Ec (2jz-Gte) PDF

Diunggah oleh

Ashok0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

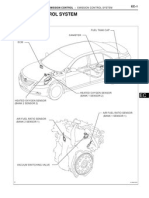

687 tayangan12 halamanThis document provides information on the emission control system for a 2JZ-GTE engine, including:

1) An overview of the purpose and functions of the main emission control systems - positive crankcase ventilation (PCV), evaporative emission control (EVAP), exhaust gas recirculation (EGR), three-way catalytic converter (TWC), and sequential multiport fuel injection.

2) Diagrams showing the layout and locations of emission control system parts on the engine.

3) Inspection procedures for the PCV, EVAP, EGR, and TWC systems, checking for proper operation and looking for cracks, leaks, blockages or other issues. Replacement of faulty components

Deskripsi Asli:

Judul Asli

EC%20(2JZ-GTE).pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document provides information on the emission control system for a 2JZ-GTE engine, including:

1) An overview of the purpose and functions of the main emission control systems - positive crankcase ventilation (PCV), evaporative emission control (EVAP), exhaust gas recirculation (EGR), three-way catalytic converter (TWC), and sequential multiport fuel injection.

2) Diagrams showing the layout and locations of emission control system parts on the engine.

3) Inspection procedures for the PCV, EVAP, EGR, and TWC systems, checking for proper operation and looking for cracks, leaks, blockages or other issues. Replacement of faulty components

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

687 tayangan12 halamanEc (2jz-Gte) PDF

Diunggah oleh

AshokThis document provides information on the emission control system for a 2JZ-GTE engine, including:

1) An overview of the purpose and functions of the main emission control systems - positive crankcase ventilation (PCV), evaporative emission control (EVAP), exhaust gas recirculation (EGR), three-way catalytic converter (TWC), and sequential multiport fuel injection.

2) Diagrams showing the layout and locations of emission control system parts on the engine.

3) Inspection procedures for the PCV, EVAP, EGR, and TWC systems, checking for proper operation and looking for cracks, leaks, blockages or other issues. Replacement of faulty components

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 12

EC04201

EMISSION CONTROL (2JZGTE) EMISSION CONTROL SYSTEM

EC1

1318 Author : Date :

EMISSION CONTROL SYSTEM

PURPOSE

The emission control systems are installed to reduce the amount of CO, HC and NOx exhausted from the

engine ((3), (4) and (5)), to prevent the atmospheric release of blowby gascontaining HC (1) and evapo-

rated fuel containing HC being released from the fuel tank (2).

The function of each system is shown in these table.

System Abbreviation Function

(1) Positive Crankcase Ventilation

(2) Evaporative Emission Control

(3) Exhaust Gas Recirculation

(4) ThreeWay Catalytic Converter

(5) Sequential Multiport Fuel Injection *

PCV

EVAP

EGR

TWC

SFI

Reduces HC

Reduces evaporated HC

Reduces NOx

Reduces CO, HC and NOx

Injects a precisely timed, optimum amount of fuel for reduced

exhaust emissions

Remark: * For inspection and repair of the SFI system, refer to the SFI section this manual.

EC04301

S02979

Charcoal Canister

VSV for EGR

EGR Vacuum Modulator

EGR Valve

VSV for EVAP

Check Valve

PCV Valve

EC2

EMISSION CONTROL (2JZGTE) PARTS LAYOUT AND SCHEMATIC DRAWING

1319 Author : Date :

PARTS LAYOUT AND SCHEMATIC DRAWING

LOCATION

EC04401

P19550

VSV for

EVAP

Heated Oxygen Sensor

(Bank 1 Sensor 2)

Heated Oxygen Sensor

(Bank 1 Sensor 1)

EGR Gas

Temperature

Sensor

Check Valve

Charcoal

Canister

VSV for

EGR

EGR

Vacuum

Modulator

EGR

Valve

EMISSION CONTROL (2JZGTE) PARTS LAYOUT AND SCHEMATIC DRAWING

EC3

DRAWING

P11798

PCV Valve

EC04501

P11834

Cylinder Head Side

Clean Hose

P11831

Air Intake Chamber Side

S00885

EC4

EMISSION CONTROL (2JZGTE) POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEM

1321 Author : Date :

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM

INSPECTION

1. REMOVE PCV VALVE

(a) Disconnect the PCV hose from the PCV valve.

(b) Remove the PCV valve.

2. INSTALL CLEAN HOSE TO PCV VALVE

3. INSPECT PCV VALVE OPERATION

(a) Blow air into the cylinder head side, and check that air

passes through easily.

CAUTION:

z Do not suck air through the valve.

z Petroleum substances inside the valve are harmful.

(b) Blow air into the air intake chamber side, and check that

air passes through with difficulty.

If operation is not as specified, replace the PCV valve.

4. REMOVE CLEAN HOSE FROM PCV VALVE

5. REINSTALL PCV VALVE

6. VISUALLY INSPECT HOSES, CONNECTIONS

AND GASKETS

Check for cracks, leaks or damage.

B02438

EC04601

EC3069

Check Valve (Vacuum Valve)

Gasket

P12150

P12175

Z16768

Port C

Compressed

Air

Air

Air

Air

EMISSION CONTROL (2JZGTE) EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM

EC5

1322 Author : Date :

EVAPORATIVE EMISSION (EVAP)

CONTROL SYSTEM

INSPECTION

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loose connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK

Look for deformation, cracks or fuel leakage.

3. VISUALLY INSPECT FUEL TANK CAP

Check if the cap and/or gasket are deformed or damaged.

If necessary, repair or replace the cap.

4. REMOVE CHARCOAL CANISTER

5. VISUALLY INSPECT CHARCOAL CANISTER

Look for cracks or damage.

6. CHECK FOR CLOGGED FILTER AND STUCK CHECK

VALVE

(a) Using low pressure compressed air (4.71 kPa (48 gf/cm

2

,

0.68 psi)), blow into port C and check that air flows without

resistance from the other ports.

Z16769

Port A

Compressed

Air

Z16770

Port B

Compressed

Air

Z16771

Port A

Compressed

Air

Port C

Port B

P12318

Check Valve

Z09444

Black Port

Blue Port

EC6

EMISSION CONTROL (2JZGTE) EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM

1323 Author : Date :

(b) Blow air (4.71 kPa (48 gf/cm

2

, 0.68 psi)) into port A, and

check that air does not flow from the other ports.

(c) Blow air (4.71 kPa (48 gf/cm

2

, 0.68 psi)) into port B, and

check that air does not flow from the other ports.

If operation is not as specified, replace the charcoal canister.

7. CLEAN FILTER IN CANISTER

Clean the filter by blowing 294 kPa (3 kgf/cm

2

, 43 psi) of com-

pressed air into port C while holding port A and B closed.

NOTICE:

z Do not attempt to wash the canister.

z No activated carbon should come out.

8. REINSTALL CHARCOAL CANISTER

9. INSPECT VSV FOR EVAP

(See page SF71)

10. REMOVE CHECK VALVE

11. INSPECT CHECK VALVE

(a) Check that air flows from the blue port to the black port.

(b) Check that air does not flow from the black port to the blue

port.

If operation is not as specified, replace the check valve.

12. REINSTALL CHECK VALVE

HINT:

Install the check valve with the black port facing the purge port

side of the throttle body.

S02980

Filter

Cap

S02981

Vacuum Gauge

EC04701

EMISSION CONTROL (2JZGTE) EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EC7

1324 Author : Date :

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM

INSPECTION

1. CHECK AND CLEAN FILTER IN EGR VACUUM

MODULATOR

(a) Remove the cap and 2 filters.

(b) Check the filter for contamination or damage.

(c) Using compressed air, clean the filter.

(d) Reinstall the 2 filters and cap.

HINT:

Install the filter with the coarser surface facing the atmospheric

side (outward).

2. INSTALL VACUUM GAUGE

Using a 3way connector, connect a vacuum gauge to the hose

between the EGR valve and EGR vacuum modulator.

3. INSPECT SEATING OF EGR VALVE

Start the engine and check that the engine starts and runs at

idle.

4. INSPECT VSV OPERATION WITH COLD ENGINE

(a) M/T

The coolant temperature should be below 65C (149F).

(1) Start the engine and check idling.

(2) When idling with the lever shifting in the N position,

press accelerator pedal slowly to hold the engine

speed at 3,500 4,000 rpm with the throttle opening

about (one third) 1/3.

(3) Check that the vacuum gauge indicates zero.

(b) A/T

The coolant temperature should be below 50C (122F).

(1) Chock the 4 wheels.

(2) Fully apply the parking brake.

(3) Connect a tachometer to the engine.

(4) Start the engine and check idle.

(5) Keep your foot pressed firmly on the brake pedal.

(6) Shift into the D position. Press the accelerator pedal

slowly to hold the engine speed at 1,600 1,800

rpm.

(7) Check that the vacuum gauge indicates zero.

5. INSPECT VSV OPERATION WITH HOT ENGINE

(a) M/T

Warm up the engine. The coolant temperature in 65C

(149F) or more.

(1) When idling with the lever shifting in the N position,

press accelerator pedal slowly to hold the engine

speed at 3,500 4,000 rpm with the throttle opening

about (one third) 1/3.

(2) Check that the vacuum gauge indicates low vacu-

um momentarily.

S02982

To Intake

Manifold

S02983

Engine Stopped

Air

P

Q

S02984

Engine at

3,500 rpm

Air

P

Q

EC8

EMISSION CONTROL (2JZGTE) EXHAUST GAS RECIRCULATION (EGR) SYSTEM

1325 Author : Date :

(b) A/T

Warm up the engine. The coolant temperature in 50C

(122F) or more.

(1) Chock the 4 wheels.

(2) Fully apply the parking brake.

(3) Connect a tachometer to the engine.

(4) Start the engine and check idling.

(5) Keep your foot pressed firmly on the brake pedal.

(6) Shifting into the D position. Press the accelerator

pedal slowly to hold the engine speed at 1,600

1,800 rpm.

(7) Check that the vacuum gauge indicates low vacu-

um.

6. REMOVE VACUUM GAUGE

Remove the vacuum gauge, and reconnect the vacuum hoses

to their proper locations.

7. INSPECT EGR VALVE

(a) Apply vacuum directly to the EGR valve with the engine

idling.

(b) Check that the engine runs rough or dies.

(c) Reconnect the vacuum hoses to their proper locations.

If no problem is found during this inspection, system is normal;

otherwise inspect each part.

8. INSPECT VSV FOR EGR

(See page SF69)

9. DISCONNECT VACUUM HOSES FROM EGR VACUUM

MODULATOR

Disconnect the 2 vacuum hoses from ports P and Q of the EGR

vacuum modulator.

10. INSPECT EGR VACUUM MODULATOR OPERATION

(a) Block port P with your finger.

(b) Blow air into port Q, and check that air passes through to

the air filter side freely.

(c) Start the engine, and maintain speed at 3,500 rpm.

(d) Repeat the above test. Check that there is a strong resis-

tance to air flow.

11. RECONNECT VACUUM HOSES TO EGR VACUUM

MODULATOR

Reconnect the 2 vacuum hoses to the proper locations.

S02985

S04753

S02988

EMISSION CONTROL (2JZGTE) EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EC9

1326 Author : Date :

12. REMOVE EGR PIPE

(a) Loosen the union nut of the EGR pipe.

(b) Remove the 2 bolts, EGR pipe and gasket.

13. REMOVE EGR GAS TEMPERATURE SENSOR

14. REMOVE EGR VALVE

(a) Disconnect these hoses from the EGR valve:

z Vacuum hose

z Pressure hose

(b) Remove the 2 nuts, EGR valve and gasket.

15. INSPECT EGR VALVE

Check for sticking and heavy carbon deposits.

If a problem is found, replace the EGR valve.

16. REINSTALL EGR VALVE

(a) Place a new gasket on the air intake chamber.

(b) Install the EGR valve with the 2 nuts.

Torque: 21 Nm (210 kgfcm, 15 ftlbf)

(c) Reconnect these hoses to the EGR valve:

z Vacuum hose

z Pressure hose

17. REINSTALL EGR GAS TEMPERATURE SENSOR

Torque: 20 Nm (200 kgfcm, 14 ftlbf)

18. REINSTALL EGR PIPE

(a) Temporarily install the union nut of the EGR pipe.

(b) Install a new gasket and the EGR pipe with the 2 bolts.

Torque: 28 Nm (280 kgfcm, 21 ftlbf)

(c) Tighten the union nut of the EGR pipe.

Torque: 65 Nm (650 kgfcm, 48 ftlbf)

EC04801

S03438

No.2 Front Exhaust Pipe

z Gasket

Pipe Support Bracket

z Nonreusable part

(with Front TWC)

z Gasket

z

z

z

z

EC10

EMISSION CONTROL (2JZGTE) THREEWAY CATALYTIC CONVERTER (TWC)

SYSTEM

1327 Author : Date :

THREEWAY CATALYTIC CONVERTER (TWC) SYSTEM

COMPONENTS

Z18961

Front Exhaust Pipe

z Gasket

z Nonreusable part

(with Rear TWC)

z Gasket

z Gasket

Heated Oxygen Sensor

(Bank 1 Sensor 2)

EMISSION CONTROL (2JZGTE) THREEWAY CATALYTIC CONVERTER (TWC)

SYSTEM

EC11

1328 Author : Date :

EC04901

EC12

EMISSION CONTROL (2JZGTE) THREEWAY CATALYTIC CONVERTER (TWC)

SYSTEM

INSPECTION

1. CHECK CONNECTIONS FOR LOOSENESS OR DAMAGE

2. CHECK CLAMPS FOR WEAKNESS, CRACKS OR DAMAGE

3. CHECK FOR DENTS OR DAMAGE

If any part of the protector is damaged or dented to the extent that it contacts the TWC, repair or replace

it.

4. CHECK HEAT INSULATOR FOR DAMAGE

5. CHECK FOR ADEQUATE CLEARANCE BETWEEN CATALYTIC CONVERTER AND HEAT INSU-

LATOR

Anda mungkin juga menyukai

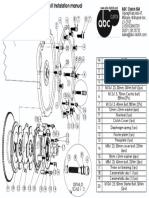

- ABC Clutch 2jzDokumen1 halamanABC Clutch 2jzOgnjen GalićBelum ada peringkat

- 2jzge EcmDokumen5 halaman2jzge Ecmmarckate3702100% (6)

- 3.3L 6-Cyl VinDokumen28 halaman3.3L 6-Cyl VingypsyshortBelum ada peringkat

- Mitsubishi FTODokumen14 halamanMitsubishi FTOJhonatan JalluranaBelum ada peringkat

- How To Service Your RB25 Ignition SystemDokumen9 halamanHow To Service Your RB25 Ignition SystemJameel KhanBelum ada peringkat

- FK Blank 2.0Dokumen122 halamanFK Blank 2.0robertoperez525Belum ada peringkat

- Toyota Tundra (2UZ FE) 2002Dokumen16 halamanToyota Tundra (2UZ FE) 2002Isaac Castillo100% (1)

- Intake Manifold Jza80: Instruction ManualDokumen10 halamanIntake Manifold Jza80: Instruction Manualapi-3833108Belum ada peringkat

- ECM I/O Signals Diagnostic GuideDokumen5 halamanECM I/O Signals Diagnostic Guideazkaz1Belum ada peringkat

- Galant CH 2 Engine Electrical PDFDokumen14 halamanGalant CH 2 Engine Electrical PDFjustcheerfulBelum ada peringkat

- Tokico Katalog Amortazatorov 2009Dokumen308 halamanTokico Katalog Amortazatorov 2009Afrie Setiawan100% (1)

- 2UZTRDDokumen33 halaman2UZTRDJd BuzzBelum ada peringkat

- Honda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025Dokumen8 halamanHonda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025izalirunk100% (1)

- At (2jz-Ge)Dokumen24 halamanAt (2jz-Ge)Jafar SadiqBelum ada peringkat

- Canter 4.5tDokumen2 halamanCanter 4.5tJ Eduardo Garcia Moreno100% (1)

- 1994 Civic Coupe Online Reference Owner's ManualDokumen210 halaman1994 Civic Coupe Online Reference Owner's ManualFlopy96100% (1)

- 2uztrd PDFDokumen33 halaman2uztrd PDFbob loblawBelum ada peringkat

- 5MT Manual Trans & DiffDokumen82 halaman5MT Manual Trans & DiffghotimeBelum ada peringkat

- Lubrication (2jz-Ge)Dokumen15 halamanLubrication (2jz-Ge)AlexendraBelum ada peringkat

- M6ha Mdwa Baxa MaxaDokumen68 halamanM6ha Mdwa Baxa Maxagabriela DiazBelum ada peringkat

- Cooling System (2Az-Fe) : On-Vehicle InspectionDokumen27 halamanCooling System (2Az-Fe) : On-Vehicle InspectionTung NguyenBelum ada peringkat

- Toyota Alphard fuse and relay box diagramsDokumen1 halamanToyota Alphard fuse and relay box diagramsSiu Kit YauBelum ada peringkat

- M24ADokumen74 halamanM24ALuis Pérez mujicaBelum ada peringkat

- Re4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresDokumen3 halamanRe4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresfulltransmissionBelum ada peringkat

- Manual Transmission AssemblycomponentsDokumen5 halamanManual Transmission AssemblycomponentsZouhair WahbiBelum ada peringkat

- Building A 5SG EngineDokumen5 halamanBuilding A 5SG Enginedhendriadi69Belum ada peringkat

- SMR7E20000000000000EBAT00 ECM Component DiagramDokumen3 halamanSMR7E20000000000000EBAT00 ECM Component DiagramSorin VasilescuBelum ada peringkat

- ToyotaDokumen6 halamanToyotaAnonymous Bo5AQr6Belum ada peringkat

- R34 EcuDokumen1 halamanR34 EcuJamie MacdonaldBelum ada peringkat

- Engine Electrical: Charging 2Dokumen50 halamanEngine Electrical: Charging 2alhimni hadi33% (3)

- Avensis Intake System PDFDokumen19 halamanAvensis Intake System PDFMladen VidovićBelum ada peringkat

- Prelude Usdm Pk2 (B20a5) Ecu PinoutDokumen1 halamanPrelude Usdm Pk2 (B20a5) Ecu PinoutluckypicturesBelum ada peringkat

- EFDokumen49 halamanEFsurya100% (1)

- S13 SR20 Guide 08Dokumen20 halamanS13 SR20 Guide 08Алексей Иванченко100% (1)

- 00 GeneralDokumen24 halaman00 Generalcrysttina100% (1)

- Yaris TS Turbo Parts Catalogue - EUDokumen35 halamanYaris TS Turbo Parts Catalogue - EUCarlos FernandoBelum ada peringkat

- Mazda rx7Dokumen3 halamanMazda rx7Jon WestBelum ada peringkat

- Almera N16 TechDokumen4 halamanAlmera N16 TechSpiros FousasBelum ada peringkat

- BeltsDokumen89 halamanBeltszul100% (2)

- RAV4 SDS (Service Delivery Sheet)Dokumen0 halamanRAV4 SDS (Service Delivery Sheet)Gilbert Vasquez SagunBelum ada peringkat

- Z4 E85 Hardtop Retrofit KitDokumen11 halamanZ4 E85 Hardtop Retrofit KitChristian MariBelum ada peringkat

- Installation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Dokumen24 halamanInstallation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Dmentall IllBelum ada peringkat

- Components: V Bank CoverDokumen2 halamanComponents: V Bank CoverAlexendraBelum ada peringkat

- Eclipse Electrical 1g PDFDokumen320 halamanEclipse Electrical 1g PDFKrzysztof BanasikBelum ada peringkat

- Wiper Linkage 2023 CatalogDokumen35 halamanWiper Linkage 2023 CatalogAlice DaiBelum ada peringkat

- Gearboxes CodesDokumen1 halamanGearboxes CodesAzlan Ahmad100% (1)

- Captiva Control Valve Body Removal PDFDokumen2 halamanCaptiva Control Valve Body Removal PDFBurhan udinBelum ada peringkat

- Система управления двигателемDokumen3 halamanСистема управления двигателемEdik Bonifacio MamaniBelum ada peringkat

- Ewd ,,uzj FZJ HDJ HZJ 100-105Dokumen447 halamanEwd ,,uzj FZJ HDJ HZJ 100-105nightevery100% (1)

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDokumen6 halamanInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeBelum ada peringkat

- G Electrical Wiring Routing: Position of Parts in Engine CompartmentDokumen8 halamanG Electrical Wiring Routing: Position of Parts in Engine CompartmentTec RomeroBelum ada peringkat

- Abandoned 1992 Toyota AE101 Turbo Project Car for Sale with 3SGTE Engine ModsDokumen1 halamanAbandoned 1992 Toyota AE101 Turbo Project Car for Sale with 3SGTE Engine ModsjaiusopBelum ada peringkat

- 2AZ-FE Emission ControlDokumen25 halaman2AZ-FE Emission ControlLuks FernandezBelum ada peringkat

- Exhaust Gas Recirculation (Egr) System (4A FE)Dokumen6 halamanExhaust Gas Recirculation (Egr) System (4A FE)Hongda Zhuo100% (1)

- 2GR-FE Emission ControlDokumen23 halaman2GR-FE Emission ControlLuks FernandezBelum ada peringkat

- Emission ControlDokumen26 halamanEmission ControllogammicBelum ada peringkat

- Exhaust Gas Recirculation (Egr) System: EngineDokumen4 halamanExhaust Gas Recirculation (Egr) System: EnginemangyanBelum ada peringkat

- Reduce Emissions with Proper Emission Control System MaintenanceDokumen16 halamanReduce Emissions with Proper Emission Control System MaintenancevixentdBelum ada peringkat

- 7.1. Emission Control SystemDokumen18 halaman7.1. Emission Control SystemChristian Icaza SamaniegoBelum ada peringkat

- Touch and See Your Solution: Finding Solutions For Your Problems in Bhagvad GitaDokumen1 halamanTouch and See Your Solution: Finding Solutions For Your Problems in Bhagvad Gitaanu50% (2)

- Geometry PuzzlesDokumen14 halamanGeometry PuzzlesAshokBelum ada peringkat

- Moral Stories IllustratedDokumen74 halamanMoral Stories IllustratedAshok100% (1)

- Crankshaft Design GuideDokumen16 halamanCrankshaft Design GuideAshokBelum ada peringkat

- Ed 7002 Efm NotesDokumen58 halamanEd 7002 Efm NotesAshokBelum ada peringkat

- Air Bearing Fundamentals-Rev ADokumen13 halamanAir Bearing Fundamentals-Rev AAshokBelum ada peringkat

- 25 Best Short Animal Stories For Kids With MoralsDokumen23 halaman25 Best Short Animal Stories For Kids With MoralsAshok80% (5)

- Fatigue CrankshaftDokumen31 halamanFatigue CrankshaftAngel Zanotti100% (1)

- 24 Generator SelectionDokumen45 halaman24 Generator SelectionAshokBelum ada peringkat

- Selection of GeneratorDokumen11 halamanSelection of GeneratorsbpathiBelum ada peringkat

- Design & Analysis of Crankshaft Bending Test Rig For Actual Engine Condition PDFDokumen8 halamanDesign & Analysis of Crankshaft Bending Test Rig For Actual Engine Condition PDFAshokBelum ada peringkat

- Backlash MitraDokumen8 halamanBacklash MitraAshokBelum ada peringkat

- Combustion Chamber Sae-Ref PaperDokumen9 halamanCombustion Chamber Sae-Ref PaperAshokBelum ada peringkat

- NASA Fastener Design ManualDokumen100 halamanNASA Fastener Design ManualAaron D. MillerBelum ada peringkat

- Basic Tools 1Dokumen13 halamanBasic Tools 1Kannan Nehru100% (1)

- Mechanical Behavior Simulation For SynchromechDokumen27 halamanMechanical Behavior Simulation For SynchromechAshokBelum ada peringkat

- Engine Troubleshooting GuideDokumen16 halamanEngine Troubleshooting GuideAshokBelum ada peringkat

- Transfer CaseDokumen41 halamanTransfer CaseAshok67% (3)

- Synchroniser 2Dokumen9 halamanSynchroniser 2AshokBelum ada peringkat

- Time ManagementDokumen30 halamanTime ManagementAshokBelum ada peringkat

- Effect of Injection Rate and Split Injections On Diesel EngineDokumen14 halamanEffect of Injection Rate and Split Injections On Diesel EngineAshokBelum ada peringkat

- Chapter10 Design of GearsDokumen16 halamanChapter10 Design of GearsAshokBelum ada peringkat

- Automotive Transmissions - Fundamentals Selection Design and Application by AshokDokumen470 halamanAutomotive Transmissions - Fundamentals Selection Design and Application by AshokAshokBelum ada peringkat

- Synchro RingDokumen9 halamanSynchro RingAshokBelum ada peringkat

- Basic Hydro Dynamic DriveDokumen68 halamanBasic Hydro Dynamic DriveAshokBelum ada peringkat

- Basics of SynchronizersDokumen78 halamanBasics of SynchronizersAnish PaiBelum ada peringkat

- Synchroniser Ring 1Dokumen6 halamanSynchroniser Ring 1AshokBelum ada peringkat

- Multi-Cone Synchronizer SystemsDokumen30 halamanMulti-Cone Synchronizer Systemsgrnflash100% (1)

- Development of A Program For Calculating Gearbox SynchronizationDokumen86 halamanDevelopment of A Program For Calculating Gearbox SynchronizationAshok50% (2)

- General Tolerances DIN ISO 2768Dokumen2 halamanGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- HKS700E Operating ManualDokumen34 halamanHKS700E Operating ManualYuryBelum ada peringkat

- GLOBE Airmotor Brochure 2017Dokumen103 halamanGLOBE Airmotor Brochure 2017Milad TilaBelum ada peringkat

- Yedek Parça Kataloğu Spare Parts Catalog: HMK 62SsDokumen332 halamanYedek Parça Kataloğu Spare Parts Catalog: HMK 62SsAdil HanBelum ada peringkat

- Duratec-R: Ford Duratec 2000Cc EngineDokumen3 halamanDuratec-R: Ford Duratec 2000Cc EngineCOURTISSBelum ada peringkat

- Service ManualDokumen37 halamanService ManualFlorian LeordeanuBelum ada peringkat

- PE3 Series ManualDokumen149 halamanPE3 Series Manualdebendra128nitrBelum ada peringkat

- Ecm Pinout Chevrolet Sail 1Dokumen2 halamanEcm Pinout Chevrolet Sail 1Henry SilvaBelum ada peringkat

- PMB7040 C Catalog Web PDFDokumen16 halamanPMB7040 C Catalog Web PDFRached Douahchua0% (1)

- CFD Analysis of Throttle Body Assembly Design OptimizationDokumen11 halamanCFD Analysis of Throttle Body Assembly Design OptimizationRodrigo PassosBelum ada peringkat

- Thomas Ogle Gas Saver Carburetor PatentDokumen11 halamanThomas Ogle Gas Saver Carburetor Patentfatihy73Belum ada peringkat

- AS 940 Sherpa-Eu - G06929004 - en - V16Dokumen36 halamanAS 940 Sherpa-Eu - G06929004 - en - V16jm5280Belum ada peringkat

- Tecumseh Service Repair Manual 2 Cycle Ah520 Ah600 Av520 Av600 Hsk600 Tvs600 Craftsman 200 Series 692508Dokumen68 halamanTecumseh Service Repair Manual 2 Cycle Ah520 Ah600 Av520 Av600 Hsk600 Tvs600 Craftsman 200 Series 692508construct404100% (2)

- Nmax 125-150 Service ManualDokumen450 halamanNmax 125-150 Service ManualRoy ChungyBelum ada peringkat

- 15 - Engine Control System: Workshop Manual - Diablo 6.0Dokumen83 halaman15 - Engine Control System: Workshop Manual - Diablo 6.0jahzooneBelum ada peringkat

- Stihl ServiceManual FC 90 95 100 110 fs90 100 110 Etc PDFDokumen66 halamanStihl ServiceManual FC 90 95 100 110 fs90 100 110 Etc PDFAmazon FireTV100% (1)

- 804Dokumen259 halaman804juanBelum ada peringkat

- VW Passat b4 Simos Injection System EngDokumen113 halamanVW Passat b4 Simos Injection System EngscribdBelum ada peringkat

- 001al) Mazda-Allegro-manual de Taller IndiceDokumen10 halaman001al) Mazda-Allegro-manual de Taller IndiceJohn Jairo MontoyaBelum ada peringkat

- DSM Automatic Transmission SpecsDokumen64 halamanDSM Automatic Transmission Specsjohn123john456100% (4)

- SUPPORT VWAGEA888EngineTuning 220922 1305Dokumen21 halamanSUPPORT VWAGEA888EngineTuning 220922 1305mohnaserBelum ada peringkat

- 05white88 89correctedDokumen2 halaman05white88 89correctedRoman NavaBelum ada peringkat

- ECM590 11000, 11155 & 11158 & AboveDokumen386 halamanECM590 11000, 11155 & 11158 & Abovebada_shamsideen73% (15)

- Digital Cruise ControlDokumen6 halamanDigital Cruise ControlNeethu Krishna KBelum ada peringkat

- New automotive technologiesDokumen91 halamanNew automotive technologiesguntoroBelum ada peringkat

- Drawworks(绞车)Dokumen10 halamanDrawworks(绞车)Omar Fathy100% (1)

- Renault Trafic fault codes EDC 15С13 F9Q760/762 G9U730Dokumen2 halamanRenault Trafic fault codes EDC 15С13 F9Q760/762 G9U730candido vargas gutierrez100% (1)

- Codigos Obd II Infiniti y NissanDokumen7 halamanCodigos Obd II Infiniti y NissanIvan OvandoBelum ada peringkat

- Owner'S Manual: Read This Manual Carefully Before Operating This VehicleDokumen84 halamanOwner'S Manual: Read This Manual Carefully Before Operating This VehicleAminullah MuhammadBelum ada peringkat

- Unit - V Engine Management System (EMS)Dokumen65 halamanUnit - V Engine Management System (EMS)Chidananda BasavannaBelum ada peringkat

- Turbine Performance MonitoringDokumen35 halamanTurbine Performance MonitoringNaval Gupta100% (2)