9 - Chapter 5-MCE PDF

Diunggah oleh

samuel_y_puntoDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

9 - Chapter 5-MCE PDF

Diunggah oleh

samuel_y_puntoHak Cipta:

Format Tersedia

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-1

CHAPTER 5: MCE

TESTING QUICK START

MCE testing may be started by selecting either the Test Selection or the MCE Auto

icons on the toolbar.

Selecting the MCE Auto icon automatically runs the Standard Test followed by the

Polarization Index test. It uses the existing testing setup values. MCE Auto is discussed in

detail on page 5-7.

Selecting the Test Selection icon allows you to verify and/or change the testing setup

values and select which test you want to run. Test Selection is discussed in detail on page

5-3.

1. Start MCEGold.

2. On the Site Navigator or WatchList highlight the asset to be tested.

3. Select the Test Selection icon on the tool bar to open the Test Selection window.

4. In the Test Selection window the default is set to MCE testing. For EMAX testing click

the EMAX tab at the top and see Chapters 6 & 7. The asset section tabs along the left

side will vary depending on the type of asset being tested. Nameplate Information is

automatically filled in by MCEGold from the nameplate data.

5. Select the asset section tab along the left side corresponding to the section to be

tested.

6. Select the test to be performed from the list of tests. The available selections are

driven by the type of asset and the asset section selected for testing. The Notes section

provides instructions that are relevant for the selected test.

7. Select the asset test location by using the drop-down list or using the search button to

open the Test Location Selection window.

8. Select the Test Frequency from the drop-down list. The Test Frequency default is

driven by the type of asset selected for testing.

9. Select the Resistance-to-Ground by entering in the Mohms if they are different from

the default. Check the Low Limit check box if you want the unit to shut down

automatically upon measuring a specified low resistance to ground value.

10. Select the Voltage from the drop-down list box. The choices are: 250, 500, 1000,

2500, and 5000.

11. Set the asset Temperature if different from the default value of 40.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-2 2008 PdMA Corporation REV. 0-04/08

12. Select the charge time from the drop-down list box. The choices are in 15 second

increments, beginning at 15 and ending at 600 seconds.

13. Click Save to save the MCE Test Setup values selected for this particular asset or

click Reset to restore the original values. Note: Original values may only be reset if

new values have not been saved. If you have clicked the Save button it will be

necessary to manually change them back to the originals and save them.

14. Click Test to go the test window.

15. Click Test on the Test window. From this point the process will differ depending on

the test being performed. Each test is covered in detail later in this chapter.

INTRODUCTION

The MCE tester measures natural characteristics of a deenergized asset and its circuit to

determine its condition. These characteristics are resistance-to-ground, capacitance-to-

ground, winding resistance, and winding inductance. MCE testing can identify faults in

the power circuit, insulation, stator, rotor, and the air gap between the rotor and stator.

The tests that can be run on a asset vary, depending on the asset type. For AC assets

(Induction, Synchronous, and Wound Rotor) the tests are AC Standard Test, Polarization

Index (PI) which includes a Dielectric Absorption Ratio, Rotor Influence Check (RIC),

and Step Voltage. For DC assets the tests are DC Standard Test, Polarization Index (PI)

which includes a Dielectric Absorption Ratio, Bar-to-Bar (Armature Circuit only), and

Step Voltage.

Both AC and DC assets have an MCE Auto test which runs the Standard test followed by

the Polarization Index test, automatically saves the test results, and displays the Fault

Zone Report at the end of testing.

The frequency and type of asset testing you perform is based on your experience with the

tester, the condition of each individual asset, and the criticality/application of each asset.

Since it may be impossible to test each and every asset in your facility, ask yourself the

following questions when deciding which assets to test.

Is the asset easily replaceable and if so, is a replacement readily available?

Would buying a new asset cost less than repairing the old asset?

Is the asset redundant or non-critical?

If you answered yes to all three of these questions, you may not want to consider this asset

for your monitoring program.

If you are unfamiliar with an asset, review its maintenance history of test results,

problems, and repairs before testing it. Talk with the operators who run it and anyone who

may have information about its repair history. This will give you a more complete picture

of the condition of the asset.

MCE test results give you a comprehensive picture of the electrical condition of the asset.

MCE results can be utilized, along with results obtained from other technologies, to get a

complete picture of the health of the asset. Some examples of other technologies include

vibration, oil analysis, and infrared thermography.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-3

Some of the MCE tests give you enough information to call an asset good or bad, based on

results from one test. Other MCE tests give you data which is best used for trending and

comparison.

Trending means comparing sequential test results for the same asset over time. This tracks

what the particular asset is doing, how it is holding up, when it may need to be cleaned,

when it needs more detailed maintenance, or when a fault develops.

Test frequency depends on the assets criticality and the condition of the asset when it is

first tested. As the asset ages, you may decide to test it more frequently to better track its

condition.

When you first start testing with the MCE, the initial test is automatically designated as

the baseline test. After maintenance is performed on an asset and it is returned to optimal

condition, measure subsequent tests against that condition by designating the first test

after the maintenance as the new baseline.

Comparison means comparing individual test results on one asset with test results from an

identical asset operating in a similar environment. By identical asset we mean the same

manufacturer, voltage and horsepower rating, cable length for MCC, etc. For example, if

there are four like assets operating side by side performing the same task, all running at

approximately the same load, each running about the same amount of time, the test data

should be very close for all of them. If all four assets are tested, and three are basically the

same, but the fourth is very different from the other three, look for potential problems with

the fourth asset.

MCE testing is performed on a deenergized asset. However, there may be energized

circuitry in the same cabinet in which you connect the tester.

FOLLOW ALL ELECTRICAL SAFETY PRECAUTIONS AND PROCEDURES

FOR WORKING IN THE VICINITY OF ENERGIZED EQUIPMENT. READ THE

ELECTRICAL SAFETY PRECAUTIONS IN CHAPTER ONE BEFORE

PERFORMING ANY TESTS.

For AC assets, test lead colors of black, blue, and red connect to phases 1, 2, and 3 (left to

right, top to bottom); green connects to ground. For DC assets, test lead colors of black

and blue connect to F1/A1 and F2/A2; the red lead is not used; green connects to ground.

The DC Bar-to-Bar pistol grip or pencil probe test leads connect to commutator bars.

Some asset circuits may have surge capacitors and/or power factor correction capacitors

installed. It is important to know about them since these components affect the values of

the collected data and increase the time and number of steps involved in troubleshooting.

Testing can be performed with the power or surge capacitors installed, however, surge

capacitors must be removed for the accurate measurement of the assets insulation

resistance-to-ground. If an asset appears faulty with the power factor capacitors installed,

disconnect them and perform the testing again to isolate the fault.

TEST SELECTION WINDOW

In this chapter, the MCE aspects of asset testing are discussed. EMAX testing is discussed

in the Power and Current Analysis chapters. The Test Selection window discussion is

followed by the Step-by-step testing procedures, Test Data Analysis on page 5-53, and

finally MCE Analysis on page 5-74.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-4 2008 PdMA Corporation REV. 0-04/08

Note: Selecting the MCE Auto test icon on the tool bar bypasses the Test Selection

window and automatically runs the Standard Test followed by the Polarization Index test

using either the default or previously saved test settings, at the end of testing the test

results are saved, and the Fault Zone Report opens.

To open the Test Selection Window click the Test Selection icon on the tool bar.

The Test Selection window is shown in Figure 5-1. The asset name is located on the title

bar to the right of the window name. The Test Selection window is used for both MCE and

EMAX testing by selecting the desired test type tab.

The asset section tabs are found along the left side of the test selection area and are

dependent on the asset type. Possible sections are Armature Circuit, Field Circuit, Resistor

Bank, Rotor, and Stator.

For AC Induction assets, the only option is Stator.

For AC Synchronous assets, options are Field Circuit and Stator.

For Wound Rotor assets, options are Stator, Rotor, and Resistor Bank.

For DC assets, options are Armature and Field Circuit.

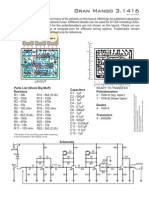

Figure 5-1: Test Selection Window

Test List

The top left section of the window contains a list of test selections for either MCE or

EMAX, depending on asset type, test type and asset section tabs selected. The test lists

section displays the various tests which may be performed based on the asset type and

asset section chosen. When a test is selected, the name of the test is highlighted blue and

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-5

the test set up area changes to values appropriate for the test selected. The test list

possibilities for MCE testing are:

MCE Auto

Standard (AC asset)

Standard (DC asset)

Polarization Index

Rotor Influence Check (RIC)

Step Voltage

Synchronous (Synchronous, Field section)

Resistor Bank (Wound Rotor, Resistor Bank section)

Commutator Bar-to-Bar (DC asset)

Asset Information

Asset Information is located on the right side. This area displays the Condition Code and

nameplate information of the asset being tested. The information comes from the

nameplate data that was entered when the asset was set up and cannot be edited on this

window. Information displayed, depending on asset type, may include: Type, Frame #, NP

Frequency, Voltage, FLA, HP, PF, Eff, Speed, Slots, and Bars. Also, Field Volts and Field

Current are listed for DC assets.

MCE Test Setup

The lower half of the Test Selection window is devoted to test set-up selections. The set-

up options depend on the asset type and test selected.

Asset Test Location

The Asset Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse button .

The Test Location Selection window opens displaying a test location graph for the type of

asset selected. See Figure 5-2. Use the graph to determine the location, then click the

down arrow in the Test Location text box, select the location from the list, and click OK.

Figure 5-2: AC Asset Test Location

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-6 2008 PdMA Corporation REV. 0-04/08

Test Frequency

Test Frequency is selected from a drop-down box. Click the down arrow and select from

the list to change the frequency. The choices are 300 or 1200 Hz depending on the section

being tested. Test Frequency is not available for the resistor bank section of a wound rotor

asset.

Resistance-to-Ground

Resistance-to-Ground provides the option to check (turn on) the Low Limit Shut Off and

enter a shut off voltage.

Voltage

Voltage is selected from a drop-down list. Click the down arrow and select from the list to

change the voltage. The voltage choices are from 250, 500, 1,000, 2,500, and 5,000.

Select a voltage of 500 or 1000 volts, based on the assets voltage. EASA (Electrical

Apparatus Service Association), in their booklet How to Get the Most From Your Electric

Motors, suggests 500 volts for assets rated <2400 volts and 1000 volts for assets rated at

>2400 volts.

Asset Temperature

The default value is 40 C. The value may be changed by typing in a new value.

Span

Span selection is only available for Bar-to-Bar testing of the armature section of DC

assets.

Charge Time

Charge time is available for the Standard test of an AC Induction, Wound Rotor,

Synchronous, and DC assets. The default value is 60 seconds. To change the charge time,

click the down arrow and select from the list of between 15 and 600 seconds.

Test Button

Click Test to advance to the test window.

Save Button

Click Save when the test set-up selections are complete. This saves the settings as default

values for that asset for subsequent tests, but is not required. If you forget to save and click

Test, you will be asked if you want to save your changes.

Reset Button

Click Reset to set values back to the pre-changed value. Note: If you have clicked the

Save button they will not reset and it will be necessary to manually change them back.

Cancel Button

Click Cancel to close the Test Selection window without saving setup changes or

proceeding to the test window. You will be asked if you want to save test setup settings.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-7

TEST WINDOW

Once the asset section and setup parameters are selected, you are ready to run the test.

This section explains each test by asset type and asset section. The test window is

discussed followed by step-by-step testing procedures. Test analysis information begins

on page 5-53.

AC Induction Assets

The MCE tests for an AC Induction asset are MCE Auto, AC Standard, Polarization

Index, RIC, and Step Voltage. They are discussed in detail in this section.

Note: To minimize the influence of stored energy on test results, perform the tests in the

following order. If a test is not to be performed, skip to the next test.

Rotor Influence Check (RIC)

Standard Test

Polarization Index (PI)/Dielectric Absorption (DA) If a PI is performed, it is not

necessary to perform a separate DA.

Some circuits may have surge capacitors and power factor correction capacitors installed.

This is important since these components affect the values of the collected data and

increase the time and number of steps involved in troubleshooting. Testing can be

performed with the power factor capacitors installed. However, a test should be taken with

surge capacitors removed for future comparison. If an asset appears faulty with the power

factor capacitors installed, disconnect them and perform the testing again to isolate the

fault.

MCE Auto Test

MCE Auto test performs a standard test followed by a Polarization Index test, then saves

the data and produces a Fault Zone Report.

MCE Auto test can be started by clicking the MCE Auto icon on the toolbar or

selecting MCE Auto from the test list in the Test Selection Window. If you select the MCE

Auto icon, the MCE Auto test window opens bypassing the Test Selection window.

If you need to change the test setup settings, select the Test Selection icon . The Test

Selection window opens, make your changes, and then select MCE Auto from the test list

and click Test. The MCE Auto Test window, Figure 5-3, opens. The MCE Auto Test

window menu consist of three options: File, View, and Options.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-8 2008 PdMA Corporation REV. 0-04/08

Figure 5-3: MCE Auto Test Window

File Menu

Save. Save (Ctrl+S) is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the MCE Auto Test and Test Selection windows and returns

you to the Home window.

View Menu

Create Message . Create Message

opens the Compose Asset Message

window (Figure 5-4). Messages created

here are viewed in the Message Center.

For more information on the Message

Center, see Chapter 3, page 3-41.

Figure 5-4: Compose Asset Message Window

Options Menu

Set Condition Code. Change the condition

code, by s el ect i ng t he opt i on but t on

corresponding to the condition (Figure 5-5). The

Asset Condition box on the MCE Auto Test

window changes and a note is automatically

generated by the software. The note is viewed in

the Message Center. For more information on

the Message Center, see Chapter 3, page 3-43.

Figure 5-5: Set Condition Code Window

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-9

Test Button

To begin testing click Test. During testing the menu items are dimmed (not available) and

the Test button changes to Stop. The test takes approximately 11 minutes.

The tester automatically proceeds from the Standard test to the Polarization Index (PI)

test. A status bar displays the testing progress. During the Standard test there is one Total

Test Progress bar. When the PI test is performed there is a PI progress bar, a Total Progress

bar, and a graph in the lower left displaying the test results. See Figure 5-6.

Figure 5-6: MCE Auto Test Window - PI Test

At the end of the PI test, the test results are automatically saved and the Fault Zone Report

is generated and displayed. See Figure 5-7.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-10 2008 PdMA Corporation REV. 0-04/08

Figure 5-7: MCE Auto Test Fault Zone Report

Fault Zone Report

File Menu

Print Preview. Print Preview, shown in Figure 5-8, displays the Fault Zone Report as it

will be printed. Using the File menu on the Print Preview window, you can export the

report to PDF or HTML or add comments before printing.

To create a PDF file, select File, Export to PDF, select the location you wish to save

the file in, enter a file name, and click Save.

To create a HTML file, select File, Export to HTML, select the location you wish to

save the file in, enter a file name and click Save.

To add comments, select File, Add Comments. In the Add Remarks window type your

comments and click Add. The comments appear in the Comments section at the

bottom of the report. They will appear on the printed report, but are not saved for the

future. Permanent comments should be entered in the Message Center using Edit,

Create Message, which is discussed on page 5-11.

To print the report click the Print icon on the Print Preview toolbar.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-11

Figure 5-8: Print Preview

Print. Print prints the report to your default printer.

Exit (Ctrl+Q). Exit the report by using File, Exit (Ctrl+Q) or clicking the Close button

(red X in the upper right corner).

Edit Menu

Create Message (Ctrl+M). You may enter permanent notes by selecting Create

Message (Ctrl+M). This opens the Compose Asset Message window shown in Figure 5-4

on page 5-8. The note is viewed from the Message Center. See the section on Message

Center in Chapter 3, page 3-41.

Options Menu

Refresh (Ctrl+R). The Refresh function is used to update the Fault Zone Report when

changes have been made to the warning settings.

Set Condition Code. Change the condition code, by selecting an option button, the

Condition Code box changes, and a note is automatically generated by the software. The

note is viewed from the Message Center. See the section on Message Center, in Chapter 3,

page 3-43.

Description/Recommendation

The blank area at the bottom of the report is designed to provide additional information,

such as descriptions of the Fault Zones and Test Types or recommended actions for the

Condition Code. It is for on screen viewing only and does not appear on the printed report.

To view a description of the Fault Zone or Test Type, click on the name in the Fault Zone

report. The description will appear in the text box at the bottom of the window.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-12 2008 PdMA Corporation REV. 0-04/08

To view the recommended course of action for a condition code, click the condition

code name. The recommended course of action will appear in the text box at the bottom of

the window. Figure 5-7 shows how the window would appear if severe condition code of

the power circuit was selected.

To View Test History

To open the Test History click on the test type result value or the date. The Test History

window opens.

AC Standard Test

The AC Standard test is reach by selecting AC Standard from the test list on the Test

Selection window. See page 5-3, Test Selection Window for more information. Verify that

the test set-up settings are correct and click Test. The AC Standard Test Window (Figure

5-9) opens.

Figure 5-9: AC Standard Test Window

The AC Standard Test window menu consist of three options: File, View, and Options.

File Menu

Save. Save (Ctrl+S) is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the AC Standard test window and returns you to the MCEGold

Home window.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-13

View Menu

Create Message. Creat e Message

opens the Compose Asset Message

wi ndow (Fi gure 5-10). Messages

created here are viewed in the Message

Center. For more information on the

Message Center, see Chapter 3, page 3-

41.

Figure 5-10: Compose Asset Message Window

Options Menu

Set Condition Code. Change the condition

code, by selecting an option button (Figure 5-

11). The Asset Condi t i on box on t he AC

Standard Test window changes and a note is

automatically generated by the software. The

note is viewed in the Message Center. For more

information on the Message Center, see Chapter

3, page 3-43

Figure 5-11: Options, Set Condition Code Menu

Step-by-Step AC Standard Testing

1. Deenergize and lock out the starter and the asset.

2. Check for low level induced voltages using a Fluke multimeter or equivalent.

Verify that the values do not exceed 0.5 VAC phase-to-phase and 15 VAC phase-to-

ground. Check for low level stored voltage by verifying less than 15 VDC phase-to-

ground.

3. Connect the MCE to the circuit, in the same manner each time, as referenced in Table

5-1. This ensures that the test data is trendable/repeatable.

Table 5-1: Test Lead Connections

4. Highlight the asset to be tested on the Site Navigator.

MCE t es t

leads

Black White Red Green

motor phase A B C gnd

T lead T1 T2 T3 gnd

vertical top mid bot gnd

horizontal left mid right gnd

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-14 2008 PdMA Corporation REV. 0-04/08

5. Select the Test Selection icon on the toolbar. The Test Selection window opens,

Figure 5-12.

Figure 5-12: Test Selection Window

6. Verify that the MCE (Test Type) and Stator (Asset Section) tabs are selected. The type

of asset determines which asset sections are available.

7. Click AC Standard from the Test List.

If all of the settings in the MCE Test Setup are correct, click Test to go directly to the

test. Go to step 16.

8. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-15

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-13.

Figure 5-13: Asset Test Location

9. Verify the Test Frequency.

Click the down arrow and select the frequency from the drop-down list. The values

are 300 or 1200.

10. Verify the Low Limit Shut Off condition.

Check the box to activate the low limit shut off and enter the desired Mohms.

11. Verify the Voltage.

Click the down arrow and select the voltage from the drop-down list. Select test

voltage based on asset nameplate voltage.

12. Enter the temperature.

Adjust the Temperature C to stator core temperature at the time of testing.

13. Select the Charge Time Seconds.

Click the down arrow and select the seconds from the drop-down list. The choices are

from 30 to 180 seconds at 15 second increments.

14. Click Save to save the settings for this asset for future testing. Or click Reset to return

the original settings. This can only be done if the new settings have not been saved.

15. Click Test to go to the testing window.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-16 2008 PdMA Corporation REV. 0-04/08

16. Click Test in the AC Standard Test Window.

17. Verify that you are about to apply X volts to the circuit by clicking Yes.

18. Testing begins, progress bars are displayed for Total Test Progress and Discharge

Progress at various times. The test values are filled in as testing proceeds. At the end

of testing Test Completed appears above the Nameplate Information area. See Figure

5-14.

To stop the test at any time, click Stop. Click Exit to close the AC Standard test

window and return to the Home window.

19. Click OK when the test is complete.

20. Re-test any individual point, if needed. If not go to step 21.

If any portion of the test needs to be re-tested, double click the tab which appears to

the right of the individual test point. This rechecks only that test point in manual

mode. See Figure 5-14.

Figure 5-14: AC Standard Test Window

21. When retesting is complete or if no re-testing is needed, click Save or select File,

Exit, or Ctrl+X, or use the close button (X in the upper right corner).

22. Click OK in the Save Complete window.

23. Click Exit in the AC Standard Test Window.

Polarization Index

The Polarization Index (PI) test is reached by selecting Polarization Index from the test list

on the Test Selection window. See page 5-3, Test Selection Window for more information.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-17

Verify that the test set-up settings are correct and click Test. The PI test window opens.

See Figure 5-15.

Figure 5-15: PI Test Window

File Menu

Save. Save (Ctrl+S) is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the PI Test window and returns you to the Home window.

Options Menu

Set Condition Code. Change the condition

code, by s el ect i ng t he opt i on but t on

corresponding to the condition (Figure 5-16).

The Asset Condition box on the PI Test window

changes and a note is automatically generated by

the software. The note is viewed in the Message

Center. For more information on the Message

Center, see Chapter 3, page 3-41.

Figure 5-16: Set Condition Code Window

Step-by-Step Polarization Index Testing

The PI test takes ten minutes. During the test the menu items are dimmed (not available)

and the Test button changes to Stop.

1. Deenergize and lock out the starter and the asset.

2. Check for low level induced voltages using a Fluke multimeter or equivalent.

Verify that the values do not exceed 0.5 VAC phase-to-phase and 15 VAC phase-to-

ground. Check for low level stored voltage by verifying less than 15 VDC phase-to-

ground.

3. Connect the MCE to the circuit, in the same manner each time, as referenced in Table

5-2. This ensures that the test data is trendable/repeatable.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-18 2008 PdMA Corporation REV. 0-04/08

Table 5-2: : Test Lead Connections

4. Highlight the asset to be tested in the Site Navigator.

5. Select the Test Selection icon on the toolbar. The Test Selection window opens,

Figure 5-17.

Figure 5-17: Test Selection Window

6. Verify that the MCE (Test Type) and Stator (Asset Section) tabs are selected. The type

of asset determines which asset sections are available.

7. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

MCE t es t

leads

Black White Red Green

motor phase A B C gnd

T lead T1 T2 T3 gnd

vertical top mid bot gnd

horizontal left mid right gnd

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-19

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-18.

Figure 5-18: Asset Test Location

8. Verify the Low Limit Shut Off condition.

Check the box to activate the low limit shut off and enter the desired Mohms.

9. Verify the Voltage.

Click the down arrow and select the voltage from the drop-down list. Select the test

voltage based on asset nameplate voltage.

10. Click Save to save the settings for this asset for future testing. Or click Reset to return

the original settings. This can only be done if the new settings have not been saved.

11. Click Test to go to the testing window.

12. Click Test in the PI Test window.

13. Verify that you are about to apply X volts to the circuit by clicking Yes.

14. As the test proceeds, the test result values are displayed in the table and plotted on the

graph. At the end of one minute the D/A ratio is computed and displayed in the D/A

Ratio text box. The progress bar displays the progress of the testing.

Note: To stop the test, click Stop.

15. Click OK in the Test Completed window. The menu item become active and the Stop

button is inactive.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-20 2008 PdMA Corporation REV. 0-04/08

16. Exit the PI Test window by selecting File, Exit, or Ctrl+X, or the close button (Red X

in the upper right corner).

17. You will be asked if you want to save test data. Click Yes or No.

If you select Yes, click OK in the Save Completed widow. The PI Test window closes

If you select No, the PI Test window closes. No test data is saved.

RIC

The RIC test is reached by selecting RIC from the test list on the Test Selection window.

See page 5-3, Test Selection Window for more information. Verify that the test set-up

settings are correct and click Test. The RIC test window opens. See Figure 5-19.

Figure 5-19: RIC Test Window

File Menu

Save. Save (Ctrl+S) is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the RIC Test window and returns you to the Home window.

View Menu

Create Message . Cr eat e Mes s age

opens the Compose Asset Message

window (Figure 5-20). Messages created

here are viewed in the Message Center.

For more information on the Message

Center, see Chapter 3, page 3-41.

Figure 5-20: Compose Asset Message Window

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-21

Options Menu

Set Condition Code. Change the condition

code, by s el ect i ng t he opt i on but t on

corresponding to the condition (Figure 5-21).

The Asset Condition box on the RIC Test

window changes and a note is automatically

generated by the software. The note is viewed in

the Message Center. For more information on

the Message Center, see Chapter 3, page 3-41.

Figure 5-21: Set Condition Code Window

Step-by-Step RIC Testing

During the test the menu items are dimmed (not available). To stop testing, use File, Exit

which becomes active after each test point.

1. Deenergize and lock out the starter, disconnect, and the asset. Follow your companys

electrical safety procedures for tagouts.

2. Check for low level induced voltages using a Fluke multimeter or equivalent.

Verify that the voltage does not exceed 0.5 VAC phase-to-phase and 15 VAC phase-

to-ground. Check for low level stored voltage by verifying less than 15 VDC phase-

to-ground.

3. Place the shaft key way in the up position. This ensures a common starting point for

all subsequent tests.

4. Ensure that the field is disconnected from the control circuit.

This is accomplished by isolating/removing the brushes from the slip rings or by

disconnecting the field leads from the diode pack in a self-exited asset. This allows

the natural magnetic field on the rotor to expand, enhancing the detection of rotor

problems.

5. Connect the MCE test leads to the circuit/asset, in the same manner each time, as

referenced in Table 5-3. This ensures that the test data is trendable/repeatable.

Table 5-3: Test Lead Connections

6. Highlight the asset to be tested in the Site Navigator.

MCE t es t

leads

Black White Red Green

motor phase A B C gnd

T lead T1 T2 T3 gnd

vertical top mid bot gnd

horizontal left mid right gnd

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-22 2008 PdMA Corporation REV. 0-04/08

7. Select the Test Selection icon on the toolbar. The Test Selection window opens,

Figure 5-22.

Figure 5-22: Test Selection Window

8. Verify that the MCE (Test Type) and Stator (Asset Section) tabs are selected. The type

of asset determines which asset section is available.

9. Select RIC from the Test List box.

10. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-23

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-23.

Figure 5-23: Test Locations

11. Click Save to save the settings for this asset for future testing. Or click Reset to return

the original settings. This can only be done if the new settings have not been saved.

12. Click Test to go to the test. The RIC test window, Figure 5-24, opens.

Figure 5-24: RIC Test Window

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-24 2008 PdMA Corporation REV. 0-04/08

13. Verify that increments to be used during testing are correct. This information is

located at the top of the RIC Test window.

To change the Increments, which automatically computes the appropriate Degrees,

click the down arrow and select the increment from the drop-down list.

The new increments are displayed and the degrees on the test data table is updated.

14. Position the rotor to the first position and click Test to begin testing.

15. At the end of each test point, you will be reminded

to position the rotor for the next test point. Move the

rotor and click Test. Repeat until the end of the

recommended test.

As the test progresses, the values will be inserted into the table and displayed in the

graph areas. The magnification of the graphs can be changed by using the down

arrows below each graph area and selecting a new value from the drop down list. The

default is Full.

16. At the end of the recommended test you will be asked if you

want to continue. Select Yes to continue testing or No to end

testing.

17. Exit the RIC Test window by selecting File, Exit, or Ctrl+X, or

the close button (X in the upper right corner).

18. You will be asked if you want to save test data. Click Yes or No.

If you select Yes, click OK in the Save Completed widow. The

RIC Test window closes.

If you select No, the RIC Test window closes. No test data is

saved.

Step Voltage

The Step Voltage test is reached by selecting Step Voltage from the test list on the Test

Selection window. See page 5-3, Test Selection Window for more information. Verify that

the test set-up settings are correct and click Test. The Step Voltage Test window opens.

Figure 5-25.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-25

Figure 5-25: Step Voltage Test

File Menu

Save. Save Data is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the Step Voltage window and returns you to the Home window.

View Menu

Create Message. Cr eat e Mes s age

(Ct rl +S) opens t he Compose Asset

Mes s age wi ndow ( Fi gur e 5- 26) .

Messages created here are viewed in the

Message Center. For more information

on the Message Center, see Chapter 3,

page 3-41.

Figure 5-26: Compose Asset Message

Graph Option Menu

Show Current/Voltage. Show Current/Voltage controls the graph display area. If just

Current/Voltage is selected one graph displays on the window. If Show Current/Voltage

and Show Current/Time are both selected then two graphs will display.

Show Current/Time. Show Current/Time controls the graph display area. If just

Current/Time is selected one graph displays on the window. If Show Current/Time and

Show Current/Voltage are both selected then two graphs will display.

Overlay Graphs. Overlay Graphs controls the graph display area. When Overlay

Graphs is selected test results are graphed on one graph.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-26 2008 PdMA Corporation REV. 0-04/08

Line Style. Line Style controls the appearance

of the line on the graph.

Show Patterns changes the graph line style from

a solid to a pattern. When a change is made to

the line style it is reflected in the Legend area of

the window, which is located just above the

Nameplate Information.

Show Markers inserts markers on the graph line. When a change is made to the line style it

is reflected in the Legend area of the window, which is located just above the Nameplate

Information.

Options Menu

Set Condition Code. Change the condition

code, by selecting an option button (Figure 5-

27). The Asset Condition box on the Step

Voltage Test window changes and a note is

automatically generated by the software. The

note is viewed in the Message Center. For more

information on the Message Center, see Chapter

3, page 3-41.

Figure 5-27: Set Condition Code Window

Step-by-Step Step Voltage Testing

During the test the menu items are dimmed (not available).

1. Deenergize and lock out the starter, disconnect, and the asset. Follow your companys

electrical safety procedures for tagouts.

2. Check for low level induced voltages using a Fluke multimeter or equivalent.

Verify that the voltage does not exceed 0.5 VAC phase-to-phase and 15 VAC phase-

to-ground. Check for low level stored voltage by verifying less than 15 VDC phase-

to-ground.

3. Connect the MCE test leads to the circuit/asset, in the same manner each time, as

referenced in Table 5-4. This ensures that the test data is trendable/repeatable.

Table 5-4: Test Lead Connections

4. Highlight the asset to be tested in the Site Navigator.

MCE t es t

leads

Black White Red Green

motor phase A B C gnd

T lead T1 T2 T3 gnd

vertical top mid bot gnd

horizontal left mid right gnd

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-27

5. Select the Test Selection icon on the toolbar. The Test Selection window opens,

Figure 5-28.

Figure 5-28: Test Selection Window

6. Verify that the MCE (Test Type) and Stator (Asset Section) tabs are selected. The type

of asset determines which asset sections are available.

7. Select Step Voltage from the Test List box.

8. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-29.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-28 2008 PdMA Corporation REV. 0-04/08

Figure 5-29: Test Locations

9. Verify the Low Limit Shut Off condition.

Check the box to activate the low limit shut off and enter the desired Mohms.

10. Click Save to save the settings for this asset for future testing. Or click Reset to return

the original settings. This can only be done if the new settings have not been saved.

11. Click Test to go to the Step Voltage test window. See Figure 5-30.

Figure 5-30: Step Voltage Test Window

12. To begin the test click Test.

13. Verify that you are about to apply X volts to the circuit by clicking Yes.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-29

14. Test values are entered in the table on the left and are displayed in graph format on the

right side of the window. The magnification of the graphs can be changed by using

the down arrows below each graph area and selecting a new value from the drop

down list. The default is Full. A progress bar at the bottom of the screen tracks the

testing progress.

Note: During the test the Test button changes to Stop, which allows you to interrupt

the testing.

15. At the end of testing click OK in the Test Completed window.

16. Exit the Step Voltage Window by selecting File, Exit, or Ctrl+X, or

the close button (X in the upper right corner).

17. You will be asked if you want to save test data. Click Yes or No.

If you select Yes, click OK in the Save Completed widow. The

Step Voltage Test window closes.

If you select No, the Step Voltage Test window closes. No test data

is saved.

AC Synchronous Assets

The MCE tests for an AC Synchronous asset are MCE Auto, AC Standard, Polarization

Index, RIC, and Step Voltage for the Stator section and MCE Auto, Synchronous,

Polarization Index, and Step Voltage for the Field section.

Note: To minimize the influence of stored energy on test results, perform the tests in the

following order. If a test is not to be performed, skip to the next test.

Rotor Influence Check (RIC)

Standard Test

Polarization Index (PI)/ Dielectric Absorption (DA). If a PI is performed, it is not

necessary to perform a separate DA.

Synchronous assets are divided into two separate sections (Stator and Field Circuit). The

asset Section of the Test Selection window defaults to Stator.

Some asset circuits may have surge capacitors and/or power factor correction capacitors

installed. This is important since these components affect the values of the collected data,

and increase the time and number of steps involved in troubleshooting. Testing can be

performed with the power factor or surge capacitors installed. However, a test should be

taken with the surge capacitors removed for future comparison. If a asset appears faulty

with the power factor capacitors installed, disconnect them and perform the testing again

to isolate the fault.

Stator Section Test

MCE Auto

MCE Auto is the same as for an AC Induction asset. See MCE Auto on page 5-7.

AC Standard

AC Standard is the same as for an AC Induction asset. See AC Standard on page 5-12.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-30 2008 PdMA Corporation REV. 0-04/08

Polarization Index

Polarization Index test is the same as for an AC Induction asset. See Polarization Index on

page 5-16.

RIC

RIC test is the same as for an AC Induction asset. See RIC on page 5-20.

Step Voltage

Step Voltage test is the same as for an AC Induction asset. See Step Voltage on page 5-24.

Field Section Tests

MCE Auto

MCE Auto is the same as for an AC Induction asset. See MCE Auto on page 5-7.

Polarization Index

Polarization Index test is the same as for an AC Induction asset. See Polarization Index on

page 5-16.

Step Voltage

Step Voltage test is the same as for an AC Induction asset. See Step Voltage on page 5-24.

Synchronous

The Synchronous test is reached by selecting the Field Tab and Synchronous from the test

list on the Test Selection window. See page 5-3, Test Selection Window for more

information. Verify that the test set-up settings are correct and click Test. The

Synchronous Test window opens. Figure 5-31.

Figure 5-31: Synchronous Test Window

File Menu

Save. Save Data is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the Synchronous Test window and returns you to the Home

window.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-31

View Menu

Create Message. Cr eat e Mes s age

(Ctrl+S) opens the Compose Asset

Message window (Figure 5-32). The

note is viewed in the Message Center.

For more information on the Message

Center, see Chapter 3, page 3-43.

Figure 5-32: Compose Asset Message

Options Menu

Set Condition Code. Change the condition

code, by selecting an option button, the Asset

Condition box on the Synchronous Test window

changes and a note is automatically generated by

the software. The note is viewed in the Message

Center. For more information on the Message

Center, see Chapter 3, page 3-41.

Figure 5-33: Set Condition Code Window

Step-by-Step Synchronous Testing

During the test the menu items are dimmed (not available).

1. Deenergize and lock out the starter, disconnect, and the asset. Follow your companys

electrical safety procedures for tagouts.

2. Check for low level induced voltages using a Fluke multimeter or equivalent.

Verify that the voltage does not exceed 0.5 VAC phase-to-phase and 15 VAC phase-

to-ground. Check for low level stored voltage by verifying less than 15 VDC phase-

to-ground.

3. Connect the MCE test leads to the circuit/asset, in the same manner each time, as

referenced in Table 5-5. This ensures that the test data is trendable/repeatable.

Table 5-5: Test Lead Connections

4. Highlight the asset to be tested in the Site Navigator.

5. Select the Test Selection icon on the toolbar. The Test Selection window opens,

Figure 5-34.

MCE t es t

leads

Black White Red Green

motor phase A B C gnd

T lead T1 T2 T3 gnd

vertical top mid bot gnd

horizontal left mid right gnd

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-32 2008 PdMA Corporation REV. 0-04/08

Figure 5-34: Test Selection Window

6. Verify that the MCE (Test Type) and Field (Asset Section) tabs are selected. The type

of asset determines which asset sections are available.

7. Select Synchronous from the Test List box.

8. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-35.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-33

Figure 5-35: Test Locations

9. Verify the Test Frequency.

Click the down arrow and select the frequency from the drop-down list. The values

are 300 or 1200.

10. Verify the Low Limit Shut Off condition.

Check the box to activate the low limit shut off and enter the desired Mohms.

11. Verify the Voltage.

Click the down arrow and select the voltage from the drop-down list. Select test

voltage based on asset nameplate voltage.

12. Enter the temperature.

Adjust the Temperature C to stator core temperature at the time of testing.

13. Select the Charge Time Seconds.

Click the down arrow and select the seconds from the drop-down list. The choices are

from 30 to 180 seconds at 15 second increments.

14. Click Save to save the settings for this asset for future testing. Or click Reset to return

the original settings. This can only be done if the new settings have not been saved.

15. Click Test to go to the Synchronous test window.

16. Verify that you are about to apply X volts to the circuit and click Yes.

17. Testing begins, progress bars are displayed for Total Test Progress and Discharge

Progress at various times. The test values are filled in as testing proceeds.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-34 2008 PdMA Corporation REV. 0-04/08

18. At the end of testing the Test button changes to Save, Test Completed appears above

the Nameplate Information section, and the progress bars disappear.

19. Re-test any individual point, if needed. If not go to step 20.

If any portion of the test needs to be re-tested, click the tab which appears to the right

of the individual test point. This retests only that test point in manual mode. (Figure

5-36)

Figure 5-36: Completed Synchronous Test Window

20. When retesting is complete or if no re-testing is needed, click Save or File, Exit, or

Ctrl+X, or use the close button (X in the upper right corner).

21. Click OK in the Save Completed window.

22. Click Exit to close the window.

AC Wound Rotor Assets

Wound rotor assets (WRMs) are divided into three separate sections (Stator, Rotor, and

Resistor Bank). The asset Section box of the Test Selection window defaults to Stator.

The MCE tests for an AC Wound Rotor asset are MCE Auto, AC Standard, Polarization

Index, RIC, and Step Voltage for the Stator section. MCE Auto, AC Standard, Polarization

Index, and Step Voltage for the Rotor section. MCE Auto, Resistor Bank, Polarization

Index, and Step Voltage for the Resistor Bank section.

Note: To minimize the influence of stored energy on test results, perform the tests in the

following order. If a test is not to be performed, skip to the next test.

Rotor Influence Check (RIC)

Standard Test

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-35

Polarization Index (PI)/ Dielectric Absorption (DA). If a PI is performed, it is not

necessary to perform a separate DA.

Some circuits may have surge capacitors and power factor correction capacitors installed.

This is important since these components affect the values of the collected data, and

increase the time and number of steps involved in troubleshooting. Testing can be

performed with the power factor capacitors installed. However, surge capacitors must be

removed to ensure valid test data. If a asset appears faulty with the power factor capacitors

installed, disconnect them and perform the testing again to isolate the fault.

Stator Section Tests

MCE Auto

MCE Auto is the same as for an AC Induction asset. See MCE Auto on page 5-7.

AC Standard

AC Standard is the same as for an AC Induction asset. See AC Standard on page 5-12.

Polarization Index

Polarization Index test is the same as for an AC Induction asset. See Polarization Index on

page 5-16.

RIC

RIC test is the same as for an AC Induction asset. See RIC on page 5-20.

Step Voltage

Step Voltage test is the same as for an AC Induction asset. See Step Voltage on page 5- 24.

Rotor Section Tests

MCE Auto

MCE Auto is the same as for an AC Induction asset. See MCE Auto on page 5-7.

AC Standard

AC Standard is the same as for an AC Induction asset. See AC Standard on page 5-12.

Polarization Index

Polarization Index test is the same as for an AC Induction asset. See Polarization Index on

page 5-16.

Step Voltage

Step Voltage test is the same as for an AC Induction asset. See Step Voltage on page 5- 24.

Resistor Bank Section Tests

MCE Auto

MCE Auto is the same as for an AC Induction asset. See MCE Auto on page 5-7.

Polarization Index

Polarization Index test is the same as for an AC Induction asset. See Polarization Index on

page 5-16.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-36 2008 PdMA Corporation REV. 0-04/08

Step Voltage

Step Voltage test is the same as for an AC Induction asset. See Step Voltage on page 5-24.

Resistor Bank Test

The Resistor Bank test is reached by selecting the Resistor Bank tab and Resistor Bank

from the test list on the Test Selection window. See page 1-3, Test Selection Window for

more information. Verify that the test set-up settings are correct and click Test. The

Resistor Bank Test window opens. Figure 5-37.

Figure 5-37: Resistor Bank Test Window

File Menu

Save. Save Data is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the Resistor Bank Test window and returns you to the Home

window.

View Menu

Create Message. Cr eat e Mes s age

(Ctrl+S) opens the Compose Asset

Message window (Figure 5-38). The

note is viewed in the Message Center.

For more information on the Message

Center, see Chapter 3, page 3-41.

Figure 5-38: Compose Asset Message Window

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-37

Options Menu

Set Condition Code. Change the condition

code by selecting an option button (Figure 5-39).

The Asset Condition box on the Resistor Bank

Test window changes and a note is automatically

generated by the software.

Figure 5-39: Set Condition Code Window

Step-by-Step Resistor Bank Testing

1. Deenergize and lock out the starter, disconnect, and the asset. Follow your companys

electrical safety procedures for tagouts.

2. Check for low level induced voltages using a Fluke multimeter or equivalent.

Verify that the voltage does not exceed 0.5 VAC phase-to-phase and 15 VAC phase-

to-ground. Check for low level stored voltage by verifying less than 15 VDC phase-

to-ground.

3. Lift the brushes to isolate the resistor bank from the rotor field.

4. Connect the MCE test leads to the circuit/asset, in the same manner each time, as

referenced in Table 5-6. This ensures that the test data is trendable/repeatable.

Table 5-6: Test Lead Connections

5. Highlight the asset to be tested in the Site Navigator.

MCE

t es t

leads

Black White Red Green

brushes br ushes

over slip

ring 1

br us hes

over slip

ring 2

br ushes

over slip

ring 3

gnd

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-38 2008 PdMA Corporation REV. 0-04/08

6. Select the Test Selection icon on the toolbar. The Test Selection window opens,

Figure 5-40.

Figure 5-40: Test Selection Window

7. Verify that the MCE (Test Type) and Resistor Bank (Asset Section) tabs are selected.

The type of asset determines which asset sections are available.

8. Select Resistor Bank from the Test List box.

9. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-39

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-41.

Figure 5-41: Test Locations

10. Verify the Low Limit Shut Off condition.

Check the box to activate the low limit shut off and enter the desired Mohms.

11. Verify the Voltage.

Click the down arrow and select the voltage from the drop-down list. Select test

voltage based on asset nameplate voltage.

12. Enter the temperature.

Adjust the Temperature C to stator core temperature at the time of testing.

13. Click Save to save the settings for this asset for future testing. Or click Reset to return

the original settings. This can only be done if the new settings have not been saved.

14. Click Test to go to the Resistor Bank Test window.

15. To begin the Resistor Bank Test, click Test.

16. Verify that you are about to apply X volts to the circuit and click Yes.

17. Testing begins, progress bars are displayed for Total Test Progress and Discharge

Progress at various times. The test values are filled in as testing proceeds. At the end

of testing Test Completed appears above the Nameplate Information area.

18. Re-test any individual point, if needed. If not go to step 19.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-40 2008 PdMA Corporation REV. 0-04/08

If any portion of the test needs to be re-tested, click the green arrow to the right of the

point. This rechecks only that test point in manual mode. See Figure 5-42.

Figure 5-42: Resistor Bank Test Window - Retest Points

19. When retesting is complete or if no re-testing is needed, click Save, or File, Exit, or

Ctrl+X, or the close button (X in the upper right corner).

20. Click OK in the Save Completed window and the Resistor Bank Test window closes.

DC Assets

The MCE tests for a DC asset are MCE Auto, DC Standard, Polarization Index, Bar-to-

Bar, and Step Voltage for the Armature section. MCE Auto, DC Standard, Polarization

Index, and Step Voltage for the Field section.

Note: To minimize the influence of stored energy on test results, perform the tests in the

following order. If a test is not to be performed, skip to the next test.

Standard Test

Polarization Index (PI). If a PI is performed, it is not necessary to perform a separate

DA.

DC assets are divided into two separate sections (Armature Circuit and Field Circuit). The

Asset Section of the Test Selection window defaults to Armature Circuit.

Armature Section Tests

MCE Auto

MCE Auto is the same as for an AC Induction asset. See MCE Auto on page 5-7.

DC Standard Test

The DC Standard Test is reached by selecting DC Standard from the test list on the Test

Selection window. See page 5-3, Test Selection Window for more information. Verify that

the test set-up settings are correct and click Test. The DC Standard Test Window (Figure

5-43) opens.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-41

Figure 5-43: DC Standard Test Window

The DC Standard Test window menu consist of three options: File, View, and Options.

File Menu

Save. Save (Ctrl+S) is not active, it appears dimmed, until after testing is complete.

Exit. Exit (Ctrl+X) closes the AC Standard test window and returns you to the MCEGold

Home window.

View Menu

Create Message. Creat e Message

opens the Compose Asset Message

window (Figure 5-44). The note is

viewed in the Message Center. For

more information on the Message

Center, see Chapter 3, page 3-41.

Figure 5-44: Compose Asset Message Window

Options Menu

Set Condition Code. Change the condition

code by selecting an option button (Figure 5-45).

The Asset Condition box on the AC Standard

Test window changes and a note is automatically

generated by the software. The note is viewed in

the Message Center. For more information on

the Message Center, see Chapter 3, page 3-43

Figure 5-45: Options, Set Condition Code Menu

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-42 2008 PdMA Corporation REV. 0-04/08

Step-by-Step DC Standard Testing

1. Deenergize and lock out the starter and asset.

2. Check for low level induced voltage using a Fluke multimeter or equivalent.

Verify that the values do not exceed 0.5 VAC phase-to-phase and 15 VAC phase-to-

ground. Check for low level stored voltage by verifying less than 15 VDC phase-to-

ground.

3. Connect the MCE test leads to the circuit, in the same manner each time, as

referenced in Table 5-7 and shown in Figure 5-46. This ensures that the test data is

trendable/repeatable.

Table 5-7: Test Lead Connections

Figure 5-46: DC Asset Circuit Connections

4. Highlight the asset to be tested in the Site Navigator.

5. Select the Test Selection icon on the tool bar to open the Test Selection window.

6. Verify that Armature Circuit is selected in the asset Section box.

7. Select DC Standard Test in the Test List box.

8. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

MCE t es t

leads

Black White Green

motor leads A1;

A1 or S1

A2;

S2 or A2

ground

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-43

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-47.

Figure 5-47: DC Asset Test Location

9. Select Test frequency for the Armature Circuit from the drop-down box.

Click the down arrow and select the frequency from the drop-down list. The values

are 300 or 1200.

10. Check the Low Limit Shut Off box and enter Mohms.

11. Select the test voltage for the resistance to ground measurement (500 for < 2400 volts

or 1000 for >2400 volts) based on asset nameplate voltage.

Click the down arrow and select the voltage from the drop-down list.

12. Adjust the Temperature C to stator core temperature at the time of testing.

13. Select Charge Time seconds.

Click the down arrow and select the charge time from the drop-down list. The choices

are from 15 to 600 seconds.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-44 2008 PdMA Corporation REV. 0-04/08

14. Click Save, to save the settings for this asset for future testing. Or click Reset to

return the original settings. This can only be done if the new settings have not been

saved.

15. Click Test to go to the DC Standard Test Window.

16. Click Test to begin testing.

17. Verify that you are about to apply X volts to the circuit by clicking Yes.

18. Testing begins, progress bars are displayed for Total Test Progress and Discharge

Progress at various times. The test values are filled in as testing proceeds. At the end

of testing Test Completed appears above the Nameplate Information area. See Figure

5-48.

To stop the test at any time, click Stop. Click Exit to close the DC Standard test

window and return to the Home window.

19. Re-test any individual point, if needed. If not go to step 20.

If any portion of the test needs to be re-tested, double click the tab which appears to

the right of the individual test point. This rechecks only that test point in manual

mode. See Figure 5-48.

Figure 5-48: DC Standard Test Window

20. When retesting is complete or if no re-testing is needed, click Save or select File,

Exit, or Ctrl+X, or use the close button (X in the upper right corner).

21. Click OK in the Save Complete window.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-45

22. Click Exit in the DC Standard Test Window.

Step-by-Step Polarization Index Testing

1. Deenergize and lock out the starter asset.

2. Check for low level induced voltage using a Fluke multimeter or equivalent.

Verify that the values do not exceed 0.5 VAC phase-to-phase and 15 VAC phase-to-

ground. Check for low level stored voltage by verifying less than 15 VDC phase-to-

ground

3. Connect the MCE test leads to the circuit, in the same manner each time, as

referenced in Table 5-8 and shown in Figure 5-49. This ensures that the test data is

trendable/repeatable.

Table 5-8: Test Lead Connections

Figure 5-49: Asset Circuit Connections

4. Highlight the asset to be tested in the Site Navigator.

5. Select the Test Selection icon on the tool bar to open the Test Selection window.

6. Verify that Armature is selected.

7. Select Polarization Index in the Test List Box.

8. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

MCE t es t

leads

Black White Green

motor leads A1;

A1 or S1

A2;

S2 or A2

ground

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-46 2008 PdMA Corporation REV. 0-04/08

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-50.

Figure 5-50: DC Asset Test Location

9. Check the Low Limit Shut Off box and enter Mohms.

10. Enter the test voltage for the resistance to ground measurement (500 for < 2400 volts

or 1000 for >2400 volts) based on asset nameplate voltage.

Click the down arrow and select the voltage from the drop-down list.

11. Click Save, to save the settings for this asset for future testing. Or click Reset to

return the original settings. This can only be done if the new settings have not been

saved.

12. Click Test to go to the PI Test Window. See Figure 5-51.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-47

Figure 5-51: PI Test Window

13. Select the test length in seconds from the drop down list.

14. Click Test to begin testing.

To stop the test at any time, click Stop. Click Exit to return to the Test Selection

window.

15. Verify that you are about to apply X volts to the circuit by clicking Yes.

16. During the testing the D/A ratio and the Polarization Index will be computed and

entered in the appropriate text boxes on the window.

17. Click OK at the end of testing in the Test Complete window.

18. Close the PI Test window by selecting File, Exit, or Ctrl+X, or the close button (red X

in the upper right corner).

19. Click Yes to save test data, in the Save Test Data window. Or No to exit without

saving test data.

20. Click OK in the Save Completed window.

Step Voltage

Step Voltage test is the same as for an AC Induction asset. See Step Voltage on page 5-24.

Bar-to-Bar

The Bar-to-Bar test is reached by selecting the Armature tab and Bar-to-Bar from the test

list on the Test Selection window. See page 5-3, Test Selection Window for more

information. Verify that the test set-up settings are correct and click Test. The Bar-to-Bar

Test window opens. Figure 5-52.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-48 2008 PdMA Corporation REV. 0-04/08

Figure 5-52: Bar-to-Bar Test Window

File Menu

Exit. Exit (Ctrl+X) closes the Bar-To-Bar Test window and returns you to the Home

window.

View Menu

Create Message. Cr eat e Mes s age

(Ctrl+S) opens the Compose Asset

Message window (Figure 5-53). The

note is viewed in the Message Center.

For more information on the Message

Center, see Chapter 3, page 3-41.

Figure 5-53: Compose Asset Message Window

Options Menu

Set Condition Code. Change the condition

code by selecting the desired condition code

opt i on but t on ( Fi gur e 5- 54) . The Asset

Condition box on the Bar-To-Bar Test window

changes and a note is automatically generated by

the software. The note is viewed in the Message

Center. For more information on the Message

Center, see Chapter 3, page 3-43.

Figure 5-54: Set Condition Code Window

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-49

Raise Leads/Lower Leads Button

The Raise Leads/Lower Leads button toggles to signify the action to be taken with the test

leads during testing.

Exit Button

The Exit Button is inactive (dimmed) during testing, but is active between moving the

leads.

Pause Button

The Pause Button is inactive (dimmed) during testing, but is active between moving the

leads.

Test

The lower left area of the Bar-to-Bar test window, Figure 5-55, informs you what action is

required. The Test Dialog box displays the testing progress. The software checks for the

leads and if no leads are found displays, Waiting for Leads in the text box. When the

leads are in position, testing begins automatically. During testing the text box displays

Read Resistance, Checking Leads, Test Completed, Waiting for Leads.

Figure 5-55:

Step-by-Step Bar-to-Bar Testing

1. Deenergize and lock out the starter and the asset.

2. Check for low level induced voltages using a Fluke multimeter or equivalent.

Verify that the values do not exceed 0.5 VAC phase-to-phase and 15 VAC phase-to-

ground. Check for low level stored voltage by verifying less than 15 VDC phase-to-

ground.

3. Connect the bar-to-bar test leads to the MCE and to the laptop parallel port.

4. Highlight the asset to be tested on the Site Navigator.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-50 2008 PdMA Corporation REV. 0-04/08

5. Select the Test Selection icon on the toolbar. The Test Selection window opens,

Figure 5-56.

Figure 5-56: Test Selection Window

6. Verify that the MCE (Test Type) and Armature (Asset Section) tabs are selected. The

type of asset determines which asset sections are available.

7. Click Bar-To-Bar from the Test List.

8. Verify the Test Location in the Test Setup section.

To insure consistent trending and assist in trouble shooting, the actual test location

should be stored for each test.

The Test Location default is Not Assigned. To assign a test location, click the down

arrow and select from the list. If the location is not known, click the browse

button . The Test Location Selection window opens displaying a test location

graph for the type of asset selected. Use the graph to determine the location, then click

the down arrow, select from the list, and click OK. See Figure 5-57.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-51

Figure 5-57: DC Asset Test Location

9. Verify the Span is correct.

10. Click Save to save the settings for this asset for future testing. Or click Reset to return

the original settings. This can only be done if the new settings have not been saved.

11. Click Test to go to the testing window

12. To begin the Bar-to-Bar Test, click Test.

13. When Waiting for Leads appears in the Test Dialog Box, position the leads. Testing

will begin automatically. The dialog box will inform you of the testing progress

beginning with Read Resistance, Checking Leads, and finally Test Complete. See

Figure 5-58.

MCE PdMA MCEGold PRODUCT SUPPORT MANUAL

5-52 2008 PdMA Corporation REV. 0-04/08

Figure 5-58: Test Dialog Box

14. During testing the test values are entered in the table on the left and are displayed in

graph format in the center of the window. The magnification of the graph can be

changed by using the down arrows below the graph area and selecting a new value

from the drop down list. The default is Full.

15. When Test Complete appears in the Test Dialog box, reposition the leads. Testing will

begin automatically.

16. Repeat Step 14 until all bars have been tested.

17. At the end of testing, you will be asked if you want to continue testing. Click Yes to

continue or No to end testing.

18. Click Exit. You will be asked if you want to save test data.

Click Yes to save the test data. Click OK in the Save Completed window. The Bar-to-

Bar test window closes.

Or click No to exit the window without saving.

Field Section Tests

MCE Auto

MCE Auto is the same as for an AC Induction asset. See MCE Auto on page 5-7.

DC Standard

DC Standard test for the Field section is the same as for the Armature section. See DC

Standard on page 5-40.

Polarization Index

The Polarization Index test for the Field section is the same as for the Armature section.

See Polarization Index on page 5-45.

PdMA MCEGold PRODUCT SUPPORT MANUAL MCE

REV. 0-04/08 2008 PdMA Corporation 5-53

Step Voltage

Step Voltage test is the same as for an AC Induction asset. See Step Voltage on page 5-24.

TEST DATA ANALYSIS INFORMATION

Standard Test

The standard test is similar for both AC and DC assets. In an AC asset, the following are

either measured or calculated during a standard test:

Resistance-to-ground

Capacitance-to-ground

Resistance phase-to-phase

Inductance phase-to-phase

Resistive imbalance (calculated)

Inductive imbalance (calculated)

Power loss