Automotive Engineering

Diunggah oleh

Irina0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

131 tayangan4 halamanAutomotive Engineering

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAutomotive Engineering

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

131 tayangan4 halamanAutomotive Engineering

Diunggah oleh

IrinaAutomotive Engineering

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

Automotive Engineering

Automotive engineering is a combination of mechanical, electrical and materials science.

Engineers in this field can design new vehicles or look for ways to improve existing

automotive engineering technology.

Inside Automotive Engineering

Automotive engineers can design and test brake systems, engines, safety mechanisms, fuel

technologies and transmissions. In the field, engineers use design software to devise new

vehicle designs or systems, including ThinkDesign Engineering, Gamma Technologies GT-

SUITE or Corel Painter Sketch Pad. Some engineers also use grinders, machine tools and

workshop presses to fabricate prototype parts for testing. Individuals interested in designing,

testing and creating automotive systems may be drawn to this line of work.

What does an automotive engineer really do?

Do you like the idea of creating and shaping new technologies in transport and mobility,

making things better, cleaner, more efficient and maybe even faster too? Then this is the

career for you! Automotive engineers work closely with:

design: either designing new products or improving existing ones

research and development: finding solutions to engineering problems

production: planning and designing new production processes

The variety of skills and tasks automotive engineers get involved are almost endless! Here are

some examples to get you started:

developing new test procedures, using both conventional and innovative methods

bringing new products to market and being involved in problem-solving and project

management

devising and organising tests, to answer questions from clients, consumers and other

engineers involved in vehicle development

anticipating vehicle or component behaviour in different conditions with computer

modelling software

analysing and interpreting technical data into reports or presentations and answering

any queries about the results

building an individual specialism within a larger team and working independently

contributing to regular team meetings to update colleagues on progress, problems and

new developments

managing all details of projects, including projected costs

recognising the benefits of engineering developments to related departments in order

to market projects and secure internal funding

negotiating costs of development and engineering work with commercial departments

monitoring any related systems or engineering issues associated with the component

and final product

supervising technical staff, engineers or designers (dependent upon specific role)

operating in cross-functional or internationally-based teams to design experiments in

order to test the validity and competence of new technology.

Automobile engineering

Some of the engineering attributes and disciplines that are of importance to the automotive

engineer and many of the other aspects are included in it:

Safety engineering: Safety engineering is the assessment of various crash scenarios and their

impact on the vehicle occupants. These are tested against very stringent governmental

regulations. Some of these requirements include: seat belt and air bag functionality testing,

front and side impact testing, and tests of rollover resistance. Assessments are done with

various methods and tools, including Computer crash simulation (typically finite element

analysis), crash test dummies, and partial system sled and full vehicle crashes.

Fuel economy/emissions: Fuel economy is the measured fuel efficiency of the vehicle in

miles per gallon or kilometers per litre. Emissions testing includes the measurement of vehicle

emissions, including hydrocarbons, nitrogen oxides (NOx), carbon monoxide (CO), carbon

dioxide (CO2), and evaporative emissions.

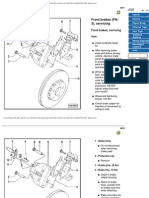

Vehicle dynamics: Vehicle dynamics is the vehicle's response of the following attributes:

ride, handling, steering, braking, comfort and traction. Design of the chassis systems of

suspension, steering, braking, structure (frame), wheels and tires, and traction control are

highly leveraged by the vehicle dynamics engineer to deliver the vehicle dynamics qualities

desired.

NVH engineering (noise, vibration, and harshness): NVH is the customer's feedback (both

tactile [felt] and audible [heard]) from the vehicle. While sound can be interpreted as a rattle,

squeal, or hoot; a tactile response can be seat vibration, or a buzz in the steering wheel. This

feedback is generated by components either rubbing, vibrating, or rotating. NVH response can

be classified in various ways: powertrain NVH, road noise, wind noise, component noise, and

squeak and rattle. Note, there are both good and bad NVH qualities. The NVH engineer works

to either eliminate bad NVH, or change the bad NVH to good (i.e., exhaust tones).

Vehicle Electronics: Automotive electronics is an increasingly important aspect of

automotive engineering. Modern vehicles employ dozens of electronic systems. These

systems are responsible for operational controls such as the throttle, brake and steering

controls; as well as many comfort and convenience systems such as the HVAC, infotainment,

and lighting systems. It would not be possible for automobiles to meet modern safety and fuel

economy requirements without electronic controls.

Performance: Performance is a measurable and testable value of a vehicles ability to perform

in various conditions. Performance can be considered in a wide variety of tasks, but it's

generally associated with how quickly a car can accelerate (e.g. standing start 1/4 mile

elapsed time, 060 mph, etc.), its top speed, how short and quickly a car can come to a

complete stop from a set speed (e.g. 70-0 mph), how much G-force a car can generate without

losing grip, recorded lap times, cornering speed, brake fade, etc. Performance can also reflect

the amount of control in inclement weather (snow, ice, rain).

Shift quality: Shift quality is the drivers perception of the vehicle to an automatic

transmission shift event. This is influenced by the powertrain (engine, transmission), and the

vehicle (driveline, suspension, engine and powertrain mounts, etc.) Shift feel is both a tactile

(felt) and audible (heard) response of the vehicle. Shift quality is experienced as various

events: Transmission shifts are felt as an upshift at acceleration (12), or a downshift

maneuver in passing (42). Shift engagements of the vehicle are also evaluated, as in Park to

Reverse, etc. SEAN

Durability / corrosion engineering: Durability and corrosion engineering is the evaluation

testing of a vehicle for its useful life. Tests include mileage accumulation, severe driving

conditions, and corrosive salt baths.

Package / ergonomics engineering: Package engineering is a discipline that designs/analyzes

the occupant accommodations (seat roominess), ingress/egress to the vehicle, and the drivers

field of vision (gauges and windows). The package engineer is also responsible for other areas

of the vehicle like the engine compartment, and the component to component placement.

Ergonomics is the discipline that assesses the occupant's access to the steering wheel, pedals,

and other driver/passenger controls.

Climate control: Climate control is the customers impression of the cabin environment and

level of comfort related to the temperature and humidity. From the windshield defrosting, to

the heating and cooling capacity, all vehicle seating positions are evaluated to a certain level

of comfort.

Drivability: Drivability is the vehicles response to general driving conditions. Cold starts

and stalls, RPM dips, idle response, launch hesitations and stumbles, and performance levels.

Cost: The cost of a vehicle program is typically split into the effect on the variable cost of the

vehicle, and the up-front tooling and fixed costs associated with developing the vehicle. There

are also costs associated with warranty reductions, and marketing.

Program timing: To some extent programs are timed with respect to the market, and also to

the production schedules of the assembly plants. Any new part in the design must support the

development and manufacturing schedule of the model.

Assembly feasibility: It is easy to design a module that is hard to assemble, either resulting in

damaged units, or poor tolerances. The skilled product development engineer works with the

assembly/manufacturing engineers so that the resulting design is easy and cheap to make and

assemble, as well as delivering appropriate functionality and appearance.

Quality management: Quality control is an important factor within the production process,

as high quality is needed to meet customer requirements and to avoid expensive recall

campaigns. The complexity of components involved in the production process requires a

combination of different tools and techniques for quality control.

Development Engineer

A development engineer has the responsibility for coordinating delivery of the engineering

attributes of a complete automobile (bus, car, truck, van, SUV, motorcycle etc.) as dictated by

the automobile manufacturer, governmental regulations, and the customer who buys the

product.

Much like the Systems Engineer, the development engineer is concerned with the interactions

of all systems in the complete automobile. While there are multiple components and systems

in an automobile that have to function as designed, they must also work in harmony with the

complete automobile. As an example, the brake system's main function is to provide braking

functionality to the automobile. Along with this, it must also provide an acceptable level of:

pedal feel (spongy, stiff), brake system noise (squeal, shudder, etc.), and interaction with

the ABS (anti-lock braking system)

Another aspect of the development engineer's job is a trade-off process required to deliver all

the automobile attributes at a certain acceptable level. An example of this is the trade-off

between engine performance and fuel economy. While some customers are looking for

maximum power from their engine, the automobile is still required to deliver an acceptable

level of fuel economy. From the engine's perspective, these are opposing requirements.

Engine performance is looking for maximum displacement (bigger, more power), while fuel

economy is looking for a smaller displacement engine (ex: 1.4 L vs. 5.4 L). The engine size,

though is not the only contributing factor to fuel economy and automobile performance. Other

attributes include: automobile weight, aerodynamic drag, transmission gearing, emission

control devices, and tires.

The development engineer is also responsible for organizing automobile level testing,

validation, and certification. Components and systems are designed and tested individually by

the Product Engineer. The final evaluation though, has to be conducted at the automobile

level to evaluate system to system interactions. As an example, the audio system (radio) needs

to be evaluated at the automobile level. Interaction with other electronic components can

cause interference. Heat dissipation of the system and ergonomic placement of the controls

need to be evaluated. Sound quality in all seating positions needs to be provided at acceptable

levels.

Other automotive engineering roles

Other automotive engineers include those listed below:

Aerodynamics engineers will often give guidance to the styling studio so that the

shapes they design are aerodynamic, as well as attractive.

Body engineers will also let the studio know if it is feasible to make the panels for

their designs.

Anda mungkin juga menyukai

- Automotive EngineeringDokumen6 halamanAutomotive EngineeringЛукаФилиповићBelum ada peringkat

- Automotive ProblemsDokumen9 halamanAutomotive ProblemsRonel FillomenaBelum ada peringkat

- Automotive EngineeringDokumen5 halamanAutomotive EngineeringJANBelum ada peringkat

- Automotive EngineeringDokumen31 halamanAutomotive EngineeringTboiBelum ada peringkat

- Automotive EngieneeringDokumen7 halamanAutomotive Engieneeringvlastimir cernosBelum ada peringkat

- Advanced Business ProcessDokumen10 halamanAdvanced Business ProcessHarry DhaliwalBelum ada peringkat

- What Is Automotive EngineeringDokumen3 halamanWhat Is Automotive EngineeringdutchrvlogsBelum ada peringkat

- Co1 (Dac)Dokumen17 halamanCo1 (Dac)ashifsha930Belum ada peringkat

- Hazare Et Al-2015-Systems EngineeringDokumen17 halamanHazare Et Al-2015-Systems EngineeringJúlio CortêsBelum ada peringkat

- AdamsCar DSDokumen0 halamanAdamsCar DSOvidiu DanielBelum ada peringkat

- Minor Project (Research Report)Dokumen50 halamanMinor Project (Research Report)Atul DahiyaBelum ada peringkat

- AIAG Cqi 14 Warranty Key TermsDokumen13 halamanAIAG Cqi 14 Warranty Key TermsLipeca75% (8)

- ToolsDokumen2 halamanToolssuhail356Belum ada peringkat

- Nouveau Document Microsoft WordDokumen11 halamanNouveau Document Microsoft Wordsoukehal wail mohamed redhaBelum ada peringkat

- CompappppDokumen2 halamanCompapppppatricknotrickstarBelum ada peringkat

- Lecture 1Dokumen9 halamanLecture 1Rohit SharmaBelum ada peringkat

- Sem1 Pnumatic Bumper ReportDokumen33 halamanSem1 Pnumatic Bumper Reportdhanshri kolekarBelum ada peringkat

- AutomobileDokumen1 halamanAutomobileSaumyaBelum ada peringkat

- Engineering Economics: Modern Design ProcessDokumen10 halamanEngineering Economics: Modern Design ProcessBenny BasitBelum ada peringkat

- CDR - Critical Design ReviewDokumen8 halamanCDR - Critical Design ReviewManny GarciaBelum ada peringkat

- Project Draft CopymainDokumen10 halamanProject Draft Copymainadas76333Belum ada peringkat

- ECU Measurement Calibration and Diagnostics BrochureDokumen44 halamanECU Measurement Calibration and Diagnostics Brochureemmaclick100% (2)

- Specification and Design of Electronic Control UnitsDokumen7 halamanSpecification and Design of Electronic Control UnitspbollaganiBelum ada peringkat

- Project Presentation - Energy Efficient Car DesignDokumen26 halamanProject Presentation - Energy Efficient Car DesignSalar SalahiBelum ada peringkat

- Automotive Wheel Alignment System: by Michael Danek Isaac KousariDokumen26 halamanAutomotive Wheel Alignment System: by Michael Danek Isaac KousariSandra MarkivBelum ada peringkat

- Aircraft Landing Gear Design ProjectDokumen20 halamanAircraft Landing Gear Design Projectchristo.t.josephBelum ada peringkat

- Siemens SW Developing Advanced Driver Assistant Systems WP - tcm53-81245Dokumen14 halamanSiemens SW Developing Advanced Driver Assistant Systems WP - tcm53-81245Cupareanu FlorinBelum ada peringkat

- Process Point AnalysisDokumen8 halamanProcess Point Analysiskitisakp990% (1)

- Exploring Automotive Embedded Systems and Their Applications - Skill-Lync BlogsDokumen10 halamanExploring Automotive Embedded Systems and Their Applications - Skill-Lync Blogslakshmivs23Belum ada peringkat

- Design and Development of A Steering Wheel For AnDokumen10 halamanDesign and Development of A Steering Wheel For AnArema JrBelum ada peringkat

- 机械设计英文版 PDFDokumen390 halaman机械设计英文版 PDFArifa Jamal100% (1)

- Honda Motor Company LimitedDokumen5 halamanHonda Motor Company LimitedAntariksh BhandariBelum ada peringkat

- Research Challenges For Code Complex BeginnersDokumen45 halamanResearch Challenges For Code Complex BeginnersASWIN.M.MBelum ada peringkat

- Idiada Sim4u Workshop Motorsport 2010Dokumen108 halamanIdiada Sim4u Workshop Motorsport 2010Cristi AntonBelum ada peringkat

- Mechanical Engineering 1Dokumen5 halamanMechanical Engineering 1Pranav WaghBelum ada peringkat

- Solidworks WhitePaper Industry Sim Analysis Machines PDFDokumen9 halamanSolidworks WhitePaper Industry Sim Analysis Machines PDFMuhammad Salim Abdul AzisBelum ada peringkat

- Raith Andreas Wises 2011Dokumen6 halamanRaith Andreas Wises 2011Mihai IovaBelum ada peringkat

- Shivaramu H T Numaan Naveed Ahmed Devdarsh C Ajay and Santhosh Kumar T CDokumen8 halamanShivaramu H T Numaan Naveed Ahmed Devdarsh C Ajay and Santhosh Kumar T CHemanth C KBelum ada peringkat

- MMW Automotive EngineeringDokumen7 halamanMMW Automotive EngineeringNiño Jay BadangBelum ada peringkat

- CarMaker WhitepaperDokumen9 halamanCarMaker WhitepapersegiropiBelum ada peringkat

- Vehicle Dynamics: Submitted By: 18AU02 Submitted To: P.Ghilman HaiderDokumen14 halamanVehicle Dynamics: Submitted By: 18AU02 Submitted To: P.Ghilman Haiderahmad razaBelum ada peringkat

- Advanced Design EngineeringDokumen22 halamanAdvanced Design EngineeringKevin OnyangoBelum ada peringkat

- Rebuttal - IMECE2017 71479 1Dokumen13 halamanRebuttal - IMECE2017 71479 1williamBelum ada peringkat

- Class Notes Car DesignDokumen2 halamanClass Notes Car DesignAndy ShawBelum ada peringkat

- Modern Techniqes of Automotive NVHDokumen7 halamanModern Techniqes of Automotive NVHatuladeupesBelum ada peringkat

- MSD Chapter 2Dokumen15 halamanMSD Chapter 2Gopi GopiBelum ada peringkat

- The Vehicle Management SystemDokumen12 halamanThe Vehicle Management Systembmatovu50% (4)

- PMP ReportDokumen17 halamanPMP ReportManny GarciaBelum ada peringkat

- 1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringDokumen37 halaman1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringMr. K.S. Raghul Asst Prof MECHBelum ada peringkat

- Chasis DinamométricoDokumen6 halamanChasis Dinamométricojose romeroBelum ada peringkat

- Dynamic Analysis of Car Suspension Using ADAMSCarDokumen10 halamanDynamic Analysis of Car Suspension Using ADAMSCarHussain TariqBelum ada peringkat

- CQI Wessex ISO-TS CORE TOOLS Presentation John Skinner 11dec12Dokumen54 halamanCQI Wessex ISO-TS CORE TOOLS Presentation John Skinner 11dec12Gabryel BogdanBelum ada peringkat

- Auto ConDokumen9 halamanAuto ConkiranhujareBelum ada peringkat

- Automotive Storage and PackagingDokumen68 halamanAutomotive Storage and PackagingViswanath AdithamBelum ada peringkat

- HEXAGON MI Flyer Energy A4 EN WebDokumen2 halamanHEXAGON MI Flyer Energy A4 EN WebSanjay ShelarBelum ada peringkat

- 1.vehicle OverviewDokumen34 halaman1.vehicle OverviewShashikumar ChanchiBelum ada peringkat

- Course Catalog - Garage One - Automobile & Engine DesignDokumen6 halamanCourse Catalog - Garage One - Automobile & Engine DesignAmit SainiBelum ada peringkat

- Ergonomics in Welding ShopDokumen6 halamanErgonomics in Welding ShopFikri RahimBelum ada peringkat

- PHD Thesis in Automobile EngineeringDokumen4 halamanPHD Thesis in Automobile Engineeringbskb598g100% (2)

- Multi Cooker Recipe BookDokumen6 halamanMulti Cooker Recipe BookIrina100% (1)

- Hugh Fearnley-Whittingstall's Asparagus: What You NeedDokumen1 halamanHugh Fearnley-Whittingstall's Asparagus: What You NeedIrinaBelum ada peringkat

- Pagini 24-25Dokumen2 halamanPagini 24-25IrinaBelum ada peringkat

- Past SimpleDokumen2 halamanPast SimpleIrinaBelum ada peringkat

- Pork Recipes by Hugh Fearnley WhittingstallDokumen8 halamanPork Recipes by Hugh Fearnley WhittingstallIrinaBelum ada peringkat

- As A ConjunctionDokumen2 halamanAs A ConjunctionIrinaBelum ada peringkat

- Multi-Cooker CompleteDokumen67 halamanMulti-Cooker CompleteIrina100% (1)

- To + Infinitive: Verbs Followed by InfinitiveDokumen4 halamanTo + Infinitive: Verbs Followed by InfinitiveIrinaBelum ada peringkat

- What Is Materials EngineeringDokumen2 halamanWhat Is Materials EngineeringIrinaBelum ada peringkat

- Complete The Following Sentences Using The Correct Degree of The Adjective Given in The BracketsDokumen1 halamanComplete The Following Sentences Using The Correct Degree of The Adjective Given in The BracketsIrinaBelum ada peringkat

- Industrial EngineeringDokumen2 halamanIndustrial EngineeringIrina0% (1)

- English Present - TestsDokumen2 halamanEnglish Present - TestsIrinaBelum ada peringkat

- Mother Goose Nursery Rhymes Ab2de6bbDokumen14 halamanMother Goose Nursery Rhymes Ab2de6bbIrina100% (1)

- A Guide To Complete The ThesisDokumen24 halamanA Guide To Complete The ThesisIrinaBelum ada peringkat

- PHD Initial Research Proposal TemplateDokumen24 halamanPHD Initial Research Proposal TemplateIrina100% (2)

- Gender Stereotype and Children's LitDokumen45 halamanGender Stereotype and Children's LitIrinaBelum ada peringkat

- Exit Children ExcerptDokumen3 halamanExit Children ExcerptIrina100% (1)

- Nodelman ArticleDokumen14 halamanNodelman ArticleIrinaBelum ada peringkat

- The Delights of ImpossibilityDokumen19 halamanThe Delights of ImpossibilityIrinaBelum ada peringkat

- Glossary of Legal Terms AM ENGDokumen38 halamanGlossary of Legal Terms AM ENGIrinaBelum ada peringkat

- Technical English Vocabulary and Grammar Alison Pohl Nick Brieger 2002Dokumen148 halamanTechnical English Vocabulary and Grammar Alison Pohl Nick Brieger 2002StellaMarisEnglish0% (1)

- STEPS Archetype DefinitionsDokumen4 halamanSTEPS Archetype DefinitionsIrinaBelum ada peringkat

- Literarywork AnalysisDokumen45 halamanLiterarywork AnalysisIrinaBelum ada peringkat

- Glossary of Financing InstrumentsDokumen8 halamanGlossary of Financing InstrumentsIrinaBelum ada peringkat

- Service Schedule FordDokumen2 halamanService Schedule FordsmokefieldBelum ada peringkat

- 2008 Nissan Rogue PDFDokumen309 halaman2008 Nissan Rogue PDFCatalin StoicescuBelum ada peringkat

- Driver EvaluationDokumen4 halamanDriver Evaluationkrunalb@inBelum ada peringkat

- Connector CatalogDokumen47 halamanConnector CatalogDonnie Grant100% (2)

- Chrysler-Fiat Strategic AllianceDokumen37 halamanChrysler-Fiat Strategic AllianceMey Sandrasigaran50% (2)

- Quick Guide Proxi enDokumen17 halamanQuick Guide Proxi enaiigee100% (1)

- Listino Prezzi Volkswagen GolfDokumen10 halamanListino Prezzi Volkswagen GolfLudigBelum ada peringkat

- LMC Ford Truck CatalogDokumen168 halamanLMC Ford Truck CatalogFelipe Stang GonzálezBelum ada peringkat

- ToyotaDokumen42 halamanToyotaZainab KachwalaBelum ada peringkat

- Mahindra XUV My Part - CHinmayDokumen16 halamanMahindra XUV My Part - CHinmayPranay NarayaniBelum ada peringkat

- Police Log September 22, 2016Dokumen12 halamanPolice Log September 22, 2016MansfieldMAPoliceBelum ada peringkat

- ThesisDokumen132 halamanThesisJony M. TemnikarBelum ada peringkat

- Founded: Company BriefDokumen2 halamanFounded: Company BriefRitesh KumarBelum ada peringkat

- Audio Visual Navegation SystemDokumen93 halamanAudio Visual Navegation SystemjuliokohutBelum ada peringkat

- Audi C5 A6 Brake SystemsDokumen98 halamanAudi C5 A6 Brake SystemsTim Eaton100% (7)

- Polo Allstar LeafletDokumen2 halamanPolo Allstar LeafletZaraki KenpachiBelum ada peringkat

- Chevrolet Camaro First GenerationDokumen5 halamanChevrolet Camaro First Generationapi-323099156Belum ada peringkat

- Dashboard Warnings On Your Peugeot 406Dokumen3 halamanDashboard Warnings On Your Peugeot 406Yusto Malik Omondi100% (1)

- HUNDAIDokumen3 halamanHUNDAIasad100% (1)

- 03 Wa HCV 1-4Dokumen4 halaman03 Wa HCV 1-4jaiganeshan89Belum ada peringkat

- History of The Camaro TimelineDokumen1 halamanHistory of The Camaro Timelinenathandmiller100% (1)

- Manual Caja 4T65EDokumen14 halamanManual Caja 4T65EJaime Espinoza G100% (1)

- Tata Indigo Diesel ManualDokumen151 halamanTata Indigo Diesel ManualErgün YiğitBelum ada peringkat

- Toyota Cost Reduction KeiretsuDokumen25 halamanToyota Cost Reduction Keiretsuaisuda100% (1)

- Ford Motor Company-BCG MATRIXDokumen8 halamanFord Motor Company-BCG MATRIXSherry Yong PkTian0% (1)

- Service Manual E352dn-4512-420-430Dokumen9 halamanService Manual E352dn-4512-420-430pcokrjBelum ada peringkat

- Electronic Stability Control Systems: Automotive Industry StandardsDokumen20 halamanElectronic Stability Control Systems: Automotive Industry StandardsZvezdan DjurdjevicBelum ada peringkat

- Handcontrol PDFDokumen241 halamanHandcontrol PDFpaoadamsBelum ada peringkat

- AutomotiveDokumen167 halamanAutomotivedongdeBelum ada peringkat

- VW VIN Shopping TipsDokumen1 halamanVW VIN Shopping TipsNenad Jovanic50% (2)