- Alstrom Series ASTEG Steam Generator BrochureDokumen2 halamanAlstrom Series ASTEG Steam Generator BrochureAnonymous 7xHNgoKE6eBelum ada peringkat

- Check-Trol: Isolation Flow Control FlangeDokumen2 halamanCheck-Trol: Isolation Flow Control FlangeAnonymous 7xHNgoKE6eBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 0.6mm Low-Profile, Double Action TypeDokumen3 halaman0.6mm Low-Profile, Double Action TypeshyhuBelum ada peringkat

- ASME General 100 QuestionsDokumen54 halamanASME General 100 Questionsatulpatil99100% (2)

- BME301 - Material Engineering Notes - 2023 - 24Dokumen15 halamanBME301 - Material Engineering Notes - 2023 - 24kec.abhishek463Belum ada peringkat

- Plasticity and Structure of SoilDokumen28 halamanPlasticity and Structure of SoilJazmine ValenzonaBelum ada peringkat

- Jakarta 2Dokumen120 halamanJakarta 2Anang QosimBelum ada peringkat

- Micro Air 120 PDFDokumen2 halamanMicro Air 120 PDFFrancois-Belum ada peringkat

- Foundation 2Dokumen333 halamanFoundation 2akem mig100% (1)

- Direct Tensile Test of ConcreteDokumen7 halamanDirect Tensile Test of ConcreteBunkun15100% (1)

- M Tech I Sem II Mid TDDokumen4 halamanM Tech I Sem II Mid TDMir Mustafa AliBelum ada peringkat

- Kaong PS, Silang, Boq 11jun2021Dokumen11 halamanKaong PS, Silang, Boq 11jun2021Fred PascuaBelum ada peringkat

- Appendix A 072115 WebDokumen61 halamanAppendix A 072115 WebbariscBelum ada peringkat

- AC018KN4DCH - WBMF Front Wind Baffle SubmittalDokumen2 halamanAC018KN4DCH - WBMF Front Wind Baffle SubmittalChin Heng LimBelum ada peringkat

- Roofing SafetyDokumen38 halamanRoofing SafetyDhârâñî KûmârBelum ada peringkat

- Final Report ErsDokumen68 halamanFinal Report ErsWanBelum ada peringkat

- Alloy Steels - Engineering Materials & Metallurgy Questions and Answers - SanfoundryDokumen6 halamanAlloy Steels - Engineering Materials & Metallurgy Questions and Answers - SanfoundrySample UseBelum ada peringkat

- Ultrasonic Welding of ThermoplasticsDokumen17 halamanUltrasonic Welding of ThermoplasticsSyed Farhan RazaBelum ada peringkat

- Astm A307Dokumen1 halamanAstm A307SAlman Khan100% (1)

- Boq National Library Timor LesteDokumen24 halamanBoq National Library Timor Lestekrisna kingBelum ada peringkat

- Tests On Rocks: Soil MechanicsDokumen5 halamanTests On Rocks: Soil MechanicsWaqas Sadiq100% (1)

- Electrolytic Plasma Treatment Processing of Conductive MaterialsDokumen5 halamanElectrolytic Plasma Treatment Processing of Conductive Materialsnicu1212Belum ada peringkat

- Steel Grade: Material Data SheetDokumen3 halamanSteel Grade: Material Data SheetHDBelum ada peringkat

- ACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis ReportDokumen7 halamanACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis Reportdwi sutiknoBelum ada peringkat

- ASTM D149-2009 (2013) - 2500 DIelectricDokumen3 halamanASTM D149-2009 (2013) - 2500 DIelectricmateoBelum ada peringkat

- Indian Standard: Code of Practice FOR Design and Construction Pile Foundations OFDokumen44 halamanIndian Standard: Code of Practice FOR Design and Construction Pile Foundations OFKhushaliBelum ada peringkat

- Meyco Segment HR PDFDokumen16 halamanMeyco Segment HR PDFFabioSoaresBelum ada peringkat

- Slickline Basics.11 20Dokumen10 halamanSlickline Basics.11 20Rio de MarioBelum ada peringkat

- Columns and StrutsDokumen10 halamanColumns and StrutsamitsagaBelum ada peringkat

- Jet Pump Technical DataDokumen11 halamanJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- B353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateDokumen49 halamanB353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateVraja DasiBelum ada peringkat

- An Interface Element For The Simulation of Delamination in Unidirectional Fiber-Reinforced Composite LaminatesDokumen19 halamanAn Interface Element For The Simulation of Delamination in Unidirectional Fiber-Reinforced Composite LaminatesKamal ShayedBelum ada peringkat