1116-01 Method Statement For Gas Works

Diunggah oleh

hasan_676489616100%(3)100% menganggap dokumen ini bermanfaat (3 suara)

1K tayangan3 halamanThis document provides a method statement for installing and testing LPG gas pipe works at Shoreline Apartments 1&3 in Palm Jumeirah. It outlines procedures for preparing the work area, installing and painting pipes, hanging supports, leak testing using nitrogen at 1.5 times working pressure, and safety precautions. Upon satisfactory completion and testing, the engineer will sign a test certification to be provided to relevant parties.

Deskripsi Asli:

Judul Asli

1116-01 method statement for gas works.doc

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOC, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document provides a method statement for installing and testing LPG gas pipe works at Shoreline Apartments 1&3 in Palm Jumeirah. It outlines procedures for preparing the work area, installing and painting pipes, hanging supports, leak testing using nitrogen at 1.5 times working pressure, and safety precautions. Upon satisfactory completion and testing, the engineer will sign a test certification to be provided to relevant parties.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

100%(3)100% menganggap dokumen ini bermanfaat (3 suara)

1K tayangan3 halaman1116-01 Method Statement For Gas Works

Diunggah oleh

hasan_676489616This document provides a method statement for installing and testing LPG gas pipe works at Shoreline Apartments 1&3 in Palm Jumeirah. It outlines procedures for preparing the work area, installing and painting pipes, hanging supports, leak testing using nitrogen at 1.5 times working pressure, and safety precautions. Upon satisfactory completion and testing, the engineer will sign a test certification to be provided to relevant parties.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

THE PALM JUMEIRAH

SHORELINE APARTMENTS 1&3

JAP006-C400a

Date: 09.07.00!

Pa"e: 1 #$ 3

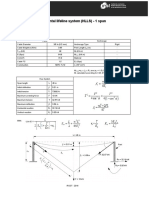

METHOD STATEMENT FOR INSTALLATION AND TESTING OF LPG GAS WORKS

1.0 PURPOSE

To define the method and procedures for installation of LP gas pipe works in shore line apartments

on this project.

2.0 SCOPE OF WORKS

The Method is applicable to all LP gas works in the project.

3.0 PROCEDURE

Before commencement following works are required to be carried out.

a) Check work area is clean and safe.

b) Check materials to be used hae an approed material submittal and inspection.

c) Check drawings to be used hae an approed shop drawings submittal.

4.0 INSTALLATION

Painting pipes! "nsure that the surface is free of dust and all other contaminants before

proceeding for painting# appl$ wash primer with brush and rolling brush as first coat on pipe#

appl$ topcoat colored enamel paint with brush and rolling brush# gie sufficient time for dr$ing

to touch and to full$ cure# painting shall compl$ to specification %&''&.

Mark the routing of pipe work on slab ( concrete according to approed shop drawings.

)i* hangers and supports according to approed shop drawings.

Measure the length of pipe required# marking due allowance for an$ pipe fittings to be used.

Cut the pipe to the measured length.

The t$pe of jointing method shall be welding for copper and steel pipe works as per

manufacturer recommendation.

Close necessar$ open ends with end caps to keep pipe clean.

THE PALM JUMEIRAH

SHORELINE APARTMENTS 1&3

JAP006-C400a

Date: 09.07.00!

Pa"e: #$ 3

Painting pipes! "nsure that the surface is free of dust and all other contaminants before

proceeding for painting# appl$ wash primer with brush and rolling brush as first coat on pipe#

appl$ topcoat red enamel paint with brush and rolling brush# gie sufficient time for dr$ing to

touch and to full$ cure.

Carr$ out leakage test as follows+

,itrogen will be used as a test media. Pressuri-ing c$linders will be used to pressuri-e each

completed line to the required test pressure.

Test head with pressure gauge and ale connection to the pressuri-ing c$linders shall be

connected to the installation.

.fter finishing the mounting of pipes the section to be tested of s$stem will be tested with

pressure of %.& times of the working pressure of the s$stem.

Before testing the section all air must be ented.

.ll ales in the lines shall be in an open position during testing

.ll open pipes will be closed with plugs.

/nder no circumstance shall a ale in a line be used as a bulkhead between different

sections of the piping s$stem.

The pressure will be increased up to the test pressure with % bar interals and the test takes

01 minutes# in that period the piping s$stem shall withstand the test pressure specified

without showing an$ eidence of leakage or other defects# an$ reduction of test pressures as

indicated b$ pressure gauges shall be deemed to indicate the presence of a leak unless such

reduction can be readil$ attributed to some other cause.

2n case of unsatisfactor$ test# the place of leakage is repaired or replaced and the test is

repeated.

/pon satisfactor$ completion of the testing process the "ngineer shall sign the Test

Certification proided b$ the Contractor# copies of Test Certification shall be gien to the

"ngineer# "mplo$er and releant .uthorities.

The nitrogen will be kept in the pipes and will not be released until the time of commissioning.

THE PALM JUMEIRAH

SHORELINE APARTMENTS 1&3

JAP006-C400a

Date: 09.07.00!

Pa"e: 3 #$ 3

5.0 REFERENCE DOCUMENTS

.pproed 3rawings.

Project 4pecification.

.pproed materials.

6.0 INSPECTION & MEASURING EQUIPMENT USED

Measuring Tapes.

Pressure gauge.

7.0 SAFET

4afet$ equipment to be worn at all times.

The pipes should be laid on a reasonable flat surface free from large stones or sharp

projections. 3ifferent pipes are best stocked separatel$.

4tocks should be limited to % m height and be shaded properl$ b$ canas or similar to aoid

damage from /5 radiation.

Pipes should not be dragged along rough surface. Loading 6 unloading of pipes should be

carried out b$ hand and use of skids should be aoided. Pipes should not be dropped on

hard surface.

Care should be taken before loading to check the ehicle load carr$ing area is free from nails

and other projections. Pipes shall be properl$ supported during transportation. Pipe should

neer be thrown.

Lock ales and put warning tape during the testing of circuit.

!.0 A""#$%&'("

2nspection and checklist.

Pressure test certificate.

Anda mungkin juga menyukai

- Method Statement For LPG Systems Work Installation, Testing & CommissioningDokumen6 halamanMethod Statement For LPG Systems Work Installation, Testing & CommissioningDong Vanra100% (1)

- Installation of Rockwool InsulationDokumen8 halamanInstallation of Rockwool InsulationHSE RHIBelum ada peringkat

- Removing and Installing Underground Storage TanksDokumen7 halamanRemoving and Installing Underground Storage TanksM Waqas Habib100% (1)

- Air Terminal Device Installation MethodDokumen13 halamanAir Terminal Device Installation MethodAnish Kumar100% (1)

- Air Compressor Installation Method StatementDokumen14 halamanAir Compressor Installation Method Statementhoang nguyenBelum ada peringkat

- Method Statement For Lifting Cryognic TankDokumen5 halamanMethod Statement For Lifting Cryognic TankYawar QureshiBelum ada peringkat

- Fire Hose Rack & Reel Testing ProcedureDokumen2 halamanFire Hose Rack & Reel Testing ProcedureDong VanraBelum ada peringkat

- Work Method Statement FOR HVAC DuctingCopper PipesDokumen9 halamanWork Method Statement FOR HVAC DuctingCopper PipesSameer JogasBelum ada peringkat

- METHOD STATEMENT Sluice Gates InstallDokumen9 halamanMETHOD STATEMENT Sluice Gates Installjameel100% (2)

- Method Statement of Hydro TestDokumen4 halamanMethod Statement of Hydro Testsharan21v100% (2)

- Safe Work Pipes DemolitionDokumen5 halamanSafe Work Pipes DemolitionahmadBelum ada peringkat

- Method Statement River CrossingDokumen2 halamanMethod Statement River CrossingDeny Cahyo NBelum ada peringkat

- Installation Of Ductile Iron Flange Type Joint MethodDokumen10 halamanInstallation Of Ductile Iron Flange Type Joint MethodshahidBelum ada peringkat

- Job Hazard AnalysisDokumen9 halamanJob Hazard Analysisananthu.uBelum ada peringkat

- METHOD STATEMENT - Floor Drain & FCO InstallationDokumen5 halamanMETHOD STATEMENT - Floor Drain & FCO InstallationGerlie Dimayuga100% (2)

- Method for Removing Fire Fighting Pipes from Existing NetworkDokumen1 halamanMethod for Removing Fire Fighting Pipes from Existing NetworkAamer Abdul MajeedBelum ada peringkat

- Inspection and Test Plan for Earth Works Site PreparationDokumen2 halamanInspection and Test Plan for Earth Works Site PreparationMustafa313100% (3)

- Installation Method for Gas DetectionDokumen2 halamanInstallation Method for Gas DetectionvictorBelum ada peringkat

- Method Statement For Installation of Automatic Sliding DoorDokumen6 halamanMethod Statement For Installation of Automatic Sliding DoorKalid JmalBelum ada peringkat

- MOS For Underground Pipe Water InstallationDokumen2 halamanMOS For Underground Pipe Water InstallationMukhlish AkhatarBelum ada peringkat

- Method of Statement For Cold CuttingDokumen12 halamanMethod of Statement For Cold Cuttingbabjihanumanthu100% (2)

- Surface GI Conduit Installation Method StatementDokumen4 halamanSurface GI Conduit Installation Method StatementJaneBelum ada peringkat

- METHOD STATEMENT - Flow TestDokumen5 halamanMETHOD STATEMENT - Flow TestGerlie Dimayuga50% (2)

- Method Statement For Pipe Line Re-RoutingDokumen6 halamanMethod Statement For Pipe Line Re-RoutingChris100% (1)

- Method Statement - Relocation of Water MeterDokumen5 halamanMethod Statement - Relocation of Water MeterMG50% (2)

- Method Statement For Installation of Underground Duct For Electrical and ELV CablesDokumen39 halamanMethod Statement For Installation of Underground Duct For Electrical and ELV CablesAnandu Ashokan100% (1)

- Method Statement For Installation of Water Spray Deluge System - LPG TankDokumen13 halamanMethod Statement For Installation of Water Spray Deluge System - LPG Tankpunk cm100% (2)

- CPVC Method StatementDokumen2 halamanCPVC Method StatementPrashanth A67% (3)

- RISK ASSESSMENT Vertical Storage Tank For HSD FaisalabadDokumen17 halamanRISK ASSESSMENT Vertical Storage Tank For HSD Faisalabadahmed100% (1)

- Method Statement for New Petrol Filling Station DemolitionDokumen15 halamanMethod Statement for New Petrol Filling Station DemolitionmuthunayakeBelum ada peringkat

- PETRONAS RAPID Project Insulation Method StatementDokumen11 halamanPETRONAS RAPID Project Insulation Method StatementAmirHakimRusliBelum ada peringkat

- Method Statement Construction WorkDokumen1 halamanMethod Statement Construction WorkNazNazirah100% (4)

- Installation of Fire Alarm System Method StatementDokumen9 halamanInstallation of Fire Alarm System Method StatementiamajumalBelum ada peringkat

- Method Statement for Testing Commissioning Foam SystemDokumen3 halamanMethod Statement for Testing Commissioning Foam SystemDong Vanra100% (1)

- METHOD OF BLINDING CONCRETE WORKSDokumen6 halamanMETHOD OF BLINDING CONCRETE WORKSMohd Muksin100% (1)

- 03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineDokumen6 halaman03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineHimanshu NiveriyaBelum ada peringkat

- Method Statement For Underground PVC Pipe InstallationDokumen44 halamanMethod Statement For Underground PVC Pipe InstallationSaad Amer100% (1)

- Method Statement For Establishment of Site FacilitiesDokumen9 halamanMethod Statement For Establishment of Site FacilitiesNaveen GladsonBelum ada peringkat

- Subcontractor Hse Mobilization Checklist PDFDokumen2 halamanSubcontractor Hse Mobilization Checklist PDFshareyhouBelum ada peringkat

- Risk Assessment - Wall Reinforcement and FormworkDokumen4 halamanRisk Assessment - Wall Reinforcement and FormworkSarfraz Randhawa100% (1)

- 001 MEP - Method Floor&Wall PenetrationDokumen7 halaman001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- Method Statement For Dismantling Joinery UnitsDokumen7 halamanMethod Statement For Dismantling Joinery UnitsVijayakumar KarunanidhiBelum ada peringkat

- Cold Cutting PDFDokumen9 halamanCold Cutting PDFAshraf BottaniBelum ada peringkat

- Method Statement-Hard Landscaping WorksDokumen7 halamanMethod Statement-Hard Landscaping WorksbhupsjangirBelum ada peringkat

- PIPELINE HYDROSTATIC TEST REPORTDokumen6 halamanPIPELINE HYDROSTATIC TEST REPORTHalil GüneyBelum ada peringkat

- Erect Pre-Cast Concrete Stairs MethodDokumen2 halamanErect Pre-Cast Concrete Stairs MethodBaguma Grace Gariyo100% (3)

- Method Statement For Lifting WorksDokumen12 halamanMethod Statement For Lifting WorksBeomHee Lee100% (1)

- Method Statement For Hydrant As Per PVN CommentsDokumen23 halamanMethod Statement For Hydrant As Per PVN CommentsAbcd efgh100% (1)

- Method Statement For Pump InstallationsDokumen4 halamanMethod Statement For Pump InstallationsAnonymous xyZH2OaUV100% (1)

- Method Statement HDPE PDFDokumen1 halamanMethod Statement HDPE PDFshameemBelum ada peringkat

- Method Statement For Trail Pit Excavation (Manual)Dokumen18 halamanMethod Statement For Trail Pit Excavation (Manual)Rawoofuddin ChandBelum ada peringkat

- Method Statement For I Beam InstallationDokumen5 halamanMethod Statement For I Beam InstallationHafiz NurahimBelum ada peringkat

- Method Statement For Lifting, Moving and Shifting Material at Site ActivitiesDokumen6 halamanMethod Statement For Lifting, Moving and Shifting Material at Site ActivitiesAndriano100% (2)

- Method Statement for Footing Concrete PourDokumen4 halamanMethod Statement for Footing Concrete PourRizky V 'dHee'Belum ada peringkat

- Method Statement FOR Sanitary SewerageDokumen42 halamanMethod Statement FOR Sanitary Seweragemd_rehan_2100% (3)

- Method Statement - Repair and Rehabilitation of Ad-Dhana Soccer Field - Revision 0Dokumen9 halamanMethod Statement - Repair and Rehabilitation of Ad-Dhana Soccer Field - Revision 0MGBelum ada peringkat

- Job Safety Analysis for HDPE Pipe InstallationDokumen12 halamanJob Safety Analysis for HDPE Pipe InstallationtusharDJBelum ada peringkat

- Pilot Trenching MOSDokumen6 halamanPilot Trenching MOSshah1980Belum ada peringkat

- 0983-03 Method Statement For Installation & Testing of Fire Fighting PipesDokumen4 halaman0983-03 Method Statement For Installation & Testing of Fire Fighting Pipeshasan_67648961650% (2)

- Fire Sprinkler Installation MethodDokumen3 halamanFire Sprinkler Installation MethodAnkit KumarBelum ada peringkat

- 2014 68 Eu PDFDokumen96 halaman2014 68 Eu PDFAlienshow100% (1)

- Delayed PWHTDokumen4 halamanDelayed PWHThasan_676489616Belum ada peringkat

- API 5L - 43rd and 44th Ed - Comparison r1Dokumen68 halamanAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- Cross Cut TestDokumen1 halamanCross Cut Testhasan_676489616Belum ada peringkat

- Method of Statement Piping Fab. ErectionDokumen22 halamanMethod of Statement Piping Fab. Erectionhasan_676489616Belum ada peringkat

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- Acid PipingDokumen1 halamanAcid Pipinghasan_676489616Belum ada peringkat

- Duty CycleDokumen1 halamanDuty Cyclehasan_676489616Belum ada peringkat

- Celex:02014l0068 20140717:en:txtDokumen118 halamanCelex:02014l0068 20140717:en:txtedwinBelum ada peringkat

- LNG Tank Dismantling MS RevCDokumen14 halamanLNG Tank Dismantling MS RevChasan_676489616100% (1)

- Paul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDokumen438 halamanPaul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDavor Katunarić100% (1)

- PNFJ8000Dokumen71 halamanPNFJ8000seenu189100% (1)

- Horizontal Life Line CalculationDokumen1 halamanHorizontal Life Line Calculationhasan_676489616100% (1)

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- Europe steel standards overviewDokumen14 halamanEurope steel standards overviewhasan_676489616Belum ada peringkat

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDokumen24 halamanPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishBelum ada peringkat

- Tank Construction Quality ProceduresDokumen36 halamanTank Construction Quality ProceduresJagdish Busa100% (2)

- Fall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public ConsultDokumen40 halamanFall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public Consultlwin_oo2435100% (3)

- Solar Power Plant ReportDokumen1 halamanSolar Power Plant Reporthasan_676489616Belum ada peringkat

- OSHA - 29CFR - Construction StandardsDokumen22 halamanOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- E SN854Dokumen2 halamanE SN854hasan_676489616Belum ada peringkat

- 1926.501 - Duty To Have Fall ProtectionDokumen4 halaman1926.501 - Duty To Have Fall Protectionhasan_676489616Belum ada peringkat

- FITTINGS ButtweldDokumen5 halamanFITTINGS ButtweldThamaraikani ManiBelum ada peringkat

- Stainless Steels For H2SO4Dokumen4 halamanStainless Steels For H2SO4Marshel LeninBelum ada peringkat

- E SN882Dokumen2 halamanE SN882hasan_676489616Belum ada peringkat

- Din 2614Dokumen11 halamanDin 2614hasan_676489616Belum ada peringkat

- German test point system standardDokumen3 halamanGerman test point system standardhasan_676489616Belum ada peringkat

- E SN883Dokumen2 halamanE SN883hasan_676489616100% (1)

- ASME B16.47 Series B FlangeDokumen4 halamanASME B16.47 Series B Flange41h189Belum ada peringkat

- Din 2461-66Dokumen7 halamanDin 2461-66hasan_676489616Belum ada peringkat

- Museum of Modern Literature, GermanyDokumen14 halamanMuseum of Modern Literature, GermanyAntonio CampoverdeBelum ada peringkat

- Diaz Chavez Grecia - FB APDokumen2 halamanDiaz Chavez Grecia - FB APChristianTeofiloGallegosCentenoBelum ada peringkat

- Cpar Lesson 1Dokumen24 halamanCpar Lesson 1Chrisly GuadayoBelum ada peringkat

- Steam TypographyDokumen44 halamanSteam Typographyapi-262086052Belum ada peringkat

- Tonkova Babjak ... BAR 1350 2005 1 1 PDFDokumen26 halamanTonkova Babjak ... BAR 1350 2005 1 1 PDFDada MamusaBelum ada peringkat

- Pacita Abad: Renowned Filipino Artist Known for Her Extensive Global TravelsDokumen7 halamanPacita Abad: Renowned Filipino Artist Known for Her Extensive Global Travels061584Belum ada peringkat

- Arts App. Soul MakingDokumen13 halamanArts App. Soul MakingJonathan LorenzoBelum ada peringkat

- Perceptibility by Barry SchwabskyDokumen3 halamanPerceptibility by Barry SchwabskyCarlos Alberto Avendaño RestrepoBelum ada peringkat

- Kodai GazetteDokumen21 halamanKodai GazetteElango RajaBelum ada peringkat

- Lava Ultimate Frame Ifu Na-En PDFDokumen4 halamanLava Ultimate Frame Ifu Na-En PDFcriveliBelum ada peringkat

- Annotated Mona LisaDokumen10 halamanAnnotated Mona Lisajordanb46Belum ada peringkat

- Stele of Revealing (WP)Dokumen5 halamanStele of Revealing (WP)Dgray93lon100% (1)

- Traditional Kerala ArchitectureDokumen47 halamanTraditional Kerala ArchitectureMohammed Al SabahBelum ada peringkat

- Lesson 1 - Integrative Art As Applied To Contemporary ArtDokumen41 halamanLesson 1 - Integrative Art As Applied To Contemporary Artjsantos.k12254390Belum ada peringkat

- Catalogue of Greek and Etruscan Vases in the British Museum Vol. Vases of the Finest PeriodDokumen496 halamanCatalogue of Greek and Etruscan Vases in the British Museum Vol. Vases of the Finest PeriodVLADIMIRO LAMIBelum ada peringkat

- Productivity OutputDokumen1 halamanProductivity OutputAmer Gonzales100% (1)

- Discovery Featuring Silver & Jewelry, Couture & Textiles, Country Americana - Skinner Auction 2712MDokumen76 halamanDiscovery Featuring Silver & Jewelry, Couture & Textiles, Country Americana - Skinner Auction 2712MSkinnerAuctionsBelum ada peringkat

- 21st Century Lit Topic For MID-TERMDokumen54 halaman21st Century Lit Topic For MID-TERMAvegail Constantino0% (1)

- Grade 9 Art Lesson 3Dokumen24 halamanGrade 9 Art Lesson 3KC ChavezBelum ada peringkat

- Coptic Mural Painting Techniques & SubjectsDokumen9 halamanCoptic Mural Painting Techniques & SubjectsMarius CiuluBelum ada peringkat

- Art App 01Dokumen22 halamanArt App 01Joarder Hafiz UllahBelum ada peringkat

- Pre-Final Examination Contemporary Philippine Arts From The RegionsDokumen4 halamanPre-Final Examination Contemporary Philippine Arts From The RegionsRutchel100% (1)

- Industrial RevolutionDokumen5 halamanIndustrial RevolutionSurekha ChandranBelum ada peringkat

- National Museum of Fine ArtsDokumen6 halamanNational Museum of Fine Artsxandra ylaineBelum ada peringkat

- World's Tallest Hindu Temple Planned for Mayapur, IndiaDokumen10 halamanWorld's Tallest Hindu Temple Planned for Mayapur, IndiaVirendra Kumar GajbhiyeBelum ada peringkat

- Obsidian Glass Rock Formation UsesDokumen10 halamanObsidian Glass Rock Formation UsesThomaz JudeaBelum ada peringkat

- Extreme Monster Demon Hentai Anime Magazine PDFDokumen2 halamanExtreme Monster Demon Hentai Anime Magazine PDFKelly25% (4)

- Art AppreciationDokumen7 halamanArt AppreciationReus BaskervilleBelum ada peringkat

- Finishes To ConcreteDokumen19 halamanFinishes To Concretenikhita0412Belum ada peringkat