Stainless Steel Fitting Specifications Guide

Diunggah oleh

ChickenChick07Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Stainless Steel Fitting Specifications Guide

Diunggah oleh

ChickenChick07Hak Cipta:

Format Tersedia

Stainless Steel fitting specifications

Welding Fittings

As-Welded Grade

as-welded fittings are welded

using ASME qualified welding procedures

and can be supplied in a wide range of

diameters and wall thicknesses from any of

the weldable corrosion resistant alloys.

Welding elbows can be provided with

smooth flow or mitered construction, tees

and crosses can be drawn outlet or nozzle-

welded types and reducers can be conical or

bell-shaped Alaskan manufacturers as-

welded fittings to ANSI B16.9, ANSI B16.28

or MSS SP-43 dimensions, with weld ends

furnished square cut. Fittings with special

dimensions or

those that require beveled. belied or roll-

grooved ends can be provided. Spot

radiography or 100% radiography of welded

seams can also be performed. Alaskan

pickles and passivates its fittings to maintain

corrosion resistance and to prevent surface

discoloration from free iron oxidation. As-

welded fittings are commonly used with as-

welded pipe and tubing in pulp and paper

mills, food processing plants and other

industries where corrosion resistance is

essential.

ASTMA 774

This specification covers as-

welded stainless steel pipe fittings for low

pressure piping intended for low to

moderate temperatures and general

corrosive service where heat treatment is

not required for corrosion resistance.

Fittings are normally furnished per MSS

SP-43 dimensions unless otherwise agreed

upon between the purchaser and

manufacturer.

A 774 is generally considered to be the

most applicable ASTM specification for as-

welded fittings.

Stainless Steel fitting specifications

Welding Fittings (Continued)

ASTM A 403

This specification includes seamless and

welded wrought austenitic stainless steel butt

welding fittings and consists of two general

Classes. WP and CR. Class WP fittings are

manufactured to the dimensional requirements

of ANSI B16.9 or ANSI B16.28 and have

pressure ratings equal to that prescribed for

the specific matching pipe. Class CR fittings

are manufactured to the dimensional

requirements end pressure ratings of MSS SP-

43. Both Classes require carbide solution heat

treatment which includes rapid cooling to

prevent reprecipitation of carbides, Fitting sub-

classes covered by ASTM A 403 include the

following specific requirements:

Sub-class Requirement

WP.S Seamless construction

WP-W Welded fittings where fitting

construction welds are 100%

radiographed or ultrasonically

examined and where side med.

with the addition of filter metal

in any starting material (e.g.,

welded pipe) are 100%

radiographed

WF-WX Welded fittings where all welds

are 100% radiographed

or ultrasonically examined.

CR Seamless or welded fittings

with no nondestructive testing

required.

Special fittings with sizes and shapes not

included in the above dimensional

specifications can be ordered per A 403,

provided they are marked S9 and meet all

other requirements of the sub-class specified.

ASME SA-403

This specification includes seamless

- and welded wrought austenitic stainless

steel butt welding fittings intended for use as

commercial components that comply with

Sections I, IV and VIII and nuclear power plant

components that comply with Section III of

the ASME Boiler and Pressure Vessel Code.

With the exception of changes in tensile

properties of 304L 316L and 316N, and the

additional requirements for ASME Code

documentation,

this specification is identical to

ASTM A 403. Alaskan produces and stocks

SA-403 quality fittings, welded with filler

metal and stamped with the U symbol (Sec

tion VIII) under a Certificate of

Authorization from the American Society of

Mechanical Engineers.

ASTM B 361

This specification includes seamless

and welded aluminum and alumi

num alloy butt welding fittings

manufactured to the dimensional

requirements of ANSI B16.9 and B16.28 and

are generally available

. in diameters and schedule wall

thicknesses shown In ANSI B36,10 and ANSI

B36.19 (See page 40).

ASTM B 363

This specification covers seamless and

welded unalloyed titanium butt welding

fittings intended for general corrosion

resisting and elevated temperature service.

Dimensions are in accordance with ANSI

B18.9 or MSS SP-43 standards and are

generally available in diameters and schedule

well thicknesses shown in ANSI B36.10 and

ANSI 636.19 (See page 40). Alaskan

manufactures these fittings using ASME

qualified welders and welding procedures.

ASTM B 366

This specification includes seamless and

welded wrought nickel and nickel alloy butt

welding fittings and consists of two general

Classes, WP and CR. Class WP fittings are

manufactured to the dimensional

requirements of ANSI B16.9 or ANSI B16.28

and have pressure ratings equal to that

prescribed for the specified matching pipe.

Class CR fit tings are manufactured to the

dimensional requirements and have

pressure ratings of MSS SP-43.

Heat treating is optional as agreed upon

with the purchaser. Fitting sub-classes

covered by ASIM B 366 include the

following specific requirements:

Sub-class Requirement .

WP-S Seamless construction

WP-W Welded fittings where fitting

construction welds are 100%

radiographed or ultrasonically

examined end where welds

made with the addition of filler

metal in any starting material

(e.g.. welded pipe) are 100%

radiographically examined.

WP-WX Welded fittings where all

welds are 100% radiographi-

cally or ultrasonically exam

ined

CR Seamless or welded fittings

with no nondestructive testing

required.

Anda mungkin juga menyukai

- Fittings in Steel PipeDokumen2 halamanFittings in Steel Pipekumar sandeepBelum ada peringkat

- Codes Standards For YANBU ProjectDokumen7 halamanCodes Standards For YANBU ProjectBehçet Serdal CanbazBelum ada peringkat

- ASME Pipe and Valve Standards GuideDokumen4 halamanASME Pipe and Valve Standards GuidecatdoBelum ada peringkat

- Astm 860Dokumen9 halamanAstm 860Pilar Medrano MenaBelum ada peringkat

- ASME Standard List of Piping and FittingsDokumen7 halamanASME Standard List of Piping and Fittingsjuantamad02Belum ada peringkat

- ASME - ANSI B16 Standards PDFDokumen8 halamanASME - ANSI B16 Standards PDFgaurav_10683368850% (2)

- Astm A403Dokumen7 halamanAstm A403mtpiping2572100% (1)

- Super DuplexDokumen6 halamanSuper DuplexMaqsood Ibn Shaikhul ArfeenBelum ada peringkat

- ASME StandardsDokumen8 halamanASME Standardsanappan100% (1)

- Essential Buttweld Pipe Fittings GuideDokumen4 halamanEssential Buttweld Pipe Fittings Guidekamal_mdBelum ada peringkat

- SpecificationsDokumen7 halamanSpecificationsMarine SleimanBelum ada peringkat

- ASME/ANSI B16 Standards For Pipes and FittingsDokumen14 halamanASME/ANSI B16 Standards For Pipes and FittingsEquilibrium EngineersBelum ada peringkat

- Piping NoteDokumen9 halamanPiping NoteSanal SBelum ada peringkat

- ASME B16 Standards For Pipes and FittingsDokumen7 halamanASME B16 Standards For Pipes and FittingsEHT pipeBelum ada peringkat

- Guidelines for selecting flangesDokumen6 halamanGuidelines for selecting flangesMohit BauskarBelum ada peringkat

- ASTM A 403/A 403M - 96: Dimensions and TolerancesDokumen4 halamanASTM A 403/A 403M - 96: Dimensions and Tolerancessumit_b123Belum ada peringkat

- ASME Standards SummaryDokumen2 halamanASME Standards SummarycippygeorgeBelum ada peringkat

- ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged FittingsDokumen17 halamanASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged FittingsVinit DhandeBelum ada peringkat

- Elbow Component For Piping Direction ChangeDokumen16 halamanElbow Component For Piping Direction ChangeKyaw Kyaw AungBelum ada peringkat

- Steel Flanges Ansi Stnd1Dokumen36 halamanSteel Flanges Ansi Stnd1Harshvardhan MishraBelum ada peringkat

- Astm A 403 / A 403M - 06Dokumen7 halamanAstm A 403 / A 403M - 06negg 348100% (1)

- JCM Split Tee and Weld On Outlets For Industrial ServiceDokumen1 halamanJCM Split Tee and Weld On Outlets For Industrial ServiceochableBelum ada peringkat

- Astm Piping SpecsssssssDokumen1 halamanAstm Piping SpecsssssssAjithBelum ada peringkat

- Standards in The Valve IndustryDokumen2 halamanStandards in The Valve IndustryessnelsonBelum ada peringkat

- Astm Material Summary For BoltsDokumen6 halamanAstm Material Summary For Boltsangelufc99Belum ada peringkat

- Aashto 167M PDFDokumen8 halamanAashto 167M PDFjodasi30Belum ada peringkat

- Awwa C200 PDFDokumen6 halamanAwwa C200 PDFangel darioBelum ada peringkat

- 317L Buttweld FittingsDokumen5 halaman317L Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalDokumen5 halamanFerritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalJosé Ramón GutierrezBelum ada peringkat

- FastenersDokumen46 halamanFastenerser_lalitgargBelum ada peringkat

- Are You Properly Specifying Materials - Part 3 PDFDokumen3 halamanAre You Properly Specifying Materials - Part 3 PDFasmasm123Belum ada peringkat

- ASTM Specifications GuideDokumen7 halamanASTM Specifications GuideSherif AdelBelum ada peringkat

- Astm A403 Standard PDFDokumen12 halamanAstm A403 Standard PDFHugo Marcelo Valdivia AguileraBelum ada peringkat

- Hottappingrequirement1 160722152313Dokumen94 halamanHottappingrequirement1 160722152313ansherina2Belum ada peringkat

- Hottappingrequirement1 160722152313 PDFDokumen94 halamanHottappingrequirement1 160722152313 PDFadel100% (1)

- A 394Dokumen6 halamanA 394sontakkesd100% (2)

- Astm A134Dokumen4 halamanAstm A134Francisco HernandezBelum ada peringkat

- Pipe Fittings STDDokumen4 halamanPipe Fittings STDimrancenakkBelum ada peringkat

- A 928 - A 928M - 04 Qtkyoc9boti4tqDokumen6 halamanA 928 - A 928M - 04 Qtkyoc9boti4tqsachinguptachdBelum ada peringkat

- Norsok L001Dokumen2 halamanNorsok L001Walid Labidi50% (2)

- ASTM DescriptionDokumen4 halamanASTM Descriptionsalman khanBelum ada peringkat

- General Provisions: Chapeer ADokumen9 halamanGeneral Provisions: Chapeer AJerry M. Davila MartelBelum ada peringkat

- General Q and ADokumen10 halamanGeneral Q and AmohamedqcBelum ada peringkat

- 9-Csc Asme SpecificationsDokumen5 halaman9-Csc Asme SpecificationsDany FerdianBelum ada peringkat

- Stainless Steel Pipe SpecificationsDokumen11 halamanStainless Steel Pipe SpecificationsGonzalo MazaBelum ada peringkat

- Asme Sa 106 Grade B PipesDokumen1 halamanAsme Sa 106 Grade B PipesFerroPipEBelum ada peringkat

- ASTM BoltsDokumen3 halamanASTM BoltsAnonymous IwqK1NlBelum ada peringkat

- PmsDokumen3 halamanPmsKurian JoseBelum ada peringkat

- ASME Specification For Fastener MaterialsDokumen11 halamanASME Specification For Fastener MaterialsAnonymous IwqK1Nl100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDari EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyBelum ada peringkat

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDari EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsBelum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Q Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedDokumen2 halamanQ Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedChickenChick07Belum ada peringkat

- Steel BracingsDokumen6 halamanSteel BracingsLleiLlei100% (1)

- Product Bulletin Hazardous Area Classifications Protections en 123358Dokumen8 halamanProduct Bulletin Hazardous Area Classifications Protections en 123358mohamed abourayaBelum ada peringkat

- Q Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedDokumen2 halamanQ Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedChickenChick07Belum ada peringkat

- TEP10 Natural Gas Liquefaction - 2008Dokumen28 halamanTEP10 Natural Gas Liquefaction - 2008viknesh100% (1)

- SM4NS 4ar T V91a PDFDokumen1 halamanSM4NS 4ar T V91a PDFChickenChick07Belum ada peringkat

- STAHL Poster Safety RealityDokumen1 halamanSTAHL Poster Safety Realityedwardesjr100% (1)

- Mesh To Micron ConverterDokumen1 halamanMesh To Micron ConverterAniket royBelum ada peringkat

- Guidelines DuctileIronPipeInstallGuide PDFDokumen134 halamanGuidelines DuctileIronPipeInstallGuide PDFSIBINBelum ada peringkat

- Conditioning Orifice Plates Reduce Piping Requirements by Up to 96Dokumen8 halamanConditioning Orifice Plates Reduce Piping Requirements by Up to 96Uber_KonstruktorBelum ada peringkat

- Workshop Inspection Checklist: Safe@WorkDokumen4 halamanWorkshop Inspection Checklist: Safe@WorkChickenChick07Belum ada peringkat

- ASME B31.3 InterpretationsDokumen44 halamanASME B31.3 InterpretationsChickenChick07Belum ada peringkat

- Support Bracket KitDokumen1 halamanSupport Bracket KitChickenChick07Belum ada peringkat

- AUGI - Creating 2D Drawings From 3D AutoCAD ModelsDokumen23 halamanAUGI - Creating 2D Drawings From 3D AutoCAD ModelsMohan ShanmugamBelum ada peringkat

- DEA Skirt With Fixation PDFDokumen1 halamanDEA Skirt With Fixation PDFChickenChick07Belum ada peringkat

- ASME B31.3 InterpretationsDokumen44 halamanASME B31.3 InterpretationsChickenChick07Belum ada peringkat

- Stainless Steel Fitting Specifications GuideDokumen2 halamanStainless Steel Fitting Specifications GuideChickenChick07Belum ada peringkat

- DEA Skirt With Fixation PDFDokumen1 halamanDEA Skirt With Fixation PDFChickenChick07Belum ada peringkat

- Support Bracket KitDokumen1 halamanSupport Bracket KitChickenChick07Belum ada peringkat

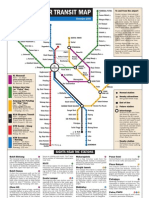

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- SM4NS 4ar T V91aDokumen1 halamanSM4NS 4ar T V91aChickenChick07Belum ada peringkat

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- Support Bracket KitDokumen1 halamanSupport Bracket KitChickenChick07Belum ada peringkat

- Conditioning Orifice Plates Reduce Piping Requirements by Up to 96Dokumen8 halamanConditioning Orifice Plates Reduce Piping Requirements by Up to 96Uber_KonstruktorBelum ada peringkat

- Stainless Steel Fitting Specifications GuideDokumen2 halamanStainless Steel Fitting Specifications GuideChickenChick07Belum ada peringkat

- Stainless Steel Fitting Specifications GuideDokumen2 halamanStainless Steel Fitting Specifications GuideChickenChick07Belum ada peringkat

- Conditioning Orifice Plates Reduce Piping Requirements by Up to 96Dokumen8 halamanConditioning Orifice Plates Reduce Piping Requirements by Up to 96Uber_KonstruktorBelum ada peringkat

- P07023 Oshiro Et AlDokumen15 halamanP07023 Oshiro Et AlChickenChick07Belum ada peringkat

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- Design of Reinforced Concrete Linings of Pressure Tunnels and ShaftsDokumen8 halamanDesign of Reinforced Concrete Linings of Pressure Tunnels and Shaftssnyckersg100% (1)

- Completions Basics: Key Downhole Tools and Their FunctionsDokumen89 halamanCompletions Basics: Key Downhole Tools and Their FunctionsMuhammad Shahrukh100% (1)

- CALC No. 1 Georgette R01 NewDokumen9 halamanCALC No. 1 Georgette R01 NewvtalexBelum ada peringkat

- Minimising Noise and Vibration in Cross Rail.Dokumen16 halamanMinimising Noise and Vibration in Cross Rail.Gaurav KumarBelum ada peringkat

- Ch.10 Prev Year QuestionsDokumen86 halamanCh.10 Prev Year QuestionsAyyappan SudharshanBelum ada peringkat

- Valves: Types and Working PrinciplesDokumen73 halamanValves: Types and Working PrinciplesEhab AbowardaBelum ada peringkat

- Research and Development of Heat Resistant Materials For Advanced - 2015 - EnginDokumen14 halamanResearch and Development of Heat Resistant Materials For Advanced - 2015 - EnginDicky Pratama PutraBelum ada peringkat

- Adhesion Measurement of Films Using Indentation ExperimentsDokumen18 halamanAdhesion Measurement of Films Using Indentation ExperimentsEnriqe PuentesBelum ada peringkat

- CHM 101 - Hybridization and Shapes of MoleculesDokumen12 halamanCHM 101 - Hybridization and Shapes of Moleculeslokpored NojporesBelum ada peringkat

- Lanthanide Shift Reagents 1Dokumen9 halamanLanthanide Shift Reagents 1Til SenBelum ada peringkat

- Water Tank DesignDokumen5 halamanWater Tank DesignJournalNX - a Multidisciplinary Peer Reviewed JournalBelum ada peringkat

- School Practice Test 1207 Epa Web Study GuideDokumen36 halamanSchool Practice Test 1207 Epa Web Study GuideSirrelius Jolly100% (3)

- Final Exam 2Dokumen12 halamanFinal Exam 2dubo201Belum ada peringkat

- Week 11 Mass Transfer GuideDokumen26 halamanWeek 11 Mass Transfer GuideMalek Marry AnneBelum ada peringkat

- Ce4257 1 IntroductionDokumen27 halamanCe4257 1 IntroductionLiew Yen ChingBelum ada peringkat

- Physics 2008 JC PrelimsDokumen825 halamanPhysics 2008 JC PrelimsTay Chen RongBelum ada peringkat

- Advances On Optical Fiber SensorsDokumen113 halamanAdvances On Optical Fiber SensorsLeo Yea LiuBelum ada peringkat

- Quantum Numbers and Periodic Trends Formative Assessment - PaperDokumen11 halamanQuantum Numbers and Periodic Trends Formative Assessment - Paperapi-546337950Belum ada peringkat

- NSEJS Guide for Physics, Chemistry, Biology and MathematicsDokumen349 halamanNSEJS Guide for Physics, Chemistry, Biology and MathematicsVarsha Bhargava70% (20)

- 2023-08-18 Enzymes KineticsDokumen52 halaman2023-08-18 Enzymes KineticsAjay MahalkaBelum ada peringkat

- Climate and Weather Guide Lesson 3.2Dokumen1 halamanClimate and Weather Guide Lesson 3.2aminahBelum ada peringkat

- Special Manufacturing ProcessesDokumen2 halamanSpecial Manufacturing ProcessesGopinath GangadhariBelum ada peringkat

- SINTER Plant ESP DetailsDokumen1 halamanSINTER Plant ESP Detailssurya325kiranBelum ada peringkat

- Ulman Part 10Dokumen1.000 halamanUlman Part 10Yana RahmadaniBelum ada peringkat

- Fluid Machine ExamDokumen2 halamanFluid Machine ExamHagosMebrahtuBelum ada peringkat

- Sustainable Marine Structures Vol 5 No 2 September 2023Dokumen59 halamanSustainable Marine Structures Vol 5 No 2 September 2023Bilingual PublishingBelum ada peringkat

- Mohammad Faisal Haroon - Envr506 - Week7Dokumen4 halamanMohammad Faisal Haroon - Envr506 - Week7Hasan AnsariBelum ada peringkat

- Hydrogel Coatings Prevent Marine Fouling at Low SpeedsDokumen21 halamanHydrogel Coatings Prevent Marine Fouling at Low Speedss_brizzolaraBelum ada peringkat

- Plate Tectonics: How Earth's Surface MovesDokumen32 halamanPlate Tectonics: How Earth's Surface MovesAmy Sara100% (1)

- Dielectric Waveguides and Optical Fibers: Slab Waveguide, Modes, V-Number Modal, Material, and Waveguide DispersionsDokumen34 halamanDielectric Waveguides and Optical Fibers: Slab Waveguide, Modes, V-Number Modal, Material, and Waveguide Dispersionszoex924Belum ada peringkat