Band Clamping Systems Air Tool

Diunggah oleh

albertodsa0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

203 tayangan8 halamanBandimex Befestigungssysteme GmbH was founded in 1982 and has developed into an internationally active company. The careful choice of materials, their processing on the most modern machines and critical test procedures guarantee the high quality standards of our products.

Deskripsi Asli:

Judul Asli

Bandimex Tools Adapters.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniBandimex Befestigungssysteme GmbH was founded in 1982 and has developed into an internationally active company. The careful choice of materials, their processing on the most modern machines and critical test procedures guarantee the high quality standards of our products.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

203 tayangan8 halamanBand Clamping Systems Air Tool

Diunggah oleh

albertodsaBandimex Befestigungssysteme GmbH was founded in 1982 and has developed into an internationally active company. The careful choice of materials, their processing on the most modern machines and critical test procedures guarantee the high quality standards of our products.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 8

Band Clamping Systems

Universal Hose and Pipe Clamps

Made in Germany

2

Bandimex Befestigungssysteme GmbH

With our fastening technologies, we provide universal and

economical solutions in numerous applications, such as hose

clamping, sign fastening etc.

The careful choice of materials, their processing on the most

modern machines and critical test procedures guarantee the

high quality standards of our products.

A well assorted stock of raw materials and finished products

as well as a highly motivated team of qualified staff form the

basis for the quick and reliable supplying of our customers.

Bandimex Befestigungssysteme GmbH was founded in

1982 and has developed into an internationally active com-

pany. Our products have opened a wide range of applications

and are used worldwide in many different branches of industry.

www.nguyenxuong.com

Tool, Adapter, HD-Adapter

and Air Tool

13

Bandimex Tool

Tensioning capability over 1,0 t

Cat.No. kg

W 001 Bandimex Tool 2,00

Bandimex Adapter

to apply Bandimex Preformed Clamps.

For use with the Bandimex Tool W 001 fixed in a vise.

Cat.No. kg

V 001 Bandimex Adapter 0,7

Bandimex HD-Adapter

to apply Bandimex Preformed Clamps.

For use with the Bandimex Tool W 001 fixed in a vise as well as

for portable applications.

Cat.No. kg

V 050 Bandimex HD-Adapter 0,7

Cat.No. kg

V 015 Cutter Blade Kit for Bandimex Adapter V 001 and V 050 0,1

Bandimex Air Tool

for high volume production clamping

of Bandimex Preformed Clamps.

Cat.No. kg

V 440 Bandimex Air Tool 28,5

The Bandimex Air Tool V 440 is an air controlled tool for applying

Bandimex Preformed Clamps. Operated by pedal both hands

are free to manipulate the object to be clamped.

An ideal, proven tool to clamp hose, cables and ropes of various

constructions. Each clamp is pulled down with exactly the same

preset pressure in seconds.

Cat.No. kg

V 920 Cutter Blade Kit for Bandimex Air Tool V 440 0,1

All replacement parts for the Bandimex Air Tool V 440 are sepa-

rately available.

www.nguyenxuong.com

Instructions Preformed Clamps

23

Apply with the Bandimex Tool W001 and Bandimex Adapter V001 (a) or

V050 (b).

Place Bandimex Tool in vise, put Bandimex Adapter on nose of tool. Slip

Preformed Clamp in tool and grip tail end with excenter lever.

Insert hose into clamp and apply tension. To control tensioning, hold thumb

on that side of buckle where band enters. When band stops moving through

buckle, maximum tension has been applied.

Roll hose over until shear hook engages behind buckle edge, at the same time

reversing handle by

1

4 to

1

2 turn (depending on type and size of hose).

(a)

Pull on cutter lever to cut band.

(b)

Turn disc by hand until tight. Put ratchet wrench on hex nut and operate until

band is sheared off.

The finished Bandimex

Preformed Clamp requires no

hammering or crimping.

(a)

(b)

www.nguyenxuong.com

The BANDMEX air tool is an air controlled, automatic

tensioning tool for applying BANDMEX preformed

clamps.

Operated by pedal both hands are free to

manipuIate the object to be cIamped.

An ideal, proven tool to clamp hose, cables and ropes

of various constructions with outer diameters of 10 to

150 mm (3/8" to 6").

Each clamp is pulled down with exactly the same

preset pressure in seconds.

BANDMEX preformed clamps come in 18 diameters and

combinations of 5 band width, a total of 36 various clamps

are available. f this is not enough on request we can also

manufacture additional combinations of diameters and

widths.

BANDIMEX AIR TOOL V 440

InstaIIation of air tooI

Screw down base plate to the work bench in such a manner that the tensioning head has sufficient distance to the edge of

the bench to allow easy and unobstructed mounting of clamps on all sizes hose.

The air inlet is a " male tapered thread, attach a " f x f Withworth swivel adapter or just a " female coupling, or quick

coupler adapter, attach 3/8" (10 mm) hose. Pressure setting at the incorporated service unit should not be less than 85 psi

(6 bar), and not more than 115 psi (8 bar), it is set at 100 psi (7 bar), when tool leaves factory.

Fill vessel of oiler (service unit) with light oil, adjust set screw of oiler to obtain minimum oil mist in air stream. Keep insides

of aluminium guide rails well greased with Molykote or other high grade grease. Check the two cutter blade screws for

tightness once in a while.

The footpedal may be screwed to the floor.

Adjusting functions:

On the tables and pressure gauges settings are shown in ,bar' and ,psi'. For exact adjusting ,psi'-settings should be

employed.

1. PuII Pressure: Step on pedal pistion is pulling in (keep the pedal down!) turn knob and set pressure reading

on the gauge to the pressure required according to band width of clamp (refer to schedule)

- losen counter nut on top of knob before turning, and fasten again after setting

2. PuII Speed: Losen counter nut

Slower: Turn screw to the right

Attention: Don't turn the screw past stop

Faster: Turn screw to the left

Press down pedal repeatedly while adjusting until requested speed is obtained.

3. Timer: This unit regulates the period of time between beginning of cycle (pressure build-up), and

release of the pressure, and rules the time used for applying a clamp. When the clamp is

pulled down and piston stops at the set reading, the pressure should ,stand' for 1 or 2 seconds

to allow the clamp to settle.

Less time: Turn the knob to the Ieft

More time: Turn the knob to the right

Max. time delay: 10 seconds

The timer is set at approx. 2 seconds by manufacturer. (Depends on length of pull down of

clamp tail.)

4. HoId Pressure: n order to keep the clamp from losing tension during the cut-off operation, and to guarantee

a secure locking of the buckle, a certain amount of pressure must be maintained in the cylinder.

This pressure varies according to width of band (refer to schedule), and is set in the same

manner as described under 1., but after the timer has released the pull pressure.

www.nguyenxuong.com

Time reIais PuII speed

PuII HoId

pressure pressure

Pull Pressure V 440 Hold Pressure V 440

bar psi bar psi

" 0.9 13 0.3 4

3/8" 2.1 30 0.35 5

" 3.0 42 0.45 6

5/8" 3.8 53 0.50 7

" 4.6 65 0.65 9

Operating Instructions

1. Push tailed end of preformed clamp into tensioning head.

2. Step on pedal (keep depressed untiI cIamp has been cut-off)

3. After timer has released pull-up pressure, watch pressure gauge on right side of panel, and roll up hose

together with clamp just before the reading previously set on this gauge is reached, e.g. if setting is at 8 psi,

then roll-over should start at approx. 12 psi. After roll-up, the cutter hook will engage on top edge of buckle.

4. Pull forward cutter lever cut off clamp.

5. Release pedal piston returns remove band tail.

Depending on the type of the hose to be clamped set pull pressure a little lower or up to 10% higher.

For type 316 steel (V4A) use 10% less, for Hi-C steel 30% less pressure.

KEEP PEDAL DEPRESSED UNTIL CLAMP HAS BEEN CUT OFF!

Befestigungssysteme Germany

www.nguyenxuong.com

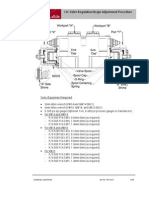

The BANDIMEX air tool is an air controlled, full

automatic tensioning tool for applying BANDIMEX

performed clamps.

Operated by pedal both hands are free to

manipulate the object to be clamped.

The tools control panel allows optimal adjustment

for various kinds and sizes of hoses.

An ideal tool to clamp hose, cables and ropes of

various constructions with outer diameters of 10 to

150 mm (3/8 to 6).

Each clamp is pulled down with exactly the same

preset pressure in seconds.

BANDIMEX performed clamps come in 18 diameters and

combinations of 5 band width, a total of 36 various

clamps are available. If this is not enough on request we

can also manufacture additional combinations of

diameters and widths.

BANDIMEX AIR TOOL V 800

Installation of air tool

Screw down base plate to the work bench in such a manner that the tensioning head has sufficient distance to the edge of the bench to

allow easy and unobstructed mounting of clamps on all sizes hose.

The air inlet is a female tapered thread. Its also possible to use the male tapered thread. Pressure setting at the incorporated

service unit should not be less than 101 psi (7 bar), and not more than 116 psi (8 bar), it is set according to these values, when tool

leaves factory.

Fill vessel of oiler (service unit) with special oil for service units (e.g. Festo OFSW-32), adjust set screw of oiler to obtain minimum oil mist

in air stream. Check the two cutter blade screws for tightness once in a while. The footpedal may be screwed to the floor.

Adjusting functions:

On the tables and pressure gauges settings are shown in bar and psi. For exact adjusting psi-settings should be employed.

1. Pull Pressure: Step on pedal piston is pulling in (keep the pedal down!) turn knob and set pressure reading

on the gauge to the pressure required (refer to schedule!)

- loosen counter nut on top of knob before turning, and fasten again after setting

2. Timer Pull Pressure: This unit regulates the period of time between beginning of cycle (pressure build-up), and

switching to hold pressure. The setting is very accurate and individually adjustable for each hose size. We

recommend to take more time the larger the hoses are; so its possible to re-adjust the hose before cutting.

When the clamp is pulled down and piston stops at the set reading, the pressure should remain for

1 or 2 seconds to allow the clamp to settle.

3. Pull Speed: Regulates the speed of piston.

Slower: Turn screw to the right

Attention: Dont turn the screw past stop

Faster: Turn screw to the left

Press down pedal repeatedly while adjusting until requested speed is obtained.

4. Hold Pressure: In order to keep the clamp from losing tension during the cut-off operation, and to guarantee

a secure locking of the buckle, a certain amount of pressure must be maintained in the cylinder.

This pressure varies according to width of band (refer to schedule), and is set in the same

manner as described under 1., but after the timer has released the pull pressure.

5. Timer Hold Pressure: This unit regulates the period of time between switching to hold pressure and automatically cut-off

operation. The setting is very accurate and individually adjustable for each hose size. We

recommend to take more time the larger the hoses are; so its possible to re-adjust the hose before cutting.

www.nguyenxuong.com

Timer Timer

Pull Pressure Hold Pressure

Pull Pressure Hold Pressure

Pull Speed

Guideline for Stainless Steel (CrNi):

Pull Pressure Hold Pressure

Band width

of clamp

bar psi bar psi

0.6 9 0.30 4

1.7 25 0.35 5

2.5 37 0.45 6

3.3 48 0.50 7

4.1 60 0.65 9

For type 316 steel (CrNiMo) use 10% less, for Hi-C steel 30% less pressure.

The above values for pull and hold pressure are approximate.

They may vary according to the types of hose and couplings applied.

Operating Instructions

1. Push tailed end of preformed clamp into tensioning head as far as possible.

2. Step on pedal (keep depressed until clamp has been cut-off)

3. After timer has released pull-up pressure roll up hose together with clamp and position buckle under the cutter

hook. After roll-up, the cutter hook will engage on top edge of buckle.

4. When preselected time has passed at the timer of hold pressure, Tool will cut off the tail of clamp

automatically.

5. Release pedal piston returns remove band tail.

KEEP PEDAL DEPRESSED UNTIL CLAMP HAS BEEN CUT OFF!

Befestigungssysteme Germany

www.nguyenxuong.com

Anda mungkin juga menyukai

- Prophetic Dance - Mary JonesDokumen7 halamanProphetic Dance - Mary Jonesm28181920Belum ada peringkat

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDari EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceBelum ada peringkat

- Wireline NotesDokumen46 halamanWireline NotesDavide Boreaneze100% (15)

- REXROTH Service Manual PVC PSSFDokumen6 halamanREXROTH Service Manual PVC PSSFRaghavendra DeshpandeBelum ada peringkat

- Reciprocating Compressors:: Operation and MaintenanceDari EverandReciprocating Compressors:: Operation and MaintenancePenilaian: 4 dari 5 bintang4/5 (7)

- HL2-90 Compressor Instr ManualDokumen12 halamanHL2-90 Compressor Instr ManualCosmin Iulian100% (3)

- Create SOAP Notes Using Medical TerminologyDokumen4 halamanCreate SOAP Notes Using Medical TerminologyLatora Gardner Boswell100% (3)

- Technical Seminar Agenda and Generator System OverviewDokumen86 halamanTechnical Seminar Agenda and Generator System OverviewKenneth100% (1)

- CAT Pumps Service ManualDokumen8 halamanCAT Pumps Service ManualAnonymous alQXB11EgQBelum ada peringkat

- GX Audit Internal Audit Risk and Opportunities For 2022Dokumen26 halamanGX Audit Internal Audit Risk and Opportunities For 2022Muhammad SamiBelum ada peringkat

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDari EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementBelum ada peringkat

- Tools Threading MachineDokumen20 halamanTools Threading MachinedayglisBelum ada peringkat

- Kuster Company ManualDokumen28 halamanKuster Company ManualarjmandquestBelum ada peringkat

- Instruction Manual Air Compressor HL2/160Dokumen12 halamanInstruction Manual Air Compressor HL2/160Denis Silva100% (1)

- Atestat EnglezaDokumen29 halamanAtestat EnglezaAdrianaBelum ada peringkat

- Tools AutoclaveDokumen20 halamanTools Autoclaveade_salmanBelum ada peringkat

- Autoclave - Tools, Installation. Operation and MaintenanceDokumen16 halamanAutoclave - Tools, Installation. Operation and Maintenancemaz234Belum ada peringkat

- Manual Sc32.PDF Prenza Hidraulica GatesDokumen16 halamanManual Sc32.PDF Prenza Hidraulica GatesEsteban Sándiga GrandaBelum ada peringkat

- 2014 FR C Pneumatics ManualDokumen12 halaman2014 FR C Pneumatics Manualnhstechnology0% (1)

- 2012 FIRST Robotics Competition Pneumatics ManualDokumen13 halaman2012 FIRST Robotics Competition Pneumatics ManualEstuardoABelum ada peringkat

- Atomic Aquatics Ti2Dokumen20 halamanAtomic Aquatics Ti2aki009Belum ada peringkat

- Plunger Pump Service Manual: Installation and Start-Up InformationDokumen6 halamanPlunger Pump Service Manual: Installation and Start-Up InformationSubhendu KarBelum ada peringkat

- AccuStream 13968 Abrasive Regulator Install Kit For OMAXDokumen4 halamanAccuStream 13968 Abrasive Regulator Install Kit For OMAXAdelaBelum ada peringkat

- FIS113eng Hi Temp BellowsDokumen8 halamanFIS113eng Hi Temp Bellowsmahesh_eilBelum ada peringkat

- TM1100 DM CDTM InstrucDokumen12 halamanTM1100 DM CDTM InstrucJuan Carlos LibrerosBelum ada peringkat

- For Screw Compressor Minimum Pressure Valve Type MPVLDokumen3 halamanFor Screw Compressor Minimum Pressure Valve Type MPVLhmltdt9221100% (1)

- Manual SSW10Dokumen31 halamanManual SSW10Victor RodriguezBelum ada peringkat

- Automatic Gas Manifolds Installation, Operation & Maintenance ManualDokumen20 halamanAutomatic Gas Manifolds Installation, Operation & Maintenance ManualtaibkBelum ada peringkat

- Nordson EFD 736HPA NV Installation Guide PDFDokumen4 halamanNordson EFD 736HPA NV Installation Guide PDFFelipePerezBelum ada peringkat

- Manual Chris CoffeeDokumen15 halamanManual Chris CoffeeAnonymous onhjGNBelum ada peringkat

- Hypro D50 Service ManualDokumen32 halamanHypro D50 Service Manualjimi9488Belum ada peringkat

- Nitrox Stik Setup and Use GuideDokumen15 halamanNitrox Stik Setup and Use GuideRicardo BanderasBelum ada peringkat

- Hot-Tap Saddle: Installation InstructionsDokumen2 halamanHot-Tap Saddle: Installation InstructionsSusan Sue Berrospi MerinoBelum ada peringkat

- 2007 Pneumatics Manual GuideDokumen16 halaman2007 Pneumatics Manual GuideEstuardoABelum ada peringkat

- HP Regulators v2Dokumen9 halamanHP Regulators v2Danny SánchezBelum ada peringkat

- Change piston settings for pressure sensorsDokumen17 halamanChange piston settings for pressure sensorsMargaret Daugherty100% (1)

- Breathing Air Distribution System Technical Rescue Cart Instruction Manual - EN PDFDokumen30 halamanBreathing Air Distribution System Technical Rescue Cart Instruction Manual - EN PDFSERGIOBelum ada peringkat

- CNC CAT Tool Changer GuideDokumen5 halamanCNC CAT Tool Changer GuidecaecinelliBelum ada peringkat

- PNEUMATIC PAPER BOWL MAKING MACHINE DOCUMENTDokumen37 halamanPNEUMATIC PAPER BOWL MAKING MACHINE DOCUMENTParminder SinghBelum ada peringkat

- Sno 450 XRDokumen20 halamanSno 450 XRMelvin HrsBelum ada peringkat

- Saunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesDokumen6 halamanSaunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesJose Gregorio FerrerBelum ada peringkat

- VDO Gauge InstallationDokumen4 halamanVDO Gauge Installationurule2kBelum ada peringkat

- LSC Valve Regulation Begin Adjustment Procedure: Tools/Equipment RequiredDokumen5 halamanLSC Valve Regulation Begin Adjustment Procedure: Tools/Equipment RequiredthierrylindoBelum ada peringkat

- Valve Body Adjustments 904Dokumen4 halamanValve Body Adjustments 904Petar RutesicBelum ada peringkat

- 3 OVBalanceControl Book 022311Dokumen16 halaman3 OVBalanceControl Book 022311shivas34regalBelum ada peringkat

- Twister Manual 2108Dokumen16 halamanTwister Manual 2108Proveedora de servicios y suministros PSSBelum ada peringkat

- SB 8540.3 - 1800 and 2000 Industrial RegDokumen12 halamanSB 8540.3 - 1800 and 2000 Industrial RegImam BuchairiBelum ada peringkat

- TDS010 - 400 Series Pneumatic Actuators Technical DataDokumen6 halamanTDS010 - 400 Series Pneumatic Actuators Technical DataRicardoBalderasBelum ada peringkat

- Convertidor Mechanical S108KDokumen8 halamanConvertidor Mechanical S108KALBERTOBelum ada peringkat

- Air Springs Cab - ConvolutedDokumen98 halamanAir Springs Cab - ConvolutedСергей ЕгоровBelum ada peringkat

- PRS09 TC V PDFDokumen4 halamanPRS09 TC V PDFengp3077Belum ada peringkat

- Peart 150 Underpressure Drilling Machine Operating InstructionsDokumen21 halamanPeart 150 Underpressure Drilling Machine Operating InstructionsRyan LeckieBelum ada peringkat

- Válvula de Presión y Vacío para TransformadoresDokumen2 halamanVálvula de Presión y Vacío para Transformadoreslaime_floresBelum ada peringkat

- NuFlo EZ-In User Manual - PEDDokumen32 halamanNuFlo EZ-In User Manual - PEDsarkaft100% (1)

- KPS03 Installation InstructionsDokumen12 halamanKPS03 Installation InstructionsHybrid RacingBelum ada peringkat

- Operations-And Maintenance Instructions For FansDokumen16 halamanOperations-And Maintenance Instructions For Fanskeyur1109Belum ada peringkat

- PV211 ManualDokumen2 halamanPV211 Manualسمية صلاحBelum ada peringkat

- WRAITH Aero & PDW Owner's ManualDokumen10 halamanWRAITH Aero & PDW Owner's ManualrhokahinBelum ada peringkat

- SaundersHC4OM AutomatedValvesFeb08Dokumen6 halamanSaundersHC4OM AutomatedValvesFeb08Arrow HeadBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDari EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationBelum ada peringkat

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDari EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationBelum ada peringkat

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeDari EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeBelum ada peringkat

- KoL Mekflu - 9Dokumen104 halamanKoL Mekflu - 9Maha D NugrohoBelum ada peringkat

- Performance of Filler Material in GabionsDokumen4 halamanPerformance of Filler Material in GabionsPreetham N KumarBelum ada peringkat

- 2015 StoneAge - LowresDokumen51 halaman2015 StoneAge - LowresAZLAN ABDULLAIBelum ada peringkat

- Lab No.7: Measurement of Coupling Coefficient, Directivity and Insertion Loss of A Directional CouplerDokumen3 halamanLab No.7: Measurement of Coupling Coefficient, Directivity and Insertion Loss of A Directional CouplerM. Ahmad RazaBelum ada peringkat

- Numerical Methods NotesDokumen21 halamanNumerical Methods Notesdean427Belum ada peringkat

- Climate Change ReactionDokumen2 halamanClimate Change ReactionAngelika CotejoBelum ada peringkat

- Comparing Means of Two GroupsDokumen8 halamanComparing Means of Two GroupsRobert Kier Tanquerido TomaroBelum ada peringkat

- Concept Deck de BosBoerderij - Dec2023Dokumen32 halamanConcept Deck de BosBoerderij - Dec2023Bruna San RomanBelum ada peringkat

- M and S - Capstone Marketing Across Cultures Fons TrompenaarsDokumen398 halamanM and S - Capstone Marketing Across Cultures Fons TrompenaarsBof BeosBelum ada peringkat

- HB Im70 QRDokumen1 halamanHB Im70 QROsamaBelum ada peringkat

- Handouts For Semantics GradDokumen8 halamanHandouts For Semantics GradPhuong Thao DangBelum ada peringkat

- WHIRLPOOL AWE 2214 User ManualDokumen19 halamanWHIRLPOOL AWE 2214 User ManualSilvestru NemorovBelum ada peringkat

- Optimize Your Portfolio With Modern TheoriesDokumen65 halamanOptimize Your Portfolio With Modern Theoriesastro9jyotish9asim9mBelum ada peringkat

- Future TenseDokumen6 halamanFuture TenseMuhammad Ibnu LaksonoBelum ada peringkat

- Forest Ecosystems and EnvironmentsDokumen152 halamanForest Ecosystems and EnvironmentsSufyan MaharBelum ada peringkat

- Rabuddha HarataDokumen67 halamanRabuddha HaratasagggasgfaBelum ada peringkat

- National Artists of the PhilippinesDokumen66 halamanNational Artists of the Philippinesshey mahilumBelum ada peringkat

- SAP Untangled: An Introductory Guide To SAP For New HomesDokumen28 halamanSAP Untangled: An Introductory Guide To SAP For New HomestempuserBelum ada peringkat

- Tectonics, Vol. 8, NO. 5, PAGES 1015-1036, October 1989Dokumen22 halamanTectonics, Vol. 8, NO. 5, PAGES 1015-1036, October 1989atoinsepeBelum ada peringkat

- Current Electricity O LevelDokumen59 halamanCurrent Electricity O LevelNoah OkitoiBelum ada peringkat

- Right to Personal Liberty and Judicial Process in IndiaDokumen636 halamanRight to Personal Liberty and Judicial Process in IndiaDrDiana PremBelum ada peringkat

- Circle, Cube, and CuboidsDokumen27 halamanCircle, Cube, and CuboidsYohanes DhikaBelum ada peringkat

- Tie Technology DK SKDokumen32 halamanTie Technology DK SKVladimir PleșcaBelum ada peringkat

- SPXDokumen6 halamanSPXapi-3700460Belum ada peringkat

- Pamantasan NG Lungsod NG Maynila - Freshmen AdmissionDokumen6 halamanPamantasan NG Lungsod NG Maynila - Freshmen AdmissionPoppy HowellBelum ada peringkat