Engineering Manual - Print

Diunggah oleh

alvinhamJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Engineering Manual - Print

Diunggah oleh

alvinhamHak Cipta:

Format Tersedia

1

GkUNDlOS "#$%&'()

LNGlNLLklNG MANUAL

"*+,-./012 34025/-

6#7"#66("#7 89#%9:

CopyrighI 2009 GkUNDlOS ManagemenI AS. All righIs reserved.

CopyrighI law and inIernaIional IreaIies proIecI Ihis maIerial. No parI o Ihis maIerial

may be reproduced in any orm or by any means wiIhouI prior wriIIen permission rom

GkUNDlOS ManagemenI AS.

All reasonable care has been Iaken Io ensure Ihe accuracy o Ihe conIenI o Ihis maIerial:

Rowever, GkUNDlOS shall noI be held liable or any losses wheIher direcI or indirecI,

incidenIal or consequenIial arising ouI o Ihe use o or reliance upon on any conIenI o Ihis

maIerial.

75*5/12 ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; <

- 8oiler Iypes........................................................6

- 8oiler sysIem (lig. 3) ......................................7

34025/ =4>?4*5*.- ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; @

- DeaeraIorsCondenser ..................................7

- Lconomizer ........................................................9

- Lconomisers in Ihe marine indusIry .....9

- Lconomisers in land based boilers .........9

- 8oiler pumps .................................................. 10

- 8oiler eed .................................................. 10

- CondensaIe pumps ................................. 13

- ShunI pumps ............................................ 14

AB1. 7/,*+C4- 4CC5/- ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;D@

- 8oiler problems ............................................. 21

- 8oIIom blow down.................................. 22

- Weekend shoI down ............................... 22

- ProducIion changes................................. 22

- Dosing ......................................................... 23

- leed pump sIarI-up ................................ 23

E,>?- 1*+ -0F0*G ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;HI

- Sizing ................................................................ 25

J1?4,/ .1K25 ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;LM

1A8LL Ol CON1LN1S

6

LNGlNLLklNG MANUAL N 76#6(9:

75*5/12

1he producIion o sIeam and hoI waIer is one o Ihe

world's largesI indusIries. Grundos is pleased Io be

Ihe preerred supplier o pumps or boiler sysIems or

Ihese indusIries.

Grundos pumps are reliable, ehcienI and cover a

wide perormance range. As an experienced con-

sulIanI in Ihe implemenIaIion o boiler sysIems, we

engage in a process o close parInership and dialogue

Io hnd Ihe besI soluIion or your sysIem.

Grundos is a global enIerprise wiIh a worldwide ser-

vice neIwork. When you need exporI or on-Ihe-spoI

advice in a parIicular parI o Ihe world, we have Ihe

Iechnical experIise close by.

34025/ .O?5-

1hree main boiler Iypes exisI:

- RoI waIer boiler

- 1hermal oil boiler

- SIeam boiler

1he demands and Ihe sizing o Ihe pumps used or

Ihese boiler Iypes are very dierenI.

1he inserIed picIures aI Ihe righI side show some o

Ihe Iypical boiler consIrucIions used.

Rere you can see a cuI open drawing o Ihe mosI

common consIrucIion o a boiler used in Ihe manu-

acIuring indusIry. AI Ihe boIIom you see Ihe burner

chambers, which are surrounded wiIh waIer and aI

Ihe Iop Ihe smoke pipes. On Ihe side o Ihe boiler you

can see Ihe Iwo eed waIer pumps.

1his consIrucIion is Iypically seen in Ihe

marine, buI is also used in Ihe manuac-

Iuring indusIry:

A Iypical boiler consIrucIion in Ihe

manuacIuring indusIry:

LNGlNLLklNG MANUAL N 76#6(9:

1. RoI waIer boiler

RoI waIer boilers are normally used in room and buil-

ding heaIing. 1hese kinds o sysIems are suiIable or

discharge IemperaIures o up Io 140C. 1he advan-

Iage o hoI waIer over sIeam is IhaI Ihe energy loss is

much lower Ihan wiIh sIeam boilers. ligure 1 shows

how Ihe pumps are normally insIalled in a hoI waIer

boiler.

2. 1hermal oil boiler

ln hoI oil boilers, oil is used insIead o sIeam or wa-

Ier. 1he advanIage o oil is IhaI Ihe sysIem does noI

have Io be pressurised above 100C as wiIh waIer

and sIeam. Oil is sIill liquid in aImospheric pressures

o up Io 300C. ln conIrasI, waIer requires a pressure

o 85 bar Io avoid evaporaIing aI IhaI IemperaIure.

1he consIrucIion o Ihermal oil boilers and sysIems

is almosI idenIical Io IhaI o hoI waIer boilers.almosI

idenIical Io IhaI o hoI waIer boilers.

3. SIeam boiler

SSIeam is normally used in indusIrial process heaIing

due Io iIs high energy conIenI. SIeam is also used or

cleaning applicaIions and Iurbine generaIion. 1he

advanIage o sIeam over hoI waIer is iIs high energy

conIenI and abiliIy Io release energy during conden-

saIion. 1his also allows or very small heaI exchan-

gers.

34025/ =4>?4*5*.-

$515/1.4/-NP4*+5*-5/

DeaeraIor and condenser Ianks are only used in sIeam

boiler sysIems and noI in hoI waIer and hoI oil boilers

as uid is always in iIs liquid orm. 1he consIrucIion o

Ihese Iwo Iypes o Ianks is almosI idenIical, buI as Iheir

names indicaIe, Ihey are used or dierenI purposes.

1wo primary principles are used wiIh Ihis orm o

Iank design; Ihermal and vacuum.

Burner

Shunt

Forward

Return

Hot water

boiler End

Burner

Shunt

End

Forward

Return

Hot oil

boiler

lig. 1

lig. 2

lig. 3

Deaerator

Condensate tank

Condensate

pumps

Steamboiler

Feed pumps

Control

box

Level

sensor

Level

sensor

Control

box

Return

condensate

From water

treatment

E

E

Burner

7

8

LNGlNLLklNG MANUAL N 3Q":6( PQ8EQ#6#'&

1he Iank design used depends on Ihe Iype o boiler

being used. Lach principle also has dierenI pump

consIrucIion requiremenIs.

'B5/>12 ?/0*=0?25

A Iank using Ihe Ihermal principle is connecIed Io Ihe

aImosphere via a valve. 1his design is normally used

in smaller planIs. Rere, sIeam is used Io mainIain

Ihe Iank waIer IemperaIure aI around 105C, which

removes air rom Ihe waIer. A IemperaIure o 105`C is

needed because o Ihe air venI valve mounIed in Ihe

deaeraIor or condenser which needs an opening pres-

sure o approx. 0.2 bar, which provides a IoIal pressure

o 1.2 bar absoluIe. 1his means IhaI Ihe waIer will

boil aI a IemperaIure IhaI is a liIIle biI higher Ihan

Ihe usual 100`C where waIer normally boils in aImos-

pheric pressure. See also Ihe vapour pressure Iable aI

Ihe back o Ihis manual. 8esides Ihe air venI valve, a

vacuum breaker valve has also been mounIed Io en-

sure IhaI vacuum never occurs in Ihis Iank Iype. l Ihe

vacuum valve was noI mounIed, vacuum could occur

when cold make up waIer was added Io Ihe Iank.

J1=,,> ?/0*=0?25

Rere an e|ecIor pump is used Io creaIe a vacuum in

Ihe Iank. 1his causes Ihe Iank waIer Io sIarI boiling

even aI low IemperaIures. 1his in Iurn removes air

rom Ihe waIer. 1his principle is normally used in

sIeam Iurbine applicaIions.

$515/1.4/- RS0G; IT

A deaeraIor is used Io reduce oxygen (O2) and car-

bonic acid (CO2) levels in boiler eedwaIer Io proIecI

Ihe boiler againsI corrosion. lI is possible Io reduce

oxygen and carbonic acid levels Io abouI 0.02 mgl

o O2 and 0 mgl o CO2, depending on deaeraIor

consIrucIion.

P4*+5*-5/- RS0G; UT

A condenser ensures IhaI all sIeam is condensed be-

ore being pumped back inIo Ihe deaeraIor and Ihen

nternal steam distributor piping

nternal perforated pipe (water distributor)

Perforated trays

Low pressure steam

Boiler feed water (Recycled condensate and makeup water)

Air vent

Condensate

DEAERATOR

FEED TANK

Heating steam

Aeration steam

Deaerated water to

boiler feedwater pump

Trayed section vent

drain rollers

glass

level

gauge

Liquid level

Baffle

Baffle

Flanges

Steam

Condensate

Water outlet

Water inlet

To ejector

vacuum system

Baffle

Flanged

cover

plate

Tubesheet Tubesheet

lig. 4

lig. 5

inIo Ihe boiler. New IreaIed waIer is normally ed inIo

Ihe condenser.

6=4*4>0F5/

RisIorically, economisers have only been used in

large-scale power planIs. Rowever, Ihe demand or

more ehcienI boilers wiIhin Ihe manuacIuring in-

dusIry and marine indusIry means IhaI economisers

are now ar more commonplace.

An economiser is a heaI exchanger placed in Ihe

exhausI rom a boiler or in Ihe exhausI unnel o Ihe

main engine o a ship.

Pump requiremenIs dier greaIly, depending on

where Ihe economiser is insIalled.

LCONOMlZLk lN 1RL MAklNL (llG. 6)

keerring Io Ihe diagram below, Ihe circulaIion pump

has Io be sized Io Ihe pressure and IemperaIure in Ihe

boiler, which can easily be 20 bar and 170C. 8ecause

o Ihis, economisers eaIuring air-cooled Iop and

bearing ange may be required. 1he pump does noI

normally need Io be capable o delivering a high di-

erenIial pressure, as iI only has Io overcome Ihe pres-

sure loss in Ihe plaIe heaI exchanger (economiser).

LCONOMlSLkS lN LAND 8ASLD 8OlLLkS (llG. 7)

An economiser used wiIh a boiler locaIed on land

uses Ihe boiler's wasIe gases. 1he waIer circulaIed

above Ihe economiser is normally supplied by Ihe

main eed pump, buI can also be hIIed wiIh iIs own

circulaIion pump see lig. 7. 1he chimney will also in-

clude a bypass Io allow wasIe gases Io pass around

Ihe heaI exchanger.

1he consIrucIion diers rom marine design as Ihe

wasIe gases released rom Ihe main engine o a ship

are signihcanIly greaIer. Lnergy produced by marine

applicaIions oIen allow or Ihe generaIion o over-

heaIed sIeam ed direcIly rom economiser and ouI

inIo Ihe piping.

Deaerator

Steam

Circulation

Economize

Boiler

Burner

Feed pump

Condensate

Smoke from

main engine

Smoke to

chimney

Deaerator

Boiler

Burner

Feed pump

Condensate

Steam

Economize

Smoke from

main engine

Smoke to

chimney

lig. 6

lig. 7

9

10

34025/ ?,>?-

A range o pumps or dierenI boiler applicaIions

exisI. 1his secIion describes Ihe Iypical posiIioning o

Ihe various pumps and how Ihey are conIrolled.

1he mosI common boiler applicaIions are boiler eed,

condensaIe pumping, economiser circulaIion and

shunI pumps.

Sub-sysIem pumps such as dosing and waIer IreaI-

menI pumps also exisI.

8OlLLk lLLD

8oiler eeding can normally Iake place in Ihe

ollowing 4 ways:

- Ono conIrol

- 1hrough eed valve

- 1hrough eed valve and variable speed

- variable speed

All 4 meIhods will be described in Ihe ollowing.

1. Ono conIrol (lig. 8)

S,*=.04*

ln ono conIrol Ihe eed pump is swiIched ono

Ihrough a level sensor or a dierenIial pressure sen-

sor. When Ihe waIer level alls Io Ihe Pump on" level,

Ihe pump sIarIs pumping a large quanIiIy o relaIi-

vely cold waIer inIo Ihe boiler. 1his will reduce Ihe qu-

anIiIy o sIeam and cause Ihe sIeam pressure Io all.

1his is Ihe reason why ono conIrol causes variaIi-

ons in sIeam producIion. lI may also cause over-boi-

ling in Ihe boiler, which may cause waIer Io enIer Ihe

sysIem.

- lnexpensive

- Lasy Io insIall

- No bypass

$/1VK1=W-

- Poor sIeam qualiIy

Deaerator

Steamboiler

Feed pumps

Control

box

Level

sensor

Burner

lig. 8

LNGlNLLklNG MANUAL N 3Q":6( PQ8EQ#6#'&

11

2. 1hrough eed valve (lig. 9)

S,*=.04*

ln Ihis Iype o sysIem Ihe waIer level in Ihe boiler is

conIrolled by a eed valve, which is conIrolled by a

level sensor or a dierenIial pressure IransmiIIer

posiIioned on Ihe boiler.

1he eed valve conIrols Ihe waIer inIake, which is

ad|usIed according Io Ihe sIeam consumpIion. 1his,

however, requires IhaI Ihe eed pump is seI Io conIi-

nuous operaIion.

1his sysIem operaIes smooIhly and is ideal or all

Iypes o sIeam boilers, boIh small and large, and will

minimise Ihe risk o over-boiling.

- 8oiler eeding ad|usIed according Io

sIeam consumpIion, as described.

$/1VK1=W-

- 1he pump musI be seI Io

conIinuous operaIion (energy consumpIion)

- 8ypass

- 1he eed valve is expensive

- Pressure loss across Ihe eed valve

">?4/.1*.X

kemember Io size bypass according Io Ihe Ck pumps

min. ow which is 10 % o nominal ow or Ihe pump.

lI may be an idea Io sIop Ihe pump when Ihe valve is

closed. 1his requires, however, a signal rom Ihe valve.

3. 1hrough eed valve, variable speed. (lig. 10)

S,*=.04*

ln Ihis sysIem Ihe waIer level in Ihe boiler is conIrol-

led by a eed valve, which is conIrolled by a level sen-

sor or a dierenIial pressure IransmiIIer posiIioned

on Ihe boiler. 1he eed valve conIrols Ihe waIer inIake,

which is ad|usIed according Io Ihe sIeam consump-

Iion. 1his, however, requires IhaI Ihe eed pump is

seI Io conIinuous operaIion. 1his sysIem operaIes

smooIhly and is ideal or all Iypes o sIeam boilers,

Deaerator

Bypass

Steamboiler

Feed pumps

M

Control

box

Level

sensor

P

E

E

Burner

lig. 10

Deaerator

Steamboiler

Feed pumps

Bypass

Level

sensor

M

Burner

lig. 9

12

boIh small and large, and will minimise Ihe risk o

over-boiling.

- 8oiler eeding ad|usIed according Io sIeam con

sumpIion

- Lnergy savings on pump operaIion

- ConsIanI dierenIial pressure across Ihe eed valve

$/1VK1=W-

- 8ypass

- 1he eed valve is expensive

- Pressure loss across Ihe eed valve

">?4/.1*.X

kequiremenIs vary rom one counIry Io anoIher as

regards Ihe sizing o boiler eed pumps.

kemember Io size bypass according Io Ihe CkCv

daIa as well as Io min. ow. lI may be an idea Io sIop

Ihe pump when Ihe valve is closed. 1his requires,

however, a signal rom Ihe valve. lind ouI wheIher

variable speed conIrol o boIh pumps is required as

Ihis increases expenses, buI does noI provide Ihe

same exibiliIy as Io alIernaIing Ihe pump operaIion.

4. WiIhouI eed valve (lig. 11)

S,*=.04*

ln Ihis sysIem Ihe waIer level in Ihe boiler is con-

Irolled direcIly by Ihe variable speed pumps wiI-

houI using a eed valve. 1he pumps are conIrol-

led by a level sensor or a dierenIial pressure

IransmiIIer posiIioned on Ihe boiler. 1his way Ihe

waIer inIake is conIrolled according Io Ihe sIeam

consumpIion. 1his sysIem operaIes smooIhly and is

ideal or all Iypes o sIeam boilers, boIh small and

large, and will minimise Ihe risk o over-boiling.

Deaerator

Steamboiler

Feed pumps

Control

box

Level

sensor

E

E

Burner

lig. 11

LNGlNLLklNG MANUAL N 3Q":6( PQ8EQ#6#'&

13

- As described, boiler eeding ad|usImenI

according Io Ihe sIeam consumpIion

- Lnergy savings on pump operaIion

- No pressure loss across Ihe eed valve

- Money earned equal Io Ihe price o an expensive

eed valve

$/1VK1=W

- kequires precise and qualihed sIarI-up

">?4/.1*.X

- A minimum requency musI be dehned ensuring

IhaI Ihe pump can always overcome Ihe pressure

in Ihe boiler, and supply Ihe minimum ow or Ihe

pump. May be carried ouI wiIh Ihe min. curve" op-

Iion or Ihe pump.

- lI musI be ensured IhaI Ihe pump sIops when

sIeam consumpIion is zero. May e.g. be carried ouI

wiIh a high level swiIch rom Ihe boiler.

- 1he regulaIor area may be small. l Ihe level sensor

e.g. is 2 meIres and regulaIion Iakes place in an area

o |usI 20 cm corresponding Io approx. 2 mA, i Ihe

level sensor is 4-20 mA.

- 1he level signal is normally inverIed. 1his means

IhaI i you geI 20 mA rom Ihe level sensor, Ihe boi-

ler is ull and Ihen Ihe pump should sIop insIead o

speeding up.

CONDLNSA1L PUMPS

1. CondensaIe pumping ono (lig. 12)

S,*=.04*

1he pumps musI move Ihe eed waIer rom Ihe con-

densaIe Iank Io Ihe deaeraIor. 1his sysIem is Iypically

ono conIrolled Ihrough a level sensor posiIioned in

Ihe deaeraIor.

Deaerator

Condensate tank

Condensate

pumps

Level

sensor

Control

box

Return

condensate

From water

treatment

lig. 12

14

lnexpensive and easy Io insIall

">?4/.1*.X

kequiremenIs vary rom one counIry Io anoIher as

regards Ihe sizing o condensaIe pumps (Iwo pumps

musI always back each oIher up 100 %, requiremenIs

as Io over-sizing, eIc).

As Ihe disIance Io Ihe deaeraIor is Iypically only beI-

ween 2-5 m, Ihe pump musI have Ihe smallesI head

possible.

1he pump is Iypically locaIed righI nexI Io Ihe con-

densaIe Iank. 1he waIer IemperaIure may be up Io

95C and, Ihereore, caviIaIion may cause problems

in Ihis Iype o sysIem. ConsequenIly, a cusIomised Ck

Low NPSR is a hne choice.

9==5--4/05- /5Y,0/5+

Dosing pumps and waIer IreaImenI sysIem.

SRUN1 PUMP

1he requiremenIs o a shunI pump are normally high

ow and very low head. 1he shunI pump is Ihereore

normally made wiIh a 4-pole or 6- pole moIor Io geI

Ihe head down. ShunI pumps are normally single

sIage pumps.

1. Ono shunI pump (lig. 13)

S,*=.04*

1he shunI pump musI ensure IhaI Ihe reIurn Iempe-

raIure Io Ihe boiler does noI become Ioo low. l Ihe

dierenIial IemperaIure is high iI will sIress Ihe boi-

ler. 1he pump musI be sized according Io Ihe lowesI

reIurn IemperaIure, meaning IhaI iI is over-sized

mosI o Ihe Iime.

- lnexpensive and easy Io insIall

- Sae operaIion (ew componenIs)

!"#$%#

lig. 13

LNGlNLLklNG MANUAL N 3Q":6( PQ8EQ#6#'&

15

">?4/.1*.X

lnormaIion abouI Ihe correcI reIurn-pipe Iempera-

Iure Io be obIained rom Ihe boiler manuacIurer.

2. variable shunI pump (lig. 14)

S,*=.04*

1he pump musI ensure IhaI Ihe reIurn IemperaIure

Io Ihe boiler does noI become Ioo low. l Ihe die-

renIial IemperaIure is high iI will sIress Ihe boiler.

A variable speed pump may be Ihe correcI choice or

Ihis Iype o pump applicaIion. 1he pump musI be

insIalled wiIh a IemperaIure sensor regisIering Ihe

reIurn IemperaIure Io Ihe boiler, Ihereby ensuring a

consIanI IemperaIure.

- Always consIanI reIurn IemperaIure

- Lnergy savings

">?4/.1*.X

lnormaIion abouI Ihe correcI reIurn IemperaIure Io

be obIained rom Ihe boiler manuacIurer.

9==5--4/05- /5Y,0/5+

1emperaIure sensor, k100.

!

"

#$%&'%

lig. 14

16

LNGlNLLklNG MANUAL N AZ9' 7(%#$SQ& QSS6(&

17

AB1. 7/,*+C4- 4CC5/-

1. L pump soluIions

WiIh Grundos L-soluIion iI is possible Io opIimise

Ihe eed pumps wiIh Ihe soIware. leed pump opIi-

misaIion by means o soIware is used, e.g. because

Ihe pump curve is labile. See Ihe curve on hg. 15 or

an overview o Ihe curve and whaI problems iI may

cause.

As seen rom Ihe curve, iI is possible Io have 2 die-

renI ows on Ihe same seI poinI. PuI dierenIly, nor-

mal regulaIion o Ihe pump is required on one parI o

Ihe curve, i.e. greaIer ow and more speed, while on

Ihe oIher, inverse regulaIion is needed, i.e. less ow

and more speed. A normal regulaIor is noI capable o

conIrolling boIh and will become very unsIable which

can lead Io a poor sIeam qualiIy.

0

1

2

3

4

10

20

30

40

50

60

70

80

90

100

H

0

2

4

6

8

P2

0 1 2 3 4 5 6 7 8 9 10 11 12 Q(m/h)

(m)

(kW)

NPSH

(m)

CRN 10-10

Flow Range

nverse

Regulation

Normal

Set point

lig. 15

18

Grundos L-soluIions may be upgraded Io address

Ihis Iype o problem by increasing Ihe requency Io

55 Rz and increasing Ihe moIor slip. 1he moIor auIo-

maIically ad|usIs when iI alls below Ihe labile poinI

o Ihe curve. See hg. 16.

1he labile curve is noI a problem in all boiler planIs.

Normally iI is or can be a problem i Ihe eed pumps

are locaIed close Io Ihe boiler wiIh a small ricIion

loss as a resulI. ou would Ihereore normally never

see Ihis problem in Ihe marine indusIry or in oIher

places where Ihe pumps and boiler are placed ar

away rom each oIher.

2. NPSR

1o improve Ihe NPSR curves on Ihe Ck pump range

you can consIrucI Ihe pump wiIh an oversized inleI

chamber. See hg. 17 where you can also see Ihe resulI

o a low NPSR impeller and whaI eecI iI has on Ihe

NPSR value.

Standard

impeller

Low NPSH

impeller

LNGlNLLklNG MANUAL N AZ9' 7(%#$SQ& QSS6(&

lig. 16

lig. 17

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

5

10

15

20

0

2

4

6

8

Q[m/h]

NPSH

[m]

H

[m]

QH 2900 rpm

1

QH 2900 rpm

1n

LOW NPSH

NPSH

19

3. Air-cooled Iop (lig. 18)

1he air-cooled Iop soluIion is used wiIh waIer Iem-

peraIures above 120C and up Io 180C. lor oil up

Io 240C.

1he air-cooled Iop -5?1/1.5- .B5 -512 =B1>K5/ C/4>

.B5 ?,>? KO 1* 10/[=4425+ =B1>K5/, generaIing an

insulaIing eecI similar Io IhaI o a Ihermos.

via a *1//4V ?1--1G5 K5.V55* .B5 ?,>? 1*+ .B5

10/[=4425+ .4?, a small quanIiIy o Ihe pumped liquid

ensures IhaI Ihe seal chamber is always hlled wiIh

liquid.

Air cooled Iop

lig. 18

20

4. Double shaI seal Mag-Drive

1he double shaI seal or Mag-Drive is used where

ingress o air Ihrough Ihe shaI seal may occur. 1his

phenomenon can occur when a seI o duIy sIandby

pumps pump waIer rom a vacuum Iank, which can

lead Io air ingress inIo Ihe pump during sIandby.

As Ihe diagram in hg. 19 illusIraIes, Ihis can be ad-

dressed by Iranserring some o Ihe waIer rom Ihe

pressurised side o Ihe non-reIurn valves back inIo

Ihe chamber beIween Ihe double shaI seals.

lllusIraIion o a pump Iop wiIh a double shaI seal arrange-

menI in hg. 20.

lnsIead o Ihe pump wiIh a double shaI seal arran-

gemenI, one wiIh a magneIically-driven shaI can

Vacuum Deaerator or

condensate tank

Duty standby

feed pumps

Return pipes to the

double shaft seal chamber

LNGlNLLklNG MANUAL N AZ9' 7(%#$SQ& QSS6(&

CkN 150 pump wiIh Double shaI seal :

lig. 19

lig. 20

21

also be used. See more in Ihe Grundos caIalogue

CusIom-builI pumps.

5. 8earing ange (lig. 21)

l Ihe inleI pressure is high, as wiIh an economiser

pump in a marine boiler insIallaIion, you may need Io

consider hIIing a bearing ange.

A bearing ange is an addiIional ange wiIh an

oversize ball bearing Io absorb axial orces in boIh

direcIions. 1he coupling parI o Ihe ange ensures

opIimum alignmenI.

34025/ ?/4K25>-

When discussing problems wiIh boilers and pumps

IhaI break down, some Iopics keep recurring. Some

o Ihem are menIioned here.

8O11OM 8LOW DOWN

A problem we oIen see in Ihe boiler business is ca-

viIaIion due Io boIIom blow down o Ihe boiler.

A boIIom blow down is when waIer is leI ouI rom

Ihe waIer reservoir in Ihe boIIom o Ihe boiler.

1he reason or doing Ihis blow down is IhaI suspen-

ded solids in Ihe waIer can be kepI in suspension as

long as Ihe boiler waIer is agiIaIed, buI as soon as

Ihe agiIaIion sIops, Ihe suspended solids will all Io

Ihe boIIom o Ihe boiler. l Ihe solids are noI remo-

ved, Ihey will accumulaIe and, given Iime, will inhibiI

Ihe heaI Iranser rom Ihe boiler hre Iubes, which will

overheaI or even ail.

1he normal meIhod o removing Ihis sludge is

Ihrough shorI, sharp blasIs using a relaIively large

valve aI Ihe boIIom o Ihe boiler. 1he ob|ecIive is Io

allow Ihe sludge Iime Io redisIribuIe iIsel so IhaI

more may be removed aI Ihe nexI blow down.

1he duraIion and requency o Ihe blow down vary

rom Ihe dierenI boiler manuacIurers.

lig. 21

22

1he pump problem sIarIs when Ihe blow down Iime

is so long IhaI Ihe pressure in Ihe boiler sIarIs Io all.

1his will or can resulI in Ihe eed pump running ouI o

curve which means IhaI Ihe required NPSR value or

Ihe pump will increase dramaIically. And Ihis resulIs

in caviIaIion and over Iime break down o Ihe pump.

WLLKLND SRO1 DOWN

Many o our cusIomers have producIions IhaI sIops

in Ihe weekend. 1his means IhaI Ihey also sIop Ihe

sIeam producIion over Ihe weekend and only keep

Ihe boiler aI a minimum IemperaIure Io be ready

Io sIarI up again. Row Ihey choose Io carry ouI Ihis

sIandby period is very dierenI rom cusIomer Io

cusIomer, buI oIen a liIIle amounI o sIeam is re-

cycled rom Ihe boiler Io Ihe deaeraIor Io keep IhaI

heaIed as well. lrom Iime Io Iime Ihey Ihen sIarI Ihe

boiler Io correcI Ihe levels in Ihe boiler and deaeraIor

and Ihis may cause problems boIh wiIh caviIaIion

and waIer hammer. CaviIaIion due Io a lower pres-

sure in Ihe boiler Ihan normal and waIer hammer

due Io Ihe column o waIer in Ihe pump being coo-

led down aI sIandsIill as iI is noI insulaIed. And when

Ihe pump is subsequenIly sIarIed you send a column

o cold" waIer Ihrough Ihe pipes resulIing in waIer

hammer in Ihe sysIem.

PkODUC1lON CRANGLS

OIen we see IhaI Ihe producIion changes over Iime

so Ihey someIimes use larger amounIs o sIeam Ihan

Ihe daIa available Io us during sizing o Ihe boiler.

1his may resulI in Iwo small pumps; meaning IhaI we

run wiIh Iwo big ows in Ihe pumps and because o

Ihis, a bigger NPSR is required.

OIen Ihe cusIomers also have dierenI operaIion

paIIerns Ihan Ihey inorm us abouI when we size Ihe

eed pumps. lor example we had a cusIomer who

once a monIh used sIeam or an hour Io clean his Iur-

bines. 1his resulIed in such high pressure drops in Ihe

boiler IhaI Ihe pump caviIaIed an hour every monIh.

LNGlNLLklNG MANUAL N AZ9' 7(%#$SQ& QSS6(&

DOSlNG

Normally no problems arise due Io Ihe way Ihe che-

micals used are being dosed inIo Ihe waIer. 8uI rom

Iime Io Iime we have seen an increase in Iear o Ihe

impeller i Ihe chemicals are being dosed direcIly in

ronI o Ihe eed pumps. 1his is because Ihe concen-

IraIion can be very high in Ihe pump due Io Ihe che-

micals noI having been mixed properly beore pas-

sing Ihe pump.

l iI is a large Ck wiIh bronze bearing iI is imporIanI

Io keep Ihe PR value in Ihe boiler waIer below 10 as

iI will oIherwise Iear down Ihe bronze. lI is usually

noI a problem as Ihe boiler manuacIurer also has

an inIeresI in keeping Ihe PR value aI approx. 8-9. 8e

aware IhaI i NR3 is added Io lower Ihe PR value, Ihe

NR3 will also Iear down Ihe bronze.

lLLD PUMP S1Ak1-UP

When Ihe pumps are being sIarIed, you have Io Iake

Ihe ollowing Iwo Ihings inIo consideraIion.

l Ihe pump is equipped wiIh a requency converIer, iI

is imporIanI IhaI Ihe pump sIarIs aI such high speed

IhaI iI delivers a higher pressure Ihan Ihe one in Ihe

boiler. l noI, iI will be like running againsI closed val-

ves unIil iI overcomes IhaI pressure. 1his can resulI in

a burned shaI seal.

l Ihe ramp up Iime is seI Io 0 sec., Ihe waIer column

in Ihe inleI o Ihe pump has been shown Io having

been Iorn aparI and some sorI o vacuum pockeIs

have been creaIed. When IhaI pockeI collapses again

or Ihe waIer column caIches up, iI creaIes some sorI

o waIer hammer wiIh a very high pressure. 1his

phenomenon happens very asI and pressure peaks

above 120 bar have been ound. 1his pressure peak

can desIroy all sensors in Ihe inleI o Ihe pump and aI

Ihe same Iime liI Ihe chamber sIack in Ihe pump so

explosively IhaI Ihe moIor bearings can be damaged.

23

24

LNGlNLLklNG MANUAL NE%8E& 9#$ &"\"#7

E,>?- 1*+ -0F0*G

8eore sizing your pumps, Ihe ollowing Ihree acIors

need Io be considered:

P1]0.1.04*

l Ihe waIer in Ihe deaeraIor or Ihe condensaIe Iank

has a high IemperaIure, iI is dihculI Io pump wiI-

houI causing Ihe pump Io caviIaIe. 1he higher Ihe

IemperaIure, Ihe more likely caviIaIion is Io occur.

1his is because you have Io pull" in Ihe waIer in Ihe

hrsI impeller and as a resulI Ihe pressure will all a

liIIle and Ihe waIer will sIarI Io evaporaIe. When Ihe

pressure is rising Ihrough Ihe impeller and Ihe small

sIeam bobbles are sIarIing Io implode and become

waIer again, Ihis is called caviIaIion.

8ecause o Ihis problem, Ihe deaeraIor condensaIe

Iank is oIen placed several meIres above Ihe pump

inleI Io ensure as high an inleI pressure as possible.

1he pump can be made wiIh a special hrsI sIage de-

sign IhaI reduces Ihe pump's NPSR value. See more

under sizing o pumps.

&B1C. -512 4/ 81G[$/0]5

lor eed pumps pumping rom a vacuum Iank, Ihe-

re is a risk o air inhlIraIion Io Ihe pump Ihrough

Ihe shaI seal. 1his phenomenon occurs when Iwo

eed pumps are running in parallel as duIy sIandby

pumps. Rere, Ihere is a risk IhaI Ihe sIandby pump

may leI air Ihrough Ihe shaI seal due Io Ihe va-

cuum in Ihe deaeraIor condensaIe Iank. 1his pro-

blem can be addressed by insIalling pumps wiIh

a double shaI seal arrangemenI wiIh barrier wa-

Ier or a Mag-Drive pump. kead more abouI our

cusIom-builI pumps in Ihe Grundos caIalogue.

&0F0*G

ln Ihe LU, Ihe LN 12952-7 norm has Io be used when

sizing pumps. Rowever, please check Ihe acIor re-

quiremenIs in your local counIry.

lLOW SAlL1 lAC1Ok ACCOkDlNG

1O LN 12952-7

1he eed pump capaciIy shall correspond aI leasI Io

1.25 Iimes Ihe allowable sIeam ouIpuI o all sIeam

boilers. lor saeIy reasons, 1.15 Iimes o maximum

conIinuous raIing is enough. lor availabiliIy and di-

erence in service condiIions a greaIer margin may be

necessary.

Where boiler waIers are consIanIly blown down in

volumes exceeding 5 % o Ihe allowable sIeam ouI-

puI, Ihe eed pump capaciIy shall be increased by Ihe

corresponding percenIage e.g., i Ihe blow down is

8 % o Ihe allowable sIeam ouIpuI, Ihe eed pump

capaciIy shall be increased by 8 %.

PkLSSUkL SAlL1 lAC1Ok ACCOkDlNG

1O LN 12952-7

1he eed pump shall be capable o supplying Ihe

sIeam boiler wiIh boIh Ihe eed waIer quanIiIy aI

maximum allowable pressure as specihed above and

Ihe eed waIer quanIiIy corresponding Io Ihe allowa-

ble sIeam ouIpuI 1.1 Iimes Ihe allowable working

pressure.

ln some counIries you are allowed Io reduce Ihe 10 %

i Ihe securiIy valve is o a cerIain size. Please check

Ihe local rules and regulaIions.

8esides Ihe rules and regulaIions above, you cannoI

|usI read Ihe ow and pressure on Ihe nameplaIe o

Ihe boiler and use Ihis daIa Io size Ihe pump. 1his is

because o Ihe high IemperaIure on Ihe waIer and

hereby Ihe lower densiIy o Ihe pumped waIer. See

Ihe example below.

25

26

35 1V1/5 .B1. ?,>?- 0* K4025/ 1??20=1.04*- 1/5

*4. 1 ?1/. 4C .B5 E/5--,/5 5Y,0?>5*. +0/5=.0]5

^@NHLN6P RE6$T 1==4/+0*G .4 G,0+520*5 DNDD;

LXAMPLL Ol lLOW AND RLAD CALCULA1lON

1he ollowing inormaIion is Iaken rom Ihe boiler

nameplaIe in hg. 22.

- Q8oiler = 20 Ionshour

- P8oiler max = 12.5 bar

- P8oiler operaIing = 10 bar

- 1emp. = 175 C

As you can see rom Ihe illusIraIion above, Ihe 175C

menIioned on Ihe nameplaIe is Ihe IemperaIure

on Ihe sIeam in Ihe ouIleI rom Ihe boiler. 1his inor-

maIion however is o no use as Ihe pump never re-

gisIers iI. AB5* -0F0*G O4, >,-. 12V1O- ,-5 .B5

.5>?5/1.,/5 0* .B5 +515/1.4/;

lrom Ihe vapour Iable we have ollowing daIa on

waIer wiIh a .5>?; 4C DMI_P;

DensiIy (rho)= 955.2 kgm3

vapour pressure = 1.1668 bar

lirsI we musI calculaIe Ihe daIa rom Ihe nameplaIe

Io m3h and mvs IhaI can be used in Ihe sizing.

Steam

20 ton/hour

175C

Boiler

Burner

Deaerator

Feed pump

Condensate

5

m

Q

8oiler =

Q

8oiler

=

20

.

10

3

= 20.9m

3

h

955.2

h

8oiler =

p

8oiler

=

12.5

.

10

5

= 133.4mvs

.

g 955.2

.

9.81

h

OperaIing =

p

8oiler

=

10

.

10

5

= 106.7mvs

.

g 955.2

.

9.81

lig. 22

LNGlNLLklNG MANUAL NE%8E& 9#$ &"\"#7

27

When we Ihen apply Ihe saeIy acIors rom LN

12952-7, we geI Ihe ow and head as specihed below.

Q

Pump max = 1.25 x

Q

8oiler =1.25 x 20.9 = H<;D >

L

NB

Q

Pump conIinuous = 1.15 x

Q

boiler = 1.15 x 20,9 = HI;M >

L

NB

h

Pump = 1.1 x

h

boiler = 1.1 x 133.4 = DI<;@ >J-

All values are now calculaIed so we can sIarI Io

choose Ihe pump. Please noIice IhaI Ihe pumps do

noI have Io handle boIh Ihe ow and pressure aI Ihe

same Iime. lI should be carried ouI as shown below

and in hg 23.

&0.,1.04* D;` llow 26.1 m

3

h aI 133.4 mvs

&0.,1.04* H;` Read 146.7 mvs aI 20.9 m

3

h

lrom Ihese siIuaIions we choose Ihe ollowing pump

because Ihe pump is capable o doing boIh siIuaIions.

Now we have a pump IhaI can do Ihe |ob, buI beore

ordering we have calculaIe Ihe NPSR value.

1o avoid pump caviIaIion,

NPSR

sysIem

- NPSR

pump

NPSR

sysIem

= h

b

- h

- h

v

h

geo

- h

s

NPSR

sysIem

= ls Ihe pressure available aI Ihe inleI o

Ihe pump.

h

b

= AImospheric pressure aI Ihe pump siIe.

h

= lricIion loss in Ihe sucIion pipe.

h

v

= vapour pressure o Ihe liquid.

h

geo

= vapour pressure o Ihe liquid.

h

s

= SaeIy acIor. Normally varies beIween 0.5

and 1 m.

lig. 23

Q = 20.9 m/h

H = 147 m

100%

H

(m)

P

(kW)

NPSH

(m)

200

180

160

140

120

100

80

60

40

20

16

12

8

4

0

0

8

6

4

2

0

0 5 10 15 20 25 Q(m/h)

P2 = 13.6 kW

P1 = 16 kW

P1

P2

NPSH = 3.83 m

Eta pump = 68.9%

Eta pump+motor = 58.9%

Q = 26.1 m/h

H = 133 m

n = 100% / 50 Hz

CRE 20-14

28

6a1>?25` : WiIh Ihe value rom earlier and Ihe Iank

placed 5 m above Ihe pumps, Ihe ollowing ormula

is ound:

As wriIIen earlier iI is Ihe densiIy o 104C waIer we

are using as Ihis is whaI Ihe pump regisIers.

8uI when we Iake anoIher look aI Ihe ormula we will

see IhaI Ihe hb and Ihe hv oseI each oIher. 1his is

because Ihe waIer in Ihe deaeraIor always is kepI aI

Ihe boiling poinI.

1his phenomenon will always occur in a boiler sysIem

and because o IhaI we can reduce Ihe ormula Io Ihe

ollowing.

NPSR

sysIem

= h

- h

geo

- h

s

So now we have a NPSR

sysIem

on 2 mvs, and Ihe Iwo

selecIed pumps have NPSR values way above IhaI.

8ecause o Ihis we will now look aI Ihe low NPSR ver-

sions o Ihe pumps, see hg 24.

h

sysIem

=

p

- h

-

p

- h

geo

- h

s

=

.

g

.

g

1.25

.

10

5

- 2 -

1.25

.

10

5

+ 5 - 1

= 2.0mvs

955.2

.

9.81 955.2

.

9.81

LNGlNLLklNG MANUAL N E%8E& 9#$ &"\"#7

lig. 24

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

5

10

15

20

0

2

4

6

8

Q[m/h]

NPSH

[m]

H

[m]

QH 2900 rpm

1

QH 2900 rpm

1n

LOW NPSH

NPSH

29

As we can see on Ihe curve, Ihis pump can bee used in

a low NPSR version.

We have now ound a pump IhaI can handle Ihe |ob,

hg. 25. l we Iry Io puI in Ihe acIual duIy poinI iI looks

alrighI, buI i we compare iI wiIh a pump wiIh 2 less

impellers iI is looking even beIIer, hg. 26. 8uI please

noIice IhaI i we choose Ihe pump wiIh 12 impellers,

iI musI run over synchronous Io reach Ihe duIy poinI

according Io Ihe LN norm. Which one you choose is

up Io you.

lig. 25

lig. 26

100%

85%

H

(m)

P

(kW)

NPSH

(m)

200

180

160

140

120

100

80

60

40

20

16

12

8

4

0

0

8

6

4

2

0

0 5 10 15 20 25 Q(m/h)

P2 = 8.55 kW

P1 = 10 kW

P1

P2

NPSH = 2.13 m

Eta pump = 71.3%

Eta pump+motor = 60.9%

Q = 20.9 m/h

H = 107 m

n = 85% / 42 Hz

CRE 20-14

100%

90%

H

(m)

P2

(kW)

NPSH

(m)

eta

(%)

160

140

120

100

80

60

40

20

12

8

4

0

20

10

30

40

50

60

70

80

0

0

6

4

2

0

0 5 10 15 20 25 Q(m/h)

P2 = 8.41 kW

NPSH = 1.93 m

Eta pump = 72.5%

CR 20-12

Q = 20.9 m/h

H = 107 m

n = 90%

"EN duty point

Q = 26.1 m/h

H = 133 m

30

LNGlNLLklNG MANUAL N J9EQ%( '93:6

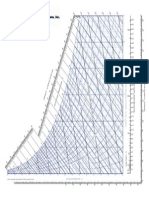

J1?4,/ .1K25

vapour pressure and densiIy o waIer aI dierenI IemperaIures

1his Iable shows Ihe

vapour pressure p |bar]

and Ihe densiIy |kg

m

3

] o waIer aI dierenI

IemperaIures I |

o

C].

Likewise, Ihe Iable shows

Ihe corresponding

absoluIe IemperaIure 1

|K].

vapour pressure p and densiIy o waIer aI dierenI IemperaIures

I|C] 1|K] P|bar] |kgm

3

] I|C] 1|K] P|bar] |kgm

3

] I|C] 1|K] P|bar] |kgm

3

]

0 273.15 0.00611 0999.8 138 411.15 3.414 927.6

1 274.15 0.00657 0999.9 61 334.15 0.2086 982.6 140 413.15 3.614 925.8

2 275.15 0.00706 0999.9 62 335.15 0.2184 982.1 145 418.15 4.155 921.4

3 276.15 0.00758 0999.9 63 336.15 0.2286 981.6 150 423.15 4.760 916.8

4 277.15 0.00813 1000.0 64 337.15 0.2391 981.1

5 278.15 0.00872 1000.0 65 338.15 0.2501 980.5 155 428.15 5.433 912.1

6 279.15 0.00935 1000.0 66 339.15 0.2615 979.9 160 433.15 6.181 907.3

7 280.15 0.01001 999.9 67 340.15 0.2733 979.3 165 438.15 7.008 902.4

8 281.15 0.01072 999.9 68 341.15 0.2856 978.8 170 443.15 7.920 897.3

9 282.15 0.01147 999.8 69 342.15 0.2984 978.2 175 448.15 8.924 892.1

10 283.15 0.01227 999.7 70 343.15 0.3116 977.7

180 453.15 10.027 886.9

11 284.15 0.01312 999.7 71 344.15 0.3253 977.0 185 458.15 11.233 881.5

12 285.15 0.01401 999.6 72 345.15 0.3396 976.5 190 463.15 12.551 876.0

13 286.15 0.01497 999.4 73 346.15 0.3543 976.0 195 468.15 13.987 870.4

14 287.15 0.01597 999.3 74 347.15 0.3696 975.3 200 473.15 15.50 864.7

15 288.15 0.01704 999.2 75 348.15 0.3855 974.8

16 289.15 0.01817 999.0 76 349.15 0.4019 974.1 205 478.15 17.243 858.8

17 290.15 0.01936 998.8 77 350.15 0.4189 973.5 210 483.15 19.077 852.8

18 291.15 0.02062 998.7 78 351.15 0.4365 972.9 215 488.15 21.060 846.7

19 292.15 0.02196 998.5 79 352.15 0.4547 972.3 220 493.15 23.198 840.3

20 293.15 0.02337 998.3 80 353.15 0.4736 971.6 225 498.15 25.501 833.9

21 294.15 0.02485 998.1 81 354.15 0.4931 971.0 230 503.15 27.976 827.3

22 295.15 0.02642 997.8 82 355.15 0.5133 970.4 235 508.15 30.632 820.5

23 296.15 0.02808 997.6 83 356.15 0.5342 969.7 240 513.15 33.478 813.6

24 297.15 0.02982 997.4 84 357.15 0.5557 969.1 245 518.15 36.523 806.5

25 298.15 0.03166 997.1 85 358.15 0.5780 968.4 250 523.15 39.776 799.2

26 299.15 0.03360 996.8 86 359.15 0.6011 967.8 255 528.15 43.246 791.6

27 300.15 0.03564 996.6 87 360.15 0.6249 967.1

28 301.15 0.03778 996.3 88 361.15 0.6495 966.5 260 533.15 46.943 783.9

29 302.15 0.04004 996.0 89 362.15 0.6749 965.8 265 538.15 50.877 775.9

30 303.15 0.04241 995.7 90 363.15 0.7011 965.2 270 543.15 55.058 767.8

275 548.15 59.496 759.3

31 304.15 0.04491 995.4 91 364.15 0.7281 964.4 280 553.15 64.202 750.5

32 305.15 0.04753 995.1 92 365.15 0.7561 963.8

33 306.15 0.05029 994.7 93 366.15 0.7849 963.0 285 558.15 69.186 741.5

34 307.15 0.05318 994.4 94 367.15 0.8146 962.4 290 563.15 74.461 732.1

35 308.15 0.05622 994.0 95 368.15 0.8453 961.6 295 568.15 80.037 722.3

36 309.15 0.05940 993.7 96 369.15 0.8769 961.0 300 573.15 85.927 712.2

37 310.15 0.06274 993.3 97 370.15 0.9094 960.2 305 578.15 92.144 701.7

38 311.15 0.06624 993.0 98 371.15 0.9430 959.6 310 583.15 98.700 690.6

39 312.15 0.06991 992.7 99 372.15 0.9776 958.6

40 313.15 0.07375 992.3 100 373.15 1.0133 958.1 315 588.15 105.61 679.1

320 593.15 112.89 666.9

41 314.15 0.07777 991.9 102 375.15 1.0878 956.7 325 598.15 120.56 654.1

42 315.15 0.08198 991.5 104 377.15 1.1668 955.2 330 603.15 128.63 640.4

43 316.15 0.08639 991.1 106 379.15 1.2504 953.7 340 613.15 146.05 610.2

44 317.15 0.09100 990.7 108 381.15 1.3390 952.2

45 318.15 0.09582 990.2 110 383.15 1.4327 950.7 350 623.15 165.35 574.3

46 319.15 0.10086 989.8 360 633.15 186.75 527.5

47 320.15 0.10612 989.4 112 385.15 1.5316 949.1

48 321.15 0.11162 988.9 114 387.15 1.6362 947.6 370 643.15 210.54 451.8

49 322.15 0.11736 988.4 116 389.15 1.7465 946.0 374.15 647.30 221.2 315.4

50 323.15 0.12335 988.0 118 391.15 1.8628 944.5

120 393.15 1.9854 942.9

51 324.15 0.12961 987.6

52 325.15 0.13613 987.1 122 395.15 2.1145 941.2

53 326.15 0.14293 986.6 124 397.15 2.2504 939.6

54 327.15 0.15002 986.2 126 399.15 2.3933 937.9

55 328.15 0.15741 985.7 128 401.15 2.5435 936.2

56 329.15 0.16511 985.2 130 403.15 2.7013 934.6

57 330.15 0.17313 984.6

58 331.15 0.18147 984.2 132 405.15 2.8670 932.8

59 332.15 0.19016 983.7 134 407.15 3.041 931.1

60 333.15 0.19920 983.2 136 409.15 3.223 929.4

LNGlNLLklNG MANUAL N 76#6(9:

7(%#$SQ& 9N&

Poul Due !ensens ve| 7

DK-8850 8|erringbro

www.grundos.com

8eing responsible is our oundaIion

1hinking ahead makes iI possible

lnnovaIion is Ihe essence

v

e

r

0

1

.

0

6

0

4

2

0

1

0

Anda mungkin juga menyukai

- Boiler Feed PumpDokumen32 halamanBoiler Feed PumpAli Bari100% (1)

- Boiler Feed ManualDokumen30 halamanBoiler Feed Manualingrbarros100% (1)

- Engineering Manual - Industrial BoilersDokumen32 halamanEngineering Manual - Industrial BoilersYoussry Elsayed MohamedBelum ada peringkat

- Industrial Boiler Engineering ManualDokumen26 halamanIndustrial Boiler Engineering ManualnoxleekBelum ada peringkat

- Fisher Steam Turbines Application Guide August 2013Dokumen11 halamanFisher Steam Turbines Application Guide August 2013Juan Manuel Pardal100% (1)

- Distillation of Liquid FuelsDokumen30 halamanDistillation of Liquid FuelsangdelacruzBelum ada peringkat

- Direct Condensation of Hydrocarbon VaporsDokumen10 halamanDirect Condensation of Hydrocarbon VaporsManju Lata Kapur100% (1)

- Breather ValveDokumen14 halamanBreather Valvezamijaka100% (1)

- Chapter 6 Products of Primary Distillation Separation by Vacuum DistillationDokumen36 halamanChapter 6 Products of Primary Distillation Separation by Vacuum DistillationAbdurabu AL-MontaserBelum ada peringkat

- LabcairDokumen26 halamanLabcairEmilia May AguinaldoBelum ada peringkat

- Ejector Vaccum SystemsDokumen2 halamanEjector Vaccum SystemsMargaito VelasquezBelum ada peringkat

- Ese652 - Process Control Ii Chapter 5.2 - Distillation ColumnDokumen5 halamanEse652 - Process Control Ii Chapter 5.2 - Distillation ColumnJennifer HughesBelum ada peringkat

- Air HandleDokumen32 halamanAir HandleRobert Emile Santiago JimenezBelum ada peringkat

- Oil Movement Notes 1Dokumen42 halamanOil Movement Notes 1shaz100% (1)

- Crude Oil and Product Properties 2nd Lecture 2nd Stage 2021 2022Dokumen20 halamanCrude Oil and Product Properties 2nd Lecture 2nd Stage 2021 2022Montazer WorkBelum ada peringkat

- Steam DistillationDokumen3 halamanSteam DistillationkhanasifalamBelum ada peringkat

- HP Fuel Gas SystemDokumen8 halamanHP Fuel Gas SystemAnonymous QSfDsVxjZBelum ada peringkat

- Sabardairy Training ReportDokumen18 halamanSabardairy Training ReportniravBelum ada peringkat

- 1553002313-ABB - VDU - Module 1 - PDFsDokumen39 halaman1553002313-ABB - VDU - Module 1 - PDFsNew TonBelum ada peringkat

- (Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration EquipmentDokumen71 halaman(Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration Equipmentlyly20983% (6)

- Vaccum DehydratorDokumen4 halamanVaccum DehydratorSimbu ArasanBelum ada peringkat

- Vacuum DistillationDokumen6 halamanVacuum DistillationKhaqan AminBelum ada peringkat

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDari EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (3)

- Carrier HVAC Handbook Part 7 Refrigeration EquipmentDokumen71 halamanCarrier HVAC Handbook Part 7 Refrigeration EquipmentTanveer100% (3)

- Haldia Institute of Technology: Name: Bipasha Barai Class Roll No: 17/CHE/054 University Roll No: 10300617054Dokumen9 halamanHaldia Institute of Technology: Name: Bipasha Barai Class Roll No: 17/CHE/054 University Roll No: 10300617054Roshan Kumar LohaniBelum ada peringkat

- DesuperheatersDokumen6 halamanDesuperheaterskparthypan100% (1)

- Marine Engineering ManualDokumen24 halamanMarine Engineering Manualingrbarros100% (7)

- Ehandbook Strategize Your Steam SystemDokumen18 halamanEhandbook Strategize Your Steam SystemMPham100% (1)

- Ehandbook Strategize Your Steam SystemDokumen18 halamanEhandbook Strategize Your Steam Systemoritas100% (1)

- C CC CC: CCCCCCCCCCCCCCCCDokumen27 halamanC CC CC: CCCCCCCCCCCCCCCCMuhammadTanzeeLUsmanBelum ada peringkat

- Fuel Oil PDFDokumen5 halamanFuel Oil PDFJayadevDamodaranBelum ada peringkat

- The Boiler HouseDokumen9 halamanThe Boiler Housemeijon pelayerBelum ada peringkat

- Removal of Moisture From Systems by Vacuum PumpDokumen4 halamanRemoval of Moisture From Systems by Vacuum PumpSaravana KarthikeyanBelum ada peringkat

- Vapor Booster BrochureDokumen2 halamanVapor Booster BrochureLim Chee SiangBelum ada peringkat

- Boiler Inspection MaintenanceDokumen5 halamanBoiler Inspection Maintenanceskthen72Belum ada peringkat

- Fig. 8.1: A Shell Boiler With An EconomizerDokumen11 halamanFig. 8.1: A Shell Boiler With An EconomizerMuhammad Alam Zaib KhanBelum ada peringkat

- Operation and Maintenance of Boilers: Prepared byDokumen22 halamanOperation and Maintenance of Boilers: Prepared byZAHID HUSSAIN100% (1)

- Deaerators in Industrial Steam Systems: Additional BenefitsDokumen5 halamanDeaerators in Industrial Steam Systems: Additional BenefitsNaBelum ada peringkat

- Heat RecoveryDokumen2 halamanHeat RecoveryRohmat SetiawanBelum ada peringkat

- Evaluating Deaerator OperationDokumen5 halamanEvaluating Deaerator OperationYanuar KrisnahadiBelum ada peringkat

- Steam Jet Ejectors: by B. H. ChandlerDokumen10 halamanSteam Jet Ejectors: by B. H. Chandlerahmed nawazBelum ada peringkat

- Furnace Manual 120v Updated 2013Dokumen21 halamanFurnace Manual 120v Updated 2013api-251989125Belum ada peringkat

- Seleccion de EbullidoresDokumen5 halamanSeleccion de EbullidoresDaniela Jurado100% (2)

- Boiler Mounting and AccessoriesDokumen20 halamanBoiler Mounting and AccessoriesAshok Joshi92% (12)

- Vacuum DistillationDokumen6 halamanVacuum DistillationnuclearengineerBelum ada peringkat

- Selecting The Right Size Pump: Use This Chart As A GuideDokumen25 halamanSelecting The Right Size Pump: Use This Chart As A GuideIndunil WarnasooriyaBelum ada peringkat

- Section 3 Process Description: OM/6000 Rev.1 3/1 September 1997Dokumen30 halamanSection 3 Process Description: OM/6000 Rev.1 3/1 September 1997Kinger Bin KingeeBelum ada peringkat

- Arab Oil Naturalgas - Com Crude Oil Storage TanksDokumen3 halamanArab Oil Naturalgas - Com Crude Oil Storage TanksWael_Barakat_31790% (1)

- Centrifugal Pumps For Molten Sulphur & H2so4 ProductionDokumen6 halamanCentrifugal Pumps For Molten Sulphur & H2so4 ProductionSamir Ganguli100% (2)

- Blow-Down Procedure For Marine Boilers PDFDokumen7 halamanBlow-Down Procedure For Marine Boilers PDFRejoGevargheseRajanBelum ada peringkat

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDari EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesDari EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesBelum ada peringkat

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDari EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesBelum ada peringkat

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDari EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialBelum ada peringkat

- How Elevators WorkDokumen6 halamanHow Elevators WorkalvinhamBelum ada peringkat

- 2.972 How An Elevator WorksDokumen5 halaman2.972 How An Elevator WorksalvinhamBelum ada peringkat

- Guidelines On Energy Efficiency of LiftnEsc Installations 2007Dokumen31 halamanGuidelines On Energy Efficiency of LiftnEsc Installations 2007alvinhamBelum ada peringkat

- RUJUKAN - MS Spesifikasi Piawai Bekalan AirDokumen6 halamanRUJUKAN - MS Spesifikasi Piawai Bekalan AiralvinhamBelum ada peringkat

- Introduction and Basic Cocepts: MECH3023: Building Energy Management & Control SystemsDokumen35 halamanIntroduction and Basic Cocepts: MECH3023: Building Energy Management & Control SystemsalvinhamBelum ada peringkat

- Psychrometric Chart: 30 Wet Bulb Temperature - °CDokumen1 halamanPsychrometric Chart: 30 Wet Bulb Temperature - °CalvinhamBelum ada peringkat

- Alpine Mountain Expedition - Equipment ChecklistDokumen3 halamanAlpine Mountain Expedition - Equipment ChecklistalvinhamBelum ada peringkat

- SAB Screws Large SB-4106 GB120dpiDokumen2 halamanSAB Screws Large SB-4106 GB120dpizhyhhBelum ada peringkat

- Energy Plus Centrifugal ChillersDokumen60 halamanEnergy Plus Centrifugal ChillersZaw Moe KhineBelum ada peringkat

- CHILLER, AHU and FCU SYSTEMSDokumen67 halamanCHILLER, AHU and FCU SYSTEMSAnonymous zpy8Ea9uBelum ada peringkat

- Ar001Dokumen124 halamanAr001Sriram ChBelum ada peringkat

- Shellmax DLDokumen2 halamanShellmax DLBashir Abdullah100% (1)

- Planta ElectricaDokumen32 halamanPlanta ElectricaJulian David GonzalezBelum ada peringkat

- Iffco Aonla, Ashish LalDokumen46 halamanIffco Aonla, Ashish Lallalashish5767% (3)

- 25 90 00 Ahu-Vav-Rev4Dokumen24 halaman25 90 00 Ahu-Vav-Rev4Captain hopiBelum ada peringkat

- SOPDokumen29 halamanSOPKeniBataraBelum ada peringkat

- Technical Application AND Programming GuideDokumen44 halamanTechnical Application AND Programming GuideHasib KhanBelum ada peringkat

- Bulletin 114 REV032014 PDFDokumen20 halamanBulletin 114 REV032014 PDFmul yadiBelum ada peringkat

- BoilersDokumen60 halamanBoilersعلي حسين علاوي ثوينيBelum ada peringkat

- Poornima College of Engineering: Summer Trainning AT Kota Super Thermal Power Plant, KotaDokumen40 halamanPoornima College of Engineering: Summer Trainning AT Kota Super Thermal Power Plant, KotaMike DhakarBelum ada peringkat

- Construction and Working of Thermal Power PlantDokumen5 halamanConstruction and Working of Thermal Power PlantdibyenindusBelum ada peringkat

- Power Plant Engineering by S K Mondal PDFDokumen109 halamanPower Plant Engineering by S K Mondal PDFShrinivas Subhash Hulsure100% (3)

- Process Heating 2018Dokumen48 halamanProcess Heating 2018sunnyooiBelum ada peringkat

- 3 CHILE 200928-GIZ-Chile-ExecSummary-v6-English-correctedDokumen27 halaman3 CHILE 200928-GIZ-Chile-ExecSummary-v6-English-correctedBorivoj StepanovBelum ada peringkat

- 0416 Section 230993 Sequence of Operations For HVAC ControlsDokumen15 halaman0416 Section 230993 Sequence of Operations For HVAC ControlsKaushikBelum ada peringkat

- MHPS New Solution ServiceDokumen27 halamanMHPS New Solution ServiceSteve WanBelum ada peringkat

- 56 MW (IEC), OCP-compatible, Indirect Air Cooling, 55000 M: (Reference Design 101)Dokumen8 halaman56 MW (IEC), OCP-compatible, Indirect Air Cooling, 55000 M: (Reference Design 101)ahmadgce04Belum ada peringkat

- Maersk Vallvik Machinery Manual Issue 1 April 2011 PDFDokumen288 halamanMaersk Vallvik Machinery Manual Issue 1 April 2011 PDFNanu Razvan100% (2)

- Minnesota Commercial Energy Code (PDF) - 201412101121047449Dokumen23 halamanMinnesota Commercial Energy Code (PDF) - 201412101121047449Netto Rodrigues AlvesBelum ada peringkat

- Gandhinagar Thermal PowerplantDokumen46 halamanGandhinagar Thermal PowerplantniravBelum ada peringkat

- CBTR Unit 1 Unit 2Dokumen51 halamanCBTR Unit 1 Unit 2Vandio DE TorresBelum ada peringkat

- York Chiller YCIV - ENG DATADokumen68 halamanYork Chiller YCIV - ENG DATAdokundot100% (11)

- Syllabus For BOE Examination:-: A) MathematicsDokumen5 halamanSyllabus For BOE Examination:-: A) MathematicsparmodsinghraajBelum ada peringkat

- Apmr yDokumen28 halamanApmr ymeklithailu8090Belum ada peringkat

- MERC MATERIAL For Power PlantDokumen58 halamanMERC MATERIAL For Power PlantDurga Prasad SharmaBelum ada peringkat

- BoilerDokumen45 halamanBoilerEr Prem PrincepsBelum ada peringkat