4.liquid2 Extraction Full

Diunggah oleh

Muhammad Zaidi MisniJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

4.liquid2 Extraction Full

Diunggah oleh

Muhammad Zaidi MisniHak Cipta:

Format Tersedia

1

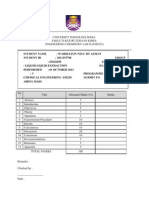

TABLE OF CONTENT

TITLE PAGE

Table of Content 1

1.0 Abstract 2

2.0 Introduction 3-4

3.0 Objectives 5

4.0 Theory 5-6

5.0 Apparatus and material 7

6.0 Experimental procedure 8

7.0 Results 9

8.0 Calculation 10-14

9.0 Discussion 15-16

10.0 Conclusion 16

11.0 Recommendations 16

References 17

Appendices 17

2

ABSTRACT

This simple experiment is conducted to determine the distribution of coefficient and

mass transfer coefficient with the aqueous phase as the continuous medium through liquid-

liquid extraction as the objectives of this experiment. Besides that, this experiment is also

based on the solubility of the solution used. In the experiment A, liquid-liquid extraction

column is used to obtain feed, raffinate and extract samples. The samples is taken for being

titrate with the different concentration of NaOH which is 0.1 M and 0.025 M. Moreover, the

value of mass transfer coefficient from liquid-liquid extraction are; 0.44 kg/min if titrated

with 0.1 M NaOH and -0.257 kg/min if titrated with 0.025 M NaOH. For the experiment B,

separators funnel is used to separate two solutions of different solubility and densities, and

then titration is done with different of NaOH concentration which is 0.1 M and 0.025 M. The

values for distribution coefficient by titration with 0.1 M are 7.78 in 1.0 ml of propionic acid,

2.30 in 3.0 ml of propionic acid and 1.80 in 5.0 ml of propionic acid. The experiment was

completely and successfully done.

3

INTRODUCTION

Liquid-liquid extraction, also known as solvent extraction and partitioning, is a

method to separate compounds based on their relative solubility in two different immiscible

liquids, which is water as usual and an organic solvent (propionic acid). It is an extraction of

a substance from one liquid phase into another liquid phase. Liquid-liquid extraction is a

basic technique in chemical laboratories, where it is performed using a separator funnel. This

type of process is commonly performed after a chemical reaction as part of the work-up.

Furthermore, this is the separation of a substance from a mixture by preferentially dissolving

that substance in a suitable solvent. By this process a soluble compound is usually separated

from an insoluble compound.

The basic principle behind extraction involves the contacting of a solution with

another solvent that is immiscible with the original. The solvent is also soluble with a specific

solute contained in a solution. Two phases are formed after the addition of solvent, due to the

differences in densities. The solvent is chosen so that the solute in the solution has more

affinity toward the added solvent. Therefore, mass transfer of the solute from the solution to

the solvent occurs. Further separation of the extracted solute and the solvent will be necessary.

However, these separation costs may be desirable in contrast to distillation and other

separation processes for situations where extraction is applicable.

A general extraction column has two input stream and two output streams. The input

streams consist of a solution feed at the top containing the solute to be extracted and a solvent

feed at the bottom which extracts the solute from the solution. The solvent containing the

extracted solute leaves the top of the column and is referred to as the extract stream. The

solution exits the bottom of the column containing only small amounts of solute and is known

as the raffinate. Further separation of the output streams may be required through other

separation process. Solvent extraction is used in nuclear reprocessing, ore processing, the

processing of perfumes and the production of vegetable oils and biodiesel.

4

Flow Sheet

Figure 1 : Liquid-liquid extraction column schematic diagram

Figure 2 : Extraction Flow sheet for an Extraction Column

5

OBJECTIVES

1. To conduct the simple experiments regarding liquid-liquid extraction.

2. To determine the distribution coefficient for the system organic solvent-propionic acid

water and show its dependence on concentration.

3. To demonstrate how a mass balance is performed on the extraction column and to

measure the mass transfer coefficient with the aqueous phase as the continuous

medium.

THEORY

In liquid-liquid extraction, two phases must be brought into contact to permit transfer

of material and then be separated. Extraction equipment may be operated batch wise or

continuous. The extract is the layer of solvent plus extracted solute and the raffinate is the

layer from which solute has been removed. The extract may be lighter or heavier than the

raffinate, and so the extract may be shown coming from top of the equipment in some cases

and from the bottom in others. The operation may of course be repeated if more than one

contact is required, but when the quantities involved are large and several contacts are needed,

continuous flow becomes economical.

In dilute solutions at equilibrium, the concentration of the solute in the two phases is

called the distribution coefficient or distribution constant K.

K=Y/X

Where the Y and X are the concentrations of the solute in the extract and the raffinate phases

respectively. The distribution coefficient can also be given as the weight fraction of the solute

in the two phases in equilibrium contact:

K =y*/x

Where y* is the weight fraction of the solute in the extract and x is the weight fraction of the

solute in the raffinate.

The rate at which a soluble component is transferred from one solvent to another will

be dependent, among other things, on the area of the interface between the two immiscible

6

liquids. Therefore it is very advantageous for this interface to be formed by droplets and films,

the situation being analogous to that existing in packed distillation columns. The theory for

the system Trichloroethylene-Propanoic acid-Water is as follows:

Let Vw : Water flow rate, lt/s

Vo : Trichloroethylene flow rate, lt/s

X : Propionic acid concentration in the organic phase, kg/lt

Y : Propionic acid concentration in the aqueous phase, kg/lt

Subscripts: 1: Top of column

2: Bottom of column

Mass Balance:

Propionic acid extracted from the organic phase (raffinate).

= Vo (

) (8.1.1)

Propionic acid extracted by the aqueous phase (extract)

= Vw (

-0) (8.1.2)

Therefore theoretically,

Vo (

) = Vw (

-0) (8.1.3)

Mass transfer coefficient:

MTC=Rate of acid transfer/volume of packing mean driving force (8.1.4)

Where Log mean driving force: (

) / ln (

: Driving force at the top of the column = (

-0)

: Driving force at the bottom of the column = (

*)

Where

* is the concentration in the organic phase which would be in equilibrium with

concentration

in the aqueous phase. The equilibrium values can be found using the

distribution coefficient found in the first experiment.

7

APPARATUS AND MATERIALS

Apparatus:

Liquid-liquid extraction column

Water pump

Separator funnel

Burette

Conical flask

Volumetric flask

Measuring cylinder

Materials:

0.1 M NaOH solution

0.025 M NaOH solution

Distillates product solution

Raffinate product solution

Feed solution

Propionic acid

8

PROCEDURES

Experiment A

1. Make sure valve V6 and V11 are closed.

2. Valve S1, C3 and S3 are switched on.

3. The feed flow rates (C1) are adjusted until maximum.

4. S4 is switched on.

5. When the water reaches the top column, C1 is set to 250 cc/min.

6. Wait for 20 minutes.

7. 150mL sample from raffinate, feed and extract is taken.

8. 15 mL from each sample is taken in Experiment A and 3 drops of phenolphthalein is

added.

9. Each sample is titrated with 0.1M NaOH.

10. Step 8 and 9 is repeated with 0.025 M NaOH.

11. For each moles of NaOH is titrated twice.

Experiment B

1. 50mL of water, 50mL of organic solvent and 1mL of propionic acid is added into a

conical flask and is shakes well.

2. Step 1 is repeated with 3 and 5 mL of propionic acid.

3. Two layers of solution is formed (immiscible) and 10mL from each upper and bottom

layer is taken.

4. 3 drops of phenolphthalein is added into each sample.

5. Each ample is titrated with 0.1 M of NaOH.

9

RESULT

Experiment A

Concentration of

NaOH (M)

Raffinate (mL)

Feed (mL)

Extract (mL)

0.1 M 2.1 35.5 14.7

0.025 M 2.9 114.3 48.5

Water flow rate : 0.20 L/min

Organic flow rate : 0.20 L/min

Packing dimension : Length = 1.2 m

Diameter = 50 mm

Experiment B

Volume of propionic

acid (mL)

Volume of NaOH(mL)

Concentration of

NaOH(M)

Upper Bottom

1.0 21.0 2.7

0.1 M

3.0 60.0 26.0

5.0 100.0 55.4

10

CALCULATIONS

Formula for finding distribution coefficient (Experiment B):

K = Y/X

Where Y: Concentration of solute in exact phase.

X: Concentration of solute in raffinate phase.

For 0.1M of NaOH

1. 1.0mL of propionic acid

Upper (Y) Bottom (X)

M

1

V

1

= M

2

V

2

(0.1M)(21.0 10

-3

L) = (M

2

)(1.0 10

-3

L)

M

2

= 2.10 M

M

1

V

1

= M

2

V

2

(0.1M)(2.70 10

-3

L) = (M

2

)(1.0 10

-3

L)

M

2

= 0.27 M

K = Y/X

= 2.10M / 0.27M

= 7.78

2. 3.0mL of propionic acid

Upper (Y) Bottom (X)

M

1

V

1

= M

2

V

2

(0.1M)(60.0 10

-3

L) = (M

2

)(3.0 10

-3

L)

M

2

= 2.00 M

M

1

V

1

= M

2

V

2

(0.1M)(26.0 10

-3

L) = (M

2

)(3.0 10

-3

L)

M

2

= 0.87 M

K = Y/X

= 2.00M / 0.87M

= 2.30

3. 5.0mL of propionic acid

Upper (Y) Bottom (X)

M

1

V

1

= M

2

V

2

(0.1M)(100 10

-3

L) = (M

2

)(5.0 10

-3

L)

M

2

= 2.00 M

M

1

V

1

= M

2

V

2

(0.1M)(55.4 10

-3

L) = (M

2

)(5.0 10

-3

L)

M

2

= 1.11 M

K = Y/X

=2.00M / 1.11M

= 1.80

11

Formula for finding mass transfer coefficient (Experiment A):

M

1

V

1

= M

2

V

2

Where:

M

1

= concentration of NaOH

M

2

= concentration of propionic acid

V

1

= volume of NaOH

V

2

= volume of propionic acid

Rate of acid transfer = Vw (Y

1

0)

Vo (X

1

X

2

) = Vw (Y

1

0)

K = Y

1

/X*

Log mean driving force = (X

1

-X

2

) / ln (X

1

/X

2

)

Where:

X

1

: Driving force at the top of the column = (X

2

0)

X

2

: Driving force at the bottom of the column = (X

1

- X

1

*)

Packing dimension : Length = 1.2m

Diameter = 50mm

Radius = (

) = 0.025m

Therefore, packing volume, V = r

2

L

= ( 0.025m)

2

(1.2m)

= 2.36 10

-3

m

3

= 2.36 L

For 0.1M of NaOH

Raffinate:

M

1

V

1

= M

2

V

2

(0.1)(2.110

-3

) = M

2

(0.015)

M

2

= 0.014M of propionic acid X

1

Feed:

M

1

V

1

= M

2

V

2

(0.1)(35.510

-3

) = M

2

(0.015)

M

2

= 0.237M of propoinic acid

Extract:

M

1

V

1

= M

2

V

2

(0.1)(14.710

-3

) = M

2

(0.015)

M

2

= 0.098M of propoinic acid Y

1

Rate of acid transfer = Vw (Y

1

- 0)

= (0.20 L/min)(0.098 mol/L)

= 0.0196 mol/min

12

Finding the value of X

2

:

Vo (X

1

-X

2

) = Vw (Y

1

-0)

(0.20 L/min)(0.014 mol/L - X

2

) = 0.0196 mol/min

X

2

= 0.084 mol/L @ M

Finding the log mean driving force:

X

1

= (X

2

-0)

= 0.084 M

K = Y

1

/ X*

X* = Y

1

/ K At equilibrium, assume K = 7.78 (from experiment B)

= 0.098 / 7.78

= 0.013 M

X

2

= (X

1

-X

1

*)

= 0.014 M 0.013M

= 0.001M

Log mean driving force = (X

1

-X

2

) / ln (X

1

/X

2

)

= ( 0.084 0.001)M / ln (0.084 / 0.001)

= 0.019

Finding the mass transfer coefficient:

Mass transfer coefficient =

=

= 0.44 mol/L.min

= 0.44 M/min

= 0.44 kg/min

13

For 0.025M of NaOH

Raffinate:

M

1

V

1

= M

2

V

2

(0.025)(2.910

-3

) = M

2

(0.015)

M

2

= 0.00483 M of propionic acid X

1

Feed:

M

1

V

1

= M

2

V

2

(0.025)(114.310

-3

) = M

2

(0.015)

M

2

= 0.1905 M of propoinic acid

Extract:

M

1

V

1

= M

2

V

2

(0.025)(48.510

-3

) = M

2

(0.015)

M

2

= 0.0808 M of propoinic acid Y

1

Rate of acid transfer = Vw (Y

1

- 0)

= (0.20 L/min)(0.0808 mol/L)

= 0.0162 mol/min

Finding the value of X

2

:

Vo (X

1

-X

2

) = Vw (Y

1

-0)

(0.20 L/min)(0.00483 mol/L - X

2

) = 0.0162 mol/min

X

2

= - 0.0762 mol/L @ M

Finding the log mean driving force:

X

1

= (X

2

-0)

= - 0.0762 M

K = Y

1

/ X*

X* = Y

1

/ K At equilibrium, assume K = 7.78 (from experiment B)

= 0.323 / 7.78

= 0.0104 M

X

2

= (X

1

-X

1

*)

= 0.00483 M 0.0104 M

= -0.00557 M

Log mean driving force = (X

1

-X

2

) / ln (X

1

/X

2

)

= ( -0.0762+ 0.00557)M / ln (-0.0762 / -0.00557)

= -0.02670

14

Finding the mass transfer coefficient:

Mass transfer coefficient =

=

= -0.257 mol/L.min

= -0.257 M/min

= -0.257 kg/min

15

DISCUSSION

In this experiment, we want to identify the distribution of coefficient and to identify

the mass transfer coefficient. This experiment is referred to the solubility which is the solvent

is also soluble with a specific solute contained in the solution and also about the separation of

a substance from a mixture by preferentially dissolving the substance in a suitable solvent.

For the first experiment, which is to determine the mass transfer coefficient, we used

the liquid-liquid extraction column to get the feed, raffinate and extract solution to be the

samples. The samples then are titrated with 0.1 M NaOH and 0.025 M NaOH. The value of

mass transfer coefficient when titrated with 0.1 M NaOH is 0.44 kg/min while titrated with

0.025 M, the value of mass transfer coefficient is -0.257 kg/min. Result for this experiment

shows that the experiment is failed because the values of mass transfer coefficient supposedly

in positive. Besides that, we cannot show that the relation between mass transfer rate with the

concentration of NaOH. For the actual result, this experiment can shows the increment of

mass transfer rate when the concentration of NaOH is decreasing.

For the second experiment, which is to determine the distribution coefficient, we used

the titration method from the upper (Y) and bottom (X) layer sample. By titration with 0.1 M,

the values are 7.78 in 1.0 ml of propionic acid, 2.30 in 3.0 ml of propionic acid and 1.80 in

5.0 ml of propionic acid. From the result in this experiment, if titrated with 0.1 M NaOH, it

shows that the value of distribution coefficient decrease as the volume of propionic acid

increase. This experiment is totally successful because those results followed the actual

results which is the value of distribution coefficient must be decrease when the volume of

propionic acid is increasing.

Several error occurred during this experiment progress that totally effect the result of

first experiment which is for finding the mass transfer coefficient. The most common error is

the position of the eye during taking the volume value at the burette. As the solution, the eye

position should be straight to the scale and must be perpendicular to the meniscus. Besides

that, the error also occurred while using the apparatus that is not properly clean. We should

used the clean apparatus to avoid the oil emission and impurities at the beaker, conical flask

or burette. If the apparatus not clean, we should used the distilled water to clean up those

apparatus.

16

Besides that, the experiment should be repeated at least 2 or 3 times to get the

accurate values and the mistake during the experiment progress can be identified. However,

the first experiment only done with one trial that cause the experiment being failed.

Furthermore, we choose light pink color for the color indicator during titration, but to get all

the same color might be hard enough to identify. As the color is not same in each titration, the

value of mass transfer coefficient will be different from the actual and made the experiment

failed. This is because the color indicates that the NaOH is at equilibrium with the sample

solution.

CONCLUSIONS

As the conclusion, the values for distribution coefficient by titration with 0.1 M are

7.78 in 1.0 ml of propionic acid, 2.30 in 3.0 ml of propionic acid and 1.80 in 5.0 ml of

propionic acid. This experiment is only done for 0.1 M of NaOH and the results for this

experiment is totally successful. The value of mass transfer coefficient from liquid-liquid

extraction are; 0.44 kg/min if titrated with 0.1 M NaOH and -0.257 kg/min if titrated with

0.025 M NaOH. However, in this experiment, the value of mass coefficient must be positive

not negative. Therefore, this experiment is recognized as failed.

RECOMMENDATIONS

These are some recommendations must be followed during the experiment. Before

starting the experiment, we must made sure the apparatus is clean. However, if the apparatus

is not clean, we must cleaned up those apparatus using distilled water. Furthermore, the eye

position should be perpendicular to the meniscus and the scale. In addition, the experiment

must repeated at least 2 or 3 times. Those ways is done to make sure the values is accurate.

Besides that, titration process should be repeat several times to get the average values. Then,

we must used magnetic stirrer during the titration process. Finally, we needed to make sure

the changes of color is constant in every titration.

17

REFERENCES

W. McCabe, J. Smith, and P. Harriot, (2005). Unit Operations of Chemical

Engineering, 7

th

ed. McGraw-Hill.

Bennett, C. O., and J. E. Myers, Momentum, Heat and Mass Transfer, 3rd

Edition,McGraw-Hill, 1983.

Perry, R.H., and D. Green, Perrys Chemical Engineering Handbook, 6th

Edition,McGraw-Hill, 1984.

http://en.wikipedia.org/wiki/Liquid-liquid_extraction

http://rothfus.cheme.cmu.edu/uolab/lle/projects/t8_foo.pdf

http://www.scribd.com/doc/5552507/3-Liquid-liquid-extraction

APPENDICES

Liquid-liquid extraction column Separator funnel

Anda mungkin juga menyukai

- The Letter and The Cosmos How The Alphabet Has Shaped The Western View of The WorldDokumen285 halamanThe Letter and The Cosmos How The Alphabet Has Shaped The Western View of The Worldmarnekib100% (3)

- Sapta Loka - Souls Journey After DeathDokumen10 halamanSapta Loka - Souls Journey After DeathBrad Yantzer100% (1)

- Liquid Liquid ExtractionDokumen40 halamanLiquid Liquid ExtractionApurba Sarker Apu93% (29)

- Liquid Liquid Extraction ExperimentDokumen22 halamanLiquid Liquid Extraction ExperimentMohd Sharu Mamat67% (12)

- Unit Operations 2 Laboratory Experiment 8 Batch Leaching of Nacl-Sand Mixture With Water As SolventDokumen13 halamanUnit Operations 2 Laboratory Experiment 8 Batch Leaching of Nacl-Sand Mixture With Water As SolventMeredith VillareteBelum ada peringkat

- Alphabet of LinesDokumen46 halamanAlphabet of LinesNancy Cordero AmbradBelum ada peringkat

- Report Distillation ColumnDokumen20 halamanReport Distillation ColumnAzam Najmi33% (3)

- Lesson Plan in Science and HealthDokumen3 halamanLesson Plan in Science and HealthKennan Azor100% (1)

- Raoult's LawDokumen5 halamanRaoult's LawEn CsakBelum ada peringkat

- Liquid Liquid ExtractionDokumen16 halamanLiquid Liquid ExtractionShahrizatSmailKassimBelum ada peringkat

- Afm PPT 2.1Dokumen33 halamanAfm PPT 2.1Avi malavBelum ada peringkat

- 04 Script Examples Solid Liquid ExtractionDokumen11 halaman04 Script Examples Solid Liquid ExtractionLei YinBelum ada peringkat

- SLE Experiment (REPORT)Dokumen8 halamanSLE Experiment (REPORT)Kuknesvary PuniamurthyBelum ada peringkat

- Liquid-Liquid Extraction Processes and EquilibriumDokumen52 halamanLiquid-Liquid Extraction Processes and EquilibriumThelunatic ModBelum ada peringkat

- Gas AbsorptionDokumen24 halamanGas AbsorptionShalini Krishnan100% (1)

- 2nd Perdev TestDokumen7 halaman2nd Perdev TestBETHUEL P. ALQUIROZ100% (1)

- Extractive Distillation ReportDokumen17 halamanExtractive Distillation ReportAmanda Brown100% (1)

- Engineering Thermodynamics Work and Heat Transfer 4th Edition by GFC Rogers Yon Mayhew 0582045665 PDFDokumen5 halamanEngineering Thermodynamics Work and Heat Transfer 4th Edition by GFC Rogers Yon Mayhew 0582045665 PDFFahad HasanBelum ada peringkat

- English Language and Applied Linguistics Textbooks Lo Res USDDokumen61 halamanEnglish Language and Applied Linguistics Textbooks Lo Res USDJames Blackburn Quéré Cutbirth100% (2)

- Jawaharlal Nehru Technological University Kakinada: III Year B. Tech. Petrochemical Engineering II SemDokumen37 halamanJawaharlal Nehru Technological University Kakinada: III Year B. Tech. Petrochemical Engineering II SemHashmi AshmalBelum ada peringkat

- Gas Absorption Theory, Apparatus, ProcedureDokumen16 halamanGas Absorption Theory, Apparatus, Proceduresolehah misni100% (1)

- Material Balances and ApplicationsDokumen42 halamanMaterial Balances and ApplicationsAntonio HernandezBelum ada peringkat

- Flow Patterns and Power Consumption of MixersDokumen26 halamanFlow Patterns and Power Consumption of MixersNawal DaBomb100% (1)

- Gas Absorption: Determining Drag and Flooding FlowsDokumen5 halamanGas Absorption: Determining Drag and Flooding FlowsDean Joyce AlborotoBelum ada peringkat

- Constructed Wetland Design Guidelines for DevelopersDokumen32 halamanConstructed Wetland Design Guidelines for DevelopersBere QuintosBelum ada peringkat

- Liquid LiquidDokumen8 halamanLiquid LiquidAnonymous b9fcR5Belum ada peringkat

- LleDokumen30 halamanLlefirstlove_492_736373Belum ada peringkat

- Liquid Liquid Extraction ExperimentDokumen17 halamanLiquid Liquid Extraction Experimentmhd badhrul bin baharBelum ada peringkat

- Lab LleDokumen20 halamanLab LleMuhamad Baihakhi Shamsudin100% (1)

- Gas AbsorptionDokumen19 halamanGas AbsorptionAnonymous NyvKBW100% (3)

- Liquid Liquid ExtractionDokumen11 halamanLiquid Liquid Extractionvisha lkumar vermaBelum ada peringkat

- Absorption Lecture Note - DR Akinsiku PDFDokumen7 halamanAbsorption Lecture Note - DR Akinsiku PDFGlory UsoroBelum ada peringkat

- CHE504 - Lab Report On Distillation ColuDokumen27 halamanCHE504 - Lab Report On Distillation ColuMuhammad Irfan MalikBelum ada peringkat

- Gas Diffusion UnitDokumen20 halamanGas Diffusion Unitsolehah misniBelum ada peringkat

- GAS ABSORPTION - ReportDokumen6 halamanGAS ABSORPTION - Reportgzairene8762Belum ada peringkat

- Gas Absorption and Gas StrippingDokumen14 halamanGas Absorption and Gas StrippingEK63Belum ada peringkat

- Chapter 4Dokumen43 halamanChapter 4aliBelum ada peringkat

- Packed Distillation Column ExperimentDokumen20 halamanPacked Distillation Column ExperimentChan Chun ChenBelum ada peringkat

- AgitationDokumen10 halamanAgitationKenneth Jireh Taboco100% (2)

- MSOCHA3 Tutorial 1 Multicomponent AbsorptionDokumen5 halamanMSOCHA3 Tutorial 1 Multicomponent AbsorptionTshwarelo MahlakoaneBelum ada peringkat

- Fluid Flow Through Packed BedDokumen9 halamanFluid Flow Through Packed BedAmartya MitraBelum ada peringkat

- Vapor Liquid EquilibriumDokumen7 halamanVapor Liquid Equilibriummahbub1332100% (1)

- Azeotropic Mass BalanceDokumen25 halamanAzeotropic Mass BalancesowjanyaavkBelum ada peringkat

- TareaDokumen3 halamanTareaAydee GarciaBelum ada peringkat

- CONTINUOUS DistillationDokumen5 halamanCONTINUOUS DistillationNaseer SattarBelum ada peringkat

- Absorption of Carbon Dioxide Into WaterDokumen11 halamanAbsorption of Carbon Dioxide Into WaterEstelle Jean CauilanBelum ada peringkat

- Separation Processes - I (CHE F244) Total Marks - 15 Due Date & Time: 01/07/2020, 5:00 PM AssignmentDokumen4 halamanSeparation Processes - I (CHE F244) Total Marks - 15 Due Date & Time: 01/07/2020, 5:00 PM AssignmentElliot AldersonBelum ada peringkat

- Series and Parallel Pumps: Flow Rate & PressureDokumen11 halamanSeries and Parallel Pumps: Flow Rate & PressureKevin Devastian100% (1)

- CSTR 40LDokumen16 halamanCSTR 40LhishamBelum ada peringkat

- Intro CSTRDokumen6 halamanIntro CSTREmmanuel PlazaBelum ada peringkat

- Chapter 4 - StudentDokumen69 halamanChapter 4 - Studenteja70Belum ada peringkat

- Chapter - 1Dokumen9 halamanChapter - 1Sahil PatilBelum ada peringkat

- Exp - 2 Bubble Cap Distillation ColumnDokumen13 halamanExp - 2 Bubble Cap Distillation ColumnAdawiyah Al-jufri100% (1)

- Fluidization: Chemical Engneering PracticeDokumen24 halamanFluidization: Chemical Engneering PracticeFarhan M JafrI100% (1)

- Plug Flow ReactorDokumen16 halamanPlug Flow Reactormirdza94Belum ada peringkat

- Tutorial DistillationDokumen3 halamanTutorial DistillationManu Indivare Nundoolall100% (1)

- Complete PDFDokumen56 halamanComplete PDFJames EdwardsBelum ada peringkat

- Gas Absorption Process FundamentalsDokumen34 halamanGas Absorption Process Fundamentalslickaa200100% (1)

- CSTR SeriesDokumen14 halamanCSTR SeriesElina Nes100% (1)

- Experiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Dokumen5 halamanExperiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Janice YanBelum ada peringkat

- Experiment 1 Solid Liquid ExtractionDokumen6 halamanExperiment 1 Solid Liquid ExtractionDivaan Raj Karunakaran0% (1)

- AbsorptionDokumen54 halamanAbsorptionBebo El MasryBelum ada peringkat

- Gas Absorption Lab ReportDokumen3 halamanGas Absorption Lab ReportNur Shaffikha Azmi100% (1)

- Review On Solid Liquid Extraction Processe1Dokumen71 halamanReview On Solid Liquid Extraction Processe1Chetan DebBelum ada peringkat

- Isothermal Batch ReactorDokumen5 halamanIsothermal Batch ReactorSrikanthBelum ada peringkat

- Solved Problem Question (Gas Ab)Dokumen2 halamanSolved Problem Question (Gas Ab)Seruzna IshxBelum ada peringkat

- Liquid Liquid ExtractionDokumen19 halamanLiquid Liquid ExtractionNiteshmeeBelum ada peringkat

- Liquid Liquid ExtractionDokumen25 halamanLiquid Liquid ExtractionsyafiqBelum ada peringkat

- LleDokumen17 halamanLlemirdza94Belum ada peringkat

- Lab 1Dokumen5 halamanLab 1Muhammad Zaidi MisniBelum ada peringkat

- Thermodynamic: Production of MethylamineDokumen31 halamanThermodynamic: Production of MethylamineMuhammad Zaidi MisniBelum ada peringkat

- Assignment1 FluidDokumen15 halamanAssignment1 FluidMuhammad Zaidi MisniBelum ada peringkat

- Fluid FlowDokumen12 halamanFluid FlowMuhammad Zaidi MisniBelum ada peringkat

- Final Cooling TowerDokumen14 halamanFinal Cooling TowerMuhammad Zaidi MisniBelum ada peringkat

- Lab2 Flow MeterDokumen7 halamanLab2 Flow MeterMuhammad Zaidi MisniBelum ada peringkat

- Fluid FlowDokumen12 halamanFluid FlowMuhammad Zaidi MisniBelum ada peringkat

- Cover LetterDokumen1 halamanCover LetterMuhammad Zaidi MisniBelum ada peringkat

- Rujukan Dan Bibliografi: Dan Tamadun Asia - Penerbit Universiti Malaya. Kuala Lumpur: Penerbit Universiti MalayaDokumen1 halamanRujukan Dan Bibliografi: Dan Tamadun Asia - Penerbit Universiti Malaya. Kuala Lumpur: Penerbit Universiti MalayaMuhammad Zaidi MisniBelum ada peringkat

- Hatfield JohnDokumen27 halamanHatfield JohnMuhammad Zaidi MisniBelum ada peringkat

- Mat565 BVPDokumen12 halamanMat565 BVPMuhammad Zaidi MisniBelum ada peringkat

- Data Pre Processing in WEKADokumen5 halamanData Pre Processing in WEKAPrashant SunejaBelum ada peringkat

- Escaping The Digital Dark AgeDokumen5 halamanEscaping The Digital Dark AgeKarlos lacalleBelum ada peringkat

- "Difference Between Private and Public Nuisance": Law of TortsDokumen4 halaman"Difference Between Private and Public Nuisance": Law of Tortsaridaman raghuvanshiBelum ada peringkat

- The Confidence Myth and What It Means To Your Career: by Tara MohrDokumen4 halamanThe Confidence Myth and What It Means To Your Career: by Tara MohrdargeniBelum ada peringkat

- Compiled XiiDokumen34 halamanCompiled XiiMridul VermaBelum ada peringkat

- SampleAdmissionTestBBA MBADokumen4 halamanSampleAdmissionTestBBA MBAm_tariq_hnBelum ada peringkat

- The STP Guide To Graduate Student Training in The Teaching of PsychologyDokumen101 halamanThe STP Guide To Graduate Student Training in The Teaching of PsychologyNeilermindBelum ada peringkat

- WBI06 01 Rms 20190124Dokumen17 halamanWBI06 01 Rms 20190124Imran MushtaqBelum ada peringkat

- University of Leicester - Involving Your AudienceDokumen4 halamanUniversity of Leicester - Involving Your Audiencevalentina zabalaBelum ada peringkat

- 55fbb8b0dd37d Productive SkillDokumen6 halaman55fbb8b0dd37d Productive SkilldewiBelum ada peringkat

- Equipment BrochureDokumen60 halamanEquipment BrochureAmar BeheraBelum ada peringkat

- Test Bank For Environmental Science For A Changing World Canadian 1St Edition by Branfireun Karr Interlandi Houtman Full Chapter PDFDokumen36 halamanTest Bank For Environmental Science For A Changing World Canadian 1St Edition by Branfireun Karr Interlandi Houtman Full Chapter PDFelizabeth.martin408100% (16)

- Reservoir Characterization 3 LoggingDokumen47 halamanReservoir Characterization 3 LoggingMohamed AbdallahiBelum ada peringkat

- Cost-effective laboratory thermostats from -25 to 100°CDokumen6 halamanCost-effective laboratory thermostats from -25 to 100°CCynthia MahlBelum ada peringkat

- Audit of Organizational Communication NetworksDokumen17 halamanAudit of Organizational Communication NetworksLissette ObleaBelum ada peringkat

- Sony Kdl-42w654a rb1g PDFDokumen100 halamanSony Kdl-42w654a rb1g PDFMihaela CaciumarciucBelum ada peringkat

- Notes On Unit - 4 - Employees Roles in Service MarketingDokumen3 halamanNotes On Unit - 4 - Employees Roles in Service MarketingSridhar Gowda67% (3)

- Renato Cristin Heiddegger and LeibnizDokumen10 halamanRenato Cristin Heiddegger and Leibnizaida100% (1)

- Developing and Validating a Food Chain Lesson PlanDokumen11 halamanDeveloping and Validating a Food Chain Lesson PlanCassandra Nichie AgustinBelum ada peringkat

- SW GDLoader GettingStarted v3-0 enDokumen41 halamanSW GDLoader GettingStarted v3-0 enEduardo QuispeBelum ada peringkat

- Friction Stir Welding: Principle of OperationDokumen12 halamanFriction Stir Welding: Principle of OperationvarmaprasadBelum ada peringkat