Ci2805sozen PDF

Diunggah oleh

edgarc999Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ci2805sozen PDF

Diunggah oleh

edgarc999Hak Cipta:

Format Tersedia

Concrete international / MAY 2006 45

T

hrough the centuries, the art and science of building

have evolved in a state of tension between two

approaches to overcoming the physical world: the use of

(1) theory; and (2) unquestioning reliance on observation.

To develop a new code or improve an existing one, it is

helpful to appreciate this tension.

WHY BUILDING CODES?

Because supporting sciences do not always provide

crisp answers to engineering problems, building requires

the use of judgment. Judgment has soft boundaries and is

influenced strongly by what is considered to be acceptable

risk. To reduce the probability of innocent or deliberate

misuse, boundaries must be placed on judgment. Hardy

Cross answered the question, why building codes?

succinctly by suggesting they were developed to keep

out the fools and the rascals.

1

Simple as it may appear, it is difficult to answer the

companion question, what should a building code

include? Well-meaning, intelligent, and experienced

professionals take extreme and often contradictory

positions on this issue. The arguments circle around

strength, serviceability, and beauty. Some strongly assert

that the code should be limited to concerns about public

safety and focus only on strength. Others assert that the

built environment is communal property and the code

should also address serviceability, though they stop

short of beauty (that would seem to go with serviceability).

The arguments are also layered by the options of holding

the engineer responsible starting at the time of design

(prescriptive code) or only if a problem arises after

construction (performance-based code).

A building code is a social contract. It is therefore out

of place to frame it completely in a rational domain.

There is, however, a tension in all building codes between

science and engineering practice caused primarily by the

fact that, in the practice of engineering, the choice is not

only between right and wrong, but also between good

This point of view article is presented for reader interest by the editors.

However, the opinions expressed are not necessarily those of the

American Concrete Institute. Reader comment is invited. This article

was extracted from a talk given at the first meeting of the African Code

Congress in Tripoli, Libya, November 2005.

Point of View

The Building of a

Building Code

The tension between theory and observation

BY METE A. SZEN

46 MAY 2006 / Concrete international

and bad. Two examples cited in the following illustrate

the tension between theory and observation in design.

WEB REINFORCEMENT

The conflict in the proportioning of web reinforcement

in beams was (and continues to be) poorly understood

physics and reasonably-well understood experience.

To keep the discussion simple, we will stay away from

questions concerning beams without web reinforcement

and focus on vertical web reinforcement (perpendicular

to the longitudinal reinforcement) in reinforced concrete

beams subjected to monotonically increasing shear.

The first all-inclusive vision on design of web

reinforcement in the U.S. may be ascribed to Richart.

2

It is relevant to note that he started his experimental

investigation in the early 1900s, but could not bring

himself to publish a full report until 1927. In retrospect,

we may presume that he was seeking a compact and

crisp solution that never came to be. It is not an

exaggeration to claim that anyone else working on web

reinforcement, before and after Richart, started or ended

with variations of the truss analogy by Mrsch.

Once we make the egotistical imposition of calling a

beam a truss, things fall into place (Fig. 1). Considering

the equilibrium of a joint with the forces shown and an

imaginary strut conveniently at 45 degrees to the horizontal,

we arrive at the rigorous result that

(1)

where A

w

is the cross-sectional area of all legs of one

stirrup or hoop,

w

is the unit stress in the stirrup, d is

the effective depth, s is the stirrup spacing, and V is the

total applied shear force.

Using Eq. (1) as a way to understand the experimental

results, Richart ran up against a wall. Although theory

demanded that all shear be resisted by the web

reinforcement, test results consistently indicated other-

wise. If he followed rigid theory, the contractors would

be up in arms. If he dismissed one part of the derivation,

all other parts would become questionable. For example,

he referred to the expression for shear strength

derived previously by Slater et al.

3

as plausible, which

was given as

(2)

where

w

is the web reinforcement ratio for vertical

stirrups (A

w

/bs), b is the width of the compression flange,

and jd is the internal lever arm based on the straightline

formula.

The very recognition of Eq. (2) stood the truss analogy

on its head, as the expression implied the existence of a

shear resistance (0.005

w

) that appeared to have nothing

to do with the amount of web reinforcement provided.

Ergo, the truss analogy was irrelevant.

Eventually, Richart went against his faith in theory and

suggested the form

(3)

where C is a constant stress related to compressive

strength of concrete (such as 0.03

c

, where

c

is the

cylinder strength).

It is important to note that Eq. (3) refers to working

stresses and even more important to quote his last conclusion:

For descriptions and discussions bearing on the

details of the action of web reinforcement, the text

may well be consulted, and the information there

contained may be expected to aid in comprehending

the behavior of the reinforced concrete beam under a

variety of conditions and to give knowledge that may

be useful in design and constructionmatters that

cannot be summarized here.

2

The last clause is noteworthy and admirable. Richart

was admitting that he did not have a complete handle on

the problem. He had started with the truss analogy and

ended up with a form that dismissed the truss analogy.

Nevertheless, the second term on the right-hand side of

Eq. (3) was interpreted in terms of the truss analogy. It

was sheer contradiction, but the inconsistency was of

little concern to the code writers. Richarts half-theory

was considered to be better than none and remained in

that form in the ACI Code until the 1960s.

Until the 1950s, research was seldom a full-time job for

a structural engineer. Advances in the field were typically

made by practicing engineers or gifted instructors who

could devote part of their time to investigating problems

of interest to the profession, such as Richart. World War II

changed the scene in structural engineering as it did in

many other segments of society. There developed a small

group of almost full-time researchers. A few years after WWII,

they investigated a series of shear failures experienced

V

s

d

f A

w w

=

( )

bjd

V

f

w w

= + 005 . 0

w w

f C

bjd

V

+ =

Fig. 1: Schematic representation of the truss analogy for shear in

concrete beams with web reinforcement

Concrete international / MAY 2006 47

by reinforced concrete warehouse frames. Their kick-off

statement is still valid:

All engineers interested in concrete construction

are aware of the abundance of excellent research

work being conducted in all phases of concrete

technology. Engineers are also equally familiar with a

variety of experience showing that concrete has been

a most reliable and economical engineering material.

Nevertheless, in spite of these extensive research

programs and in spite of the successful use of concrete

in structures of all types, the fact remains

.

that the

fundamental behavior of concrete members in

transferring shear load, one of the most common

design features, is not fully understood, and in certain

specific cases design practice has been used that has

resulted in costly failures.

4

The warehouses had been designed in accordance

with the ACI Code. There had to be something lacking in

the code requirements developed by Richart and fellow

committee members. A joint committee of the American

Concrete Institute and the American Society of Civil

Engineers was formed. They sponsored tests to investigate

the problem

5

and reported their findings in 1963.

Some of the principles they found appropriate for the

shear problem are worth mentioning in part:

1. Diagonal tension is a combined-stress problem;

2. Failure may occur immediately on formation of a

diagonal-tension crack or at a higher load;

3. The shear corresponding to the formation of the

diagonal-tension crack, ignoring any possible

increase, defines the strength of the beam without

web reinforcement; and

4. Distributions of shear and flexural stresses over the

cross section of a reinforced concrete beam are not known.

Principle 4 did not stop the committee members from

using principal tensile stresses determined from mechanics

to come up with the conclusion that the main parameters

affecting the unit shear strength of a reinforced concrete

beam without web reinforcement (defined arbitrarily as

v

u

= V

u

/bd for a rectangular section, where v

u

is the unit

shear strength and V

u

is the shear strength) were M/Vd

(the ratio of moment to the product of the shear force

and the effective depth), (the longitudinal reinforcement

ratio), and the tensile strength of the concrete assumed

to be proportional to

c

f . Faced with the squalor of the

experimental results, the final expression was

(4)

(although a longer form including and M/Vd continues to

grace the ACI Code). Suspicions about size effect were

relegated to the background. The effect of longitudinal

reinforcement was virtually eliminated by lumping it in

with the factor M/Vd. The main issue was, of course, the

selection of web reinforcement. Reference was made to

the then-current expression in the code

(5)

where K = (sin() + cos())sin() and is the angle

between the web reinforcement and the horizontal. The

factor K, derived from the truss analogy, was the compromise

between the theory and the test results. The committee

members observed, in relation to past developments:

Although the nature of this design procedure has

not been changed significantly since 1921, the limitations

and maximum values have been altered in nearly every

revision of the ACI Code. Like the basic design principles,

the limitations and maximum values have tended to be

products of logical reasoning rather than systematic

laboratory tests.

6

The implication is clear. Tests are better than thinking,

and the tests need to be done under laboratory control.

They continued:

In general, the design criteria for web reinforcement

of the 1956 ACI code were not developed directly from

laboratory tests. They are not in full accord with our

basic understanding of the function of web reinforcement

and the mechanisms of failure. However, it is a fact

that the design criteria have withstood the test of time.

No structural failures known to Committee 326 can be

directly traced to possible inadequacies of these design

provisions for members with web reinforcement.

6

Observation had again triumphed over theory. We are

indebted to the committee for reminding us once again

that a design algorithm may not be in accordance with

the facts, but its results may satisfy the functional

requirements of the structure. Every code writer and code

evaluator should be aware of this antithetical position.

When the time came for the committee to make design

recommendations, they started with characteristics

unanimously recognized as correct. The first two are

worth repeating:

1. Both the web reinforcement and the concrete

compression zone contribute to the shear capacity of

the member.

c c

f v = 2

w w c

f K f

bjd

V

v + = = 03 . 0

Fig. 2: Illustration of shear resistance mechanism for concrete

beams with web reinforcement

48 MAY 2006 / Concrete international

2. The web reinforcement not only helps to carry

part of the total shear, but it also increases the ability

of the compression zone to resist shear.

6

The first characteristic suggested that the truss

analogy was incorrect, but there was a subtle change

from Richarts vision. The way to see the shear resistance

was through the mechanism illustrated in Fig. 2. With the

section cut as it was, it made sense if the possibility of

friction along the inclined crack (aggregate interlock) and

doweling effect of the longitudinal bars were ignored. It

did not quite make as good sense, however, if one decided

to cut the section as shown in Fig. 3. That section too

would have to be in equilibrium, but it was difficult to

invoke the effect of the web reinforcement on a section

not intersecting the stirrup unless one accepted that the

shear strength of the concrete changed with the section.

The second characteristic is interesting. In a beam

with web reinforcement, the contribution of the concrete

could improve compared with that of a beam without

web reinforcement. Accordingly, the diagonal tension

cracking load ceased to be a waypoint in determining the

total shear capacity.

After agreeing that the web reinforcement would yield

before shear failure (in members of normal proportions),

the joint committee argued their way to the design expression

(6)

where

wy

is the yield stress of the web reinforcement.

The last term in Eq. (6) appears to be based on the

diagonal tension cracking load despite the characteristic

that, in a beam with web reinforcement, the contribution

of the concrete can be more than that in a comparable

beam without web reinforcement.

The sequence discussed previously with respect to shear

strength of reinforced concrete beams with web reinforce-

ment was presented primarily to trace the flow of thinking

in a case where the profession was faced with a problem

that did not have a theoretical solution that could match

the observations. The theory was not adequate. The

observations were limited. The result was an agreement,

not a theory, that could be used to design within the

limits of a domain limited to the ranges of the variables

included in the experiments. Unfortunately, no limits were

initially expressed on variables not included in the tests.

Almost half a century after the paper by Anderson,

4

we

are still in the state he described. We have a plethora of

test results and many theoretical approaches, but it is

difficult (if not impossible) to claim that the problem has

been solved. Yet, the code goes on.

THE LOAD TEST

Perhaps the best example of the tension between

theory and observation in engineering practice is the

load test as defined in Chapter 20 of ACI 318-05.

7

A load

test is required if there is doubt (expressed by a licensed

engineer) that a part or all of a structure meets the

requirements of ACI 318-05. Could this doubt be dispelled

by analysis? Yes, but in many cases involving doubt, the

load test is preferred because it tends to be more efficient

at putting an end to dispute.

The magnitude of the test load is currently defined as

(7)

where W is the total test load, D is the permanent load,

and L is the live load.

The first question that presents itself is, why doesnt

the combination of permanent and live loads within the

parentheses match any of the design load combinations

included in Chapter 9? The direct answer is very simple.

The load test, as defined in Eq. (7), has been serving the

profession well. Even if the design load has changed, the

test load need not change. This is an elegantly pragmatic

action, but it creates a disturbing disconnect between the

design load and the test load.

At one time, the typical design load was 1.4D + 1.7L,

while the test load was defined by Eq. (7). Well then, why

the factor 0.85? Answer: To reduce the likelihood of devel-

oping permanent deformations during the test. That

seems like a non sequitur. Fundamentally, the load test is

to dispel doubts about the strength of the structure with

respect to the requirements of the code. Is that question

addressed fully if the test load is less than the specified

design load, even if we forget about the material (under-

strength) factors? Answer: No load-tested structure has

ever given problems in service. This oft-repeated response

embodies, in a nutshell, the essence of the engineering

approach. Once that response is accepted as sufficient

proof, all other questions about appropriate selection of

load level, loaded elements (with respect to number and

position), and consequences of observed cracks recede

into the background. The load test is not a logical proce-

dure to settle a question of safety, but it works. Why?

Because it works. As opposed to theory, the load test is

Fig. 3: The shear resistance mechanism illustrated in Fig. 2

requires the concrete shear strength V

c

to change based on the

location that the section is cut

c wy w u

f f K v + = 2

( ) L D W 7 . 1 4 . 1 85 . 0 + =

Concrete international / MAY 2006 49

pure engineering. It is a complex and

certainly unabashed combination of

theory and test.

SOME SIMPLE RULES

What Oliver Wendell Holmes

wrote in 1881 about common law is

not irrelevant to building codes:

The life of the law has not been

logic: it has been experience. The

felt necessities of the time, the

prevalent moral and political

theories, intuitions of public

policy, avowed or unconscious,

even the prejudices which judges

share with their fellow men, have

had a good deal more to do than

the syllogism in determining the

rules by which men should be

governed. The law embodies the

story of a nations development

through many centuries, and it

cannot be dealt with as if it

contained only the axioms and

corollaries of a book of mathematics.

In order to know what it is, we

must know what it has been, and

what it tends to become. We must

alternately consult history and

existing theories of legislation. But

the most difficult labor will be to

understand the combination of the

two into new products at every

stage. The substance of the law at

any given time pretty nearly

corresponds, so far as it goes,

with what is then understood to

be convenient; but its form and

machinery, and the degree to

which it is able to work out

desired results, depend very

much upon its past.

8

There is no absolute truth that

governs all segments of a building

code uniformly. A building code is

doomed to vacillations between

theory and test. Theres no prescription

for developing a building code that

can be guaranteed to be successful,

but there are simple rules, derived

from experience, that deserve mention:

1. Keep it simple. Simple is easier

said than done. There needs to be at

least one and maybe more members of

CIRCLE READER CARD #13

50 MAY 2006 / Concrete international

the code committee who understand what will be under-

stood by the rank and file and who are modest (to speak

in simple terms) and assertive (to convince the others).

All well-understood aspects of structural design are

simple and ought to be stated in simple and direct terms.

Little is gained by complicated formulations of those

aspects that are not well understood. Statements of

simple limits will do;

2. Make certain that the users understand the code

leads to a structure with minimum safety standards. It

should be clear to the engineering community that good

engineering does not mean beating the code (producing

structures that barely satisfy the code). The design community

should understand that algorithms included in the code

are not necessarily predictive. Their function is simply to

help produce a safe and serviceable structure and not to

determine response. (In this respect, it is instructive to

refer to the title of Table 9.5(b) of ACI 318-05,

7

Maximum

Permissible Computed Deflections. Why does it contain

the qualifier Computed?);

3. Stick to a single perspective. This simple goal is

almost unattainable. It is difficult to filter out approaches

based not only on safety and serviceability but also on

sales of certain products and desires of certain individuals

to push pet procedures. Still, it is worth the try;

4. Avoid textbook material. Methods and procedures

may be included in a code if they are governed by judgment.

For example, the definition of how reinforcement should

be distributed in a flat plate can indeed be accomplished

by analysis, but that option can lead to wide and awkward

variations in practice. Certainly, minima and maxima for

sizes and amounts of reinforcement belong in the code

even though some of them can be determined theoretically;

5. Do not change the code unless dangerous practices

are perceived or failures occur in the building inventory,

and do not change the code unless the new clauses/

procedures are checked by at least three practicing

engineers who have not been involved in their development.

Above all, do not change the code because of tests in the

laboratory or theory unless their results are confirmed

in the field;

6. Do not fine-tune the code from version to version.

Even if the changes result in sensible improvements, it is

preferable to stay with the original requirements unless

the change makes a difference of more than 20%;

7. Do not change the location of code clauses in the

interest of logical flow. Reshuffling clauses in the code or

redefining existing notation are likely to lead to omissions

and errors in design;

8. Do not revise the code in less than 7 years. Indeed,

if the code has to be changed every few years, it may be

claimed that it is continually immature and should not

have been set out as a code in the first place. Advances in

knowledge do not represent good reasons for changing

the code. Errors in practice do. Every time the code

clauses are revised, or new ones proposed, they need to

be checked in several design offices by professionals who

have had nothing to do with their development;

9. A building code has to appeal to the local building

technology and to local conditions. It is wrong to apply a

code vetted in a northern climate to buildings in a

southern climate; to base the code in a seismic region on

experience in a seismically inert region; or to adopt the

fire-related clauses of a code developed in the tropics in a

cold climate. Physics may be universal, but engineering

practice is not; and

10. Keep the code committee small. Having more than

12 members diffuses the responsibility. The larger a

committee is, the more likely it is to produce nonsense

for which none feels responsible. Above all, prefer the

wise to the brilliant in selecting members.

References

1. Cross, H., Engineers and Ivory Towers, McGraw-Hill Book Co.,

New York, 1952, 141 pp.

2. Richart, F.E., An Investigation of Web Stresses in Reinforced

Concrete Beams, Bulletin 166, University of Illinois Engineering

Experiment Station, 1927, 106 pp.

3. Slater, W.A.; Lord, A.R.; and Zipprodt, R.R., Shear Tests of

Reinforced Concrete Beams, Technologic Paper No. 314, U.S. Bureau

of Standards, 1926, pp. 386-495.

4. Anderson, B.G., Rigid Frame Failures, ACI Journal, Proceedings

V. 53, Jan. 1957, pp. 625-636.

5. Elstner, R.C., and Hognestad, E., Laboratory Investigation of

Rigid Frame Failure, ACI Journal, Proceedings V. 53, Jan. 1957,

pp. 637-668.

6. ACI-ASCE Committee 326, Shear and Diagonal Tension, ACI

Journal, Proceedings V. 59, No. 1, Jan. 1962, pp. 1-30; No. 2, Feb. 1962,

pp. 277-333; No. 3, Mar. 1962, pp. 353-395.

7. ACI Committee 318, Building Code Requirements for Structural

Concrete (ACI 318-05) and Commentary (318R-05), American

Concrete Institute, Farmington Hills, MI, 2005, 430 pp.

8. Holmes, O.W., Jr., The Common Law, 32nd printing, Little,

Brown and Co., Boston, 1938, 422 pp.

Selected for reader interest by the editors.

ACI Honorary Member Mete A. Szen is

the Kettelhut Distinguished Professor of

Structural Engineering at Purdue

University, West Lafayette, IN.

Anda mungkin juga menyukai

- Reinforcement 12Dokumen8 halamanReinforcement 12edgarc999Belum ada peringkat

- CSC STEEL PRODUCT GUIDEDokumen43 halamanCSC STEEL PRODUCT GUIDEedgarc999Belum ada peringkat

- COR-TEN Steel A006enDokumen18 halamanCOR-TEN Steel A006enjosealopez66Belum ada peringkat

- Guide and Specification SeqmentalDokumen105 halamanGuide and Specification Seqmentaledgarc999Belum ada peringkat

- Design of Circular Steel Arches With Hollow Circular Cross-Sections According To EC3Dokumen9 halamanDesign of Circular Steel Arches With Hollow Circular Cross-Sections According To EC3edgarc999Belum ada peringkat

- Prestressed Concrete Bridges - Nigel HewsonDokumen397 halamanPrestressed Concrete Bridges - Nigel HewsonNguyễn Xuân Nguyên86% (7)

- Podolny and Muller - Construction and Design of Pre Stressed Concrete Segmental BridgesDokumen569 halamanPodolny and Muller - Construction and Design of Pre Stressed Concrete Segmental Bridgesjosereyesv100% (5)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Research PhilosophyDokumen4 halamanResearch Philosophygdayanand4uBelum ada peringkat

- AFRICAN SYSTEMS OF KINSHIP AND MARRIAGEDokumen34 halamanAFRICAN SYSTEMS OF KINSHIP AND MARRIAGEjudassantos100% (2)

- GCSE Bearings: Measuring Bearings Test Your UnderstandingDokumen5 halamanGCSE Bearings: Measuring Bearings Test Your UnderstandingSamuel KalemboBelum ada peringkat

- Java Interview Questions: Interfaces, Abstract Classes, Overloading, OverridingDokumen2 halamanJava Interview Questions: Interfaces, Abstract Classes, Overloading, OverridingGopal JoshiBelum ada peringkat

- Comal ISD ReportDokumen26 halamanComal ISD ReportMariah MedinaBelum ada peringkat

- Revolutionizing Via RoboticsDokumen7 halamanRevolutionizing Via RoboticsSiddhi DoshiBelum ada peringkat

- Ejercicio 1.4. Passion Into ProfitDokumen4 halamanEjercicio 1.4. Passion Into ProfitsrsuaveeeBelum ada peringkat

- Summer Internship ReportDokumen135 halamanSummer Internship Reportsonal chandra0% (1)

- Activity 1 DIASSDokumen3 halamanActivity 1 DIASSLJ FamatiganBelum ada peringkat

- College Wise Form Fillup Approved Status 2019Dokumen4 halamanCollege Wise Form Fillup Approved Status 2019Dinesh PradhanBelum ada peringkat

- The Five Laws of Light - Suburban ArrowsDokumen206 halamanThe Five Laws of Light - Suburban Arrowsjorge_calvo_20Belum ada peringkat

- NBPME Part II 2008 Practice Tests 1-3Dokumen49 halamanNBPME Part II 2008 Practice Tests 1-3Vinay Matai50% (2)

- EAPP Q2 Module 2Dokumen24 halamanEAPP Q2 Module 2archiviansfilesBelum ada peringkat

- Advanced VLSI Architecture Design For Emerging Digital SystemsDokumen78 halamanAdvanced VLSI Architecture Design For Emerging Digital Systemsgangavinodc123Belum ada peringkat

- Belonging Through A Psychoanalytic LensDokumen237 halamanBelonging Through A Psychoanalytic LensFelicity Spyder100% (1)

- Topic 1 in 21st CneturyDokumen8 halamanTopic 1 in 21st CneturyLuwisa RamosBelum ada peringkat

- Pale Case Digest Batch 2 2019 2020Dokumen26 halamanPale Case Digest Batch 2 2019 2020Carmii HoBelum ada peringkat

- Overlord Volume 1 - The Undead King Black EditionDokumen291 halamanOverlord Volume 1 - The Undead King Black EditionSaadAmir100% (11)

- Sergei Rachmaninoff Moment Musicaux Op No in E MinorDokumen12 halamanSergei Rachmaninoff Moment Musicaux Op No in E MinorMarkBelum ada peringkat

- Pharmaceuticals CompanyDokumen14 halamanPharmaceuticals CompanyRahul Pambhar100% (1)

- Abbreviations (Kısaltmalar)Dokumen4 halamanAbbreviations (Kısaltmalar)ozguncrl1Belum ada peringkat

- Sample Letter of Intent To PurchaseDokumen2 halamanSample Letter of Intent To PurchaseChairmanBelum ada peringkat

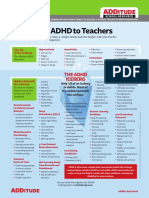

- Explaining ADHD To TeachersDokumen1 halamanExplaining ADHD To TeachersChris100% (2)

- 11th AccountancyDokumen13 halaman11th AccountancyNarendar KumarBelum ada peringkat

- 2015 Ssang Yong Rexton Y292 Service ManualDokumen1.405 halaman2015 Ssang Yong Rexton Y292 Service Manualbogdanxp2000Belum ada peringkat

- Earth Drill FlightsDokumen2 halamanEarth Drill FlightsMMM-MMMBelum ada peringkat

- Political Philosophy and Political Science: Complex RelationshipsDokumen15 halamanPolitical Philosophy and Political Science: Complex RelationshipsVane ValienteBelum ada peringkat

- (Template) Grade 6 Science InvestigationDokumen6 halaman(Template) Grade 6 Science InvestigationYounis AhmedBelum ada peringkat

- Sound! Euphonium (Light Novel)Dokumen177 halamanSound! Euphonium (Light Novel)Uwam AnggoroBelum ada peringkat

- Environmental Science PDFDokumen118 halamanEnvironmental Science PDFJieyan OliverosBelum ada peringkat