Concrete Coating

Diunggah oleh

jachoijachoiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Concrete Coating

Diunggah oleh

jachoijachoiHak Cipta:

Format Tersedia

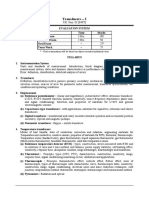

!!"# #%&'()*+, -.

/,&0+

#-00-1)2 3-415 *1

!6&'*.*'7,*-1+ .-8 #-7,*19

!,&&) 715 #-1'8&,&

SSPC: The Society for Protective Coatings

40 24th Street, 6th Floor Pittsburgh, PA 15222-4656

Copyright 2011

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete Aug. 2011

1

SSPC Checklist of Items Commonly Found in

Specifications for Coating Steel and Concrete

NOTE: Use applicable portions of this document for each project, and add requirements

not listed here as appropriate to produce a competent design.

General contract considerations

Coordinate with owners front-end documents (General Conditions, Additional

General Conditions, Special Conditions, etc.)

Define scope of project fully (Get detailed field conditions if maintenance work)

Contract specifications (using CSI three-part Section format)

GENERAL

Scope of Project

Areas to be coated and not to be coated

Site Access and Storage Area

Site Investigation Clause

References (sometimes called Applicable Documents)

SSPC PA 1 Shop, Field, and Maintenance Painting of Steel

For coating concrete surfaces:

SSPC-PA 7, Applying Thin Film Coatings to Concrete

SSPC-TU 10, Procedures for Applying Thick Film Coatings and

Surfacings Over Concrete Floors

Surface preparation

Others

Precedence of Documents

Definitions

Submittals (pre-work)(Many of these continue during work)

Contract errors, omissions, and other discrepancies, including conflicting

requirements, ambiguous requirements

Procedures for Corrective Action

Project-specific Work Plan or Process Control Procedures (PCPs)

Project-specific Health, safety, and environmental compliance plans

Site access/security requirements

Project-specific Confined space entry plans (permit required and non-

permit required)

Procurement of necessary materials

Procurement of necessary job site and support equipment

Assigning the management team to the project

Obtaining craft workers with the necessary skills

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete Aug. 2011

2

Mobilization of all of the above

Worker training and personal protective equipment (PPE)

Inspection and test plan (ITP) (including forms with criteria for

conformance and nonconformance)

ITP Log to match requirement and schedules of other work procedures

Qualifications

Qualifications of the coating contractor

Qualifications of certified protective coating specialist (PCS)

Qualifications of a coating inspection company

Qualifications of a quality control (QC) coating inspector

Qualifications of individuals performing abrasive blasting, water

jetting, coating application

Qualifications of a certified industrial hygienist (CIH)

Qualifications of a testing laboratory for coatings

Qualifications of a testing laboratory for abrasives

Certifications for materials used

Regulatory requirements

Field sampling requirements

Pre-construction conference, coordination and progress meetings

Manufacturers product data sheets for materials to be used

Shelf-life of applicable materials

Rules for shelf-life extension

Manufacturers material safety data sheets for materials to be used

Samples of specified liquid coatings

Coating draw-down films (cured films of uniform thickness applied to

cardboard or other substrates)

Laboratory test results

Certificates of product conformity to specification

Requests for Information (RFI) Log

Contract Change Order Log

Submittal Log

Daily production reports (including safety reports)

Daily inspection and test reports (DIRs)

Corrective Action Requests (CARs)

Nonconforming Work Log

Corrective Action Log

Preventive Action Log

Other reports that would provide meaningful data

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete Aug. 2011

3

Submittals Required during Production

All Logs

Production, inspection, and other reports

CARs

Other reports or information affecting production or conformity to

requirements

PRODUCTS

Coating materials and thinners (other than as specified by mfg.)

Contrasting colors for multi-coat systems

Abrasives

Test Kits

Amine blush testing

Salt testing

EXECUTION

Deliver, Store, Mix, Apply, and Cure Coatings According to SSPC-PA 1 (for steel

surfaces) or SSPC PA 7 or TU 10 for concrete surfaces)

Equipment for Surface Preparation and Coating Application

Kits and Equipment for Testing for Surface Cleanliness and Profile and Film

Thickness

Specified Types of Coating Materials Delivered and Their Verification

Field mock-up (as part of verifying procedures during start-up particularly for

coating of concrete)

Acceptable Ambient Conditions

Periods of control

During surface preparation

During coating application and initial curing (specify initial cure time)

During other operation

Parameters of control

Air temperature

Surface temperature

Dew point/relative humidity

Wind speed

Surface contaminants

Lighting for all work areas (as prescribed in SSPC-Guide 12)

Blast Cleaning of Surfaces for Coating Application

Desired results

Allowable methods

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete Aug. 2011

4

Ambient conditions for surface preparation

Pre-cleaning of Surfaces for Painting Prior to Surface Preparation

Profile shape/height/peak density

Protection of areas not to be prepared

Other Methods of Surface Preparation (e.g. Water jetting; Hand and Power Tool

cleaning; Scarifying, etc.)

Desired results

Allowable methods

Ambient conditions for surface preparation

Pre-cleaning of Surfaces for Painting Prior to Surface Preparation

Profile shape/height/peak density

Protection of areas not to be prepared

Coating Application

Condition in container

The ratio by volume of the components to combine

Instruction for mixing components

Amounts of thinner, if any, permitted

Ambient conditions for application and curing (length of cure)

Induction time at different temperatures

Pot life at different temperatures

Allowable application methods

Stripe coating

Protection of areas not to be coated

Protection of painted surface during curing

Initial cure period

Recoat window

Acceptable wet/dry film thickness range

Repairs (how much allowable and special requirements)

QC Inspection and Documentation Requirements

Final inspection

Punch List

Clearing of Punch List

Clearing of Nonconforming Work Log

Clearing of Corrective Action Log

Review of docs for completion/certification of documentation

Warranty & correction period requirements/criteria

Clean-up and proper disposal of wastes

Clean up of site to condition at start of project

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- ط§ظ„ظƒط´ظƒظˆظ„Dokumen861 halamanط§ظ„ظƒط´ظƒظˆظ„عون لنشر المعرفةBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Concrete Plate and Shell DeisgnDokumen142 halamanConcrete Plate and Shell DeisgnjachoijachoiBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Diaphragm Secant Pile Walls (Wharmby SESoc 2010) PDFDokumen62 halamanDiaphragm Secant Pile Walls (Wharmby SESoc 2010) PDFjachoijachoiBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hilti Product Technical Guide Vol 2 Anchor FasteningDokumen496 halamanHilti Product Technical Guide Vol 2 Anchor FasteningjachoijachoiBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Hilti Product Technical Guide Vol 2 Anchor FasteningDokumen496 halamanHilti Product Technical Guide Vol 2 Anchor FasteningjachoijachoiBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Cssbi 57Dokumen69 halamanCssbi 57jachoijachoiBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Sacs MarcieladewaDokumen15 halamanSacs MarcieladewajachoijachoiBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Communication StructuresDokumen29 halamanCommunication StructuresjachoijachoiBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- P-Delta Analysis ParametersDokumen2 halamanP-Delta Analysis ParametersjachoijachoiBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- User Manual: International Industry of Metallic Formwork SystemsDokumen9 halamanUser Manual: International Industry of Metallic Formwork Systemsjachoijachoi100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- DowGroundworks 1Dokumen1 halamanDowGroundworks 1jachoijachoiBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- 3126B Serial DCS02760 Arr 2077523 Repair ManualDokumen1.196 halaman3126B Serial DCS02760 Arr 2077523 Repair Manualviemey1952100% (4)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Steel Structures: Engr. Dr. Muhammad AslamDokumen29 halamanSteel Structures: Engr. Dr. Muhammad AslamArslan RaoBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Untes Chiller HEDokumen5 halamanUntes Chiller HEAnarBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- $R5AM2WWDokumen2 halaman$R5AM2WWSurood SuruBelum ada peringkat

- Process Industry Practices ElectricalDokumen10 halamanProcess Industry Practices ElectricaljowarBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- State-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateDokumen18 halamanState-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateShaker QaidiBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Chapter 4Dokumen23 halamanChapter 4syedmuhammadtariqueBelum ada peringkat

- Transducers PDFDokumen2 halamanTransducers PDFNahush BapatBelum ada peringkat

- Lateral Stiffness Characteristics of Tall PDFDokumen19 halamanLateral Stiffness Characteristics of Tall PDFLaila Monteiro A MeloBelum ada peringkat

- Heat InputDokumen2 halamanHeat InputjovanradovanoviBelum ada peringkat

- Innermost - Main CatalogueDokumen214 halamanInnermost - Main CatalogueLiteHouseBelum ada peringkat

- IndexDokumen50 halamanIndexSonja Stojaković100% (1)

- ASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance AlloysDokumen2 halamanASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloysanon_5892313360% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Triangle VI SpecificationsDokumen3 halamanTriangle VI Specificationscivil.jdriveroincBelum ada peringkat

- How Does A Siphon Work?Dokumen8 halamanHow Does A Siphon Work?Govarthanan GopalanBelum ada peringkat

- Carborundum Universal Ltd. (CUMI) : HistoryDokumen3 halamanCarborundum Universal Ltd. (CUMI) : HistoryNavjot SidhuBelum ada peringkat

- Qualitest Canada BrochureDokumen7 halamanQualitest Canada BrochureBala SingamBelum ada peringkat

- Advance Manufacturing Technology 26100720014Dokumen10 halamanAdvance Manufacturing Technology 26100720014matrika adhikariBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- C3Dokumen18 halamanC3Nick LeeBelum ada peringkat

- Insulation BOQ Area Wise (Square MTR.)Dokumen11 halamanInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanBelum ada peringkat

- A Procedure For Calculation of Torque Specifications For Bolted Joints With Prevailing TorqueDokumen8 halamanA Procedure For Calculation of Torque Specifications For Bolted Joints With Prevailing TorquedavlascBelum ada peringkat

- SSC 6mo Spec Sheet PDFDokumen2 halamanSSC 6mo Spec Sheet PDFsiswoutBelum ada peringkat

- M114700 Rev F1329945174Dokumen40 halamanM114700 Rev F1329945174arkaaaaa100% (1)

- Antifoams For Cutting FluidsDokumen8 halamanAntifoams For Cutting Fluidsiskricaman7Belum ada peringkat

- Formal Report EXP 5 Thin Layer Chromatography of Siling Labuyo ExtractDokumen3 halamanFormal Report EXP 5 Thin Layer Chromatography of Siling Labuyo ExtractJan Eric Balete0% (1)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Volvo 8400 City Bus Brochure For Sales KitDokumen8 halamanVolvo 8400 City Bus Brochure For Sales KitER Balram YadavBelum ada peringkat

- Trex 06166Dokumen82 halamanTrex 06166OSDocs2012Belum ada peringkat

- Wire AbbreviationsDokumen6 halamanWire Abbreviationssarat chandBelum ada peringkat

- Distillation of Ethanol-Water Solution Using Enthalpy-Concentration DiagramDokumen16 halamanDistillation of Ethanol-Water Solution Using Enthalpy-Concentration DiagramChiara PatrianaBelum ada peringkat

- PowerPoint Sample: BioDiesel Production Power Point PresentationDokumen16 halamanPowerPoint Sample: BioDiesel Production Power Point PresentationJohn MelendezBelum ada peringkat