Basic Cashew Processing Steps

Diunggah oleh

AquarianTruths0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

959 tayangan3 halamanBasic Cashew Processing

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniBasic Cashew Processing

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

959 tayangan3 halamanBasic Cashew Processing Steps

Diunggah oleh

AquarianTruthsBasic Cashew Processing

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

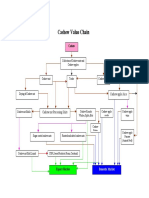

Cashew Processing

1. Processing of the Cashewnut

2. Processing at Orchard level

3. Processing of raw nuts at factories

4. Major Processors & Exporters

5. Manufacturers & Suppliers of Machinery

TOP

1. PROCESSING OF CASHEWNUT

Processing of cashewnuts refers to the conversion of raw cashewnuts in shell to its blanched graded

kernel form. The processing units are mainly concentrated in the states of Kerala, Tamil Nadu, Karnataka,

Goa, Andhra Pradesh, Maharashtra and Orissa. The process is highly labour intensive and the work force

consists mainly of women.

(a) Drum roasting: This is one of the oldest and more widely used methods. The nuts are fed into a

rotating red hot drum which will ignite the shell maintaining its temperature because of the burning of the

shell liquid. The drum is kept in rotation for 3-4 minutes and the roasted nuts are discharged from the

lower end of the drum and immediately covered by ash after sprayed with little water, so as to absorb the

oil on the surface. This facilitates the removal of the remaining oil on the shell. Due to draw backs of the

method is superseded by oil bath roasting.

(b) Oil bath roasting: In this method conditioned nuts are passed through CNSL bath heated to 170-

2000C by conveyer buckets for 1-2 minutes during which period the shell gets heated rupturing the wall

and releasing the oil into the bath. The oil is recovered by continuous over flow arrangement. The roasted

nuts are centrifuged to remove adhering oil, cooled and shelled by hand and leg operated shelling

machines. The kernel with the adhering testa is scooped out using a sharp needle.

(c) Steam roasting: The raw nuts are steam cooked at about 120-140 lbs/sq inch pressure. Shell oil can

be extracted in later stages by crushing. The nuts are shelled by hand and leg operated shelling

machines.

A general comparison of the above three methods would show that the oil bath method and steam

roasting systems require more initial investment and higher maintenance costs: the drum roasting method

being the cheapest. From the point of view of environmental pollution the safest is the steam roasting

method.

TOP

2. Processing at Orchard Level

The processing of cashew in the orchard is mainly confines to removal of raw nuts from cashew apple

and drying. Harvest only fully matured nuts. Usually, nuts are picked when they fall off from the tree. Best

quality nuts are obtained, where fresh fallen fruits are collected. The apples are removed and the nuts are

sun dried for 2 - 3 days to reduce moisture from 25 percent to below 9 percent. It is very essential to dry

the nuts after harvest to prevent spoilage during subsequent storage. This helps the kernel to retain their

quality, particular the flavour. However, if cashew apples are used for processing, it is better to harvest

them from the tree without damaging the apples. The mature nuts will sink in water while the

immature/unfilled ones will float. This test could be used to find out whether the nuts are mature or not.

TOP

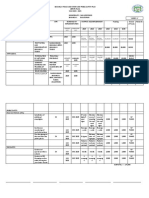

3. Processing of raw nuts at factories

The nuts which are required to be processed at factory should be dried again for 1-2 days to reduce and

maintain the moisture level of 7 - 8 percent. The processing of raw nuts involves roasting, shelling, drying,

peeling, grading and packing. The steps involved in commercial processing of cashew nuts are detailed

below :-

Roasting

Roasting of raw nuts is done to separate adhering shell from the kernel. There are three types of roasting

viz, drum roasting, oil bath roasting and steam roasting. Steam roasting is the commonly used method by

most of the processing units. In the case of steam roasting, the raw nuts are steam roasted at about 100-

lb pressure for about 25-30 minutes. Then the nuts are allowed to cool for 24 hours and taken for shelling.

Shelling

Cashew nuts after roasting and cooling are to be shelled to remove kernels. One has to be very careful

while shelling the nuts. Hands are to be protected from Cashew Nut Shell Liquid (CNSL) which is highly

corrosive. Hand gloves should be used while shelling. For the same reason, it is advisable to dust the

nuts with wood ash. Commercial processing units use foot operated shell cutters (mechanical device) for

shelling. This device consists of a pair of blade (knives) shaped in the counter of half a nut which could be

operated by foot. The blades cut through the shell all around the nut, leaving the kernel untouched. After

shelling the kernels and shell pieces are separated manually. The nuts have to be grouped into various

sizes, each size matching a pair or blades of appropriate size.

Drying

The kernels after shelling will have moisture content of more than 6 per cent. Drying of these kernels is

necessary to prevent fungus attack during subsequent storage and to facilitate peeling of testa. The

kernels are to be dried to moisture content of about 4 - 5 per cent. This is done by drying the kernels in

hot chambers at 70 - 80 C in perforated trays for about 6 - 8 hours. Uniform drying could be achieved with

a cross flow drier using forced hot air circulation through the kernel layers. In order to ensure uniform

drying, the position of the trays has to be changed frequently, as scorching may occur at hotter places.

Excess drying of kernels leads to kernels becoming very brittle resulting in higher breakage. After drying,

the kernels are kept in the moist chamber for 24 hours which facilitates easy removal of testa (peeling)

and minimizes broken kernels.

Peeling

This process involves the removal of testa (seed coat) from the kernel. Peeling is done using a sharp

knife or bamboo piece. Care has to be taken while removing the testa. If kernels are scorched more it

results in poor quality kernels.

Grading

Kernels are graded according to the size manually. In the International Market bold whole kernels fetch

premium price. The grading standards developed in India refer to white whole (undamaged) kernels and

indicate the number of kernels per lb of weight. The largest kernels come in the grade W 210 (440-

460/kg) and the smallest of the seven grades is W 500 (1000-1100/kg). Generally, Brazilian kernels have

a relatively high proportion of large wholes, with the extra attraction of the 180"s grade, known as Special

Large Wholes. The white whole kernels are priced according to size. Further classification refers to

broken kernels, butts, splits, pieces, small pieces and whether kernels are white or scorched.

Packaging

As far as possible packaging material used should be eco-friendly and recyclable and containers are

hermetically sealed after filling carbon dioxide.

Anda mungkin juga menyukai

- Chapter 1: Abnormal Behavior in Historical ContextDokumen22 halamanChapter 1: Abnormal Behavior in Historical ContextEsraRamos100% (2)

- The Complete Book On CashewDokumen25 halamanThe Complete Book On Cashewofficemva50% (2)

- Flow Charts of Cassava ProductsDokumen23 halamanFlow Charts of Cassava ProductsJDVBelum ada peringkat

- Milk Powder ProductionDokumen64 halamanMilk Powder ProductionirvaniBelum ada peringkat

- Business Plan On Bagasse PDFDokumen64 halamanBusiness Plan On Bagasse PDFbiswajitBelum ada peringkat

- Project - Key Resources and Value PropositionDokumen5 halamanProject - Key Resources and Value PropositionMuniaBelum ada peringkat

- Coconut Water PreservationDokumen15 halamanCoconut Water Preservationgj657Belum ada peringkat

- Essay On Covid 19Dokumen15 halamanEssay On Covid 19Priyanka Dubey67% (3)

- Cashew Nut ProcessngDokumen12 halamanCashew Nut Processngortum100% (1)

- Cashew Nut ProcessingDokumen8 halamanCashew Nut ProcessingSunil ParikhBelum ada peringkat

- Cashew Nut ProcessingDokumen9 halamanCashew Nut ProcessingYashodhan_Kulk_4424Belum ada peringkat

- Assignment On Cashew Nut Processing (Food Processing Management)Dokumen10 halamanAssignment On Cashew Nut Processing (Food Processing Management)Slesha Patil100% (2)

- Oil and Fat Technology Lectures IIIDokumen42 halamanOil and Fat Technology Lectures IIIaulger100% (1)

- Cashew Value ChainDokumen9 halamanCashew Value ChainAtish100% (1)

- Mango CultivationDokumen4 halamanMango CultivationPartha SaradhiBelum ada peringkat

- Stain Removal Guide for FabricsDokumen34 halamanStain Removal Guide for FabricsDeepanBelum ada peringkat

- 077 Soap ProductionDokumen3 halaman077 Soap Productionkkd108Belum ada peringkat

- Preliminary Project Report and Business Idea On Tender Coconut WaterDokumen8 halamanPreliminary Project Report and Business Idea On Tender Coconut WaterKamal BharakhdaBelum ada peringkat

- Byproducts From Cassava ProcessingDokumen29 halamanByproducts From Cassava ProcessingasokmithraBelum ada peringkat

- Coconut Oil ProcessingDokumen3 halamanCoconut Oil ProcessinglumengentiunBelum ada peringkat

- Packaging of Sugar ConfectioneryDokumen12 halamanPackaging of Sugar ConfectioneryProf C.S.Purushothaman100% (6)

- Coconut Oil-WorldDokumen4 halamanCoconut Oil-WorldCharith LiyanageBelum ada peringkat

- Natural RubberDokumen15 halamanNatural Rubberphyrdows100% (1)

- Conventional Pineaple Production KenyaDokumen41 halamanConventional Pineaple Production KenyaOlajide Emmanuel OlorunfemiBelum ada peringkat

- Rubber: CPE 728-Primary Processing of Plantation and Special CropsDokumen8 halamanRubber: CPE 728-Primary Processing of Plantation and Special CropsMarjun CaguayBelum ada peringkat

- Arch Pharmalabs API Manufacturing SitesDokumen6 halamanArch Pharmalabs API Manufacturing SitesChandan VirmaniBelum ada peringkat

- Kuliah Resin 2Dokumen64 halamanKuliah Resin 2Nabilatun SholikhaBelum ada peringkat

- Municipal Recycling Business PlanDokumen10 halamanMunicipal Recycling Business PlanBianca NeveBelum ada peringkat

- DetergentpowderDokumen11 halamanDetergentpowdermahadevsoapworks.2022Belum ada peringkat

- EDHEC MBA Microeconomics: Price Discrimination and Corporate Valuation Case StudyDokumen4 halamanEDHEC MBA Microeconomics: Price Discrimination and Corporate Valuation Case StudyVivek HaldarBelum ada peringkat

- Fatima Fertilizer Annual ReportDokumen106 halamanFatima Fertilizer Annual ReportMuhammad Imran Umer100% (1)

- MBA Semester 1 Assignments With AnswerDokumen8 halamanMBA Semester 1 Assignments With AnswerRajesh SinghBelum ada peringkat

- Cashew Processing in BeninDokumen64 halamanCashew Processing in BeninRakesh Gupta100% (1)

- Production Processing and Utilization of Rosemary in EthiopiaDokumen27 halamanProduction Processing and Utilization of Rosemary in Ethiopiaanon_701158751Belum ada peringkat

- 005 - Business Plan - Cashew Processing - FinalDokumen20 halaman005 - Business Plan - Cashew Processing - FinalPrasad Nale100% (1)

- An Overview of Groundnut Oil Extraction PDFDokumen14 halamanAn Overview of Groundnut Oil Extraction PDFAndriatsitohaina RabenaivoBelum ada peringkat

- Low-Cost Production of Charcoal Briquettes From Organic WasteDokumen10 halamanLow-Cost Production of Charcoal Briquettes From Organic WasteMarcAguilarBelum ada peringkat

- Dcoffee IdeaDokumen7 halamanDcoffee IdeaDhananjay DubeyBelum ada peringkat

- Business Plan On Production & Distribution of MushrumDokumen40 halamanBusiness Plan On Production & Distribution of MushrumSayed Monjur Morshed Sabuj100% (3)

- Coconut Products: 1.0 Product and Its ApplicationsDokumen6 halamanCoconut Products: 1.0 Product and Its ApplicationsAgri NetBelum ada peringkat

- MRS Mijan Coconut Oil ProductionDokumen22 halamanMRS Mijan Coconut Oil ProductionMAVERICK MONROEBelum ada peringkat

- Managing Cashew Shell Liquid UnitDokumen23 halamanManaging Cashew Shell Liquid UnitPankaj Jadhav100% (1)

- PNS BAFPS 22 2007 - Virgin Coconut OilDokumen8 halamanPNS BAFPS 22 2007 - Virgin Coconut OilmaelizeBelum ada peringkat

- Coco SapDokumen2 halamanCoco SapJames VillanuevaBelum ada peringkat

- 6 - Potato Powder and Flakes Manufacturing UnitDokumen38 halaman6 - Potato Powder and Flakes Manufacturing UnitMaqsood AhmedBelum ada peringkat

- Powder Detergent Ingredents (Pakistan)Dokumen2 halamanPowder Detergent Ingredents (Pakistan)Kashif SaleemBelum ada peringkat

- PEANUT PROCESSING: A Profitable Small BusinessDokumen8 halamanPEANUT PROCESSING: A Profitable Small BusinesskalaamolBelum ada peringkat

- Coconut Milk Powder, Spray DriedDokumen3 halamanCoconut Milk Powder, Spray DriedE Delos SantosBelum ada peringkat

- Brand PersonalityDokumen4 halamanBrand PersonalityBidita RahmanBelum ada peringkat

- Manage Distribution Operations & FulfillmentDokumen34 halamanManage Distribution Operations & FulfillmentMaroa Al HabsiBelum ada peringkat

- Fruit Juice Concentrates GuideDokumen26 halamanFruit Juice Concentrates GuideAakash GillBelum ada peringkat

- Preparation of Laundry Soap From Used Cooking Oils: Getting Value Out of WasteDokumen10 halamanPreparation of Laundry Soap From Used Cooking Oils: Getting Value Out of WasteGshsghBelum ada peringkat

- Canola Oil Physical Chemical Properties 1Dokumen6 halamanCanola Oil Physical Chemical Properties 1elpancaseroBelum ada peringkat

- Spent Coffee Grounds Heat Coffee RoastingDokumen15 halamanSpent Coffee Grounds Heat Coffee RoastingMJundiBelum ada peringkat

- Tajudeen Adejare Aderibigbe, Abiola Azeezjimoh, ChijiokeolisahDokumen10 halamanTajudeen Adejare Aderibigbe, Abiola Azeezjimoh, ChijiokeolisahIOSRjournalBelum ada peringkat

- An Assignment On: The Marketing Plan of "Pure Honey"Dokumen19 halamanAn Assignment On: The Marketing Plan of "Pure Honey"wasab negiBelum ada peringkat

- Process Design Matrix and Executive SummaryDokumen8 halamanProcess Design Matrix and Executive SummaryTheresaHightBelum ada peringkat

- Cashew ProcessingDokumen15 halamanCashew ProcessingSudhakumar PaalepuBelum ada peringkat

- Cashew Nut Processing1Dokumen5 halamanCashew Nut Processing1Noo ThailandBelum ada peringkat

- Cashew Nut ProcessingDokumen9 halamanCashew Nut ProcessingBysani Vinod KumarBelum ada peringkat

- Cashew Processing PDFDokumen5 halamanCashew Processing PDFDeoo Milton EximoBelum ada peringkat

- Postharvest handling of coconutDokumen13 halamanPostharvest handling of coconutApril Ervas100% (1)

- BrochureDokumen2 halamanBrochureRajib DasBelum ada peringkat

- KPI and Supplier Performance Scorecard ToolDokumen7 halamanKPI and Supplier Performance Scorecard ToolJayant Kumar JhaBelum ada peringkat

- Frontier DL650 Maintenance Guide Ver 1.0Dokumen25 halamanFrontier DL650 Maintenance Guide Ver 1.0philippe raynalBelum ada peringkat

- Dladla Effect 2013Dokumen231 halamanDladla Effect 2013TheDreamMBelum ada peringkat

- Paket 4Dokumen6 halamanPaket 4Lovis ShalahuddinBelum ada peringkat

- SureFlo RDokumen2 halamanSureFlo RKen NgBelum ada peringkat

- Meditation ProjectDokumen2 halamanMeditation Projectapi-411448305Belum ada peringkat

- AMGG-S - 1 - Environmental Safeguard Monitoring - 25.03.2021Dokumen48 halamanAMGG-S - 1 - Environmental Safeguard Monitoring - 25.03.2021Mahidul Islam RatulBelum ada peringkat

- Us Errata Document 11-14-13Dokumen12 halamanUs Errata Document 11-14-13H VBelum ada peringkat

- Oxyprobe PDFDokumen16 halamanOxyprobe PDFSrinivasa RBelum ada peringkat

- 'S Outfits and Emergency Escape Breathing Devices (Eebd)Dokumen11 halaman'S Outfits and Emergency Escape Breathing Devices (Eebd)Thurdsuk NoinijBelum ada peringkat

- CN LSHC The Future of Pharmacy en 031120Dokumen8 halamanCN LSHC The Future of Pharmacy en 031120marina_netBelum ada peringkat

- B-64483EN-2 - 05 - 01 Dual Check Safety - CONNECTION MANUAL - Password - RemovedDokumen270 halamanB-64483EN-2 - 05 - 01 Dual Check Safety - CONNECTION MANUAL - Password - Removedretox9000Belum ada peringkat

- Persuasive Speech On Behalf of Inspector GooleDokumen4 halamanPersuasive Speech On Behalf of Inspector GooleSahanaBelum ada peringkat

- Nabertherm RHTH Tube Furnace SOPDokumen4 halamanNabertherm RHTH Tube Furnace SOPIyere PatrickBelum ada peringkat

- PPC Production PlantDokumen106 halamanPPC Production PlantAljay Neeson Imperial100% (1)

- Portfolio FOR ANADokumen6 halamanPortfolio FOR ANAholdap toBelum ada peringkat

- Arthropods: A Guide to the Diverse PhylumDokumen10 halamanArthropods: A Guide to the Diverse Phylumpkkalai112Belum ada peringkat

- GP Series Portable Generator: Owner's ManualDokumen48 halamanGP Series Portable Generator: Owner's ManualWilliam Medina CondorBelum ada peringkat

- 2013 - Sara E. TraceDokumen35 halaman2013 - Sara E. TraceDewi WulandariBelum ada peringkat

- Greek God and Goddess ListDokumen3 halamanGreek God and Goddess Listapi-359276609Belum ada peringkat

- Weld Procedure Specification (WPS) : Joint Design Welding SequenceDokumen1 halamanWeld Procedure Specification (WPS) : Joint Design Welding SequenceRicardo SoaresBelum ada peringkat

- Yoga Nidra MethodDokumen13 halamanYoga Nidra MethodPrahlad Basnet100% (2)

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADokumen3 halamanBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaBelum ada peringkat

- Reflexes Guide: 20+ Human Reflexes ExplainedDokumen37 halamanReflexes Guide: 20+ Human Reflexes ExplainedSalman KhanBelum ada peringkat

- Food Regulations MalaysiaDokumen4 halamanFood Regulations MalaysiaSyafi'ie Syukri100% (1)

- Brian Cody Mcgonegal ResumeDokumen2 halamanBrian Cody Mcgonegal Resumeapi-348833348Belum ada peringkat

- Rexnord Thomas Flexible Disc Couplings - Series 71 - 8Dokumen2 halamanRexnord Thomas Flexible Disc Couplings - Series 71 - 8Orlando ReisBelum ada peringkat