Empire Undercarriage Brochure

Diunggah oleh

elias667Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Empire Undercarriage Brochure

Diunggah oleh

elias667Hak Cipta:

Format Tersedia

1-800-EMPIRE-1

www.empirecat.com

TRACK ASSURANCE

:warranty

Track assurance program for Genuine Cat Undercarriage

coverage is four years, 4000 hours, or until the assembly is

100% worn whichever comes frst.

Whats covered:

u Oil leaks and breakage on new link assemblies, roller, and idlers

u Oil leaks on dealer rebuilt exchange rollers and

re-welded/re-shelled idlers

u Breakage, under normal use, of new track shoes and

sprockets/sprocket segments

u Bushings with end grooving exceeding Cat re-use guidelines at turn time

u Severe heavy spalling that covers 30% or more of the link rail surface

u Loose hardware

LINKS

Hardened for long life and

excellent sealability.

Special heat treat processes

give Cat links consistent

surface hardness, superior

hardening depth, and strong

core hardness. This results in excellent wear

resistance, strength, and durability for

unmatched sealability and long life.

ROLLERS

Manufactured for increased life and low

costs. Cat rollers are through hardened for long

wear life, unmatched structural support, and

resistance to deformation. Cat's Duo-Cone seals

help ensure lifetime lubrication to extend life,

permit roller reshelling, and lower your costs.

SEGMENTS

Hardened for

improved wear

resistance. High

surface hardness and

excellent hardened depth and core hardness

mean Cat segments provide long wear life,

resistance to bending and breakage, and

maximum hardware retention. The bolt-on

design reduces replacement time.

PINS AND BUSHINGS

Matched to links for strength and sealability. Cat

pins and bushings are dimensionally matched to the

links and manufactured to provide excellent track

joint integrity. This design helps ensure maximum

sealability. High surface and core hardness translate

into increased strength and wear resistance.

SEALS

Designed for long life and

low costs. To keep

abrasives out and oil in, the

Caterpillar rigid seal design

combines high wear

resistance and load

protection. The result is a "wet" joint at turn

time, which extends bushing life and lowers

your cost.

IDLERS

Manufactured for more wear resistance and

less downtime. Whether cast, forged, or

fabricated, Cat idlers provide superior structural

support and rebuild capabilities. Special heat

treat processes help ensure proper hardness levels, providing wear

resistance. Duo-Cone seals help ensure lifetime lubrication. eliminating

idler maintenance and lowering operating costs.

TRACK SHOES

Hardened and tempered

for better wear resistance.

Caterpillar track shoes are

furnace hardened and

tempered for strength and

resistance to bending and

breakage. We offer a variety of track shoe

options to meet the requirements of your work

environment.

1

4

5

2

3

6

7

4

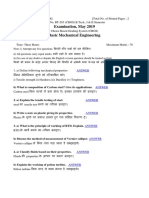

PINS AND BUSHINGS

Matched to links for

strength and sealability.

Cat pins and bushings are

dimensionally matched to

the links and manufactured

to provide excellent track joint integrity. This

design helps ensure maximum sealability.

High surface and core hardness translate into

increased strength and wear resistance.

TRACK SHOES

Hardened and tempered for better

wear resistance. Caterpillar track

shoes are furnace hardened and

tempered for strength and resistance to

bending and breakage. We offer a variety of track shoe op-

tions to meet the requirements of your work environment.

SEALS

Designed for long life

and low costs. To keep

abrasives out and oil in,

the Caterpillar rigid seal

design combines high

wear resistance and load protection. The

result is a wet joint at turn time, which

extends bushng life and lowers your cost.

IDLERS

Manufactured

for more wear

resistance and

less downtime. Whether cast, forged

or fabricated, Cat idlers provide superior

structural support and rebuild capabilities.

Special heat treat processes help ensure

proper hardness levels, providing wear

resistance. Duo-Cone seals help ensure

lifetime lubrication. Eliminating idler main-

tenance and lowering operating costs.

u Professional Expertise

u Field service capabilities

u Parts exchange program

u In-territory undercarriage shop

u Custom track service management

u Wet-bushing turn within two business days

u New and parts exchange parts inventory

stocked for same-day delivery

2

3

5

6

7

Caterpillar

undercarriage components work as a powerful system to propel your machine over all

types of terrain including Arizona and Southeastern Californias soil, which is some of the most

abrasive and highest impact in the United States. These systems wear at balanced, manageable

rates, providing consistently longer life with minimal downtime. Empires undercarriage management

techniques, coupled with the systems high level of serviceability, assure maximum system

performance and lower operating costs, even in the high-abrasion and impact applications that are

typical to the southwest.

EMPIRE ADVANTAGE

CUSTOM TRACK SERVICE

To ensure you get the absolute most from your machine, Caterpillar

offers Custom Track Service (CTS), a service to help manage

undercarriage systems. Our parts and service representatives

will perform inspections to project remaining wear life, in order

to schedule maintenance. Equipped with the advanced tools

and necessary parts to perform cost-effcient, accurate

track work, CTS minimizes downtime and gets machines

back to work quickly.

BENEFITS OF A WET-BUSHING TURN

Wet turns extend the life of the link by reducing internal

heat and wear. Plus, turned bushings with new oil and

seals reduce noise for increased operator comfort.

The process consists of complete link tear down, every

pin and bushing inspected for re-usability, new seals,

bushing turned and new oil. Caterpillar bushings can be

wet-turned by Empire technicians in about two days. Most other

shops require three weeks to do a dry turn.

Empires support capabilities combined with Caterpillar quality virtually eliminates any undercarriage

related downtime and provides Ashton with the lowest cost per hour. Empire also adds value to the Ashton

Companies with operation suggestions and in-depth knowledge of undercarriage works and wear.

- Clint Schweigert, Equipment Manager

The Ashton Company

:servicability

BREAKDOWN OF AN UNDERCARRIAGE SYSTEM

1

LINKS

Hardened for long life and

excellent sealability.

Special heat treat processes

give Cat links consistient

surface hardness, superior

hardening depth and strong core hardness. This

results in excellent wear resistance, strength and

durability for unmatched sealability and long life.

ROLLERS

Manufactured for

increased life and

low costs. Cat rollers

are through hardened

for long wear life, unmatched structural

support and resistance to deformation. Cats

Duo-Cone seals help ensure lifetime lubrica-

tion to extend life, permit roller reshelling

and lower your costs.

SEGMENTS

Hardened for

improved wear

resistance.

High surface hardness and excellent

hardened depth and core hardness mean

Cat segments provide long wear life,

resistance to bending and breakage and

maximum hardware retention. The bolt-on

design reduces replacement time.

Empires management techniques and Caterpillars long lasting undercarriage

combine to provide you the most life at the lowest possible cost per hour.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Optics BasicDokumen74 halamanOptics BasickaviyanBelum ada peringkat

- MCQ MasterDokumen11 halamanMCQ MasterMonzieAir67% (9)

- Analisis de ChispaDokumen2 halamanAnalisis de Chispaelias667Belum ada peringkat

- WearDokumen31 halamanWearelias667100% (1)

- Laminite Wear Resistant Material PDFDokumen0 halamanLaminite Wear Resistant Material PDFelias667Belum ada peringkat

- Bolt-On Wear Runners and BasesDokumen2 halamanBolt-On Wear Runners and Baseselias667Belum ada peringkat

- P Met 885SPR 1Dokumen1 halamanP Met 885SPR 1elias667Belum ada peringkat

- Recom. de Soldadura XARDokumen4 halamanRecom. de Soldadura XARelias667Belum ada peringkat

- Analisis de ChispaDokumen2 halamanAnalisis de Chispaelias667Belum ada peringkat

- P♦MET 720 Arc Spray Wire Data SheetDokumen1 halamanP♦MET 720 Arc Spray Wire Data Sheetelias667Belum ada peringkat

- Tube Alloy 240 oDokumen2 halamanTube Alloy 240 oelias667Belum ada peringkat

- The Practical Reference Guide ForDokumen4 halamanThe Practical Reference Guide Forelias667Belum ada peringkat

- Chapter 2 Fluid StaticsDokumen13 halamanChapter 2 Fluid StaticsguhanBelum ada peringkat

- Ps Pre Final ExamDokumen5 halamanPs Pre Final ExamRemar Jhon PaineBelum ada peringkat

- Masatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsDokumen225 halamanMasatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsPo48HSDBelum ada peringkat

- 38CKC 8PDDokumen36 halaman38CKC 8PDjean_carlos_abreu_rBelum ada peringkat

- Hydrostatic Forces on SurfacesDokumen12 halamanHydrostatic Forces on SurfacesPajhmanAwghanBelum ada peringkat

- BT 203 Basic Mechanical Engineering May 2019 PDFDokumen2 halamanBT 203 Basic Mechanical Engineering May 2019 PDFKunta PatleBelum ada peringkat

- Algebra:: N N N N N N 1B 2B ZoneDokumen6 halamanAlgebra:: N N N N N N 1B 2B Zonevenedick sapongayBelum ada peringkat

- Titration Analysis of VinegarDokumen2 halamanTitration Analysis of VinegarSourabh DasBelum ada peringkat

- Analytical Chemist Scientist in Lynchburg Richmond VA Resume Alfred HoornikDokumen3 halamanAnalytical Chemist Scientist in Lynchburg Richmond VA Resume Alfred HoornikAlfredHoornikBelum ada peringkat

- 50Hz R410A H Air-Cooled Modular Chiller Technical Manual20130530 MailDokumen122 halaman50Hz R410A H Air-Cooled Modular Chiller Technical Manual20130530 MailCristian Andrés Pacó MoyaBelum ada peringkat

- PublishedneemfullpaperDokumen6 halamanPublishedneemfullpaperClinton John Evangelista JuadiongBelum ada peringkat

- 9A03301 Materials Science and EngineeringDokumen4 halaman9A03301 Materials Science and EngineeringsivabharathamurthyBelum ada peringkat

- Biochemistry of Bone & Muscle: Dr. Syahrijuita, M.Kes, SP - THT-KLDokumen69 halamanBiochemistry of Bone & Muscle: Dr. Syahrijuita, M.Kes, SP - THT-KLyantiBelum ada peringkat

- Matrices Incompatibilidad BogDokumen11 halamanMatrices Incompatibilidad BogIngenieria ScadiaBelum ada peringkat

- Loading LPG CalculationsDokumen12 halamanLoading LPG CalculationsJohn Green67% (3)

- Optional Strain Rate Forms For The Johnson CookDokumen17 halamanOptional Strain Rate Forms For The Johnson CookTien KimBelum ada peringkat

- 9702 m17 Ms 42Dokumen11 halaman9702 m17 Ms 42Imran ZafarBelum ada peringkat

- MCQ Gad 2Dokumen8 halamanMCQ Gad 2AlhanBelum ada peringkat

- The Reactivity Series NotesDokumen8 halamanThe Reactivity Series NotesTHEVINESHBelum ada peringkat

- Cryo Regulator RegValve PDFDokumen25 halamanCryo Regulator RegValve PDFdhaktodesatyajitBelum ada peringkat

- Determination of sulphites in water and wastewater by iodide-iodate titrationDokumen2 halamanDetermination of sulphites in water and wastewater by iodide-iodate titrationHimanshu ChaturvediBelum ada peringkat

- 50 Years After The Nobel Prize Ziegler Natta Catalysis - Claverie2013Dokumen6 halaman50 Years After The Nobel Prize Ziegler Natta Catalysis - Claverie2013Erika AndradeBelum ada peringkat

- CP de VaporDokumen6 halamanCP de VaporNatalia MorenoBelum ada peringkat

- Material BalancesDokumen15 halamanMaterial BalancesHalil İbrahim ÖzdemirBelum ada peringkat

- 2014 Catalogue QuickguidesDokumen9 halaman2014 Catalogue QuickguidesoktaBelum ada peringkat

- 221 Chloride and SulfateDokumen1 halaman221 Chloride and SulfatesofianesedkaouiBelum ada peringkat

- Cetco Hydraul EzDokumen4 halamanCetco Hydraul Ezjaredf@jfelectric.comBelum ada peringkat

- Raman Effect: Fingerprinting The UniverseDokumen2 halamanRaman Effect: Fingerprinting The UniverserachelBelum ada peringkat