Fpso - Specifications For Topsides Piping Systems

Diunggah oleh

dndudcDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fpso - Specifications For Topsides Piping Systems

Diunggah oleh

dndudcHak Cipta:

Format Tersedia

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC.

SCHEDULE Q

SPECIFICATIONS FOR TOPSIDES

PIPING SYSTEMS

1998 EDITION

"These specifications are the confidential property of Shell Deepwater Development Systems Inc. (SDDS), and are

intended for the use of SDDS personnel and their designees only. The unauthorized use of these specifications is strictly

prohibited. Unauthorized use or distribution of these specifications shall be subject to penalties and damage

compensation to SDDS."

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 2 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

FOREWORD

Schedule Q was developed under the direction of SDDS's Backbone/Standard Solutions Team, with input from

the engineering, drafting, construction, chemical, regulatory and producing operations communities.

The SDDS Catalog Team will be responsible for the maintenance and distribution of Schedule Q. Questions

or comments concerning these specifications should be directed to the Catalog Team Leader or the Schedule

Q Coordinator.

The need to issue project specific addenda is acknowledged. These revisions will be handled by the Project

Facilities Engineer and copied to the Catalog Team Leader and Schedule Q Coordinator.

Revisions in government regulations and industry codes and standards will be followed by the Catalog Team and

addenda to Schedule Q will be issued on an as-needed basis. Normally, these types of revisions will not affect

Schedule Q when it has been adopted for a specific project.

Miscellaneous changes will be handled by the Catalog Team and addenda will be issued on a periodic basis.

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 3 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

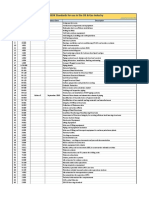

TABLE OF CONTENTS

1.0 GENERAL PAGE

1.1 Scope ...................................................................................................................... 5

1.2 Definitions................................................................................................................. 5

1.3 Applicable Documents ............................................................................................... 6

1.4 Documents Requiring Submittal .................................................................................. 7

1.5 Conflicts Between Specifications and Drawings............................................................ 7

1.6 Code Compliance...................................................................................................... 7

2.0 MATERIALS AND DESIGN

2.1 General Requirements ............................................................................................... 8

2.2 Mill Certificates, Markings and Component Data........................................................... 8

2.2.1 Mill Certificates

2.2.2 Markings

2.2.3 Contractor Furnished Components

2.3 Piping Systems......................................................................................................... 9

2.3.1 General

2.3.2 Pipe

2.3.3 Tubing and Fittings

2.3.4 Fittings and Flanges

2.3.5 Flange Bolting

2.3.6 Branch Connections

2.3.7 Vents and Drains

2.3.8 Equipment Piping

2.3.9 Insulated Piping

2.3.10 Thread Sealant

2.3.11 API 5LX Grade Piping Systems

2.3.12 Low Temperature (to -50

o

F) Piping Systems

2.3.13 Impact Testing

2.4 Valves .................................................................................................................... 18

2.4.1 Acceptable Valve Lists

2.4.2 General Requirements

2.4.3 Ball Valves

2.4.4 Check Valves

2.4.5 Valves for Marine Piping Systems

2.4.6 Valves for Sour Service

2.4.7 Butterfly Valves

2.4.8 Three-Way Valves

2.4.9 Diaphragm Valves

2.5 Protection of Components ........................................................................................ 21

3.0 COATINGS......................................................................................................................... 21

4.0 HEAT INSULATION............................................................................................................. 21

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 4 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

5.0 PIPE SUPPORTS

5.1 General Requirements .............................................................................................. 21

5.2 Support Design ........................................................................................................ 22

5.3 U-Bolts.................................................................................................................... 22

5.4 Pipe Shoes.............................................................................................................. 23

5.5 Copper-Nickel (Cu-Ni) Piping Systems ....................................................................... 23

5.6 Fiberglass (RTR) and Polyvinyl Chloride (PVC) Piping Systems ................................... 23

Appendices

1 Approved Pipe, Fitting, Flange, Bolting and Gasket Manufacturers

2 Branch Connection Schedules

3 Valve Notes and Description Codes

4 Industrial Piping Systems, Pressure / Temperature Ratings per ASME B31.3

5 Marine Piping Systems, Pressure / Temperature Ratings per ASME B31.1

6 Pipeline and Flowline Riser Piping Systems, Pressure / Temperature Ratings

7 HPV and LPD Details

8 Needle and Gauge Valve Descriptions

9 Piping Specification Class Descriptions

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 5 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

1.0 GENERAL

1.1 SCOPE

This Specification defines the material and design requirements for topsides piping systems.

Fabrication, welding, inspection and testing requirements are included in Schedule FF.

1.2 DEFINITIONS

The following definitions shall apply to this Specification:

a. "INDUSTRIAL PIPING SYSTEMS" shall mean services and associated piping systems

within the jurisdiction of the United States Mineral Management Service. Industrial

services used for the topsides are listed in Appendix 9.

b. "MARINE PIPING SYSTEMS" shall mean services and associated piping systems within

the jurisdiction of the United States Coast Guard (USCG). Marine services used for the

topsides are listed in Appendix 9.

c. "COMPONENT" shall mean any part or parts of a module, skid, equipment, instruments,

piping system or pipe spools.

d. "AFC DRAWINGS" shall mean designated Approved-For-Construction drawings and

revisions thereof which show the systems in enough detail to allow material order and

construction.

e. "APPROVE", "APPROVAL", or "APPROVED" shall mean SDDS's written approval of a

plan, procedure, process, construction/fabrication method, technique, etc. submitted by

CONTRACTOR for REVIEW.

f. "CONTRACTOR" shall mean the responsible party(s) identified in the contract documents

or purchase order.

g. "NDE" shall mean nondestructive examination and may be visual, ultrasonic, radiographic,

magnetic particle, dye penetrant, hydrostatic testing, leak testing or any other testing

procedure the intent of which is to verify that the completed WORK meets the

requirements of the AFC DRAWINGS and SPECIFICATIONS without inflicting damage to

the tested system.

h. "P&ID" shall mean the Piping and Instrument Diagrams or Mechanical Flowsheets which

define the project mechanical design details.

i. REVIEW" shall mean SDDS's right, but not obligation, to comment on a plan, procedure,

etc. submitted by CONTRACTOR. CONTRACTOR may proceed with implementation of

the plan or procedure after submittal unless instructed otherwise by SDDS.

j. "SDDS" shall mean Shell Deepwater Development Systems Inc.

k. "SDDS REPRESENTATIVE" shall mean SDDS's designated on-site personnel responsible

for the WORK.

l. "SOUR SERVICE" shall mean a hydrocarbon service where the partial pressure of

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 6 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

hydrogen sulfide (H

2

S) is greater than or equal to 0.05 psi.

m. "SPECIFICATIONS" shall mean all specifications which apply to the Topsides Piping

Systems either through contract documents, applicable industry standards, SDDS

standard specifications, or other applicable codes and government regulations.

n. "WORK" shall mean any portion of the materials, fabrication, installation, inspection

and testing of the Topsides Piping Systems.

o. The following terms used in this SPECIFICATION shall have specific meanings:

1. "Will" is used with an action by SDDS rather than CONTRACTOR.

2. "May" is used where alternatives are equally acceptable.

3. "Should" is used where a provision is preferred but not mandatory.

4. "Shall" is used where a provision is mandatory.

5. "Must" is used where a provision is a statutory requirement.

1.3 APPLICABLE DOCUMENTS

The following documents shall apply to this Specification:

a. ASME B31.1, Power Piping (except where superseded by items h. and i. below, for

MARINE PIPING SYSTEMS only) 1995 Edition with B31.3a-1996 Addenda and

B31.3b-1997 Addenda

b. ASME B31.3, Process Piping, 1996 Edition with B31.3a-1996 Addenda

c. ASME B31.4, Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum Gas,

Anhydrous Ammonia, and Alcohols, 1992 Edition

d. ASME B31.8, Gas Transmission and Distribution Piping Systems, 1995 Edition

e. API 6A, Wellhead and Christmas Tree Equipment, 17th Edition, February 1, 1996

f. API RP 14E, Design and Installation of Offshore Production Platform Piping Systems,

1991 Edition

g. 30 CFR, Chapter II, Part 250 - Oil and Gas and Sulphur Operations in the Outer

Continental Shelf, Subpart J - Pipelines and Pipeline Rights-of-Way, October, 1996

Edition

h. 46 CFR, Chapter I, Subchapter I-A - Mobile Offshore Drilling Units; October, 1996

Edition

i. 46 CFR, Chapter I, Subchapter F - Marine Engineering, Part 56 - Piping Systems and

Appurtenances; October, 1996 Edition

j. 49 CFR, Chapter I, Subchapter D - Pipeline Safety, Part 192 - Transportation of Natural

and Other Gas by Pipeline; Minimum Federal Safety Standards; October, 1996 Edition

k. 49 CFR, Chapter I, Subchapter D - Pipeline Safety, Part 195 - Transportation of

Hazardous Liquids by Pipeline, October, 1996 Edition

l. NACE MR-0175, Sulfide Stress Cracking Resistant Metallic Materials for Oil Field

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 7 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

Equipment, 1993 Edition

m. Schedule FF, Specifications for Fabrication, Inspection and Testing of Piping Systems

n. Schedule J, Specifications for Heat Insulation

o. Schedule L, Specifications for Electronic and Pneumatic Instruments and Controls;

(applicable to tubing and fittings only).

p. Schedule P, Specifications for Coatings and Markings

1.4 DOCUMENTS REQUIRING SUBMITTAL

CONTRACTOR shall submit one copy of documentation as listed in Table 1.4 to the SDDS

REPRESENTATIVE.

TABLE 1.4

DOCUMENTS REQUIRING SUBMITTAL TO THE SDDS REPRESENTATIVE

DOCUMENT SUBMITTAL TIMING SDDS

ACTION

REFERENCE

Mill Certificates & Certificates

of Compliance

As received and prior

to cutting/fabrication

REVIEW 2.2.1

COMPONENT Model Nos.

and Descriptions

With bid or 4 weeks

prior to purchase

(whichever is earlier)

REVIEW 2.2.2

1.5 CONFLICTS BETWEEN SPECIFICATIONS AND DRAWINGS

CONTRACTOR shall notify the SDDS REPRESENTATIVE in the event of conflicts between

these SPECIFICATIONS, the AFC DRAWINGS or other applicable documents. SDDS will

provide a response in a timely manner.

1.6 CODE COMPLIANCE

Topsides piping systems shall be furnished, designed, constructed and tested in accordance

with the following codes and regulations, applicable sections of the ASME Code - Section VIII,

and with these SPECIFICATIONS.

a. INDUSTRIAL PIPING SYSTEMS

1. ASME B31.3

2. API RP 14E

3. NACE MR-0175 for SOUR SERVICE

b. MARINE PIPING SYSTEMS

1. CFR Title 46, Subchapters F and I-A

2. ASME B31.1

c. Oil Export Pipeline Pig Launcher and Riser

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 8 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

1. 49 CFR, Chapter I, Subchapter D, Part 195

2. ASME B31.4

d. Gas Export Pipeline Pig Launcher and Riser

1. 49 CFR, Chapter I, Subchapter D, Part 192

2. ASME B31.8

e. Incoming Flowline Risers and Receivers / Launchers

1. 30 CFR, Part 250, Subpart J

2. ASME B31.8

2.0 MATERIALS AND DESIGN

2.1 GENERAL REQUIREMENTS

Materials shall be in accordance with applicable Piping Class Specifications and as specified

herein.

Materials for special services and alloys (other than carbon steel, P No. 1 materials) shall

conform to the requirements (hardness, impact strength, etc.) specified herein.

All materials shall be new and unused.

When the specified materials cannot be obtained, or if substitutions are necessary for other valid

reasons, substitutions may be permitted with SDDS APPROVAL.

2.2 MILL CERTIFICATES, MARKINGS AND COMPONENT DATA

2.2.1 Mill Certificates

Mill certificates signed by the mill testing laboratory shall be submitted for piping and

Certificates (or Letters) of Compliance for fittings as specified in Table 1.4. Certificates

(or Letters) of Compliance shall reference the material transfer receipts, material heat

or Serial Numbers. Third party, reformatted or other substitutes for original certificates

will not be accepted. The mill certificate shall show the results of testing required by

the material specification. This shall include impact test results when specified.

2.2.2 Markings

All COMPONENTS shall be clearly marked or stamped with data sufficient for

identification.

COMPONENTS conforming to an ASTM or ASME specifications shall be identified in

accordance with that specification.

Valves shall be marked per ASME B16.34 and provided with a tag per Appendix 3.

Improper identification is justification for rejection of a COMPONENT.

2.2.3 CONTRACTOR Furnished COMPONENTS

CONTRACTOR shall submit the manufacturer's model designations for the

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 9 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

CONTRACTOR furnished COMPONENTS, including documentation that verifies the

design pressure rating, maximum service temperature and compliance with NACE MR-

0175 when appropriate.

2.3 PIPING SYSTEMS

2.3.1 General Requirements

Materials shall be in accordance with the Piping Specification Classes listed in

Appendix 9 and as described below.

Pipe, valves, flanges, fittings, etc. used for SOUR SERVICE shall be in accordance

with ASME B31.3 and NACE MR-0175. The hardness of COMPONENTS (including

welds, heat-affected zones and parent metal) shall not exceed the value permitted by

NACE MR-0175 and defined in ASTM A370 (typically HRC 22).

Approved manufacturers for pipe, fittings, flanges, bolting, gaskets, spacer rings and

pads are listed in Appendix 1.

The identification of "severe cyclic conditions" (as defined in ASME B31.3, paragraph

300.2), and its impact on the design, fabrication, inspection and testing of the affected

piping system, shall be the responsibility of the design engineers.

The following Piping Specification Classes are generic and may have to be revised and

issued in a project specific form when piping components are selected. The project

specific form is an aid to communications with drafting and construction.

a. Class "GPL" - Gas Export Pipeline Pig Launcher and Riser

b. Class "IFJ" - Incoming Flowline Risers and Receivers/Launchers

c. Class "IFT" - Incoming Flowline Risers and Receivers/Launchers

d. Class "OPL" - Oil Export Pipeline Pig Launcher and Riser

e. Class "T" - Process Hydrocarbons, H. P. Mud, H. P. Cement, Frac and Pac

f. Class "T1" - Process Hydrocarbons, Well Equalization, Well Depressuring, H.P.

Mud, Frac and Pac

g. Class "TT" - Process Hydrocarbons (Sour Service)

2.3.2 Pipe

Piping smaller than -inch nominal size shall not be used unless APPROVED by

SDDS.

Pipe nipples are sections of pipe 12 inches or less in length. All-threaded nipples shall

not be used.

The yield strength of ASTM A106 Grade B pipe in SOUR SERVICE shall not exceed 50

ksi. This requirement may be waived by the SDDS REPRESENTATIVE if the pipe

hardness does not exceed HRC 22 and the yield strength does not exceed 75 ksi.

A sufficient number of flanged connections shall be provided in socket weld piping to

permit disconnection of items such as pumps, exchangers, instruments, control

isolating valves, etc.

Piping shall be located so as not to present overhead or tripping hazards. Minimum

clear headroom for the bottom of overhead pipe, tray and supports shall be 7'-0".

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 10 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

Threaded piping systems shall be isolated from welded piping systems in hydrocarbon

service by socket weld or flanged valves.

The outside diameter of fiberglass pipe may be larger than carbon steel piping per

ASME B36.10 (i.e. Bondstrand - 10" and larger sizes; Fiberbond - 14" and larger

sizes). Piping design (clearances, U-bolts, etc.) shall accommodate the larger pipe

diameters.

In cases where ASTM A106 Grade B is not available, API 5L Grade B seamless may

be substituted subject to SDDS's APPROVAL, provided at least one of the following

conditions applies:

a. May be used in all services, provided the mill analysis data show the manganese

plus sulfur to carbon ratio (Mn + S)/C to be above 3.5 to 1. Specimens taken from

each heat to be used shall meet the Charpy "V" Notch minimum energy absorption

requirement of 15 ft/lbs at 40

o

F. Tests to be conducted as described in ASTM

A370 specification.

b. May be used in non-pressured (open drain) and non-critical (fresh water, instrument

air and atmospheric vent) services, provided such lines are not located on or

directly connected to skids containing reciprocating equipment (compressors,

engines or pumps).

c. Fabricator to label all API 5L pipe with a paint system or inside marker tag, and

material traceability and identification method shall be APPROVED by SDDS.

2.3.3 Tubing and Fittings

Tubing and fittings may be used in 1" and smaller sizes when APPROVED by SDDS.

Tubing used in pressure piping applications, i.e. hydraulics, high pressure gases, utility

service stations, etc.; shall be in accordance with these specifications.

Tubing used in instrument service shall be in accordance with Schedule L.

All tubing shall be of domestic origin, unless specified or APPROVED otherwise by

SDDS, and per ASTM A269 Grade TP316; annealed; seamless or welded and drawn.

Table 2.3.3.1 provides pressure ratings for this tubing per ASME B31.3, Equation

304.1.2 (3c) (Lame' Method); for -20

o

F to 300

o

F. The table includes pressure ratings

for straight tubing and tubing installed with minimum 4D and 6D bends, along with

temperature derating factors for 300

o

F through 1000

o

F.

When selecting the tubing wall thickness, the thinning of the wall at the outside of a

bend must also be considered. This thinning can be approximated by multiplying the

selected wall thickness by the ratio R/(R+r), where R is the radius of the bend and r is

the outside radius of the tubing (OD/2). Derating factors for wall thinning shall be 0.888

for 4D bends and 0.923 for 6D bends.

Only the sizes and wall thicknesses in Table 2.3.3.1 may be used with compression

fittings, unless APPROVED otherwise by SDDS.

Tubing fittings shall be Parker A-Lok or Swagelok, with 316 SS bodies, nuts and

ferrules. The pressure ratings of the fittings may be less than a corresponding tubing

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 11 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

size, and should be checked for each pressure piping application.

When tubing is used in pressure piping applications, the size, grade, wall thickness,

construction (seamless or welded and drawn), minimum bend radius and fitting

descriptions shall be specified on the P&ID's.

Coned and threaded 316 SS tubing and fittings may be used in high pressure

applications when specified by SDDS. Tubing installation shall be in accordance with

the manufacturer's instructions. Tubing systems by Autoclave and Butech are

acceptable.

Tubing for use in SOUR SERVICE shall conform to the requirements of NACE MR-

0175, unless specified or APPROVED otherwise by SDDS.

The installation and testing of tubing in pressure piping applications shall be in

accordance with Schedule FF, Section 6.6.

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 12 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

TABLE 2.3.3.1

ASTM A269 GRADE TP316 TUBING -150

O

F TO 300

O

F

PRESSURE RATING, PSIG (NOTE 4)

TUBING

OD

TUBING

WALL

NO BENDS

(NOTE 1)

4D BEND RADIUS

(NOTE 2)

6D BEND RADIUS

(NOTE 2)

TEMPERATURE

DE-RATING FACTORS

W&D SEAMLESS W&D SEAMLESS W&D SEAMLESS TEMP.,

0

F FACTOR

1/4" 0.035" 4,150 5,190 3,680 4,600 3,830 4,780 UP TO 300 1,000

1/4" 0.049" 6,010 7,520 5,330 6,670 5,540 6,930 400 0.965

1/4" 0.065" 8,220 10,270 7,290 9,110 7,570 9,470 500 0.895

3/8" 0.035" 2,700 3,370 2,390 2,990 2,480 3,100 600 0.850

3/8" 0.049" 3,880 4,850 3,440 4,300 3,570 4,470 650 0.835

3/8" 0.065" 5,290 6,610 4,690 5,870 4,880 6,100 700 0.815

1/2" 0.049" 3,030 3,790 2,690 3,360 2,800 3,500 750 0.805

1/2" 0.065" 4,120 5,150 3,660 4,570 3,800 4,750 800 0.795

3/4" 0.065" 2,670 3,330 2,370 2,960 2,460 3,070 850 0.785

1" 0.065" 1,970 2,460 1,750 2,190 1,810 2,270 900 0.775

1" 0.083" 2,550 3,190 2,260 2,830 2,350 2,940 950 0.770

1,000 0.77

NOTES:

1. No bends implies the use of fittings to change directions.

2. 4D and 6D bends are4 and 6 times the tube OD respectively, i.e, use 1" bend radius for 4D on 1/4" tubing.

3. W & D pressure ratings assume single butt weld tubing with a 0.80 quality factor.

4. The pressure rating of the tubing fittigs may be the limiting factor when determining the pressure rating of a system.

5. Pressure ratings above 1000

O

F shall be reviewed on a case by case basis.

ABOVE 1,000 (NOTE 5)

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 12 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 13 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

2.3.4 Fittings and Flanges

45

o

and 90

o

ells shall be long radius (1 1/2 R) unless identified and detailed otherwise

on AFC drawings. If short radius weld ells are used, they shall be derated to 80% of

the calculated allowable working pressure if subject to pulsations.

The pressure ratings of swages and bull plugs shall conform to that of pipe, including

thread allowances for threaded ends. Swages may be specified with dual ratings, i.e.

2" S/80 BLE x 1/2" S/160 TSE.

Carbon steel, stainless steel and copper-nickel flanges shall have serrated spiral finish

facing.

Flanges which mate to flat faced flanges shall be flat faced and installed with full faced

gaskets, except in Pipe Class "MR" (uses o-ring seals) or where noted otherwise on

AFC DRAWINGS.

A spacer ring (fills the gap created by the raised face flange) shall be used when

installing a copper-nickel, fiberglass, PVC or iron flange (materials subject to

unacceptable deformation or breakage) to a raised face flange. The spacer ring

material shall not be of a dissimilar metal.

Swivel flanges shall have sufficient clearance between the hub and flange to allow

coating as described in Section 3.0, without inhibiting the ability to rotate the flange on

the hub.

Mitered joints will be permitted only with SDDS APPROVAL. Joint design, service,

location, etc. shall be detailed in a submittal to the SDDS REPRESENTATIVE.

Flange bolt holes shall straddle the piping horizontal and vertical centerlines (two-

holed).

Eccentric reducers installed with the flat side up shall be used when line size

reductions are required for pump suction connections.

Bleed rings will be permitted only with SDDS APPROVAL or when detailed on the AFC

DRAWINGS.

2.3.5 Flange Bolting

Stud lengths shall have a minimum of one thread and a maximum of three threads

exposed beyond the nuts. Stud lengths shall be adjusted accordingly for use of

washers or flange-type pipe supports. Cut studs shall not be used.

Heavy hex bolts (cap screws) shall be used for bolting of lug type butterfly valves.

CONTRACTOR shall be responsible for selecting bolt lengths.

Flange bolting shall be cadmium plated except as noted below. Cadmium plating shall

be in accordance with ASTM B766, Class 8 (0.0003" plating thickness), Type II (with

a supplementary yellow chromate treatment).

Bolting shall be 316 SS for Piping Classes "MSS", "SS" and "SSB." 316 SS bolting

may also be used in Piping Class "MR" when bolting flange to flange, but not when

bolting to the Al-Br valves.

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 14 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

Bolting shall be silicon bronze for Piping Classes "P", "UF", "V", "MR", "MV" and

"MVB" unless specified otherwise.

Bolting shall be cadmium plated for Piping Classes "G", "MGA", "H" and "PVC." The

cadmium plating shall be in accordance with ASTM B766, Class 25 (1 mil plating

thickness), Type II (with a supplementary green chromate treatment - green is used to

distinguish the 1 mil cadmium plated bolting from the 0.3 mil yellow cad plated bolting).

The nuts shall be tapped oversize to provide a Class 2 fit for the stud and nut

assembly.

Bolting shall be Fluoropolymer coated for Piping Classes "I" and "SP." The

Fluoropolymer coating process shall conform to the following requirements:

a. Material storage, handling, safety precautions and preparations shall be in

accordance with the manufacturers' recommendations.

b. Remove oil, grease, mill scale and other surface contaminants.

c. Solvent rinse

d. Zinc plate (approximately 0.3 mil)

e. Zinc-phosphate or manganese-phosphate conversion coating

f. Chromic acid dip (optional)

g. Apply Xylan primer (optional).

h. Apply Xylan 1014 solvent based polymer coating(s).

i. Cure coating system.

The total coating thickness shall be in the range of 1.0 to 1.5 mils. Nut threads shall

be coated, and the nuts shall be tapped over-size to provide a Class 2 fit for the stud

and nut assembly.

2.3.6 Branch Connections

Branch connections shall be in accordance with Appendix 2 or as specified in the

Piping Class Specification. Welded branch fittings shall not be located on a weld joint.

Stub-in branch connections may be used for atmospheric vents, open drains, gray

water and black water services (atmospheric operating pressures) when APPROVED

by SDDS or detailed on the AFC DRAWINGS.

Where couplings are used for branch connections, they shall be attached to the pipe

wall with a full penetration groove weld (bevel the pipe wall).

2.3.7 Vents and Drains

Drain connections and valves shall be provided at all low spots in lines. Also, vent

connections and valves shall be provided at all high spots where gas may be trapped.

In addition, sample, vent and drain valves shall be installed where indicated on SDDS's

drawings.

Sample, vent and drain valves shall be 1/2" minimum pipe size and shall be furnished

and installed in accordance with appropriate vent and drain details.

2.3.8 Equipment Piping

Pump suction and discharge headers shall not be "dummy-legged" to the next support

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 15 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

beam. Headers shall be extended to the next support beam and closed with a blind

flange. Weld caps may be used if no future piping tie-ins are expected.

Temporary start-up cone or basket-type strainers (screens) shall be provided in suction

lines to mechanical equipment, including, but not necessarily limited to, pumps,

compressors, and mechanical meters, and shall be located as close as possible to the

inlet flanges. Such strainers shall have a minimum of 100% (200% if possible) of line

flow area with 1/8" diameter maximum size perforations, unless otherwise specified by

SDDS.

In lines designed to carry sand-laden fluids at erosive velocities, and in lines from the

wellheads to the production manifold, all turns shall be made with a tee and butt weld

bull plug assembly or target tee (flow-tee) to minimize sand erosion.

Block valves and bypass valves shall be provided at control valves where shown on the

AFC DRAWINGS. Spools shall be provided to permit removing a control valve without

removing isolating block valves. A drain valve shall be provided to drain liquids trapped

between isolating valves. Bypass valves around control valve stations shall be globe

valves unless noted otherwise on the AFC DRAWINGS.

2.3.9 Insulated Piping

Insulated piping shall have support slide shoes in accordance with Section 5.2. Guides

and anchors shall be installed as shown on the AFC DRAWINGS.

2.3.10 Thread Sealant

Instruments, valves, hex nipples, thermowells, etc., made of stainless steel which

screw into carbon steel couplings shall be installed with Teflon tape. Stainless steel

items, such as bleed valves, drain valves or plugs, that screw into other stainless steel

threads, shall be installed with Teflon paste to prevent galling of threads. Teflon tape

and Swagelok "Blue Goop" may be used in lieu of teflon paste.

Teflon tape or liquid teflon shall be used for all carbon steel, copper-nickel, copper,

brass and monel threaded connections.

2.3.11 API 5L X Grade Piping System

Components used in API 5L X Grade piping shall be in accordance with the following

requirements:

a. Flanges may be per ASTM A694 or MSS SP 44 using the appropriate material

grade (F42 through F70). ASTM A105 flanges with a yield strength to match the

pipe may be used if APPROVED by SDDS. When ASTM A105 materials are

specified, the purchase order shall state the matching pipe wall thickness and

grade and the required design working pressure.

b. Butt weld fittings shall be seamless per ASTM A860 or MSS SP 75 using the

appropriate material grade (WPHY-42 through WPHY-70).

c. Butt weld branch connections, other than tees, shall match the material

requirements of the branch. ASTM A105 or A694 are acceptable as specified under

flanges. Tees shall be appropriate material compatible with the run pipe (see (b)

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 16 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

above).

2.3.12 Low Temperature Piping Systems

Piping Classes "ALT" and "BLT" are provided for piping systems with minimum

operating temperatures to -50 F, while Piping Classes "SS" and "SSB" are provided for

piping systems with a minimum operating temperature to -325 F. These low

temperature conditions may occur in high pressure relief, flare and blowdown systems.

Piping flexibility shall be a consideration when designing the piping layouts due to

contraction at the lower operating temperature.

2.3.13 Impact Testing

a. ASME B31.3, Chapter III - Materials

The 1994 addenda to ASME B31.3-1993 replaced the -20 F minimum temperature

for P-No. 1 materials in Appendix A with Figure 323.2.2, Minimum Temperatures

Without Impact Testing for Carbon Steel Materials. Curves define the Design

Minimum Temperatures (DMT) as a function of the wall thickness. If the DMT and

wall thickness are on or above the curve, impact testing is not required, but if below

the curve, impact testing of base materials is required. Tabulated values from the

curves with notes are provided below.

Design

Minimum

Temperature

Curve B 1)(2)

Nominal Wall

Thickness - inches

Curve A (1)(3)

Nominal Wall

Thickness inches

-20 F 0.54 (3)

-10 F 0.57 (3)

0 F 0.63 (3)

10 F 0.72 (3)

15 F 0.75 0.40

20 F 0.81 0.46

25 F 0.88 0.48

30 F 0.97 0.53

35 F 1.07 0.56

40 F 1.17 0.60

45 F 1.29 0.64

50 F 1.42 0.70

Notes:

1. Wall thicknesses which exceed the listed value for the design minimum

temperature require impact testing in accordance with ASME B31.3, Chapter

III - Materials.

2. Curve B is applicable to P-No. 1 materials, including ASTM A106 Grades B

and C and ASTM A234 Grades WPB and WPC. Curve B is also applicable

to API 5L X Grades if normalized or quenched and tempered.

3. Curve A is applicable to S-No. 1 materials, including API 5L Grades X-52,

56 and X60, except as noted above. Curve A requires impact testing for all

temperatures less than 15 F.

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 17 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

The above criteria for impact testing is not applicable to ASTM A105 forgings

(flanges, socket weld fittings, etc.), and ASTM A193 B7 and A194 2H bolting, for

which ASME B31.3 lists DMT's of -20 F, -40 F and -50 F respectively.

The temperature limits and associated impact test requirements for materials not

listed in ASME B31.3 shall be determined in accordance with ASME B31.3

paragraph 323.2.3.

The DMT may be revised by SDDS to conform with the requirements of ASME

B31.3, paragraph 301.3.1 which states, "The design minimum temperature is the

lowest component temperature expected in service." Revisions to the DMT shall

be the responsibility of the design engineer and shall be identified with a note on

the line number on the P&ID as illustrated below. A delimiter may also be

necessary on the P&ID to identify the extent of the revised DMT.

16" PL-0423-120-E / PNM (50 F DMT - See Note 4)

4. Impact testing not required for a DMT of 50 F on the 16" S/120 pipe and

fittings, wall thickness = 1.218".

b. ASME B31.3, Chapter IX - High Pressure Piping

Piping Specification Classes "T" and "TT" conform to the requirements of ASME

B31.3, Chapter IX - High Pressure Piping, which requires all materials be impact

tested in accordance with paragraph K323.3, Impact Testing Methods and

Acceptance Criteria.

c. 49 CFR, Parts 192 and 195, and 30 CFR, Part 250

Piping Specification Classes "GPL" and "OPL" conform to the requirements of 49

CFR, Parts 192 and 195 respectively, and "IFJ" and "IFT" to 30 CFR Part 250.

These regulations do not specify impact testing for listed materials beyond that

required by the applicable material specification.

The design engineer shall be responsible for determining if impact testing of base

materials is required.

2.4 VALVES

2.4.1 Acceptable Valve Lists

Acceptable Valve Lists are provided with (or referenced in) the Piping Specification

Classes, while the Valve Code Descriptions and General Notes are listed in

Appendix 3.

Valve model numbers listed in the Acceptable Valve Lists are updated per the

manufacturer's latest published information. In the event that a valve model number

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 18 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

is found to be incorrect, or is no longer manufactured, or specific details (e.g., SS

trim) regarding the valve can no longer be furnished, CONTRACTOR shall notify

SDDS's REPRESENTATIVE to resolve the matter.

When a specific valve type is called out on AFC DRAWINGS, that valve shall be

furnished in lieu of those listed in the Acceptable Valve Lists.

2.4.2 General Requirements

Steel valves shall be in accordance ASME B16.10 and ASME B16.34, including

applicable working and hydrotest pressures. Working pressures per API 6D (which

are currently lower than in ASME B16.34) are not acceptable.

Flanged end valves shall have cast-on or forged flanges unless specified or

APPROVED otherwise by SDDS.

Open-ended threaded valves shall be provided with 316 SS hex head plugs.

Open-ended socket weld valves shall be threaded at the open end and provided with

a removable 316 SS hex head plug, or shall have an integral forged or welded nipple

threaded and capped at the exposed end.

Open-ended flanged valves shall be provided with blind flanges. When indicated on

the P&ID's, blind flanges shall be drilled, tapped and provided with a -inch needle

valve and 316 SS hex head plug.

2.4.3 Ball Valves

Ball valves 1-1/2" and smaller shall have 316 SS balls and stems unless specified

otherwise. All 1/2" and 3/4" threaded ball valves shall have a full open port with 316 SS

body and trim unless specified otherwise.

Ball valves 2" and larger shall generally be provided with electroless nickel-plated,

chrome-plated, or 304 or 316 SS balls and stems. 316 stainless balls and stems shall

be provided for severe corrosive service conditions (i.e., produced water, injection

seawater (upstream of deoxygenator) and saltwater service).

Ball valves shall generally be trunnion mounted in larger sizes, especially in high

pressure services, and in services where extremely low differential pressures may be

encountered. As a guide, ball valves larger than 4" bore size in ASME/ANSI Classes

150 and 300, larger than 1-1/2" bore size in ASME/ANSI Class 900 and higher classes

shall generally be trunnion mounted. Floating ball and floating-type, non-lubricated plug

valves may be considered for sizes outside this guideline, provided that the required

operating torque is acceptable for the application and that expected differential

pressures will be high enough to insure an effective seal.

Unless specified otherwise, ball valves shall be provided with a handwheel or manual

gear operators as listed below. In general, manual gear operators are used when

breakaway torques exceed 5000 inch-pounds:

Pressure Class Valve Bore

ASME/ANSI Class 150 8" and larger

ASME/ANSI Class 300 and 600 6" and larger

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 19 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

ASME/ANSI Class 900 4" and larger

ASME/ANSI Class 1500 3" and larger

API 5000 psig 3" and larger

ASME/ANSI Class 2500 3" and larger

Socket weld ball valves shall not be used unless specified otherwise by SDDS.

Only full-open, conduit-type valves shall be used in sphere/pig launching and receiving

service. Orbit valves shall not be used, as a sphere may stop in the valve due to

significant flow paths in the valve body cavity.

2.4.4 Check Valves

Check valves shall be horizontal swing type, unless specified otherwise by SDDS.

Piston check valves shall be used with reciprocating compressors, centrifugal

compressors and high volume reciprocating pumps.

Piston check or tilting disk swing check valves shall be used with multi-stage

centrifugal pumps (oil pipeline and waterflood injection).

All full bodied check valves 1" and larger shall be furnished with bolted bonnets, and

bonnets shall be 1/2" NPT tap with plug. Clapper stops shall not be attached by

means of this bonnet tap.

All check valves in hydrocarbon service shall have bolted bonnets. Threaded bonnets

shall not be used unless specified or APPROVED otherwise by SDDS.

Check valves installed beneath relief valves (PSV) shall have the appropriate 1/2"

MNPT x 1/4" FNPT needle/test valve installed in the bonnet with a Cajon 1/2" SS-A

adaptor.

2.4.5 Valves for MARINE PIPING SYSTEMS

Valves in MARINE PIPING SYSTEMS must meet USCG requirements for acceptable

materials, valve construction and connections, etc., as related to the designated piping

service and referenced USCG piping classification. Valves employing resilient material

shall be divided into three categories as described below.

Positive shutoff valves (designated Category "P" by SDDS) are valves which are of

steel, ductile cast iron or a ductile, nonferrous alloy having a melting point above

1700

o

F. Valves shall have fire resistant packing, and metal-to-metal seating or

resilient seating that allows essentially no leakage after removal of resilient seating

material at full rated pressure [less than 10 ml/hr. (.34 fluid oz./hr.) of liquid or 3

liters/hr. (.11 std CF/hr.)of gas per inch nominal size.]

Category "A" valves are those valves employing a resilient material that would

provide effective closure of the line and would not allow appreciable leakage from

the valve if the resilient material were damaged or destroyed. The closed valve must

pass less than the greater of five percent or 15% divided by the Square Root of the

Nominal Pipe Size of its fully open flow rate through the line after complete removal

of all resilient seating material or equivalent and testing at full-rated pressure.

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 20 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

Category "B" valves are those valves employing resilient material that would not

provide effective closure of the line or would permit appreciable leakage from the

valve if the resilient material were damaged or destroyed. These valves contain

resilient seating or packing material, nonmetallic composition discs or similar

components and have not passed one of the above tests.

2.4.6 Valves for SOUR SERVICE

Additional requirements for valves in SOUR SERVICE include the following

a. Body and Bonnet

Acceptable materials shall be in accordance with ASTM A105, A216 Grade WCB,

A350 Grades LF1 and LF2 or A352 Grade LCB.

AISI 400 series stainless steel shall not be used.

b. Bolting

Body to bonnet bolting and internal bolting shall comply with Section 6 of NACE

MR-0175.

No bolting materials with yield strengths greater than 115,000 psi shall be used.

c. Internal Trim

AISI 400 Series stainless steel and precipitation hardened martensitic stainless

steel such as 17-4 PH and AISI 4340 shall not be ACCEPTABLE. Other materials

listed in NACE MR-0175 shall be ACCEPTABLE if within the hardness limits

designated therein.

Valves shall be tagged by the manufacturer to indicate compliance with NACE MR-

0175.

2.4.7 Butterfly Valves

Elastomer lined butterfly valves shall be installed without gaskets when recommended

by the valve manufacturer.

2.4.8 Three-Way Valves

Three-way valves shall be specified on the AFC DRAWINGS or data sheets.

Acceptable manufacturers include Tufline (Figure Nos. 037/037EG), Jamesbury (Figure

Nos. AM150/DM150) and Rockwell-Nordstrom (Figure Nos. 27XXX).

2.4.9 Diaphragm Valve

Diaphragm valves shall be specified on the AFC DRAWINGS or data sheets.

Acceptable valves are ITT Engineered Valves, No. 2435-903-T (2" -4") and 2435-3-T (6"

and 8").

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 21 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

2.5 PROTECTION OF COMPONENTS

CONTRACTOR shall supply and maintain protective seals which shall cover openings or ports

of COMPONENTS. At no time shall these COMPONENTS be placed into a position so as to

allow foreign matter (such as blasting material, metal shavings, coatings spray, rust, mud,

scale, rags, etc.) to contaminate their interior or damage the COMPONENT. The completed

COMPONENTS shall be shipped with openings properly covered. Acceptable protective seals

or covers shall be in order of preference: (1) manufacturer's supplied seals, (2) plywood or metal

plates attached with cadmium plated bolts or SS (stainless steel) wire or (3) equivalent plastic

plugs.

3.0 COATINGS

Coatings shall be applied to piping systems and equipment in accordance with Schedule P, Coatings

and Markings Specifications. This shall include carbon steel flange bolt holes and the flange face not

in contact with the gasket or process media.

Exposed threads in galvanized threaded piping shall be brush blasted, then coated with 1 coat of

Carboline 858 or SDDS APPROVED equal. Any other damaged galvanizing shall be protected in the

same manner. All "rough spots" shall be feathered first.

4.0 HEAT INSULATION

Heat insulation for heat conservation (HC) and personnel protection (PP) shall be applied to piping

systems and equipment as shown on the P&ID's and AFC DRAWINGS. The materials and installation

shall be in accordance with Schedule J, Specifications for Heat Insulation.

5.0 PIPE SUPPORTS

5.1 General Requirements

Piping shall be supported as necessary to prevent sagging, mechanical stresses and vibration.

Holes in pipe supports for bolts and clamps shall be drilled or punched, and deburred or ground

smooth. Pipe support surfaces (including bolt holes) shall be coated. Location and spacing

of supports shall be provided in project specific documents.

Welded attachments (lugs, dummy legs, etc.) to piping systems for use as pipe supports shall

not be used without prior SDDS APPROVAL.

Flange supports shall not be used unless APPROVED otherwise by SDDS due to fabrication

and assembly problems.

Piping (except when supported on pipe shoes) shall be fastened to pipe supports with the

appropriate size, hot-dip galvanized U-bolts, and installed with hot-dip galvanized, heavy hex

nuts, unless noted otherwise in project "tie" specifications and/or on the AFC DRAWINGS. U-

bolts shall be in accordance with the standard U-bolt details on the AFC DRAWINGS and as

described below.

Piping in areas subject to significant mechanical vibration or line pressure pulsations, including

piping on reciprocating compressors, engine or pump skids and reciprocating pumps, shall be

fastened to rigid pipe supports with bolted pipe clamps in lieu of U-bolts. A 1/8" thick liner and

pad shall be provided between the pipe, support and clamp.

A 1/8" thick neoprene pad (use Teflon for copper-nickel and copper piping) shall be provided

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 22 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

between pipe and support surface, covering the full width of the pipe support and entire contact

surface between pipe and support. Neoprene with an adhesive backing may be used, otherwise

the pad shall not be glued to the support surface unless noted on the AFC DRAWINGS.

5.2 Support Design

The design of pipe (and tray) support structures shall be based on all concurrently acting loads

transmitted into the supports. These loads include weight effects (dead and live loads), wind

effects, thermal effects (expansion and contraction), dynamic effects (flow rate changes, water

hammer, etc.), vibration effects, and the effects of support and equipment movements.

The effects of support and equipment movements may become critical on topsides modules if

primary and secondary steel deflections between the fabrication yard and after installation vary

substantially. A project specific Pipe Support Design Basis and Strategy which identifies the

appropriate load conditions and structural deflections shall be formulated by the design

engineer. This strategy may also be applicable to constructability issues.

Strategies which can be used for reducing pipe stresses and reaction loads in the pipe supports

and equipment include the following:

1. Not using u-bolts.

2. Designing flexibility into the piping system by using offsets and/or loops

3. Making pipe welds after final deflections.

5.3 U-Bolts

All u-bolts and nuts shall be hot-dip galvanized per ASTM A153 (or A123) with a minimum

coating thickness of 3 mils. All nuts shall be heavy hex.

U-bolts, except for fiberglass piping systems, shall be coated with a seamless, vulcanized, UV

resistant, 1/16" thick polyolefin material.

U-bolts for fiberglass piping systems do not require the polyolefin material coating.

Double nuts (4 per u-bolt) shall be installed on all steel and stainless steel piping systems.

Nuts shall be installed to snug the pipe to the support and secure the u-bolt to the pipe support.

Triple nuts (6 per u-bolt) shall be installed on all copper-nickel, copper and non-metallic piping

systems. Single nuts shall be installed on the top surface of the pipe support to position the

u-bolt inside surface slightly above the pipe (do not snug). Double nuts shall be installed to

secure the u-bolt to the pipe support.

Thread lengths on u-bolts with triple nuts shall be sufficient to install one nut on the top surface

of the pipe support when installed as described above.

The outside diameter of fiberglass pipe may be larger than carbon steel piping (i.e. Bondstrand

- 10" and larger sizes; Fiberbond 14" and larger sizes). U-bolts and spacing of U-bolt holes in

pipe supports shall accommodate these larger pipe diameters.

5.4 Pipe Shoes

Piping insulated for heat conservation shall have support slide shoes, guides and stops as

detailed on the AFC DRAWINGS . Pipe shoes may be omitted for operating temperatures less

than 180?F when APPROVED by SDDS.

SHELL DEEPWATER DEVELOPMENT SYSTEMS INC. Page 23 of 23

SCHEDULE Q 1998 Edition

SPECIFICATIONS FOR TOPSIDES PIPING SYSTEMS

SDDSSCHQ.WRD8.0

Pipe shoes, guides and stops are not required on piping insulated for personnel protection

unless detailed otherwise on the AFC DRAWINGS.

A 1/8" thick teflon pad is not required between pipe shoes and supports, except for exhaust

piping. The teflon shall be glued to the support with a suitable adhesive paste.

5.5 Copper-Nickel (Cu-Ni) Piping Systems

Pipe supports for copper-nickel piping systems shall have special design and placement

considerations to account for copper-nickel's high coefficient of expansion. Piping supports

shall have Teflon pads (or liners) or other suitable material to prevent chafing damage to the

piping. Where piping may be submerged, pipe supports shall be insulated from the piping to

prevent galvanic corrosion.

Copper-nickel piping shall not be in direct contact with steel structures or steel pipe supports

except in the special case of bulkhead penetrations which will be detailed on AFC DRAWINGS.

5.6 Fiberglass (RTR) and Polyvinyl Chloride (PVC) Piping Systems

Supports and spacing for fiberglass and PVC piping systems shall be in accordance with the

manufacturers recommendations.

Anda mungkin juga menyukai

- Notes On FPSO and FatigueDokumen6 halamanNotes On FPSO and Fatiguedtr17Belum ada peringkat

- Lesson Learnt From SNC On Stress AnalysisDokumen3 halamanLesson Learnt From SNC On Stress AnalysiszahoorBelum ada peringkat

- FPSO Related Piping and Pipe Stress AspectsDokumen43 halamanFPSO Related Piping and Pipe Stress AspectsSmith780512100% (3)

- 1.fpso Stress AnalysisDokumen2 halaman1.fpso Stress AnalysisSundeepGuptaBelum ada peringkat

- FPSODokumen18 halamanFPSOCarly Rheman100% (3)

- Norsok Standard Process DesignDokumen38 halamanNorsok Standard Process Designkamran5426Belum ada peringkat

- GP050402 - Free Water Knockout Drum PDFDokumen11 halamanGP050402 - Free Water Knockout Drum PDFJosefina Carmona100% (1)

- Fundamentals of FPSO PDFDokumen4 halamanFundamentals of FPSO PDFSamuel Mawutor Gamor25% (4)

- Knockout DrumDokumen9 halamanKnockout Drumgautam_96948069Belum ada peringkat

- Comparing API and ASME-ANSI Flanges Dimensions and Pressure RatingsDokumen2 halamanComparing API and ASME-ANSI Flanges Dimensions and Pressure Ratingsjorge1952100% (1)

- Safety Relief Valve Specification SheetDokumen5 halamanSafety Relief Valve Specification Sheetdgmprabhakar0% (1)

- 06 FEED Development - Onshore and OffshoreDokumen2 halaman06 FEED Development - Onshore and Offshorezdq02Belum ada peringkat

- Checklist for Chapter VIII of ASME B31.3 for Category M PipingDokumen5 halamanChecklist for Chapter VIII of ASME B31.3 for Category M PipingiaftBelum ada peringkat

- Group 3 - FpsoDokumen36 halamanGroup 3 - FpsoAzka Roby AntariBelum ada peringkat

- Floating Unit Piping Stress AnalysisDokumen4 halamanFloating Unit Piping Stress AnalysisRagerishcire Kanaalaq100% (1)

- Procedure For Column Line Stress AnalysisDokumen6 halamanProcedure For Column Line Stress AnalysisNilesh GohelBelum ada peringkat

- FPSO Design to Minimise Downtime in NWA WatersDokumen15 halamanFPSO Design to Minimise Downtime in NWA WatersRini MathewBelum ada peringkat

- MR For Ball ValvesDokumen12 halamanMR For Ball Valvesengr_umer_01100% (1)

- Corrosion Coupon Data SheetDokumen3 halamanCorrosion Coupon Data SheetKaluoji50% (2)

- Fpso Redeployment StudyDokumen23 halamanFpso Redeployment StudyMadhana GopalBelum ada peringkat

- Piping Specialty Item Design Guide ProcedureDokumen3 halamanPiping Specialty Item Design Guide ProcedureCivil Friend67% (3)

- Presentation On SPRING HANGERDokumen113 halamanPresentation On SPRING HANGERvishal MauryaBelum ada peringkat

- Basis of Design - Pig Launcher & ReceiverDokumen9 halamanBasis of Design - Pig Launcher & ReceiverAndreas Schlager100% (5)

- Air Cooler Piping Stress Analysis Using Caesar IIDokumen5 halamanAir Cooler Piping Stress Analysis Using Caesar IIsemin prsesBelum ada peringkat

- Pressure Drop of Full Bore Vs Reduced Bore Ball ValvesDokumen1 halamanPressure Drop of Full Bore Vs Reduced Bore Ball ValvesArt G. EnziBelum ada peringkat

- Piping Stress-Interview QuestionsDokumen17 halamanPiping Stress-Interview QuestionsAnkush Varshney100% (2)

- NORSOK Standards for Oil & Gas IndustryDokumen2 halamanNORSOK Standards for Oil & Gas IndustryVivi Oktavianti100% (2)

- Pig Launcher+receiverDokumen3 halamanPig Launcher+receiverwong_949618676Belum ada peringkat

- Technical Recommendations For Choke Valve SpecificationsDokumen7 halamanTechnical Recommendations For Choke Valve SpecificationsajaysapruBelum ada peringkat

- FPSODokumen2 halamanFPSOLesley Simpas GalvezBelum ada peringkat

- Oil&Gas Subsea | Subsea Technology and EquipmentsDokumen23 halamanOil&Gas Subsea | Subsea Technology and EquipmentsjujuroyaleBelum ada peringkat

- Considerations For Centrifugal Compressor Piping LayoutDokumen6 halamanConsiderations For Centrifugal Compressor Piping LayoutRakesh RanjanBelum ada peringkat

- Column Piping - Study Layout, Nozzle Orientation & Platforms RequirementsDokumen37 halamanColumn Piping - Study Layout, Nozzle Orientation & Platforms RequirementsvasuBelum ada peringkat

- Fpso Design and TechnologyDokumen57 halamanFpso Design and Technologyjokots100% (1)

- Theoretical overview of surge analysesDokumen14 halamanTheoretical overview of surge analysesdBelum ada peringkat

- Oliveros, Kyle Gio M. Bspe 5B PTQ Riser SystemsDokumen14 halamanOliveros, Kyle Gio M. Bspe 5B PTQ Riser Systemsglenn vincent floresBelum ada peringkat

- Nace Corrosion 1991 Paper No 577 Predictive Model For Co2 Corrosion Engineering PDFDokumen10 halamanNace Corrosion 1991 Paper No 577 Predictive Model For Co2 Corrosion Engineering PDFqwerty1 qwerty9Belum ada peringkat

- FPSO InformationDokumen24 halamanFPSO Informationzorro21072107Belum ada peringkat

- PSV Connection in Caesar IIDokumen8 halamanPSV Connection in Caesar IIHamzaHashim100% (1)

- FPSO CourseDokumen571 halamanFPSO CourseDigitalVault Enterprise100% (1)

- Fundamentals of Gas Pipeline Metering StationDokumen5 halamanFundamentals of Gas Pipeline Metering Stationsandeepsri9Belum ada peringkat

- Nozzle CheckDokumen11 halamanNozzle CheckincaurcoBelum ada peringkat

- 77 - 103Dokumen13 halaman77 - 103raja100% (2)

- 1 Intro To MF Hydraulics UpdDokumen38 halaman1 Intro To MF Hydraulics UpdHoang Nguyen MinhBelum ada peringkat

- LR FPSO Basic Principle TrainingDokumen75 halamanLR FPSO Basic Principle TrainingBenjamin Yohan100% (4)

- Grayloc Catalog (GLOC-105 - 11-09 - 5M) PDFDokumen32 halamanGrayloc Catalog (GLOC-105 - 11-09 - 5M) PDFlsgmz33% (3)

- Route Selection and Deepwater Pipeline DesignDokumen19 halamanRoute Selection and Deepwater Pipeline DesignSampurnanand PandeyBelum ada peringkat

- Intoduction of FPSO 01Dokumen8 halamanIntoduction of FPSO 01muhammad hanifBelum ada peringkat

- 13.date Sheet For Gate ValveDokumen2 halaman13.date Sheet For Gate ValveMrinal Kanti BhaduriBelum ada peringkat

- FPSO Topside Modules DynamacDokumen28 halamanFPSO Topside Modules DynamacJames100% (1)

- DeepC FPSO TutorialDokumen33 halamanDeepC FPSO TutorialZou Jiawei100% (1)

- ICM-SU-5140-C.1 - FlowDokumen37 halamanICM-SU-5140-C.1 - FlowShivani DubeyBelum ada peringkat

- Plant Piping Construction StandardDokumen15 halamanPlant Piping Construction StandardessamoveBelum ada peringkat

- Pa 3 PDFDokumen0 halamanPa 3 PDFNageswara Rao BavisettyBelum ada peringkat

- Piping Design Plant LayoutDokumen23 halamanPiping Design Plant Layoutluxvij100% (1)

- Saes J 002Dokumen31 halamanSaes J 002madinah123100% (1)

- Sans 347.2010Dokumen47 halamanSans 347.2010madodandembe100% (1)

- Saes A 004Dokumen22 halamanSaes A 004Branko_62100% (1)

- Sabp A 015Dokumen58 halamanSabp A 015sethu1091100% (5)

- Critical Path Method (CPM) in Project ManagementDokumen11 halamanCritical Path Method (CPM) in Project ManagementdndudcBelum ada peringkat

- Wireline Log Quality Control Reference ManualDokumen280 halamanWireline Log Quality Control Reference ManualMohamed Abd El-ma'boud83% (6)

- Anchor Handling Tug Pre-Mob InspectionDokumen8 halamanAnchor Handling Tug Pre-Mob Inspectiondndudc100% (1)

- Check List - Air Compressor InspectionDokumen1 halamanCheck List - Air Compressor Inspectiondndudc100% (4)

- Construction Quality ManualDokumen42 halamanConstruction Quality ManualBob Madlener100% (7)

- Primavera P6 Reports Tab SamplesDokumen27 halamanPrimavera P6 Reports Tab Samplestensix100% (2)

- Rigging Safety in Cranes PDFDokumen170 halamanRigging Safety in Cranes PDFLuis AcuaBelum ada peringkat

- Cathodic Protection 2007Dokumen141 halamanCathodic Protection 2007arsssyBelum ada peringkat

- Offshore Book 2010Dokumen117 halamanOffshore Book 2010Mos Woraphon100% (1)

- Primavera P6 Exercise WorksheetDokumen35 halamanPrimavera P6 Exercise Worksheetdyeyson3095% (19)

- Plant Commissioning Start Up ProcedureDokumen100 halamanPlant Commissioning Start Up Proceduremsaad292% (123)

- Certification Process of Storage Tank PDFDokumen32 halamanCertification Process of Storage Tank PDFdndudcBelum ada peringkat

- Offshore Pipelaying Dynamic PDFDokumen150 halamanOffshore Pipelaying Dynamic PDFdndudcBelum ada peringkat

- 101 6.0 Student GoldDokumen332 halaman101 6.0 Student Goldjmurzin100% (6)

- Primavera (P6)Dokumen316 halamanPrimavera (P6)Abde Ali83% (6)

- P6 - Manual Basic PDFDokumen230 halamanP6 - Manual Basic PDFdndudcBelum ada peringkat

- Construction Presentation - Container Terminal PDFDokumen60 halamanConstruction Presentation - Container Terminal PDFdndudc100% (1)

- P6 Reference ManualDokumen550 halamanP6 Reference Manualsaluthomas100% (22)

- Construction of A Breakwater and A Quay Wall Made of Box CaissonsDokumen2 halamanConstruction of A Breakwater and A Quay Wall Made of Box CaissonsAhmad Balah100% (1)

- H - Quay Walls Restoriation Method StatementDokumen34 halamanH - Quay Walls Restoriation Method StatementVimalan Kannan100% (1)

- 5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepDokumen21 halaman5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepArup NathBelum ada peringkat

- Quay Construction With Concrete Caisson PDFDokumen5 halamanQuay Construction With Concrete Caisson PDFdndudcBelum ada peringkat

- Wharf Design and AnalysisDokumen8 halamanWharf Design and AnalysisklynchelleBelum ada peringkat

- Quay Walls Design Guide Lines PDFDokumen151 halamanQuay Walls Design Guide Lines PDFkaleswara_tellakula100% (2)

- Study of Breakwaters Constructed With One Layer of Armor Stone PDFDokumen58 halamanStudy of Breakwaters Constructed With One Layer of Armor Stone PDFdndudcBelum ada peringkat

- General Description of Quay Wall Type PDFDokumen6 halamanGeneral Description of Quay Wall Type PDFdndudcBelum ada peringkat

- Quay Wall Construction PDFDokumen8 halamanQuay Wall Construction PDFdndudcBelum ada peringkat

- Sand Mound ManualDokumen60 halamanSand Mound ManualFlavio Jose MuhaleBelum ada peringkat

- Metode Konstruksi Reklamasi PantaiDokumen55 halamanMetode Konstruksi Reklamasi PantaiHosea Luahambowo100% (1)

- Cape Charles Town Harbor PDFDokumen15 halamanCape Charles Town Harbor PDFdndudcBelum ada peringkat

- Tower Script For PMO 080729Dokumen13 halamanTower Script For PMO 080729raj kiranBelum ada peringkat

- Thermostats and Dial ThermometersDokumen252 halamanThermostats and Dial Thermometersaco1970Belum ada peringkat

- ST - STR - 008 Electrolytically Deposited Coatings of Zinc Hex-Chrome FreeDokumen8 halamanST - STR - 008 Electrolytically Deposited Coatings of Zinc Hex-Chrome FreeVinicius BacellarBelum ada peringkat

- EQPT-02-21 Pipe Strain For Rotating EquipmentDokumen2 halamanEQPT-02-21 Pipe Strain For Rotating EquipmentAmanSharmaBelum ada peringkat

- BSDDokumen18 halamanBSDdenisBelum ada peringkat

- Part Number Qty Description ConditionDokumen309 halamanPart Number Qty Description ConditionMiroslaw Gabalix GabalisBelum ada peringkat

- Defence Standard 02-862 Part 1Dokumen88 halamanDefence Standard 02-862 Part 1Hattar MBelum ada peringkat

- Mec Ba Threads Bs 93Dokumen5 halamanMec Ba Threads Bs 93enricoBelum ada peringkat

- Simplified Steel DesignDokumen22 halamanSimplified Steel DesignBCXC LLAM100% (2)

- CX Series - 02 PDFDokumen132 halamanCX Series - 02 PDFcatalin9494Belum ada peringkat

- DICTIONARYDokumen11 halamanDICTIONARYMaria Patricia MerañaBelum ada peringkat

- Partslist - A025 - Backhoe 205Dokumen7 halamanPartslist - A025 - Backhoe 205Павел ХромовBelum ada peringkat

- AXIOM Iconos R200, Replacement of The Lift-Tilting Base CSTD AXD3-340.805.04 AXD3-340.841.03Dokumen32 halamanAXIOM Iconos R200, Replacement of The Lift-Tilting Base CSTD AXD3-340.805.04 AXD3-340.841.03ROMANBelum ada peringkat

- ISO split pin sizes and specificationsDokumen7 halamanISO split pin sizes and specificationsdevendraBelum ada peringkat

- Wave Spring FAQ EbookDokumen25 halamanWave Spring FAQ EbookBarisBelum ada peringkat

- CSWP Practice Exam GuideDokumen32 halamanCSWP Practice Exam GuidemortifaguilloBelum ada peringkat

- T-Rack: Innovative Rack Solutions For UltrafiltrationDokumen10 halamanT-Rack: Innovative Rack Solutions For UltrafiltrationMatias Ellena GodoyBelum ada peringkat

- Advantages of Rolled ThreadsDokumen3 halamanAdvantages of Rolled ThreadsAndrew PeterBelum ada peringkat

- Development of Draft Protocol For Testing of Structural Components and SystemsDokumen15 halamanDevelopment of Draft Protocol For Testing of Structural Components and Systemsimsurender87Belum ada peringkat

- 01 Week TLE 8 - SMAW ModuleDokumen6 halaman01 Week TLE 8 - SMAW ModuleRenato Reyes Jr.Belum ada peringkat

- Parameter All TypesDokumen1.020 halamanParameter All TypeslebronBelum ada peringkat

- Study On Design of Casing of Steam TurbineDokumen3 halamanStudy On Design of Casing of Steam Turbinesevero97Belum ada peringkat

- Komatsu D32P-1A Dozer Bulldozer Service Repair Manual SN P076093 and Up PDFDokumen22 halamanKomatsu D32P-1A Dozer Bulldozer Service Repair Manual SN P076093 and Up PDFfhsjekkdmmeBelum ada peringkat

- Pryda Steel Connectors Guide - June 2010Dokumen20 halamanPryda Steel Connectors Guide - June 2010Pawel MilewskiBelum ada peringkat

- Architectural Membranes: Case StudiesDokumen48 halamanArchitectural Membranes: Case Studiescvengr229Belum ada peringkat

- Manual de Partes TB120Dokumen208 halamanManual de Partes TB120Aurora Maria Tejada LondoñoBelum ada peringkat

- Flexicon Generalbrochure Low FacingDokumen13 halamanFlexicon Generalbrochure Low FacingAhmet MetinBelum ada peringkat

- OX Assembly ManualDokumen44 halamanOX Assembly ManualMati FernandezBelum ada peringkat

- Bolt SpecificationsDokumen3 halamanBolt SpecificationsSyed Mohammad Shabber AhmadBelum ada peringkat

- Instructions For The Safe Use Of: ShacklesDokumen2 halamanInstructions For The Safe Use Of: Shacklesreda mesbahBelum ada peringkat

- Understanding Automotive Electronics: An Engineering PerspectiveDari EverandUnderstanding Automotive Electronics: An Engineering PerspectivePenilaian: 3.5 dari 5 bintang3.5/5 (16)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- Transformed: Moving to the Product Operating ModelDari EverandTransformed: Moving to the Product Operating ModelPenilaian: 4 dari 5 bintang4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldDari EverandIconic Advantage: Don’t Chase the New, Innovate the OldPenilaian: 4 dari 5 bintang4/5 (1)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessDari EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessBelum ada peringkat

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDari EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsBelum ada peringkat

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryDari EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryPenilaian: 4 dari 5 bintang4/5 (5)

- Operational Amplifier Circuits: Analysis and DesignDari EverandOperational Amplifier Circuits: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsDari EverandDesign for How People Think: Using Brain Science to Build Better ProductsPenilaian: 4 dari 5 bintang4/5 (8)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionDari EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionBelum ada peringkat

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationDari EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorDari EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorPenilaian: 4 dari 5 bintang4/5 (7)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDari EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperiencePenilaian: 4 dari 5 bintang4/5 (19)

- Electrical Principles and Technology for EngineeringDari EverandElectrical Principles and Technology for EngineeringPenilaian: 4 dari 5 bintang4/5 (4)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableDari EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableBelum ada peringkat

- The User's Journey: Storymapping Products That People LoveDari EverandThe User's Journey: Storymapping Products That People LovePenilaian: 3.5 dari 5 bintang3.5/5 (8)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsDari EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsBelum ada peringkat

- Demystifying Embedded Systems MiddlewareDari EverandDemystifying Embedded Systems MiddlewarePenilaian: 4 dari 5 bintang4/5 (1)

- Basic Electric Circuit Theory: A One-Semester TextDari EverandBasic Electric Circuit Theory: A One-Semester TextPenilaian: 1.5 dari 5 bintang1.5/5 (2)