Buckling Non-Prismatic Steel Columns

Diunggah oleh

lele_33Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Buckling Non-Prismatic Steel Columns

Diunggah oleh

lele_33Hak Cipta:

Format Tersedia

Civil and Environmental Research www.iiste.

org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

54

Non-Linear Buckling Analysis of Non-Prismatic Steel Columns

Subjected to Axial Compression Loads

Dr. Najla'a H. AL-Shareef

Lecture, Civil Eng. /Babylon University

* E-mail of the corresponding author: dr.najlaaalshareef@yahoo.com

Abstract

This study investigates the effect of non-uniform cross-section on the behavior of steel columns subjected to

axial compression load. A nonlinear finite element model using ANSYS 12.0 has been adopted to investigate the

behavior of square and circular steel columns. The steel is assumed to behave as an elastic-plastic material with

strain hardening in compression. The type of elements have been used to model the steel; SOLID45. The axial-

load displacement curves and the deformation shapes were predicted. A parametric study on columns with square

and circular section has been done. All the analyzed columns have the same value of cross-section volume for

the column, yielding strength, and boundary conditions with different length of column. The results show that

the behavior of non-prismatic column is always by the tapering ratio and the slenderness ratio on the elastic

buckling. As the taper ratio increases, the elastic buckling load increases, in the main while the maximum

ultimate load occurs in the (prismatic column) comparing with the non-prismatic column.

Keywords: Non-uniform cross-section, Steel columns, nonlinear finite element, Elastic buckling load.

1. Introduction

Structures are generally designed on the basis of economy and safety. For common structures, economy often

requires the use of standard members because these members are relatively inexpensive and easy to obtain. For

many structures, however, using tapered members may both increase structural efficiency and be economical.

For small projects, this may not translate into overall economy, but more complex, unique, or large structures

may (and often do) take full advantage of the structural efficiency tapered members offer by reducing the amount

of material required while strategically stiffening certain parts of a member, thereby increasing the overall

performance of the structure. The use of steel members with non-uniform cross- sections either as columns or as

distressed parts of a structure with or without bending moments is very common in steel constructions. There is a

wide variety of structures such as buildings frames, bridge members, masts or cranes, etc, which are designed

with members of non-uniform cross-sections in order to minimize the required material.

A first approach and study the above-mentioned problems of columns with variable cross-sections were made by

[Dinnik, 1929 and 1932]. The main results of these studies were translated in English by [Maletsand 1925 and

1932] the same problem was studied by [Ostwald, 1910], by [Ono, 1914] and by [Morley, 1914 and 1917]. On

the history of early studies on these topics, one can refer to [Timoshenko, 1953]. [Bleich, 1924] studied

compression members the cross sectional moment of inertia of which was varying by a half sine curve. On the

other hand, the significance of the initial imperfections was noted very early and studied mainly experimentally

by [Mrston, 1897], by [Jensen, 1908] and by [Lilly, 1911], the studies of which were gathered by [Salmon,

1925]. In [Gere and Carter, 1962] provided equations and design curves for calculating the critical buckling

loads of columns with many different cross sections and four different fixity conditions: pinned-pinned, fixed-

free, fixed-pinned, and fixed-fixed. This greatly enhanced the information that had previously been available for

non-prismatic column design, particularly for tapered wide flange sections.

Numerical solution methods for non-prismatic columns are presented by [Ram and Rao, 1951], [Ku, 1979]

and [Chen et al., 1989]. Tapered column buckling under stepped axial loads was researched by analyzed using

numerical integration and a discredited column made up of prismatic sections. Tapered box columns under

biaxial loading were analyzed by [Liew et al, 1989] using moment curvature-thrust relationships and Hornes

stability criteria.

In [Liew et al, 1989], presented the formulation to solving the governing equation of the problem through a

numerical method where the eigen shapes of the member are employed. Non-uniform steel members with or

without initial geometrical or loading imperfections, that are loaded by axial forces applied concentrically or

eccentrically and by concentrated moments applied at the ends or at intermediate points, are studied. More

specifically, steel members with varying cross-sections, tapered or stepped or members consisting by two

different tapered parts are considered.

In the present study, the influence of the taper ratio and cross-sectional geometry on the stability of non-uniform

steel members that are subjected to axial loads is investigated. The problem is studied by focusing on

dimensions for square section and round section with cross-sections that may vary along the length, are usually

met in steel structures. The methodology is based on the formulation of the mathematical expression for the

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

55

Euler buckling load of an ideal column follows from consideration of equilibrium, the mechanics of bending,

geometry of the column, and material properties within the initial linear range. The effect of taper ratio on the

buckling strength of such beams is not dealt with in detail in the bibliography. Employment of a detailed finite

element analysis using the commercial nite element code ANASYS (12.0) serves herewith for verification

purposes only and both analytical and numerical results correlate with reasonable accuracy.

2. Numerical Analysis

2.1 Buckling load for a non- prismatic column

In [Gere and Carter, 1962] published a paper in the ASCE Journal of the Structural Division that provided

equations and design curves for calculating the critical buckling loads of columns with many different cross

sections and four different fixity conditions: pinned-pinned, fixed-free, fixed-pinned, and fixed-fixed. This

greatly enhanced the information that had previously been available for non-prismatic column design,

particularly for tapered wide flange sections. Gere and Carter used methods developed by Timoshenko (solution

of the differential equation of the deflection curve) and Newmark (method of successive approximations of the

deflection curve), along with an innovative shape factor to account for the cross-sectional variation along the

column, to ultimately provide a relatively concise set of equations to calculate the critical buckling load. Many

of the situations that were analyzed could be solved in closed form, but required a difficult solution process

based on Bessel functions with many related variables. However, for columns with a linear taper, circular cross

section, and pinned-pinned, fixed-pinned, or fixed-fixed end conditions, the resulting equation is simply the

product of the square of the ratio of end diameters and the critical buckling load [

o

cr

P

] of a prismatic column

for the given end conditions Table (1).

Table (1), Exact buckling load for linearly tapering solid columns of circular or square cross section [Gere and

Carter, 1962].

The research on tapered columns has yielded a great number of ways to characterize the taper of a given

member. For linearly tapering members of various cross sections, a shape factor is generally devised that is

based on the variation of the moment of inertia along the length of the member. If more complex taper scenarios

are required, then the shape factor is often based on the variation of some cross-sectional dimension along the

length of the member. [Gere and Carter, 1962] Provide the most general expression for the variation of the

moment of inertia for a linearly tapering column:

( ) 1 1

n

a

a

b

d x

x

d L

( | |

= +

( |

\

(1)

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

56

where

( ) x

is the moment of inertia at any distance (x) from the small end of the column (end a as defined in

Fig. 1), (

a

) is the moment of inertia at the small end of the column, (da) and (db) are the general dimensions at

the small and large ends of the column, respectively, and n is the shape factor given by the equation:

log

log

b

a

b

a

n

d

d

= (2)

This allows for the shape factor to be determined for any given cross section. However, for most simple shapes,

n may be evaluated by inspection. For example, knowing that

4

64

d

= for a rounded cross section, one can

deduce that for linear variation of the diameter, the moment of inertia will vary by the power of 4.

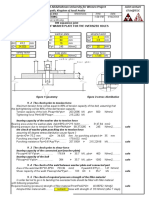

3. The Numerical Modeling and Application

3.1 The Finite Element Modeling

The commercial finite element software ANSYS 12.0 was adopted for the numerical simulation. Some previous

researchers were used shell element to model the steel [Xiong and Zha,2007] , [Guo et al,2007],

[Kwon et al, 2007], and [Ellobody,2007],while [Mohi-Aldeen, 2008] and[Zinkaah, 2010] were used solid

element. Thus, the type of element has been used to model the steel section; is SOLID45 for the 3-D modeling

of RHS column. The element is defined by eight nodes having three degrees of freedom at each node:

translations in the nodal x, y, and z directions as shown in Fig.(2). The element has plasticity, creep, swelling,

stress stiffening, large deflection, and large strain capabilities [ANSYS, 2004].

a=Smaller end

b=Larger end

L

Figure 1 Notation used to characterize tapered column geometry

Figure 2 Solid45-3D Solid [ANSYS, 2004].

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

57

Material properties specified in ANSYS 12.0 included a Young`s modulus of steel Es of 200000MPa

and Poisson`s ratio s of 0.3 [Guo et al,2007]. The steel is assumed to behave as an elastic-plastic material with

strain hardening in compression. The idealized stress-strain curve used in the numerical analysis is shown in Fig.

3 [Xiong and Zha, 2007], [Mohi Aldeen, 2008], and [Zinkaah, 2010]. The Fy

in Fig. (3) Represent the

ultimate stress steel.

3.2 Application

In spite of the software ANSYS 12.0 dose not required to proving the validity and accuracy in analysis of steel

columns, two specimens modeled then the axial loadaxial displacement curve are compared with the numerical

results, to verify the accuracy of the analysis by ANSYS 12.0. The specimens represent a square and rounded

solid steel columns. The finite element modeling and the boundary conditions of the analyzing column are

showed in Fig. 4, plowed for linear buckling analysis. Such a detailed FE model of a dimensions with taper ratio

varying a/b=0.1-1 build-up steel cross section with L and No. of element is equal to L/10 .It is found that the

analytical results presented herein correlate well with the corresponding FEA results with a maximum error less

than 0.2%.

Figure 3 Stress-strain curve[Xiong and Zha,2007], [Mohi Aldeen, 2008], and [Zinkaah, 2010]

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

58

3.2.1 Applied load

The deformation shape, the values of and the load-axial displacement curve for Square cross section column and

circular cross section are shown in Figs. 5 and 6 respectively.

Where :

u = displacement in x-axis.

v = displacement in y-axis.

Tapered ratio=a/b

Fig ure 4 Meshing and boundary conditions of columns

a) Square cross section b) Rounded cross section

a b

L.

L.

Dimension for top= a*a

Dimension for bottom= b*b

Diameter for top= a

Diameter for bottom= b

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

59

0.00 10.00 20.00 30.00

Axal Deformatiom(mm)

0.00

5000.00

10000.00

15000.00

20000.00

25000.00

A

x

a

i

l

L

o

a

d

(

N

)

a/b=1

a/b=0.9

a/b=0.8

a/b=0.7

a/b=0.6

a/b=0.5

a/b=0.4

a/b=0.3

a/b=0.2

a/b=0.1

0.00 1.00 2.00 3.00 4.00

Axail Deformation*10(mm)

0.00

5000.00

10000.00

15000.00

20000.00

A

x

a

i

l

L

o

a

d

(

N

)

a/b=0.8

a/b=0.7

a/b=0.6

a/b=0.5

a/b=1

a/b=0.9

a/b=0.4

a/b=0.3

a/b=0.2

a/b=0.1

In Fig. 7 show the comparing between two columns for the same conditions.

Figure 5 Axial load vs. axial displacement curve of square column

Figure 6 Axial load vs. axial displacement curve of circular column

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

60

0.00 0.20 0.40 0.60 0.80 1.00

a/b

0.00

10000.00

20000.00

30000.00

P

c

r

(

N

)

Square Col.

Circle Col.

In Fig. 7, one can see the critical load ratio P

cr

/P

cr0

versus the taper ratio a/b for various lengths of a tapered

column. The loading consists from a concentrated load P applied axially on the smaller end of column. It must be

noted at this point that although the differences in the critical loads seem to be small, the corresponding

differences in the critical load values may be significant depending on the both the taper ratio a/b. For example,

the load P

cr0

which used as a reference load in Table (1), corresponds to a uniform column with dimension for

square cross section (20*20mm) and 22.567mm diameter for rounded cross section, for two columns have the

same volume, the results presented (86.023%) convergence between the columns.

0.00 0.20 0.40 0.60 0.80 1.00

a/b

0.00

0.20

0.40

0.60

0.80

1.00

P

c

r

/

P

c

r

o

Square Col.

Circle Col.

The deformation shape, the values of displacement in x-direction, the values of axial displacement and the load-

axial displacement deformed shape for columns square with different cross section for columns are shown in

Figs.8-17 respectively. Form the results, the modes shape of column were changed due to varying of tapering

ratio.

Figure 6 Critical load vs. tapered ratio (a/b) curve of two types of columns.

Figure 7 Critical load ratio P

cr

/P

cr0

versus taper ratio a/b for the columns

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

61

Figure 8 Deformation shape, axial and lateral deformation for tapered ratio a/b=1

Figure 9 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.9

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

62

Figure 10 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.8

Figure11 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.7

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

63

Figure 12 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.6

Figure 13 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.5

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

64

Figure 14 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.4

Figure 15 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.3

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

65

2.1 Establishment of HMS

The deformation shape, the values of displacement in x-direction, the values of axial displacement and the load-

axial displacement deformed shape for columns circular with different cross section for columns are shown in

Figs.18-27 respectively. Form the results, the modes shape of column were changed due to varying of tapering

Figure 16 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.2

Figure17 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.1

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

66

ratio.

Figure 18 Deformation shape, axial and lateral deformation for tapered ratio a/b=1

Figure 19 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.9

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

67

Figure. 20 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.8

Figure 21 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.7

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

68

Figure 22 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.6

Figure 23 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.5

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

69

Figure24 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.4

Figure 25 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.3

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

70

3.2.2 Mode Shape

In both cases of columns with tapering ratio causes varying of mode shape in the same conditions. In Figs. (28

and 29) show the behaviour of non-prismatic column due to non-uniform cross section a long length of column.

Figure 26 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.2

Figure 27 Deformation shape, axial and lateral deformation for tapered ratio a/b=0.1

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

71

-1.00 0.00 1.00 2.00

Lateral Displacement(mm)

0.00

0.40

0.80

L

e

n

g

t

h

o

f

C

o

l

.

(

*

L

)

m

m

Square Col.

a/b=1

a/b=0.9

a/b=0.8

a/b=0.7

a/b=0.6

a/b=0.5

a/b=0.4

a/b=0.3

a/b=0.2

a/b=0.1

Undeformed Col.

-1.00 0.00 1.00 2.00

Lateral Displacement(mm)

0.00

0.40

0.80

L

e

n

g

t

h

o

f

C

o

l

.

(

*

L

)

m

m

Circle Column

a/b=1

a/b=0.9

a/b=0.8

a/b=0.7

a/b=0.6

a/b=0.5

a/b=0.4

a/b=0.3

a/b=0.2

a/b=0.1

Undeformed Col.

3.2.3 Stresses

The different failure modes are resulted from the difference stress-slenderness characteristice of steel

columns.Figs.(30 and 31) shows the results of failure for taperedd ratio. For square column with a/b=(0.1 to 0.4)

failed by buckling for arange of slendereness ratios. At a/b=(0.5 to 1), the square column failed by yielding but

the buckling failure occure in the circle column at tapered ratio, a/b=(0.7 to 1) in the same arange of slendereness

Figure 28 Mode shape for Square Column

Figure 29 Mode shape for Circle Column

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

72

ratios and yielding stresses (Fy=414 MPa.).

20.00 40.00 60.00 80.00 100.00 120.00

Slendreness Ratio(KL/r)

0.00

200.00

400.00

600.00

800.00

1000.00

S

t

r

e

s

s

e

s

(

N

/

m

m

^

2

)

Square Col.

a/b=0.1

a/b=0.2

a/b=0.3

a/b=0.4

a/b=0.5

a/b=0.6

a/b=0.7

a/b=0.8

a/b=0.9

a/b=1

Fy=414MPa

20.00 40.00 60.00 80.00 100.00

Slenderness Ratio(KL/r)

0.00

400.00

800.00

S

t

r

e

s

s

e

s

F

c

r

(

N

/

m

m

^

2

)

Circle Col.

Fy=414MPa

a/b=0.1

a/b=0.2

a/b=0.3

a/b=0.4

a/b=0.5

a/b=0.6

a/b=0.7

a/b=0.8

a/b=0.9

a/b=1

3.2.3 Comparison of results

In order to demonstrate accuracy, convergency and applicability of the finite element software ANSYS 12.0, the

buckling problem of columns with non-uniform cross section are analyzed and numerical result [Gere and

Carter, 1962] are plotted in Fig. 32, shows about 20% convergences.

Figure 30 Stresses for varying slenderness ratio and tapered ratio for Square Column

Figure 31 Stresses for varying slenderness ratio and tapered ratio for Circle Column

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

73

0.00 0.20 0.40 0.60 0.80 1.00

a/b

0.00

200.00

400.00

600.00

800.00

1000.00

P

c

r

(

N

)

Ansys Result for Square Col.

[Gere and Carter, 1962] for Square Col.

Ansys Result for Circle Col.

[Gere and Carter, 1962] for Circle Col.

3.2.4 Support Conditions

In Figs. 33 and 34, one can see the corrosponding diagram for the same colum , with different cases of

supporting condition.

0.00 0.20 0.40 0.60 0.80 1.00

a/b

0.00

400.00

800.00

1200.00

1600.00

2000.00

P

c

r

(

N

)

Support Condition For Square Col.

Fixed-Fixed[Gere and Carter, 1962]

Fixed-Pin[Gere and Carter, 1962]

Pin-Pin[Gere and Carter, 1962]

Fixed-Fixed(ANSYS Result )

Fixed-Pin(ANSYS Result )

Pin-Pin(ANSYS Result )

Figure32 Critical load vs. tapered ratio for non-prismatic

column

Figure33 Critical load vs. tapered ratio for non-prismatic square column under different cases of

support

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

74

0.00 0.20 0.40 0.60 0.80 1.00

a/b

0.00

400.00

800.00

1200.00

1600.00

2000.00

P

c

r

(

N

)

Support Condition For Circle Col.

Fixed-Fixed[Gere and Carter, 1962]

Fixed-Pin[Gere and Carter, 1962]

Pin-Pin[Gere and Carter, 1962]

Fixed-Fixed(ANSYS Result )

Fixed-Pin(ANSYS Result)

Pin-Pin(ANSYS Result)

3.2.5 Number of Element

Finally, the effect of taper ratio on number of element through meshing in the finite element software ANSYS

12.0 was plotted in Fig. 35. At the same time the shape of cross section for steel column was affected on the

number of element.

0.00 0.20 0.40 0.60 0.80 1.00

a/b

0.00

2000.00

4000.00

6000.00

8000.00

N

o

.

O

f

E

l

e

m

e

n

t

s

Square Col.

Circal Col.

5. Conclusion

In this study, the elastic buckling behavior of steel tapered column by means of determining the corresponding

elastic critical load for elastic buckling. This critical load can be used for the determination of the corresponding

member strength. More specifically, the influence of the taper ratio and cross-sectional geometry, the different

cross section and the different slenderness ratio of non-uniform steel members that are subjected to axial loads is

thoroughly investigated. The most conclusions that can be drawn from this study are:

1. The effect of tapering ratio decreases the critical load.

2. The tapering ratio affected on the location of buckling and mode shape of failure.

3. More different types of failure occure due to increasing of tapering ratio.

4. The tapering ratio affected on the number of element through meshing.

5. The influence of taper ratio is greater for critical load due to different conditions of support.

Figure 34 Critical load vs. tapered ratio for non-prismatic circle column under different cases of support

Figure 35 Number of Element vs. Tapered ratio

Civil and Environmental Research www.iiste.org

ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online)

Vol.6, No.2, 2014

75

References

ANSYS, 2006, ANSYS Structural Analysis Guide, ANSYS Release 12.0.

Dinnik, A.N. 1929 "Design of Columns of Varying Cross-Sections". Transactions, ASME, Vol. 51, p.105.

Dinnik, A.N. 1932., " Design of Columns of Varying Cross-Section"., Transactions, ASME, Vol. 54, p.165.

E.H. Salmon, "Columns", London, 1925.

Ellobody E., 2006, Buckling Analysis of High Strength Stainless Steel Stiffened and Unstiffened Slender

Hollow Section Columns, Journal of Constructional Steel Research 63, pp. 145-155.

F. Bleich, Theory and Berechnung der eisernen Brcken, Berlin,1924.

F. Lilly, "Engineering", vol. 92, London, 1911.

F. Morley, Engineering, vol. 104, London, 1917.

F. Morley, Engineering, vol. 97, London, 1914.

Gere, J.M. and Carter, W.O.1 962."Critical Buckling Loads for Tapered Columns". ASCE, Journal of the

Structural Division, Vol. 88, No. 1, p. 1.

Guo,.L. Zhang S., Kim W. J. and Ranzi,G., "Behaviour of Square Hollow Steel Tubes and Steel Tubes Filled

with Concrete.," Thin-walled Structures 45, 4 October 2007, pp.961-973.

J. Malets, Trans. ASME, vol. 51, 1925.

J. Malets, Trans. ASME, vol. 54, 1932.

Jensen, "Engineering:, vol. 85, London, 1908.

Kwon Y.B., Kim K. G. and Hancock G.J., "Compression Test of Welded Section Columns Undergoing Buckling

Interaction", Journal of Constructional Steel Research 63, 31, January 2007, pp.1590-1602.

Liew, J.Y.R et al. 1989. "Tapered Box Columns under Biaxial Loading". Journal of Structural Engineering, Vol.

115, No. 7, pp. 1697-1709.

Marston, Trans. ASCE, vol. 39, 1897.

Mohi-Aldeen M.M.K., 2008., . Nonlinear finite element analysis of plane frame composed of composite

members, M.Sc., Thesis, University of Babylon.

Ram, G. and G. Rao.1951,"Buckling of an N-Section Column". Journal of the Aeronautical Sciences, Vol. 19, No.

1, pp. 66-67.

S. Ostwald, Klassiker der exakten Wissenschaften, No 175, Leipzig, 1910.

S.P. Timoshenko, "History of Strength of Materials", New York: Mc-Graw Hill, 1953.

W. Ono, Mem., Coll. Eng. Kyushu Imp. Univ. Fakuoka, vol. 1, Japan, 1919. B.E.W. Stedman, Engineering, vol.

98, London, 1914.

Xiong D.X. and Zha X.X., 2006, A Numerical Investigation on the Behavior of Concrete-Filled Steel Tubular

Columns Under Initial Stresses, Journal of Constructional Steel Research 63, pp. 599-611

Zinkaah O.H., 2010, The Ultimate Strength and Nonlinear Behavior of Thin-Walled Steel Box Columns

Filled with Concrete, M.Sc., Thesis, University of Babylon.

Anda mungkin juga menyukai

- Seismic Response Control Using Base Isolation Strategy, PDFDokumen5 halamanSeismic Response Control Using Base Isolation Strategy, PDFAashiq MohammedBelum ada peringkat

- What Is Meant by Striking Formwork - Removal of Formwork - Minimum Period - CivilDigitalDokumen7 halamanWhat Is Meant by Striking Formwork - Removal of Formwork - Minimum Period - CivilDigitalAnonymous DlVrxSbVk9Belum ada peringkat

- Sharma Et Al-2017-Structural Concrete As PublishedDokumen9 halamanSharma Et Al-2017-Structural Concrete As PublisheddebiBelum ada peringkat

- Lecture in FortranDokumen5 halamanLecture in FortranMuhammad Al-BaghdadyBelum ada peringkat

- Dokumen - Tips Effective Length Factor For The Design of X Bracing SystemspdfDokumen5 halamanDokumen - Tips Effective Length Factor For The Design of X Bracing Systemspdfkokab22Belum ada peringkat

- 5491R 93Dokumen30 halaman5491R 93Rene Coronado VacaflorBelum ada peringkat

- AISI S912-13 - SDokumen11 halamanAISI S912-13 - SEdison BecerraBelum ada peringkat

- Flooring Design GuideDokumen81 halamanFlooring Design GuideArmin KovacevicBelum ada peringkat

- Fluid Loss of Clay Component of Geosynthetic Clay Liners: Standard Test Method ForDokumen3 halamanFluid Loss of Clay Component of Geosynthetic Clay Liners: Standard Test Method ForDanZel DanBelum ada peringkat

- Booth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)Dokumen219 halamanBooth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)CRISTIAN OMAR TUCTO ARANDABelum ada peringkat

- 179-196 Ahmad Hamid - 18 P - PDFDokumen18 halaman179-196 Ahmad Hamid - 18 P - PDFeli700Belum ada peringkat

- Study of Shear Wall With Circular Core Compared To Conventional Shear WallDokumen8 halamanStudy of Shear Wall With Circular Core Compared To Conventional Shear WallTI Journals PublishingBelum ada peringkat

- Behavior and Capacity of Headed ReinforcementDokumen9 halamanBehavior and Capacity of Headed ReinforcementjeffBelum ada peringkat

- 0302 Wind Loads On The Building With Flat RoofDokumen2 halaman0302 Wind Loads On The Building With Flat RoofFrank George Crema CremaBelum ada peringkat

- ETCulvert V2 Brochure Web PDFDokumen2 halamanETCulvert V2 Brochure Web PDFjorgesalinasengBelum ada peringkat

- The Application of Flexural Methods To Torsional Analysis of Thin-Walled Open SectionsDokumen10 halamanThe Application of Flexural Methods To Torsional Analysis of Thin-Walled Open SectionsRm1262100% (1)

- Behaviour of Axially Loaded Columns Strengthened With Carbon Fiber Reinforced PolymersDokumen22 halamanBehaviour of Axially Loaded Columns Strengthened With Carbon Fiber Reinforced Polymersbariq89100% (1)

- Ltbeamn V1.0.0 Report On Validation Tests: Référence Du Document: Drv/08-R-107/1.0.0Dokumen28 halamanLtbeamn V1.0.0 Report On Validation Tests: Référence Du Document: Drv/08-R-107/1.0.0Ionescu PaulBelum ada peringkat

- Comparative Study On Concentric Steel Braced Frame Structure Due To Effect of Aspect Ratio Using Pushover AnalysisDokumen6 halamanComparative Study On Concentric Steel Braced Frame Structure Due To Effect of Aspect Ratio Using Pushover AnalysisijsretBelum ada peringkat

- C1581 Standard Test Method For Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete Under Restrained ShrinkaDokumen7 halamanC1581 Standard Test Method For Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete Under Restrained ShrinkaRabee ShammasBelum ada peringkat

- Effective Thickness of Laminated Glass BeamsDokumen32 halamanEffective Thickness of Laminated Glass BeamsJake YalongBelum ada peringkat

- Non-Shrink GroutDokumen7 halamanNon-Shrink GroutIm ChinithBelum ada peringkat

- Bolt and Weld Capacity - Red Book 1999 PDFDokumen2 halamanBolt and Weld Capacity - Red Book 1999 PDFWhite_rabbit2885764Belum ada peringkat

- Hinge PropertiesDokumen2 halamanHinge PropertiesSantiago Felix Mota Paez100% (1)

- Wind Loads SBC Pt1Dokumen29 halamanWind Loads SBC Pt1insane88Belum ada peringkat

- Neoprene-Concrete Friction Relationships For Seismic Assessment of Existing PDFDokumen7 halamanNeoprene-Concrete Friction Relationships For Seismic Assessment of Existing PDFrasika nBelum ada peringkat

- Design For DCM ColumnsDokumen2 halamanDesign For DCM ColumnsTruong Phuoc TriBelum ada peringkat

- Stability of SpeedCore Walls Under Fire Loading Summary of Numerical AnalysesDokumen13 halamanStability of SpeedCore Walls Under Fire Loading Summary of Numerical Analysesjackcan501Belum ada peringkat

- Astm A 185-97Dokumen5 halamanAstm A 185-97MiguelitovskyBelum ada peringkat

- Shear Behavior of Headed Anchors With Large Diameters and Deep Embedments - Discussion Title 107-S14 - Mar-Apr 2010Dokumen6 halamanShear Behavior of Headed Anchors With Large Diameters and Deep Embedments - Discussion Title 107-S14 - Mar-Apr 2010ehab.attalaBelum ada peringkat

- Problem 1 025Dokumen6 halamanProblem 1 025Oscar SanchezBelum ada peringkat

- Engineering Structures: SciencedirectDokumen8 halamanEngineering Structures: SciencedirectFeleki AttilaBelum ada peringkat

- Chapter 8 - Building Types S1/S1A: Steel Moment Frames: 8.1 Description of The Model Building TypeDokumen295 halamanChapter 8 - Building Types S1/S1A: Steel Moment Frames: 8.1 Description of The Model Building Typefasih_baqai4252Belum ada peringkat

- Composite Beam ChartsDokumen8 halamanComposite Beam ChartsAnonymous 1sJXK1DKZBelum ada peringkat

- PDFDokumen3 halamanPDF6BisnagaBelum ada peringkat

- (2005) Flexural Behavior of Confined High-Strength Concrete ColumnsDokumen8 halaman(2005) Flexural Behavior of Confined High-Strength Concrete ColumnsMohammad AshrafyBelum ada peringkat

- Design Concepts For AnchorageDokumen6 halamanDesign Concepts For AnchorageChristopher Aaron SiregarBelum ada peringkat

- Structural Analysis and Design of Castellated Beam in Fixed Action PDFDokumen6 halamanStructural Analysis and Design of Castellated Beam in Fixed Action PDFjoryBelum ada peringkat

- Kang 2018Dokumen11 halamanKang 2018joeBelum ada peringkat

- CompositeMegaColumns Full ReportDokumen275 halamanCompositeMegaColumns Full ReportRonakShah100% (1)

- 8 Braces and Ties (Compatibility Mode)Dokumen16 halaman8 Braces and Ties (Compatibility Mode)susan870% (1)

- Development of A Wood-Frame Shear Wall Model in AbaqusDokumen8 halamanDevelopment of A Wood-Frame Shear Wall Model in AbaqusMaldi KokalariBelum ada peringkat

- 1542168570tieu Ban Ket Cau Cong Nghe Xay Dung 3 PDFDokumen62 halaman1542168570tieu Ban Ket Cau Cong Nghe Xay Dung 3 PDFI'm LuongBelum ada peringkat

- Astm A325m PDFDokumen8 halamanAstm A325m PDFDastaggir KarimiBelum ada peringkat

- Relating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaDokumen13 halamanRelating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaAniket DubeBelum ada peringkat

- ASC Floordeck CatalogDokumen184 halamanASC Floordeck CatalogwaynectwBelum ada peringkat

- Analysis of Large Bracing Connections Designs For Heavy ConstructionDokumen25 halamanAnalysis of Large Bracing Connections Designs For Heavy Constructiondaniel.j.mccarthyBelum ada peringkat

- Modification of The ACI Rectangular Stress Block For High-Strength ConcreteDokumen9 halamanModification of The ACI Rectangular Stress Block For High-Strength ConcretepicottBelum ada peringkat

- Serviceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapsDokumen11 halamanServiceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapspicottBelum ada peringkat

- Effect of Size ConcreteDokumen8 halamanEffect of Size ConcreteekaciptaBelum ada peringkat

- Analysis Anda Design Pre Stressd SleepersDokumen25 halamanAnalysis Anda Design Pre Stressd SleeperspoezpietaBelum ada peringkat

- Design of Reinforced Concrete Floor Systems: Professional Development SeriesDokumen7 halamanDesign of Reinforced Concrete Floor Systems: Professional Development SeriesJCS100% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDari EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionBelum ada peringkat

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDari EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionBelum ada peringkat

- Belzona Index FolderDokumen3 halamanBelzona Index Foldersrikrish24Belum ada peringkat

- Behaviour of A Sustainable Concrete in Acidic Environment: SustainabilityDokumen13 halamanBehaviour of A Sustainable Concrete in Acidic Environment: Sustainabilitym_shahbaghiBelum ada peringkat

- Commercial - Building - Electrical - Design (Inc)Dokumen17 halamanCommercial - Building - Electrical - Design (Inc)Stephany PolinarBelum ada peringkat

- 32AC219ENDokumen207 halaman32AC219ENArno RaspoetBelum ada peringkat

- Channels Steel, Ms Channels, Steel Angles - Mehta SteelsDokumen2 halamanChannels Steel, Ms Channels, Steel Angles - Mehta SteelsSebastião Barbosa da SilvaBelum ada peringkat

- Environment Degradation of Materials - 1Dokumen27 halamanEnvironment Degradation of Materials - 1NSHIMIYIMANA Jean d'AmourBelum ada peringkat

- Analysis of Performance of Pile GroupsDokumen22 halamanAnalysis of Performance of Pile GroupsGeorge TharakanBelum ada peringkat

- Introduction To ASME Section III Div1Dokumen97 halamanIntroduction To ASME Section III Div1Siampol Feepakphor83% (6)

- Surv Ivalring Civil Defense Now!: - Richard Fleetwood - January 2002 - All Rights ReservedDokumen9 halamanSurv Ivalring Civil Defense Now!: - Richard Fleetwood - January 2002 - All Rights ReservedkookaboyBelum ada peringkat

- Tremix Flooring PDFDokumen4 halamanTremix Flooring PDFdinkad29Belum ada peringkat

- JKR Flexible PavementDokumen47 halamanJKR Flexible Pavementazu100% (2)

- MuellerDokumen24 halamanMuellerAhmad NasserBelum ada peringkat

- Design GuideDokumen3 halamanDesign GuidegvmindiaBelum ada peringkat

- AIMTDR - 117 - Camera Ready PaperDokumen8 halamanAIMTDR - 117 - Camera Ready PaperKirubasankarBelum ada peringkat

- Seismic Design of RC Structures - SaatciogluDokumen146 halamanSeismic Design of RC Structures - SaatciogluAl MamunBelum ada peringkat

- Iso 20558 2 2018 PDFDokumen9 halamanIso 20558 2 2018 PDFlartaBelum ada peringkat

- Roquette Industry Paper Board Brochure Corrugating PDFDokumen36 halamanRoquette Industry Paper Board Brochure Corrugating PDFsyifa latifa zahidaBelum ada peringkat

- Compressible Flow TablesDokumen14 halamanCompressible Flow TablesDankus MemeusBelum ada peringkat

- Heizkabel 30W 400volt GBDokumen1 halamanHeizkabel 30W 400volt GBAndrei DiaconuBelum ada peringkat

- Pre Engineered BuildingDokumen10 halamanPre Engineered Buildingmonica ratertaBelum ada peringkat

- Quiz 3 SolutionsDokumen4 halamanQuiz 3 SolutionsM.USMAN BIN AHMED0% (1)

- Washer PlateDokumen2 halamanWasher PlateНемања Караклајић100% (2)

- My NoteDokumen186 halamanMy NotedianBelum ada peringkat

- As 1684.3-2010 Residential Timber-Framed Construction Cyclonic AreasDokumen10 halamanAs 1684.3-2010 Residential Timber-Framed Construction Cyclonic AreasSAI Global - APACBelum ada peringkat

- Danley Insert Plate ArmourMate BrochureDokumen12 halamanDanley Insert Plate ArmourMate BrochuresuvraBelum ada peringkat

- Es 1S71 1K251 Ac+2002 12Dokumen12 halamanEs 1S71 1K251 Ac+2002 12Popescu AlinBelum ada peringkat

- Study of Natural Fibers As An Admixture For Concrete Mix DesignDokumen9 halamanStudy of Natural Fibers As An Admixture For Concrete Mix DesignJOHN FHILIP ORIT67% (3)

- HousekeepingDokumen45 halamanHousekeepingSoriano D'cruz Rosanne100% (3)

- RH Tankless Productbrochure 101-66-10 Rev7Dokumen6 halamanRH Tankless Productbrochure 101-66-10 Rev7api-221502147Belum ada peringkat

- CASTEL Selection Criteria For Safety ValveDokumen9 halamanCASTEL Selection Criteria For Safety ValvelorenzoBelum ada peringkat