Dru Ouy Procedure Les1801

Diunggah oleh

geverett2765Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dru Ouy Procedure Les1801

Diunggah oleh

geverett2765Hak Cipta:

Format Tersedia

LES.

1801, Page 1 of 5

DFT 03/11/11

Supercedes 04/24/06

GENERAL DRYING AND FIRING INSTRUCTIONS

FOR NAFTA PHOS BOND PLASTICS

Any non-field technical advice furnished by Seller with reference to the use of its Products is given gratis, and Seller assumes no

obligation or liability for the advice given or the results obtained. All such advice is given and accepted at Buyers sole risk.

50-RAM, 85-RAM and EMERALD-RAM are registered trademarks in the following jurisdiction: US. BLU-RAM is a

registered trademark in the following jurisdictions: US, VE.

SCOPE

This Engineering Standard provides the general drying and firing instructions for Vesuvius

Phos Bond Plastics.

Do not use this standard for the drying and firing of any SiC containing plastics.

Please refer to Vesuvius Engineering Standard LES.1802 for the drying and firing of SiC

containing HS plastics.

DRYING PROCEDURES

When Phos Bond high alumina plastics are exposed to ambient conditions they tend to dry

and skin over. This surface skin can cause steam entrapment during the drying and firing of

the refractory lining.

Due to the particular property of these products, forms should be left in place until just prior

beginning the drying and firing schedule. On projects where the surface is left exposed

during installation or where forms are removed and the plastic is exposed for an extended

period of time, special precaution must be taken. See Vesuvius Global Engineering

Standard LES.1804.

LES.1801, Page 2 of 5

DFT 03/11/11

Supercedes 04/24/06

GENERAL DRYING AND FIRING INSTRUCTIONS

FOR NAFTA PHOS BOND PLASTICS

Any non-field technical advice furnished by Seller with reference to the use of its Products is given gratis, and Seller assumes no obligation

or liability for the advice given or the results obtained. All such advice is given and accepted at Buyers sole risk.

DRYING PROCEDURES (Cont.)

Immediately after Finishing is complete, the finished phos-bonded plastic lining should be

perforated using 1/8 (3mm) to 3/16 (5mm) diameter rods. The perforations will provide escape

vents for the steam that will develop during drying and firing. These steam vents should be

positioned on 8-10 (200 250mm) centers and typically penetrate to 2/3 the lining thickness. In

cases where the phos-bonded plastic is installed directly against a welded steel shell, the venting

must be full depth of plastic.

Additional venting is needed for especially thick linings.

After the vents are formed, the surface must be sprayed or misted with water until the surface is

shiny or just visibly moist. This procedure eliminates any skin that may have formed.

Due to the tendency of this type product to "skin", the initial drying phase must be done at a

relatively low temperature for an extended period of time. This allows the heat to penetrate the

full thickness of the lining. Only then can the temperature be increased to the point where

chemical bonding occurs. The initial drying period is critical to the service life of

the lining.

Vesuvius Phos Bond high alumina plastics should be protected from freezing until the firing

schedule has been completed.

See page 3 of this standard for a step by step drying and firing schedule.

LES.1801, Page 3 of 5

DFT 03/11/11

Supercedes 04/24/06

GENERAL DRYING AND FIRING INSTRUCTIONS

FOR NAFTA PHOS BOND PLASTICS

Any non-field technical advice furnished by Seller with reference to the use of its Products is given gratis, and Seller assumes no obligation

or liability for the advice given or the results obtained. All such advice is given and accepted at Buyers sole risk.

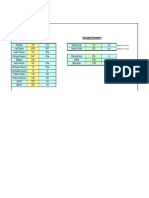

FIRING SCHEDULE

Step Duration Procedure

1 4 Hours

Ramp from ambient to 250F (120C) at a rate of

50F (25C) per hour.

2 4 Hours

Hold at 250F (120C) for four (4) hours.

3 30 Hours

Ramp to 1750F (955C) at a rate of 50F (25C)

per hour. See Note 6.

4 Variable

Ramp to operating temperature at rate of 100F

(55C) per hour.

See Note 6.

5 1 Hour/Inch (25mm) Thickness

Hold at operating temperature prior to cooling unit

back to ambient or put unit into service.

LES.1801, Page 4 of 5

DFT 03/11/11

Supercedes 04/24/06

GENERAL DRYING AND FIRING INSTRUCTIONS

FOR NAFTA PHOS BOND PLASTICS

Any non-field technical advice furnished by Seller with reference to the use of its Products is given gratis, and Seller assumes no obligation

or liability for the advice given or the results obtained. All such advice is given and accepted at Buyers sole risk.

NOTES

1. Install a low temperature thermocouple on the surface of the plastic near the middle of the

floor or hearth. The thermocouple should be protected from flame impingement. The

temperature of the furnace should be controlled from this thermocouple for at least the first

two steps.

2. If temperatures are controlled by thermocouples located on a roof or wall, the thermocouples

head can be protected from flame impingement by inserting it approximately 1/8" into the

surface of the plastic.

3. Vesuvius recommends at least three thermocouples, positioned in various locations, be used

for temperature control during drying and firing. More are never too many.

4. Once the drying and firing cycle has begun, the schedule should be followed without

interruption except in cases where steaming is noted from the surface. When this occurs,

the temperature should not be decreased, but held constant until all steaming stops.

5. Any adjustment to burners or controls should take place after the schedule has been

completed.

6. Except for EMERALD-RAM Plastics, the minimum recommended firing temperature for HS,

HSM, HS-S AND PC plastics is 1750F (955C). EMERALD-RAM Plastics must be fired to a

minimum of 2350F (1290C).

7. For units having two or more hot face refractories, use the schedule with the slowest

ramping rate.

8. Good air-flow is essential during all stages of the drying and firing schedule.

9. Flame impingement must be avoided at all times.

10. If you have any questions concerning this or any other Vesuvius Engineering Standard

document please contact the Vesuvius Linings Engineering Department.

LES.1801, Page 5 of 5

DFT 03/11/11

Supercedes 04/24/06

GENERAL DRYING AND FIRING INSTRUCTIONS

FOR NAFTA PHOS BOND PLASTICS

Any non-field technical advice furnished by Seller with reference to the use of its Products is given gratis, and Seller assumes no obligation

or liability for the advice given or the results obtained. All such advice is given and accepted at Buyers sole risk.

EXAMPLE DRYING AND FIRING SCHEDULE

0

500

1000

1500

2000

2500

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TIME FROM START OF SCHEDULE

T

E

M

P

E

R

A

T

U

R

E

(

F

)

0

200

400

600

800

1000

1200

1400

T

E

M

P

E

R

A

T

U

R

E

(

C

)

Anda mungkin juga menyukai

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Union Pump InformationDokumen12 halamanUnion Pump Informationgeverett2765Belum ada peringkat

- Union Pump InformationDokumen12 halamanUnion Pump Informationgeverett2765Belum ada peringkat

- Refrigeration IIAR 4 PR1Dokumen28 halamanRefrigeration IIAR 4 PR1geverett2765100% (3)

- Control Valve SzingDokumen10 halamanControl Valve Szinggeverett2765Belum ada peringkat

- Diesel Fuel MSDS PDFDokumen7 halamanDiesel Fuel MSDS PDFgeverett2765Belum ada peringkat

- Fisher Tank Blanketing Manual PDFDokumen19 halamanFisher Tank Blanketing Manual PDFgeverett2765Belum ada peringkat

- API Tubing TableDokumen1 halamanAPI Tubing Tablegeverett2765Belum ada peringkat

- Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and VentingDokumen99 halamanDirective 060: Upstream Petroleum Industry Flaring, Incinerating, and Ventinggeverett2765Belum ada peringkat

- Hy Lok Tube Fittings PDFDokumen56 halamanHy Lok Tube Fittings PDFHermanBelum ada peringkat

- Methanol MSDSDokumen8 halamanMethanol MSDSgeverett2765Belum ada peringkat

- Booster Pumps - Centrifugal Pump SizingDokumen1 halamanBooster Pumps - Centrifugal Pump Sizinggeverett2765Belum ada peringkat

- 0D107Line ListDokumen1 halaman0D107Line Listgeverett2765Belum ada peringkat

- Sat Jul 07 19:54:58 2007 Case: C:/Program Files/Hyprotech/HYSYS 3.2/cases/temp - HSC Flowsheet: Case (Main)Dokumen1 halamanSat Jul 07 19:54:58 2007 Case: C:/Program Files/Hyprotech/HYSYS 3.2/cases/temp - HSC Flowsheet: Case (Main)geverett2765Belum ada peringkat

- Sizing of Tank Heating CoilDokumen1 halamanSizing of Tank Heating Coilgeverett2765Belum ada peringkat

- Datasheet - Sour Water Injection PumpDokumen6 halamanDatasheet - Sour Water Injection Pumpgeverett2765Belum ada peringkat

- Flange ChartDokumen4 halamanFlange ChartKevindran CanarajBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 220 QsDokumen46 halaman220 QsPrathamesh Parker100% (1)

- Essex Crossing Phase 1 - Community PresentationDokumen68 halamanEssex Crossing Phase 1 - Community PresentationThe Lo-DownBelum ada peringkat

- ISTQB Software Testing Certification Sample Question Paper With Answers - Part IIDokumen43 halamanISTQB Software Testing Certification Sample Question Paper With Answers - Part IImanav_jdl36Belum ada peringkat

- Nsekuye JeanBosco ResumeDokumen4 halamanNsekuye JeanBosco ResumeJean NsekuyeBelum ada peringkat

- Airtel ProjectDokumen60 halamanAirtel Projectabhiserkh67% (3)

- Viper JetDokumen4 halamanViper JetJaafar Ali MohamadBelum ada peringkat

- Quick Lifting Jack - Project ReportDokumen36 halamanQuick Lifting Jack - Project ReportRoyalAryans76% (17)

- Me Selas Brochure en 2 PDFDokumen4 halamanMe Selas Brochure en 2 PDFfahrgeruste3961Belum ada peringkat

- Front Loading Washing Machine-2023!11!11 AREFDokumen15 halamanFront Loading Washing Machine-2023!11!11 AREFzakirzandan0Belum ada peringkat

- Mercedes-Benz AMA Apprenticeship Programme FlyerDokumen8 halamanMercedes-Benz AMA Apprenticeship Programme FlyercarbasemyBelum ada peringkat

- Amine Modeling For CO2 Capture: Internals SelectionDokumen7 halamanAmine Modeling For CO2 Capture: Internals SelectionGopi Kiran NBelum ada peringkat

- Administrative Manager Job DescriptionDokumen8 halamanAdministrative Manager Job DescriptionadministrativemanageBelum ada peringkat

- SQL OutputDokumen3 halamanSQL Outputrameshg2020Belum ada peringkat

- ANS-ceramic Twin Disc Gate ValveDokumen4 halamanANS-ceramic Twin Disc Gate ValveheviBelum ada peringkat

- Fall 2016Dokumen164 halamanFall 2016baoHVLAB100% (1)

- Crisc GovernanceDokumen21 halamanCrisc Governancemahendrasing2Belum ada peringkat

- Design For Six Sigma & Robust Design of Products and Processes For QualityDokumen36 halamanDesign For Six Sigma & Robust Design of Products and Processes For Qualityshankarbt83100% (1)

- HobbsDokumen41 halamanHobbsganeshanBelum ada peringkat

- 5 The Engineering and Construction Short ContractDokumen8 halaman5 The Engineering and Construction Short ContractMI MIKATIBelum ada peringkat

- Anil Ojha, 20202, GN, 15 YrsDokumen2 halamanAnil Ojha, 20202, GN, 15 Yrspeter samuelBelum ada peringkat

- Value Chain ManagementDokumen6 halamanValue Chain ManagementJohn Munene KarokiBelum ada peringkat

- Narasayya Resume PDFDokumen4 halamanNarasayya Resume PDFMilan GuptaBelum ada peringkat

- Drag Reduction Through Higher Wing Loading (Kohlman D.L. 1975)Dokumen13 halamanDrag Reduction Through Higher Wing Loading (Kohlman D.L. 1975)Demyan DemyanskyBelum ada peringkat

- My SQL (Basic)Dokumen52 halamanMy SQL (Basic)Zain Chaudhry100% (1)

- A565A565M-10 Standard Specification For Martensitic Stainless Steel Bars For High - Temperature ServiceDokumen4 halamanA565A565M-10 Standard Specification For Martensitic Stainless Steel Bars For High - Temperature Servicetjt47790% (1)

- Oracle Asm Emc TF-SRDF 02-06-0Dokumen22 halamanOracle Asm Emc TF-SRDF 02-06-0Saeed MeethalBelum ada peringkat

- Icc Tower VT Dated 180614Dokumen14 halamanIcc Tower VT Dated 180614PERVEZ AHMAD KHANBelum ada peringkat

- Yokogawa RecorderuR1000 43xxx Im D101Dokumen129 halamanYokogawa RecorderuR1000 43xxx Im D101TaufikBelum ada peringkat

- StatisticsDokumen12 halamanStatisticsmanjinderchabbaBelum ada peringkat