Manual Transferencia Automática Edificio ATS-01 PDF

Diunggah oleh

Alberto JaimeDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Manual Transferencia Automática Edificio ATS-01 PDF

Diunggah oleh

Alberto JaimeHak Cipta:

Format Tersedia

ATS-01 Ver1.

0

AUTOMATIC TRANSFER SWITCH

CONTROL UNIT

OPERATORS MANUAL

McPherson Controls

4501 NW 27 Ave

Miami, Florida 33142

Ph 305-634-1511

Fax 305-634-1461

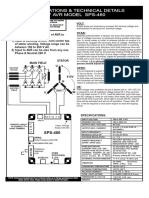

Mechanical Switch

Harness

Harness

All Voltages

208 to 240 Volts

ONLY

All the Harnesses are

manufactured in different

sizes and are ready

to install

TSP-02

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

2

TABLE OF CONTENTS

Section Page

SECTOIN 1 : INTRODUCTION

1.1 Preliminary Comments and Safety Precautions ............................................................................ 3

1.2 Background................................................................................................................................... 3

1.3 Product Overview.......................................................................................................................... 3

1.4 Functions / Features...................................................................................................................... 4

SECTOIN 2 : HARDWARE DESCRIPTION

2.1 General ......................................................................................................................................... 5

2.2 Display Window............................................................................................................................. 5

2.3 Operate Pushbuttons ................................................................................................................... 5

2.4 Panel LEDs Outputs .................................................................................................................... 5

2.5 Rear Access Area ........................................................................................................................ 5

SECTOIN 3 : OPERATOR PANEL

3.1 General ......................................................................................................................................... 8

3.2 Display Window............................................................................................................................. 8

3.3 Operate Pushbuttons .................................................................................................................... 8

3.4 Panel LED Outputs........................................................................................................................ 8

SECTOIN 4 : OPERATION

4.1 General ......................................................................................................................................... 9

4.2 Automatic Mode ............................................................................................................................ 9

4.3 Engine Test Mode ....................................................................................................................... 10

4.4 Off Mode ..................................................................................................................................... 10

4.5 Programming Mode..................................................................................................................... 10

4.6 Specification Summary................................................................................................................ 12

SECTOIN 5 : INSTALLATION INSTRUCTIONS

5.1 General ....................................................................................................................................... 12

5.2 Panel Cut-Out ............................................................................................................................ 12

5.3 Unit Dimensions ........................................................................................................................ 13

SECTOIN 6 : TYPICAL WIRING

6.1 General ....................................................................................................................................... 13

6.2 MCCB Type Wiring Diagram....................................................................................................... 13

6.3 One Coil Double Throw Type Wiring Diagram............................................................................. 14

6.4 Two Coils Double Throw Type or Magnetic Contactor Type Wiring Diagram.............................. 14

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

3

SECTION 1: INTRODUCTION

1.1 Preliminary Comments and Safety

Precautions

This technical document is intended to cover most

aspects related with the installation, operation and

maintenance of the ATS-01 Automatic Transfer

Switch Controller. This manual is for authorized and

qualified personnel only.

1.2 Background

Transfer switches are used to protect critical

electrical loads against loss of power. The normal

power is backed up by a standby (emergency) power.

The transfer switch is connected to both sources and

supplies the load with power from one of these two

sources. In the event that power is lost from normal

power, the transfer switch transfers the load to the

standby power, usually a generator and when

normal power is restored, the load is transferred

back to the utility power .

The ATS-01 module handles the mechanical parts of

the transfer mechanical initiating the transfer when

normal power falls or if street power is over or below

a set voltage or frequency. If the emergency source

is a standby generator, the ATS-01 starts the

generator and transfers to the generator after

voltage and frequency at the generator is stable.

When normal power returns, the transfer switch

automatically transfers back to normal power and

stops the engine after a set engine cool-down time

delay.

All automatic transfer switches consists of three

parts:

1. Contacts to connect and disconnect the load to

the source of power.

2. A transfer mechanism to move the contacts from

one source to another.

3. An intelligence control unit to constantly monitor

the condition of the power sources, and so

provide the brains necessary for the switch and

related circuit to operate correctly.

This manual deals with the third and last element the

Model ATS-01 ATS logic controller. All switching

functions are performed and initiated in there proper

sequence by this door mounted computer. Which

brings intelligence, supervisory and programmable

capabilities to all automatic transfer switches all over

the world?

1.3 Products Overview

The ATS-01 module is a programmable,

multi-function, microprocessor-based automatic

transfer switch controller. It is a compact,

panel-mounted device designed to replace

traditional relay and solid state logic panels and meet

the needs of markets worldwide.

The ATS-01 Controller provides an unmatched

degree of programmed flexibility. It can be used in

ether 3-Y & Delta, 1 and 1 3w system

operation, and for use with 1) MCCB type 2) Double

throw type and 3) magnetic contactor type ATS.

The ATS-01 Controller provides all the necessary

administration to ensure that the ATS switch

operates properly through a series of programmed

sensing and timing functions. The ATS-01 Controller

will:

Monitor Normal and Standby power source for

over and under voltages.

Monitor Normal and Standby power source for

over and under frequencies.

Permit customer programming displaying real

time information.

Permit customer programming of cycle mode or

fix mode displays for 3 and 1 phase voltages and

frequency.

Permit system testing of the transfer switch

with/without load from front panel.

Store customer/factory established parameters in

permanent memory.

Built-in one week exercise timer with/without load

Permit customer plant engine test with/without

load on a preset period.

Provide programmable pre-exerciser warming

signal.

Provide a pre-transfer signal to elevator controller

before transfer switch.

Provide programmable alarm output when

transfer failure.

There is no need for a PC connection and

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

4

programming software. Any and all changes can

be made in the field.

Provide the source status and fail alarms

indications on the front panel.

1.4 Functions / Features

The primary function of ATS-01 Controller is to

accurately monitor power sources and provide the

necessary intelligence to operate a transfer switch in

an appropriate and timely manner.

1.4.1 Operational Simplicity

From installation to programming to usage, the

ATS-01 Controller is designed with operational

simplicity. The controller operates with system

voltage from 160 VAC to 480 VAC at 50 or 60 Hz.

The user-friendly front panel interface simplifies

routine operation, programming and setting

adjustments.

1.4.2 Standard Features

A variety of programmable features are available to

meet wide application requirements. Individual

features or feature combinations provide the

intelligence required to tailor switches to individual

needs. The features can be programmed by the

customer. The specific variable set points associated

with standard and factory activated features are

stored in a non-volatile memory. All set points are

customer adjustable.

Feature 1: Time Delay Normal to Emergency

(TDNE)

TDNE provides a time delay when transferring the

Normal source to the Standby source. It ensures

stability of the Standby source. Timing begins when

the Standby Source becomes available.

Adjustable TDNE range: 0 ~ 300 sec.

Feature 2: Time Delay Engine Start (TDES)

TDES delays the initiation of the engine start circuit

in order to override momentary power outages or

voltage fluctuations of the Normal source. The TDES

timer shall start, when the Normal source becomes

unavailable. If the Normal source becomes available

while timing, the TDES timer will reset. The ATS-01

controller can perform the time delay engine start

function without control power for 30 seconds.

Adjustable TDES range: 0 ~ 30 sec.

Feature 3: Time Delay Emergency to Normal

(TDEN)

TDEN delays the transfer from the Standby source to

the Normal Source to permit stabilization of the

Normal Source before retransfer is made. Timing

begins when the Normal Source becomes available.

Adjustable TDEN range: 0 ~ 300 sec.

Feature 4: Time Delay Engine Cool-down

(TDEC)

TDEC permits the generator to continue to run

unloaded after retransfer to the Normal Source has

occurred. Timing begins when the transfer to normal

has been completed.

Adjustable TDEC range: 0 ~ 300 sec.

Feature 5: All Phase Under / Over voltage

Sensing

The controller monitors the voltage of each phase of

the normal and standby power source. User

adjustable settings are provided.

Adjustable Over voltage range: 110VAC ~ 550VAC

Adjustable Under voltage range: 80VAC ~ 470VAC

Feature 6: Under/Over frequency Sensing

The controller monitors the frequency of the normal

and standby power source. User adjustable settings

are provided.

Adjustable Over frequency range: 51Hz ~ 70Hz

Adjustable Under frequency range: 45Hz ~ 47Hz

Feature 7: Plant Exerciser

This feature provides for automatic test operation of

the generator. The interval is fixed at once per week

with a specific test day and time. The test period is

also programmable by custom settings. A LIGTED

RED LED between VOLT & FREQ on the display

window tells the operator the ATS is program to

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

5

NOTICE

The ATS-01 controller provides an

auxiliary contactor for external signal

output only. As such, this contactor just

can define to one of the three features

used. (Pre-transfer, Pre-exerciser or

Transfer fail alarm signal output)

exercise the generator AND THAT GENERATOR

CAN START AT ANY TIME.

Feature 8: Pre-transfer Signal Output

When the auxiliary contactor is set to a pre-transfer

signal output, the ATS-01 controller will provide a

pre-transfer signal to the elevator controller before

transferring the load from one source to another

source, with a preset time delay. The pre-transfer

returns to normal state after the transfer are

complete.

Adjustable range: 0 ~ 99 sec.

Feature 9: Pre-exerciser Signal Output

When the auxiliary contactor is set to be a

pre-exerciser signal output, the ATS-01 controller will

provide a pre-transfer signal output before exercising

the engine. It is a warning signal to avoid personal

injury, before the generator auto starts itself.

Adjustable range: 0 ~ 99 sec.

Feature 10: Transfer Fail Alarm Output

When the auxiliary contactor is set to be a transfer

fail alarm output, the auxiliary contactor may be

wired to a highly audible alarm panel to indicate

problems with the Automatic Transfer Switch. An

alarm condition will occur if a transfer has been

initiated but is never completed. This may indicate

that something is wrong with the motor or transfer

mechanism.

SECTION 2: HARDWARE DESCRIPTION

2.1 General

The purpose of this section is to familiarize the

reader with ATS-01 hardware, its organization, and

to list the unit specifications. The information

presented is divided into the following parts:

Front Display Window

Operate Pushbuttons

Panel LED Outputs

Rear Access Area

2.2 Display Window (Refer to Fig. 2-1)

A 4 digit 7-segment display is used to display all

ATS-01 Controller monitored parameters, setting

parameters and messages in easy to read formats.

For details concerning the kind of information that

can be viewed in the display window refer to

Paragraph 3.2.

2.3 Operate Pushbuttons (Refer to Fig. 2-1)

The front operator panel supports five long-life

pushbuttons. Pushbuttons accomplish their function

when pressed and released. Refer to Paragraph 3.3

for information concerning the function of specific

pushbuttons.

2.4 Panel LEDs Outputs (Refer to Fig. 2-1)

Thirteen individual LEDs are lit when performing or

indicating a specific function. For detailed

information on individual LEDs refer to Paragraph

3.4.

2.5 Rear Access Area (Refer to Figure 2-2)

The rear access area of the ATS-01 Controller is

normally accessible from the rear of panel. A wiring

connection to the ATS-01 Controller is made at the

rear of the chassis.

For detailed information of connecting wire diagram

refer to Paragraph 6.

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

6

Figure 2-1

Front Panel

Display

Window

Operator

Pushbutton

ATS status

LEDs

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

7

Figure 2-2

Rear

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

8

NOTICE

Although a wide variety of parameters and

settings can be displayed, they are not

displayed if they were not originally ordered

and programmed into the panel..

SECTION 3: OPERATOR PANEL

3.1 General

The operator panel, which is normally accessible

from the outside of a panel or door, provides a

means for being alerted to specific conditions,

receiving functional help, programming and

parameter monitoring.

3.2 Display Window

The ATS-01 controller includes a 4 digits,

7-segment display to display all monitored

parameters, setting parameters and messages in

easy to read formats.

Different displays can be presented via the display

window:

Normal source voltage and frequency parameter

display

Standby source voltage and frequency

parameter display

TDEN,TDNE and TDEC real time countdown

display

Program setting parameter display

3.3 Operate Pushbuttons

There are five front panel pushbuttons that

accomplish their functions when pressed and

released. Certain pushbuttons, like the increase ()

and decrease () pushbuttons will also continue to

scroll if they are pressed and not released during a

programming procedure.

3.3.1 Increase () Pushbutton

When the ATS-01 controller operates at normal

status, each depression of the increase () key will

change the real parameter display from one phase

to another phase. When the user initiates the

program mode, each press of the increase () key

will scroll through all available parameters. When

pressing and releasing the increase () button, the

displayed parameter can be increased by one. The

increase () pushbutton will continue to scroll if it is

pressed and not released.

3.3.2 Decrease () Pushbutton

In the normal operating state, each depression of

the decrease () key will change the real parameter

display between voltage and frequency. When the

user initiates program mode, each depression of the

Decrease () key will scroll through all available

parameters. When pressing and releasing the

decrease () button, the displayed parameter can

be decreased by one. The decrease () pushbutton

will continue to scroll if it is pressed and not

released.

3.3.3 Auto Function Pushbutton

Pushing the AUTO select key, the ATS-01 will run in

automatic mode and a LED is provided to indicate

the auto position. The ATS will transfer and

retransfer from source to source, as dictated by the

features supplied and their programmed setting

values.

3.3.4 Test Function Pushbutton

The ATS-01 is provided with a test pushbutton that

simulates a loss of normal source. By pushing the

TEST select key, the ATS-01 will run in engine test

mode. An LED is provided to indicate the test

position.

3.3.5 off Function Pushbutton

By pushing the OFF select key, the ATS-01 will run

in off mode. All the functions of the ATS-01

controller will be disabled.

When in program mode, pushing the off pushbutton

allows the user to change the program line table and

set the selected parameter using decrease () or

increase () button.

3.4 Panel LED Outputs

Auto Position (Green)

Indicates that the ATS-01 controller is set to AUTO

function

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

9

Test Position (Green)

Indicates that the ATS-01 controller is set to TEST

function

Normal-Power Source Available (Green)

Indicates that the normal source is available, and

the voltage and frequency are within the

programmed parameters.

Normal-Power Source Connected (Green)

Indicates that the transfer switch is connected to the

normal source

Standby-Power Source Available (Green)

Indicates that the standby source is available, and

the voltage and frequency are within the

programmed parameters.

Standby-Power Source Connected (Green)

Indicates that the transfer switch is connected to the

standby source

Building-Load Connected (Green)

Indicates that the load is connected to the normal or

standby source

Normal-Power over Voltage Fault (Red)

Indicates that the normal source is unavailable, and

the voltage is over the programmed parameters.

Normal-Power under Voltage Fault (Red)

Indicates that the normal source is unavailable, and

the voltage is below the programmed parameters.

Normal-Power over Frequency Fault (Red)

Indicates that the normal source is unavailable, and

the frequency is over the programmed parameters.

Normal-Power under Frequency Fault (Red)

Indicates that the normal source is unavailable, and

the frequency is below the programmed parameters.

Standby-Power over Voltage Fault (Red)

Indicates that the standby source is unavailable,

and the voltage is over the programmed

parameters.

Standby-Power under Voltage Fault (Red)

Indicates that the standby source is unavailable,

and the voltage is below the programmed

parameters.

Standby-Power over Frequency Fault (Red)

Indicates that the standby source is unavailable,

and the frequency is over the programmed

parameters.

Standby-Power under Frequency Fault(Red)

Indicates that the standby source is unavailable,

and the frequency is below the programmed

parameters.

SECTION 4: OPERATION

4.1 General

This section specifically describes the operation and

functional use of the ATS-01 Controller. It is divided

into four main categories:

Automatic mode

Engine test mode

Off mode

Programming mode

The practical use of each operation under each

category will be explained in this section. It is

assumed that prior sections are understood, and the

operator has a basic understanding of the hardware.

4.2 Automatic Mode

The automatic mode of the ATS-01 Controller

provides for automatic transfer and retransfers from

source to source, as dictated by the features

supplied and their programmed values.

The ATS-01 Controller constantly monitor the

condition of both normal and standby power sources,

thus providing the required intelligence for transfer

operations.

For example, the ATS-01 Controller automatically

initiates a transfer of power, when power fails or

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

10

when the voltage level drops below a preset value.

Exactly what the Ats-01 controller will initiate in

response to a given system condition, depends

upon the combination of standard and selected

optional features.

4.3 Engine Test Mode

The ATS-01 is provided with a test pushbutton that

simulates a loss of normal source. Pushing the

TEST key on the front of panel, the ATS-01 will run

in engine test mode. The TDES and TDNE

programmed time delays will be performed as part

of the Test. There are two pre-programmable test

modes:

With load engine test.

Without load engine test. (The TDNE time delay

will not be performed)

When the user terminates the engine test by

pressing the AUTO pushbutton again, the controller

will return to automatic mode. When normal power

is available, the transfer switch automatically

transfers back from standby source to normal

source and initiates engine shutdown, after an

engine cooling down time delay.

When the user terminates the engine test mode by

pressing the OFF pushbutton, the ATS maintains

the present status. The ATS-01 controller initiates

engine shutdown immediately, without cooling down

time delay, and returns to off mode.

4.4 Off Mode

The off mode of the ATS-01 Controller will disable

all the transferred and protected functions. The

display window and all the status LEDs will be

turned off. In the event that power is lost from the

normal source, the ATS-01 controller will not start

the engine, and the ATS will not transfer the load to

the standby source automatically.

When in program mode, pressing the off pushbutton

allows the user to change the program line table and

set the selected parameter using decrease () or

increase () button.

4.5 Programming Instructions

The ATS-01 Controller is fully programmable from

the faceplate, once in the Programming Mode

programming is very simple.

To get in programming mode, set the ATS-01on

OFF, press buttons increase () & decrease ()

together for 4 seconds. The word Vr 1.0 will

appear on the front display window for 2 seconds,

Indicating the version of the software.

You are now ready to start a line by line

programming sequence. To advance to the next line,

push the OFF button on the front panel. To change

each lines programming parameters, press the

increase () and decrease () buttons. When

pressing and releasing the increase ( ) or

decrease () key, the displayed parameter can be

increased or decreased by one. The increase () or

decrease () pushbutton will continue to scroll if it

is pressed and not released.

Always push the OFF button to advance to the

next programming line or until the word END

appears on the screen. To immediately end

programming, you simply push the OFF button at

any time and hold it for 4 seconds at any time. The

word End on the display window indicates the end

of the programming mode. Whatever you change is

now in memory.

Should you make an error or desire to return to

factory settings, stay in programming mode and

simultaneously press all 3 buttons: increase

() ,decrease () and OFF for 4 seconds. The

ATS-01 controller will now automatically program

itself to factory settings, and the word Au.Po will

appear on the display window. (See line by line

programming table for ATS-01 factory settings.)

Programming Line 1

The first thing the user needs to do is to key in the

real line voltage into the ATS-01. Read the line

voltage from the normal source from L1 to L3, on the

ATS with a good quality digital voltmeter and key-in

this volt into the ATS-01 on line 1 in programming

mode. Using the () and () buttons.

If you are using Module TSP-1 you first plug is the

voltage your ATS is going to work at 480, 380, 220,

etc.

If you use Module TSP-02 you are limited to use in

208 to 240 Volts 1 to 3 phases.

The rest is easy, follow line by line programming..

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

11

LINE BY LINE PROGRAMMING TABLE

LINE DISCRIPTION VALUE

Factory

Setting

1 System voltage setting ( 90V ~ 600V ) Key in the real volt of normal side R & T 220V

2

Is this ATS operating in 1 phase, single phase

with 3 wire, or 3 phase?

1) 1 2) 1 3W 3) 3 3

3 Selected the Switch type of ATS

1) MCCB type 2) Double throw type

3) magnetic contactor type

1

4 Manual test with or without load 1) Test without load 2) Test with load 2

5 TDEN Time delay emergency to normal 0 ~ 60 ( 0 ~ 300sec ) 1 unit = 5sec

2

(10sec)

6 TDNE Time delay normal to emergency 0 ~ 60 ( 0 ~ 300sec ) 1 unit = 5sec

2

(10sec)

7 TDES Time delay engine start 0 ~ 12 ( 0 ~ 60sec ) 1 unit = 5sec

1

(5sec)

8 TDEC Time delay engine cool-down 0 ~ 60 ( 0 ~ 300sec ) 1 unit = 5sec

12

(60sec)

9 Normal source over voltage setting 11 ~ 55 ( 110V ~550V )

25

(250V)

10 Normal source under voltage setting 08 ~ 47 ( 80V ~ 470V )

18

(180V)

11

Time delay if there is a problem with normal

source voltage output

0 ~ 99sec

( 0 = without voltage monitor function )

10sec

12 Normal source over frequency setting 51 ~ 70Hz 65Hz

13 Normal source under frequency setting 45 ~ 59Hz 55Hz

14

Time delay if there is a problem with normal

source frequency output

0 ~ 99sec

( 0 = without freq monitor function )

10

15 Standby source over voltage setting 11 ~ 55 ( 110V ~550V )

25

(250V)

16 Standby source under voltage setting 8 ~ 47 ( 80V ~ 470V )

18

(180V)

17

Time delay if there is a problem with standby

source voltage output

0 ~ 99sec

( 0 = without volt monitor function )

10

18 Normal source over frequency setting 51 ~ 70Hz 65Hz

19 Normal source under frequency setting 45 ~ 59Hz 55Hz

20

Time delay if there is a problem with standby

source frequency output

0 ~ 99sec

( 0 = without freq monitor function )

10

21 Current day of week setting 1 ~ 7 (Mon to Sun) current

22 Current hour setting 00 ~ 23 current

23 Current minute setting 00 ~ 59 current

24 Plant exerciser test day of week 1 ~ 7 (Mon to Sun) 6(Sat)

25 Plant exerciser hour 00 ~ 23 12

26 Plant exerciser minute 00 ~ 59 00

27 Engine run time on exerciser 0 ~ 60 min ( 0 = without exerciser function ) 0

28 Exerciser test with or without load 1) without load 2) with load 1

29 Display mode setting 1) cyclic mode 2) fix mode 1

30

Auxiliary contactor feature (the contactor can

only define one of the three features)

1) transfer fail alarm 2) pre-transfer signal

3) pre-exerciser signal

2

31

Pre-transfer time delay Line 30 option 2. Can

be used for elevator Pre-Transfer signal

0 ~ 99 sec

( 0 = without pre-transfer function)

10

32

Pre-exerciser time delay before engine

exerciser test. Line 30 option 3 Can be used

for engine start alarm

0 ~ 99 sec

( 0 = without pre-exerciser function)

10

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

12

4.6 Specification Summary

PARAMETER SPECIFICATION

Input Control Voltage 160 VAC to 250 VAC 50/60 Hz

Voltage Measurement Range 80 VAC to 600 VAC 50/60 HZ

Frequency Measurement Range 45HZ to 70HZ

Generator Start Relay 7A @ 250VAC Max

Transfer to Normal Relay 7A @ 250VAC Max

Transfer to Standby Relay 7A @ 250VAC Max

Auxiliary Relay

0.5A @ 120VAC

1.0A @ 24VDC

Operating Temperature -20

C ~ 70(C

Storage Temperature -35(C ~ 85(C

Operating Humidity 0 to 95% relative humidity

SECTION 5: INSTALLATION INSTRUCTIONS

5.1 General

The ATS-01 controller has been designed for front panel mounting.

5.2 Panel Cut-Out (All Dimensions in MM. )

5.3 Unit Dimensions (All Dimensions in MM. )

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

13

SECTION 6: TYPICAL WIRING

6.1 General

It is dangerous to feed high voltage to the ATS-01

Printed Circuit boards. The ATS-01 controller

operates with system voltage from 160 VAC t0 250

VAC at 50 or 60 Hz. To work at over 250VAC volts,

we have developed a clear and simple transformer

module TSP-01 that provides the safety control and

operating voltages. User just needs to key in the

real voltage (Step 1in programming mode) values of

normal source L1 ~ L3. The ATS-01 controller will

follow the scale between input volt and key in volt

and show the correct voltage on the display window.

The ATS-01 maximum work current is 6 Amps,.

When working currents are over 6 Amps, two

external power relays are recommended. (The

connecting wire diagram refers to 6.5 sections.)

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

14

6.2 3Phase 3Wire connecting wire diagram

6.2.1 MCCB Type Wiring Diagram

6.2.2 One Coil Double Throw Typical Wiring Diagram

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

15

6.2.3 Two Coil Double Throw Type or Magnetic Contactor Type Diagram

6.3 1Phase 3Wire connecting wire diagram

6.3.1 MCCB Type Wiring Diagram

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

16

6.3.2 One Coil Double Throw Typical Wiring Diagram

6.3.3 Two Coil Double Throw Type or Magnetic Contactor Type Diagram

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

17

6.4 Single Phase system connecting wire diagram

6.4.1 MCCB Type Wiring Diagram

6.4.2 One Coil Double Throw Typical Wiring Diagram

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

18

6.4.3 Two Coil Double Throw Type or Magnetic Contactor Type Diagram

6.5 Connecting wire diagram When the switch transfer current over 6 Amps

6.5.1 MCCB Type Wiring Diagram (PT1 & PT2 are unnecessary for AC220 system)

ATS-01 AUTOMATIC TRANSFER SWITCH

______________________________________________________________________________________

19

6.5.2 One Coil Double Throw Typical Wiring Diagram (PT1 & PT2 are unnecessary for AC220

system)

6.5.3 Two Coil Double Throw Type or Magnetic Contactor Type Diagram (PT1 & PT2 are

unnecessary for AC220 system)

6.2

1 3 2 7 8 52 52 10 9 5 4 6

TSP-01

ATS Transformer Module

With Multi-Voltage Plug-In Connectors

to Simplify ATS Set-Up

Features

Use In System Voltage From 200 ~ 600 VAC

Simplifies All ATS Wiring

Connects to BTS* & ATS-01* By Plug-In Connectors

Select Voltage Directly By Plug-In Connectors

Save Labor Cost By Easy Assembly & Maintenance

Circuits Are Finger Safe With High Voltage Fuses &

Epoxy Protection

Built-In 3 Phase Fuses To Protect Normal &

Emergency Circuits in ATS-01 & TSP-01

Provides Alarms Signals & Engine Start Contacts

Specifications

Fuse Function Current Fuse Capacity Connector Function Capacity

F1 Protect Normal Power Circuit 6.3 A 50KA @ 500 VAC Remote Start Remote engine start 250 VAC / 7A

F2 Protect Normal Power Circuit 1.0 A 50KA @ 500 VAC Prog. Output Programmable alarm signal output 120VAC / 0.5A

F3 Protect Normal Power Circuit 6.3 A 50KA @ 500 VAC TB2 Connect to ATS-01

300 VAC /

1 A

F4 Protect Emergency Power Circuit 6.3 A 50KA @ 500 VAC CN2 Connect to BTS 600 VAC / 8A

F5 Protect Emergency Power Circuit 1.0 A 50KA @ 500 VAC

F6 Protect Emergency Power Circuit 6.3 A 50KA @ 500 VAC

CN3CN4

CN5CN6

Connect to transformers 600 VAC / 8A

Mechanical Specifications

T

B

2

-

F

ro

m

A

T

S

-0

1

C

N

2

-

F

ro

m

B

.T

.S

.

2

0

8

V

3

8

0

V

4

4

0

V

4

6

0

V

F

1

F

2

F

3

F

5

F

4

F

6

C

N

3

C

N

4

C

N

6

C

N

5

T

B

3

N

C

.

C

N

O

.

N

O

.

C

N

C

.

R

e

m

o

t

e

S

ta

r

t

P

r

o

g

.

O

u

tp

u

t

Plug-In Connectors Range Universal Voltages

208 VAC 10% 208, 220, 240

380 VAC 10% 365, 380, 401

440 VAC 10% 415, 440

460VAC 10% 460, 480

Physical Specifications

Dimensions 280 (L) x 166 (W) x 152 (H) mm

Weight 5.5 Kg 2%

* BTSBasic Transfer Switch

* ATS-01Intelligent ATS Controller

Notes:

1. The Rate Capacity of TSP-01 is 105 VA

2. If the system voltage is from 200~240, transformer

model is not neededUse TSP-02.

UNIT: mm

Anda mungkin juga menyukai

- Ats 01 ManualDokumen34 halamanAts 01 ManualRoberto BernalBelum ada peringkat

- Lixise LXC31X0 - V1.3 - ENDokumen28 halamanLixise LXC31X0 - V1.3 - ENHector Cabrera100% (2)

- DC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayDokumen2 halamanDC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayAliBelum ada peringkat

- DST 4600A: Electronic Control CardDokumen2 halamanDST 4600A: Electronic Control Cardmuhammad arif100% (2)

- Model CM0900 1 Phase Automatic Transfer Switch ControllerDokumen16 halamanModel CM0900 1 Phase Automatic Transfer Switch ControllerLuisFdoAlvaradoSaboríoBelum ada peringkat

- Ats Korps CatalogDokumen46 halamanAts Korps CatalogRahmat Nur Ilham100% (1)

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDokumen3 halamanDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteBelum ada peringkat

- Manual de Instalación Ats Asco Serie 300 No.381333-403Dokumen8 halamanManual de Instalación Ats Asco Serie 300 No.381333-403Elías NavarroBelum ada peringkat

- Ec5000 6-09 PDFDokumen5 halamanEc5000 6-09 PDFHusi NihaBelum ada peringkat

- GAVR15Dokumen2 halamanGAVR15HerbertBelum ada peringkat

- Sx460 Automatic Voltage Regulator (Avr)Dokumen4 halamanSx460 Automatic Voltage Regulator (Avr)rajan_2002eee100% (1)

- GX - 340 - Manual STAMFORD SERIE 3 PART 450-11700Dokumen11 halamanGX - 340 - Manual STAMFORD SERIE 3 PART 450-11700Manuel Otero100% (2)

- 5210 ManualDokumen4 halaman5210 ManualBuck AbellaBelum ada peringkat

- WEG Automatic Voltage Regulator Grt7 Th4 r2 10001284109 Manual EnglishDokumen78 halamanWEG Automatic Voltage Regulator Grt7 Th4 r2 10001284109 Manual Englisht8823pcBelum ada peringkat

- R448 Manual From Mac Far Lane GeneratorsDokumen14 halamanR448 Manual From Mac Far Lane Generatorstocanh1990Belum ada peringkat

- Deep Sea Electronics PLC: 5110 Autostart Module Operating ManualDokumen40 halamanDeep Sea Electronics PLC: 5110 Autostart Module Operating ManualMaylen RivasBelum ada peringkat

- Owners+Manual Speed+controller (DGC-2013) (ENG)Dokumen7 halamanOwners+Manual Speed+controller (DGC-2013) (ENG)Quang PhamBelum ada peringkat

- SS460 InstructionsDokumen4 halamanSS460 InstructionsDiego Fernando Sanchez FlorezBelum ada peringkat

- Regulador de Tension Analogico, Manual de Instalacion Operacion y MantenimientoDokumen79 halamanRegulador de Tension Analogico, Manual de Instalacion Operacion y MantenimientoFix0% (1)

- KDGC 500 Control Panel Manual o DGC-2000 DIGITAL GENSET CONTROLLERDokumen92 halamanKDGC 500 Control Panel Manual o DGC-2000 DIGITAL GENSET CONTROLLERnoriegascribdBelum ada peringkat

- Avr Conversion InstructionsDokumen2 halamanAvr Conversion InstructionsJose PirulliBelum ada peringkat

- InteliLite AMF 2 5Dokumen80 halamanInteliLite AMF 2 5vdsantos74100% (1)

- Ea16 Manual enDokumen6 halamanEa16 Manual enabuzer1981Belum ada peringkat

- Generac - 67680 AVR Voltage RegulatorDokumen1 halamanGenerac - 67680 AVR Voltage RegulatorBojan Kitanovski50% (2)

- Sps 460Dokumen1 halamanSps 460BrianHazeBelum ada peringkat

- LXC706 V1.0 en User ManualDokumen16 halamanLXC706 V1.0 en User ManualAnonymous vqsuRyBelum ada peringkat

- 5855292-Avr Users Manual Ea63-5 CDokumen8 halaman5855292-Avr Users Manual Ea63-5 CAbhoe StankBelum ada peringkat

- Manual Stamford Avr SX421 PDFDokumen4 halamanManual Stamford Avr SX421 PDFBrooke EdwardsBelum ada peringkat

- InteliNano-AMF-1.5 - Fast User GuideDokumen2 halamanInteliNano-AMF-1.5 - Fast User GuideGiangDo100% (3)

- ESD-5100 Series Speed Control Unit ManualDokumen14 halamanESD-5100 Series Speed Control Unit ManualreckyBelum ada peringkat

- InteliLite AMF25 1 2 1 DatasheetDokumen4 halamanInteliLite AMF25 1 2 1 DatasheetStanley Florencio100% (1)

- EGCP 3 Installation Manual en TechManDokumen122 halamanEGCP 3 Installation Manual en TechManoscarafonsoBelum ada peringkat

- Intelilite NT Ac03: Reference GuideDokumen130 halamanIntelilite NT Ac03: Reference GuideadrianpetrisorBelum ada peringkat

- Gu601a En0507 PDFDokumen30 halamanGu601a En0507 PDFChhoan Nhun100% (2)

- SX440 Manual enDokumen4 halamanSX440 Manual enAnsoriBelum ada peringkat

- Specifications of Avr - SMR (Mosfet)Dokumen4 halamanSpecifications of Avr - SMR (Mosfet)Александр ЩеблыкинBelum ada peringkat

- Three-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputDokumen3 halamanThree-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputBradBelum ada peringkat

- Service: Industrial Generator SetsDokumen147 halamanService: Industrial Generator SetsmohammedBelum ada peringkat

- Manual de Servicio de Inversora V270Dokumen2 halamanManual de Servicio de Inversora V270Taz Juan GBelum ada peringkat

- MURPHY PV101-C V3.2 Configuration SoftwareDokumen47 halamanMURPHY PV101-C V3.2 Configuration SoftwareRomankoBelum ada peringkat

- Newage Mx341 Automatic Voltage RegulatorDokumen6 halamanNewage Mx341 Automatic Voltage RegulatoredgarcooBelum ada peringkat

- Zenith ZTG SeriesDokumen8 halamanZenith ZTG SeriesFlo MircaBelum ada peringkat

- Datamax Manual1Dokumen18 halamanDatamax Manual1Ricky YapBelum ada peringkat

- SX440 Manual enDokumen4 halamanSX440 Manual enMuhammad Sajjad ShadBelum ada peringkat

- SG128V07EDokumen2 halamanSG128V07EAngel Danubio Medina PerezBelum ada peringkat

- ATS420 ATS Controller User Manual V1.0Dokumen29 halamanATS420 ATS Controller User Manual V1.0Arturo HerreraBelum ada peringkat

- 350-28700-to-SX440-to - AS440 AVR Conversion InstructionsDokumen6 halaman350-28700-to-SX440-to - AS440 AVR Conversion InstructionsRamon Pujol PerramonBelum ada peringkat

- Panel Relay Remoto PDFDokumen12 halamanPanel Relay Remoto PDFroberto sanchezBelum ada peringkat

- Graduar Avr GeneracDokumen4 halamanGraduar Avr GeneracJose Godoy0% (1)

- Ec5000 6-09 PDFDokumen5 halamanEc5000 6-09 PDFAnonymous M0OEZEKoGiBelum ada peringkat

- Newage MX321 Automatic Voltage RegulatorDokumen6 halamanNewage MX321 Automatic Voltage RegulatorManuel Otero100% (10)

- Ats 01 - ATS 01E 2Dokumen25 halamanAts 01 - ATS 01E 2Omoi CamillusBelum ada peringkat

- Transfautomaticas ATS-01 PDFDokumen22 halamanTransfautomaticas ATS-01 PDFjuliosieteBelum ada peringkat

- Ats 01 Manual PDFDokumen34 halamanAts 01 Manual PDFNisar Ahmed100% (1)

- Ats 01 Manual enDokumen30 halamanAts 01 Manual enccorrea130% (1)

- Ats 380 Manual enDokumen30 halamanAts 380 Manual enMuhammad Yasir IqbalBelum ada peringkat

- Ats 22 DC ProgDokumen35 halamanAts 22 DC Progjose pirulliBelum ada peringkat

- ATS 22 ManualDokumen44 halamanATS 22 ManualOrlando Velado100% (3)

- Ats 245 Manual enDokumen35 halamanAts 245 Manual enInterplan Puerto RicoBelum ada peringkat

- Ats 385 Manual enDokumen36 halamanAts 385 Manual enMohamed SayedBelum ada peringkat

- ID-FLX-Lite-1.3.1 New Features PDFDokumen2 halamanID-FLX-Lite-1.3.1 New Features PDFAlberto JaimeBelum ada peringkat

- In NT MRS 1.4r1 Reference GuideDokumen79 halamanIn NT MRS 1.4r1 Reference GuideAlberto JaimeBelum ada peringkat

- IC NT RD 1.1 New FeaturesDokumen5 halamanIC NT RD 1.1 New FeaturesAlberto JaimeBelum ada peringkat

- NEF370 N60ENT M37 InstallationInstructionsDokumen38 halamanNEF370 N60ENT M37 InstallationInstructionsAlberto JaimeBelum ada peringkat

- Synchronous Timer Series EM 1000 - GIC INdiaDokumen2 halamanSynchronous Timer Series EM 1000 - GIC INdiaPrasadPurohitBelum ada peringkat

- Power Controllers AccessoriesDokumen4 halamanPower Controllers AccessoriesEliasBelum ada peringkat

- K 730376Dokumen2 halamanK 730376mbare800% (1)

- Delcon RelayDokumen11 halamanDelcon RelayamanurrahmanBelum ada peringkat

- Indoor Localization Using Multiple Wireless Technologies: A.K.M. Mahtab Hossain, Hien Nguyen Van, Yunye Jin, Wee-Seng SohDokumen9 halamanIndoor Localization Using Multiple Wireless Technologies: A.K.M. Mahtab Hossain, Hien Nguyen Van, Yunye Jin, Wee-Seng SohLi XuanjiBelum ada peringkat

- HAAPS High Altitude Aeronautical PlatformsDokumen17 halamanHAAPS High Altitude Aeronautical Platformshayat umar bhat100% (2)

- Power Electronics Circuit Analysis and DDokumen682 halamanPower Electronics Circuit Analysis and DVARALAKSHMI SEERAPUBelum ada peringkat

- Bsa 185065 10 PDFDokumen1 halamanBsa 185065 10 PDFjorgeBelum ada peringkat

- SWT 3000 TeleprotectionDokumen12 halamanSWT 3000 TeleprotectionZamfir ConstantinBelum ada peringkat

- How Fingerprint Scanners WorkDokumen8 halamanHow Fingerprint Scanners Worksachinsingh13788Belum ada peringkat

- DGT-FD800 Ultrasonic Flaw Detector: FeaturesDokumen4 halamanDGT-FD800 Ultrasonic Flaw Detector: Featuresلوبيز إديسونBelum ada peringkat

- E-Line E-LAN ConceptDokumen5 halamanE-Line E-LAN ConceptSery ArthurBelum ada peringkat

- 25q64jvsiq-Serial Flash MemoryDokumen78 halaman25q64jvsiq-Serial Flash MemoryEletronica01 - BLUEVIXBelum ada peringkat

- BFM2801 Mechatronic Lab 03 Diode ApplicationDokumen10 halamanBFM2801 Mechatronic Lab 03 Diode ApplicationMohdAzizul ZainalAbidinBelum ada peringkat

- OnCell G3110 G3150-HSPA SeriesDokumen2 halamanOnCell G3110 G3150-HSPA SeriesZulfadli RaniBelum ada peringkat

- Asr 9001 DatasheetDokumen5 halamanAsr 9001 DatasheetLecc0Belum ada peringkat

- Decimation PDFDokumen83 halamanDecimation PDFJose Gonzalez SapbeeBelum ada peringkat

- CEC HDMI Conference FinalDokumen48 halamanCEC HDMI Conference FinalKrishnendhu PrakasanBelum ada peringkat

- Code Hopping Decoder Using A PIC16C56: Key FeaturesDokumen14 halamanCode Hopping Decoder Using A PIC16C56: Key FeaturesrenampBelum ada peringkat

- Cas-Gps Light Vehicle System: Type VG For Portable InstallationsDokumen3 halamanCas-Gps Light Vehicle System: Type VG For Portable InstallationsAbhinandan PadhaBelum ada peringkat

- MCQ Thyristors (SCR) PDFDokumen4 halamanMCQ Thyristors (SCR) PDFpratik chakraborty80% (5)

- Tsa5512 CNV 3Dokumen21 halamanTsa5512 CNV 3soft4gsmBelum ada peringkat

- De0-Nano-Soc User Manual: November 7, 2019Dokumen80 halamanDe0-Nano-Soc User Manual: November 7, 2019LuisBelum ada peringkat

- H80BADPE Board DatasheetDokumen1 halamanH80BADPE Board Datasheetسعيد المعدنBelum ada peringkat

- Honeywell ml7420 User ManualDokumen8 halamanHoneywell ml7420 User ManualLaurensius ArdiBelum ada peringkat

- Experiment No.9 Superposition Theorems: ObjectDokumen5 halamanExperiment No.9 Superposition Theorems: ObjectMahek ShaikhBelum ada peringkat

- Microprocessor: From Wikipedia, The Free EncyclopediaDokumen12 halamanMicroprocessor: From Wikipedia, The Free Encyclopediaalaka_sp100% (1)

- Compiled Elecs QaDokumen10 halamanCompiled Elecs Qamgoldiieeee100% (1)

- AKG - N60NC Wireless - QSG - MultilingualDokumen16 halamanAKG - N60NC Wireless - QSG - MultilingualAbdalhakeem Al turkyBelum ada peringkat

- Module 5 - Digital Techniques Electronic Instrument Systems PDFDokumen42 halamanModule 5 - Digital Techniques Electronic Instrument Systems PDFanilmathew244Belum ada peringkat