4oI-Io Oll-2lo: United States Patent (191

Diunggah oleh

luanleJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

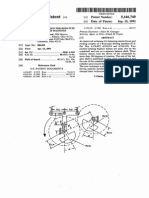

4oI-Io Oll-2lo: United States Patent (191

Diunggah oleh

luanleHak Cipta:

Format Tersedia

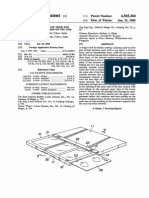

United S ta tes Pa tent [ 1 9 1

S a ka moto

[ 1 1 ] Pa tent Number:

[ 4 5 ] Da te of Pa tent:

5 , 0 3 2 , 7 4 7

J ul . 1 6 , 1 9 9 1

[ 5 4 ] S TEPPING MOTOR

[ 7 5 ] Inv entor: Ma s a f umi S a ka moto, Gnmna , J a p a n

[ 7 3 ] A s s ig nee: J a p a n S erv o C o. , L td. , Toky o, J a p a n

[ 2 1 ] A p p l . No. : 5 8 6 , 2 4 7

[ 2 2 ] F il ed: S ep . 2 1 , 1 9 9 0

[ 3 0 ] F oreig n A p p l ic a tion Priority Da te

Ma r. 1 5 , 1 9 9 0 [ J P] J a p a n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 6 2 5 7 4

[ 5 1 ] Int. C l . 5 . . . . . . . . . . . . . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . . H0 2 K 3 7 /0 0

_ [ 5 2 ] US . C l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1 0 /4 9 R; 3 1 0 /1 6 2 ;

3 1 0 /1 8 5 ; 3 1 0 /2 5 4 ; 3 1 0 /2 6 1

[ 5 3 ] r1 6 1 0 6 1 S ea rc h . . . . . . . . . . . . . . . . . . . . . 3 1 0 /4 9 R, 1 6 2 , 1 6 3 ,

3 1 0 /7 1 6 4 , 1 7 9 , 1 3 5 , 1 9 8 , 2 5 4 , 2 6 1 , 2 6 9 , 1 8 0 , 1 8 1 ,

1 1 3 4 , 2 0 0 , 2 0 1 , 2 0 2 , 2 0 3 , 2 0 4 , 2 0 5 , 2 0 6 , 2 0 7

[ 5 6 ] Ref erenc es C ited

U. S . PA TENT DOC UMENTS

4 , 7 6 1 , 5 7 4 8 /1 9 8 8 Na ka g a wa . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1 0 /1 2

4 , 8 4 3 , 2 7 0 6 /1 9 8 9 Dijken . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1 0 /2 0 8

4 , 8 5 7 , 7 8 2 8 /1 9 8 9 Tokio et a l . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1 0 /1 2

Prima ry Ex a miner S tev en L . S tep ha n

A s s is ta nt Ex a miner-Edwa rd H. To

A ttorney , A g ent, or F irm Ni1 l es & Nil l es

[ 5 7 ] A BS TRA C T

A s tep p ing motor wherein a f ol l owing f ormul a is s a tis

? ed:

where W3 2 is a tooth width of ma g netic p ol e of a s ta tor,

1 1 2 1 s a n interv a l of a dja c ent ma g netic p ol es of the s ta tor,

W, ; is a tooth width of p ol e tooth or a rotor, y ; is a n

interv a l of a dja c ent p ol e teeth of the rotor, a nd n is a n

integ er not l es s tha n 2 .

6 C l a ims , 2 Dra wing S heets

/' 2 ' -3 2 -4

If

4 oI-Io ol l -2 l o

0 1 :2 1 ? _ 0 1 1 1 5 2 3

l l l l l L J l l l l l J

3 -Y - 3 -1 3 -2 3 -3 3 -4 3 -5 3 -6 3 -7

1 J 1

3 -8 1

US . Pa tent J ul y 1 6 , 1 9 9 1 S heet 2 of 2 5 , 0 3 2 , 7 4 7

L

On 3

1 w

2 %

a mv js l nh

2 5 V ,

WBJ L .

3

_ 6

2 _ . _ Q

2

X 2

Q WL J H

2 2

H8 4

my

3 ul na

_

8 w .

4 2

4 3

8 4 .

/ 3 W

4 S W

|G. 4 (o)

3 -5

A

! G . 4 (c )

PRIOR A RT

F

F G . 4 b)

PRIOR A RT

X I

5 , 0 3 2 , 7 4 7

1

S TEPPING MOTOR

BA C KGROUND OF THE INV ENTION

1 . F iel d of the Inv ention

This inv ention rel a tes to a s tep p ing motor a nd, more

p a rtic ul a rl y , rel a tes to a n imp rov ement of a s tep p ing

motor c omp ris ing a s ta tor ha v ing ma g netic p ol es , ea c h

of s a id ma g netic p ol es ha v ing a winding wound

thereon, a nd a rotor ha v ing p ol e teeth f a c ing s a id s ta tor

ma g netic p ol es throug h a g a p .

2 . Des c rip tion of the Prior A rt

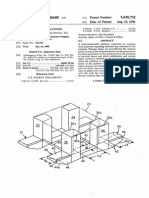

F IG. 4 (a ) is a n ex p a nded v iew of a c onv entiona l

s tep p ing motor il l us tra ting the rel a tion p os itions of the

s ta tor a nd the rotor thereof .

Ref erenc e numera l 1 denotes a y oke of the' s ta tor.

1 -1 -1 -4 a re s ta tor' ma g netic p ol es p rov ided on the y oke

1 eq uidis ta ntl y a p a rt f rom one a nother. 2 -1 -2 -4 a re s ta

tor winding s , ea c h wound a round ea c h of s a id s ta tor

p ol es . Numera l 3 is the rotor, 3 -1 -3 -5 a re p ol e teeth

p rov ided on a n outer p erip hery of the rotor 3 , _ a nd 4 is

a g a p between the s ta tor ma g netic p ol es a nd the rotor

p ol e teeth.

In the c onv entiona l s tep p ing motor s hown in F IG.

4 (a ), a tooth width W of ea c h of the s ta tor ma g netic

p ol es 1 -1 -1 -4 is s ubs ta ntia l l y the s a me a s a tooth width

W? of ea c h of the rotor p ol e teeth 3 -1 -3 -5 f a c ing the

s ta tor ma g netic p ol es , mea s uring in a p erip hera l direc

tion thereof . The number of s ta tor ma g netic p ol es is 4 ,

i f or ex a mp l e, a nd they a re dis p os ed with a n interv a l x 1

between them. The number of rotor p ol e teeth is 5 , f or

ex a mp l e, a nd they a re dis p os ed with a n interv a l y l be

, tween them whic h is dif f erent f rom s a id interv a l x 1 . The

interv a l s x , a n, or x 2 a re mea s ured f rom the c enter of one

s ta tor ma g netic p ol e, a round whic h a c oil is wound, to

the c enter of the a dja c ent s ta tor ma g netic p ol e, a round

whic h a c oil is wound, a nd the interv a l y ; is mea s ured

f rom the c enter of one rotor p ol e to the c enter of the

a dja c ent rotor p ol e.

The s ta tor winding s 2 -1 , 2 -2 , 2 -3 , a nd 2 -4 a re div ided

into f our g roup s .

In the s tep p ing motor s hown in F IG. 4 (a ), the rotor is

rota ted s tep wis e by a n a ng l e when a n el ec tric c urrent is

p a s s edv s uc c es s iv el y throug h ea c h of the f our s ta tor

winding g roup s . The motion thereof v wil l be ex p l a ined

in deta il hereunder. F IG. 4 (a ) s hows a s ta te in whic h the

p ol e tooth 3 -1 of the rotor 3 is a l ig ned with s a id s ta tor

ma g netic p ol e 1 -1 f a c ing s a id p ol e tooth 3 -1 throug h a

g a p by a n el ec tric c urrent f l owing throug h the s ta tor

winding 2 -1 to g enera te a n el ec troma g netic f orc e on

s a id s ta tor ma g netic p ol e 1 -1 . In this s ta te, s ta tor ma g

netic p ol e 1 -2 a nd rotor p ol e tooth 3 -2 p a rtia l l y ov erl a p

to ea c h other by s ubs ta ntia l l y a ha l f of one tooth width,

s o tha t a p ortion of the p ol e tooth 3 -2 of the rotor 3

p rojec ts l ef twa rdl y of the s ta tor ma g netic p ol e 1 -2 .

S imil a rl y , the s ta tor ma g netic p ol e 1 -4 a nd the rotor

p ol e tooth 3 -5 p a rtia l l y ov erl a p ea c h other by s ubs ta n

tia l l y a ha l f of one tooth width, s o tha t a p ortion of the

p ol e tooth 3 -5 of the rotor 3 p rojec ts rig htwa rdl y of the

s ta tor ma g netic p ol e 1 -4 rig htwa rds . The s ta tor ma g

netic p ol e 1 -3 , howev er, does not ov erl a p a ny p ol e

2

the rotor rig htwa rds by one ha l f of one tooth width

until the p ol e 1 -2 a nd p ol e tooth 3 -2 a re f ul l y ov erl a p

p ing .

In order to mov e the rotor a n a dditiona l s tep rig ht

wa rds , it is s uf ? c ient tha t el ec tric c urrent f l ow throug h

the s ta tor winding 2 -3 a nd not ? ow throug h s a id s ta tor

winding 2 -2 . By doing s o, the s tep p ing motor s hown in

F IG. 4 (a ) c a n be rota ted s tep wis e ea c h time a s uc c es s iv e

s ta tor winding is energ iz ed. S uc h a driv ing s y s tem is a

' s o c a l l ed one-p ha s e ex c iting s y s tem, whic h is the ba s ic

driv ing s y s tem.

In s uc h a one-p ha s e ex c iting s y s tem, howev er, onl y

one s et of s ta tor winding s is energ iz ed a t a ny one time

whil e the rema ining s ets of s ta tor winding s a re deener

g iz ed. Outp ut, theref ore, is rel a tiv el y l ow. A c c ording l y ,

a two-p ha s e ex c iting s y s tem wherein two a dja c ent ma g

netic p ol es a re ma g netiz ed a t the s a me time ha s been

2 5

3 5

5 0

5 5

tooth of the rotor 3 . In order to mov e the rotor one s tep ,

f rom the s ta te s hown in F IG. 4 (a ), it is s uf ? c ient tha t

el ec tric c urrent f l ow throug h the s ta tor winding 2 -2 a nd

not f l ow throug h the s ta tor winding 2 -1 . By doing s o,

the s ta tor ma g netic p ol e 1 -2 a ttra c ts the p ol e tooth 3 -2

of the rotor 3 , whic h op p os es a nd ov erl a p s s ta tor ma g

netic p ol e 1 -2 by one ha l f of one tooth width, by mov ing

6 5

us ed. In the two-p ha s e ex c iting s y s tem, el ec tric c urrents

a re s ent throug h the s ta tor winding s 2 -1 a nd 2 -2 s imul ta

neous l y a s s hown in F IG. 4 (b). In this s ta te, the p ol e

tooth 3 -1 ' of the rotor 3 is a ttra c ted to the s ta tor ma g

netic p ol e l -1 a nd the p ol e tooth 3 -2 is a ttra c ted to the

s ta tor ma g netic p ol e 1 -2 s o tha t the rotor 3 s top s a t a

p os ition where a ttra c ting f orc es ex erted on both of s a id

p ol e teeth of the rotor 3 a re ba l a nc ed. The rel a tions hip

between the a ng ul a r p os ition of the rotor 3 a nd a torq ue

T of rota tion thereof is s hown in F IG. 4 (a ). A s s hown in

F IG. 4 (a ), the torq ue of rota tion T is g enera ted a s a

res ul ta nt torq ue of a torq ue of rota tion T1 g enera ted by

the s ta tor ma g netic p ol e 1 -1 a nd a torq ue of rota tion T2

g enera ted by the s ta tor ma g netic p ol e 1 -2 , whic h is

l a rg er tha n tha t obta ined in the c a s e of the one-p ha s e

ex c iting s y s tem.

Howev er, emp l oy ing the c onv entiona l s tep p ing

motor in the two-p ha s e ex c iting s y s tem a s mentioned

a bov e, the torq ues of rota tion T1 a nd T2 a re in p rop or

tion to the el ec tric c urrent v a l ue f l owing throug h ea c h

winding , a nd rel a te to the a ir g a p between the s ta tor

ma g netic p ol es a nd the rotor p ol e teeth op p os ing ea c h

other s o tha t the rotor 3 s top s a t a p os ition where the

torq ues of rota tion T1 a nd T2 a re ba l a nc ed. A c c ord

ing l y , the s top p os ition of the two-p ha s e ex c iting s y s tem

is g enera l l y not a s p rec is e a s tha t of the one-p ha s e ex c it

ing s y s tem. S p ec i? c a l l y , if the torq ues of rota tion T1 a nd

T2 a re dif f erent f rom ea c h other, the res ul ta nt torq ue T

c a n not be p a s s ed throug h the orig in of the c oordina te

in F IG. 4 (a ), s o tha t p os itioning errors oc c ur.

S UMMA RY OF THE INV ENTION

A n objec t of the p res ent inv ention is to p rov ide a

s tep p ing motor whic h el imina te the def ec ts mentioned

a bov e. '

A nother objec t of the p res ent inv ention is to p rov ide

a s tep p ing motor c omp ris ing a s ta tor ha v ing ma g netic

p ol es , eq uidis ta ntl y a p a rt f rom one a nother, ea c h of s a id

ma g netic p ol es ha v ing a winding wound thereon, a nd a

rotor ha v ing p ol e teeth, eq uidis ta ntl y a p a rt f rom one

a nother f a c ing s a id s ta tor ma g netic p ol es throug h a g a p ,

wherein the f ol l owing f ormul a is s a tis ? ed:

where Ws z is the s ta tor ma g netic p ol e tooth width. x ; is

a n interv a l of a dja c ent ma g netic p ol es of s a id s ta tor,

5 , 0 3 2 , 7 4 7

3

W, ; is the rotor p ol e tooth width, y ; is a n interv a l of

a dja c ent p ol e teeth of s a id rotor, a nd n is a n integ er not

l es s tha n 2 .

A c c ording to the s tep p ing motor of the p res ent in

v ention, torq ues of rota tion g enera ted a t the a dja c ent

s ta tor ma g netic p ol es , res p ec tiv el y , a re eq ua l to ea c h

other, s o tha t f ring ing ef f ec t oc c urs a nd the s tep a ng l e

error is reduc ed.

Thes e a nd other objec ts a nd f ea tures of the p res ent

inv ention wil l bec ome a p p a rent f rom the f ol l owing

des c rip tion in c onjunc tion with the a tta c hed dra wing s .

BRIEF DES C RIPTION OF THE DRA WINGS

F IG. 1 (a ) is a n ex p a nded v iew s howing the rel a tiv e

p os itions between a s ta tor a nd a rotor of a s tep p ing

motor; '

F IG. 1 (b) is a n enl a rg ed v iew of the s tep p ing motor

s hown in F IG. 1 (a ); '

F IG. 1 (c ) is a v iew s howing the rel a tions hip between

the a ng ul a r p os ition of the rotor a nd the torq ue of rota

tion;

F IG. 1 (a ' ), F IG. 1 (e) a nd F IG. 1 0 ) a re v iews il l us tra t

ing other embodiments of the s tep p ing motor of the

p res ent inv ention; /

F IG. 2 is a p ers p ec tiv e v iew of the rotor;

F IG. 3 is a n ex p a nded v iew s howing the rel a tiv e

p os itions between the s ta tor a nd the rotor of a f urther

embodiment of the s tep p ing motor of the p res ent inv en

tion;

F IG. 4 (a ) is a n ex p a nded v iew s howing the rel a tiv e

- p os itions between the s ta tor a nd the rotor of a c onv en

tiona l s tep p ing motor;

F IG. 4 (b) is a n a l terna te v iew of a c onv entiona l s tep

p ing motor of a two-p ha s e ex c iting s y s tem: a nd

F IG. 4 (c ) s hows the rel a tions hip between the a ng ul a r

p os ition of the rotor a nd the torq ue of rota tion.

DES C RIPTION OF THE PREF ERRED

EMBODIMENTS

A n embodiment of this inv ention wil l be ex p l a ined

with ref erenc e to F IGS . 1 (a ) throug h 1 (a ).

In F IG. 1 (a ), the p a rts of the s tep p ing motor of the

p res ent inv ention whic h a re s imil a r to c orres p onding

p a rts of the p rior a rt s tep p ing motor s hown in F IGS .

(0 ) to 4 (0 ) ha v e been g iv en c orres p onding ref erenc e

numera l s a nd need not be f urther redes c ribed.

In the s tep p ing motor of this inv ention, s ta tor ma g

netic p ol es a nd rotor p ol e teeth a re a rra ng ed s o a s to

s a tis f y the f ol l owing f ormul a ,

where W, ; is the s ta tor ma g netic p ol e tooth width, x ; is

a n interv a l of a dja c ent ma g netic p ol es of the s ta tor, W, ;

is the rotor p ol e tooth width, y ; is a n interv a l of a dja

c ent rotor p ol e teeth of s a id rotor, a nd n is a n integ er

eq ua l to or more tha n 2 .

The s tep p ing motor of the p res ent inv ention op era tes

a s f ol l ows . -

In the s tep p ing motor of the p res ent inv ention, when

el ec tric c urrents a re p a s s ed throug h s ta tor winding s 2 -1

a nd 2 -2 in c a s e of the two-p ha s e ex c iting s y s tem, the

rotor p ol e teeth 3 -1 a nd 3 -3 a re a ttra c ted to the ma g ne

tiz ed s ta tor ma g netic p ol es l -l a nd 1 -2 , res p ec tiv el y , s o

a s to op p os e the s ta tor ma g netic p ol es a s s hown in F IG.

1 (a ), both rig ht s ide f a c es of -the s ta tor ma g netic p ol e 1 -1

a nd the rotor p ol e tooth 3 -1 being a l ig ned with ea c h

other a nd both l ef t s ide f a c es of the s ta tor ma g netic p ol e

2 0

2 5

3 5

4 0

5 0

5 5

6 5

4

1 -2 a nd the rotor p ol e tooth 3 -3 being a l ig ned with ea c h

other.

A c c ording l y , in the p res ent inv ention, p rec is e p os i

tioning of the rotor c a n be inc rea s ed a t both rig ht a nd

l ef t s ide f a c es thereof .

The rel a tions hip between the a ng ul a r p os ition 0 a nd

the torq ue of rota tion T of the rotor wil l be ex p l a ined

with ref erenc e to F IGS . 1 (b) a nd 1 (a ). -

A s s hown in F IG. 1 (b), the rig ht s ide f a c es of the

s ta tor ma g netic p ol e 1 -1 a nd the rotor p ol e tooth 3 -1 a re

a l ig ned with ea c h other s o tha t the torq ue of rota tion a t

this p os ition bec omes z ero. S imil a rl y , the l ef t s ide f a c es

of the s ta tor ma g netic p ol e 1 -2 a nd the rotor p ol e tooth

3 -n+l a re a l ig ned with ea c h other s o tha t the torq ue of

rota tion a t this p os ition bec omes z ero. A c c ording l y , the

a ng ul a r p os ition of the rotor is determined ba s ic a l l y by

the a bov e rel a tions hip a nd a f f ec ted l ittl e by the dif f er

enc e between el ec tric c urrent v a l ues ? owing throug h

thev s ta tor winding s 2 -1 a nd 2 -2 , res p ec tiv el y .

F urther, the res tora tion torq ue of rota tion g enera ted

when the rotor rota tes by a v ery s ma l l a ng l e f rom the

s top p os ition is l a rg er tha n tha t in the c onv entiona l

s tep p ing motor s hown in F IG. 4 (a ). This is the res ul t of

the f ring ing ef f ec t due to the ma g netic f l ux is s ued f rom

the p ortion of the s ta tor ma g netic p ol e whic h dev ia tes

f rom the s ide f a c e of the rotor p ol e tooth, a nd ma inta ins

the s ta tor ma g netic p ol e a nd the rotor p ol e tooth in

a l ig nment with ea c h other s o tha t s top p os ition p rec i

s ion is enha nc ed.

Now, the a rra ng ement of the ma g netic p ol es a nd the

p ol e teeth s hown in F IG. 1 (a ) is c omp a red with tha t

s hown in p rior a rt F IG. 4 (a ). In F IG. 4 (a ), the tooth

width W5 1 of the s ta tor ma g netic p ol es a nd the tooth

width W, 1 of the rotor p ol e teeth a re s ubs ta ntia l l y eq ua l

to ea c h other, but the interv a l x 1 of the a dja c ent s ta tor

ma g netic p ol es a nd the interv a l y l of the a dja c ent rotor

p ol e teeth a re dif f erent f rom ea c h other. On the c on

tra ry , in F IG. 1 (a ), the s ta tor ma g netic p ol es a nd rotor

p ol e teeth a re a rra ng ed s o a s to s a tis f y the f ol l owing

f ormul a ,

Wr2 = W:2 (-_ t2 ' 1 y 2 ) (l )

where n is a n integ er not l es s tha n 2 .

The rea s on why it is the integ er not l es s tha n 2 is tha t

in the a c tua l s tep p ing motor it is nec es s a ry to des ig n the

number of rotor p ol es to be a t l ea s t twic e the number of

the s ta tor ma g netic p ol es . This enha nc es the res ol v ing

p ower by reduc ing the s tep a ng l e a nd c a rry ing out the

p os itioning of the rotor by numerous p ul s es (p rec is enes s

of p os itioning c a n be inc rea s ed if , f or ins ta nc e, where

the des ired a ng ul a r c ha ng e of p os ition is 1 8 , the motor

is p os itioned in ten s tep a ng l es of 1 . 8 ra ther tha n in one

l a rg e motor s tep a ng l e of 1 8 ). In other words , if the

tooth width of the rotor is reduc ed by (x g -ny g ) c om

p a red with the tooth width of the s ta tor a s tep p ing

motor ha v ing the op timum p rec is ion in the two-p ha s e

ex c iting s y s tem c a n be obta ined.

F IG. 1 (d) s hows a nother embodiment of the s tep p ing

motor of the p res ent inv ention wherein the f ring ing

ef f ec t in the two-p ha s e ex c iting s y s tem is obta ined a t the

outs ide f a c es of the s ta tor ma g netic p ol es 1 -1 a nd 1 -2 .

In this embodiment, when the s ta tor ma g netic p ol es

1 -1 a nd l -2 a re ma g netiz ed in the two-p ha s e ex c iting

s y s tem by el ec tric c urrents ? owing throug h the s ta tor

winding s 2 -1 a nd 2 -2 , the l ef t s ide f a c es of the s ta tor

ma g netic p ol e 1 -1 a nd the rotor p ol e tooth 3 -1 a re

a l ig ned with ea c h other a nd the rig ht s ide f a c es of the

5 , 0 3 2 , 7 4 7

5

s ta tor ma g netic p ol e 1 ' -2 a nd the rotor p ol e tooth 3

(n+1 ) a re a l ig ned with ea c h other, s o tha t the f ring ing

ef f ec t c a n' be obta ined a s in the s tep p ing motor s hown in

~ F IG. 1 (b). In this c a s e, the f ol l owing f ormul a is s a tis ? ed,

Wr3 = W:2 +(X 2 ny 2 ) (2 )

where W, 3 is rotor p ol etooth width.

Tha t is , if the rotor p ol e tooth width W, 3 is inc rea s ed

by (x 1 - ny 2 ) c omp a red with the tooth width W3 2 of the

s ta tor ma g netic p ol e, op timum p rec is ion c a n be_ ob

ta ined in the two-p ha s e' ex c iting s y s tem.

F IG. 1 (e) s hows a f urther embodiment of the p res ent

inv ention wherein rotor p ol e teeth s a tis f y ing the f ormu- '

l a s (l ) a nd (2 ) a re p rov ided.

In this embodiment, a rotor p ol e tooth ha v ing tooth

width W3 s a tis f y ing f ormul a (1 ) a nd a rotor p ol e tooth

ha v ing tooth width W, 3 s a tis f y ing the f ormul a (2 ) a re

s up erp os ed in the a x ia l direc tion of the rotor with the

c enter l ines thereof being a l ig ned. A c c ording l y , the

' rig ht s ide f a c e of the rotor p ol e tooth 3 -1 ha v ing the

tooth width W? ' a nd the l ef t s ide f a c e of the rotor p ol e

tooth ha v ing the tooth width W, 3 a re a l ig ned to the

rig ht a nd l ef t s ide f a c es of the s ta tor ma g netic p ol e 1 -1 ,

res p ec tiv el y , wherea s the l ef t s ide f a c e of the rotor p ol e

tooth 3 -(n +1 ) ha v ing the tooth width W, ; a nd the rig ht

s ide f a c e of the rotor p ol e tooth ha v ing the tooth width

-W' , 3 a re a l ig ned to the l ef t a nd rig ht s ide f a c es of the

s ta tor ma g netic p ol e 1 -2 , res p ec tiv el y , s o tha t the f ring

ing ef f ec t bec omes twic e tha t in the f ormer embodi

ments in the two-p ha s e ex c iting s y s tem. ' .

A nother embodiment of the s tep p ing motor wherein

s top p os ition p rec is ion in the one-two p ha s e ex c iting

s y s tem c a n be enha nc ed is s hown in F IG. 1 (/). In the

one-two p ha s e ex c iting s y s tem, one-p ha s e ex c iting a nd

two-p ha s e ex c iting a re rep ea ted. In other words , the

one-p ha s e ex c iting a nd the two-p ha s e ex c iting a re re

. p ea ted f or the winding s in a s eq uenc e of the winding

(2 -1 ), (2 -1 a nd 2 -2 ), (2 -2 ), (2 -2 a nd 2 -3 ), (2 -3 ), v (2 -3 a nd

2 -4 ), (2 -4 ), (2 -4 a nd 2 -1 ), a nd (2 -1 ) in F IG. 1 (a ), f or

ex a mp l e.

In this embodiment, a rotor p ol e tooth ha v ing tooth

width W, ; (or W, -3 ) s a tis f y ing f ormul a (1 ) or (2 )) a nd a

rotor p ol e tooth ha v ing tooth width W, 4 whic h is s imi

l a r to the tooth width of the s ta tor ma g netic p ol e 1 -1 a re

s up erp os ed in the a x ia l direc tion of the rotor with the

c enter l ines thereof being a l ig ned. _

In this embodiment, when onl y the s ta tor ma g netic

p ol e 1 -1 is ma g netiz ed by el ec tric c urrent f l owing

throug h onl y the s ta tor winding 2 -1 both s ide f a c es of

the rotor p ol e tooth ha v ing tooth width WM a re a l ig ned

with both s ide f a c es of the s ta tor ma g netic p ol e, bec a us e

the rotor p ol e tooth is the s a me width a s the s ta tor

ma g netic p ol e s o tha t the f ring ing ef f ec t c a n be ob

ta ined. When both s ta tor ma g netic p ol es 1 -1 a nd 1 -2 a re

ma g netiz ed by el ec tric c urrents ? owing throug h both

s ta tor winding s 2 -1 a nd 2 -2 the s ta tor ma g netic p ol e 1 -1

is a l ig ned with the rotor p ol e tooth 3 -1 ha v ing tooth

width W, ; a t the rig ht s ide f a c es thereof a nd the s ta tor

ma g netic p ol e 1 -2 is a l ig ned with the rotor p ol e tooth

3 -(n+l ) ha v ing tooth width Wrz a t the l ef t s ide f a c es

thereof s o tha t the f ring ing ef f ec t c a n be obta ined a nd of

1 5

3 0

6 0

s top p os ition p rec is ion c a n be enha nc ed in the one-two _

p ha s e ex c iting s y s tem.

F IG. 2 is a p ers p ec tiv e v iew of the rotor s hown in

1 F IGS . 1 (e) or 1 (/). Ref erenc e numera l 5 denotes a rotor

p ol e tooth ha v ing tooth width w, ;, 6 denotes a rotor

p ol e tooth ha v ing tooth width W, 3 or W, 4 . This rotor

c a n be f ormed a s a rotor of the v a ria bl e rel uc ta nc e ty p e

6 5

6

ha v ing no p erma nent ma g net, f or ex a mp l e, or of the

hy brid ty p e wherein rotors 3 a nd 3 a re p rov ided on

both s ides of a p erma nent ma g net 7 ma g netiz ed into two

p ol es in the a x ia l direc tion thereof . The rotor s hown in

F IG. 2 is of the hy brid ty p e. In this c a s e, the c enter l ines

of the p ol e teeth 5 a nd 6 of the rotors a t both s ides of the

p erma nent ma g net 7 dev ia te in the p erip hera l direc tion

by y z /z f rom ea c h other. The f ring ing ef f ec t c a n be

obta ined in the two-p ha s e ex c iting s y s tem if the tooth

widths of the s ta tor ma g netic p ol es whic h a rema g ne

tiz ed by the s a me winding s a re s et s imil a r to thos e of the

rotor p ol e teeth s a tis f y ing the f ormul a s (l ) a nd (2 ), or if

the tooth width Ws z of the s ta tor ma g netic p ol e s hown

in F IGS . 1 (d) a nd 1 (e) is s et s imil a r to the tooth width of

the rotor p ol e tooth, f or ex a mp l e.

F urther, the f ring ing ef f ec t c a n be obta ined in the

one-two p ha s e ex c iting s y s tem if the rotor a nd s ta tor a re

ex c ha ng ed in tooth width with ea c h other in the s tep

p ing motor s hown in F IG. 1 (/). S uc h a s tep p ing motor

is s hown in F IG. 3 . In the s tep p ing motor s hown in

F IG. 3 , s ta tor ma g netic p ol e p ortions ha v ing dif f erent

tooth widths rel a tiv e to ea c h other a re p rov ided on

both s ides of ea c h of the s ta tor ma g netic p ol es 8 -1 , 8 -2 ,

8 -3 , . . . , s o a s to f a c e the rotor p ol e teeth. The rotor

p ol e teeth in F IG. 3 ha v e a n op timum width two-p ha s e

ex c iting s y s tem. S p ec if ic a l l y , in F IG. 3 , tooth width

W5 4 of the l ef t p ortion of the s ta tor ma g netic p ol e 8 -1 is

the s a me a s tooth width W, 3 s a tis f y ing the f ormul a (2 ),

a nd a tooth width W5 3 of the rig ht p ortion of the s ta tor

ma g netic p ol e 8 -1 is the s a me a s tooth width Wrz s a tis f y

ing the f ormul a (1 ), wherea s tooth width W, 4 of ea c h of

the rotor p ol e teeth 3 -1 , 3 -2 , 3 -3 , . . . is identic a l to tooth

width Ws z ex p l a ined in F IGS . 1 (a ), 1 (b), 1 (a ' ), 1 (e) a nd

1 (/).

When the s ta tor ma g netic p ol es 8 -1 a nd 8 -2 a re ma g

netiz ed in the two-p ha s e ex c iting s y s tem the f ring ing

ef f ec t c a n be obta ined a t the l ef t s ide of the rotor p ol e

tooth 3 -1 a nd the rig ht s ide of the rotor p ol e tooth 3 -2

with res p ec t to the s ta tor ma g netic p ol e 8 -1 , a s wel l a s

a t the rig ht s ide of the rotor p ol e tooth 3 -4 a nd the l ef t

s ide of the rotor p ol e tooth 3 -5 with res p ec t to the s ta tor

ma g netic p ol e 8 -2 , s o tha t hig h p rec is ion p os itioning c a n

be c a rried out in the two-p ha s e ex c iting s y s tem. F ur

ther, in the s tep p ing motor of the p res ent inv ention the

c ons truc tion bec omes s imp l e a nd the ma nuf a c turing

c os t c a n be reduc ed bec a us e it is not nec es s a ry to s up er

p os e the rotor p ol e teeth a s s hown in F IG. 1 (e) or 1 (/),

onc e the p res s mol d is p rep a red f or the s ta tor.

A s s ta ted a bov e, a c c ording to the p res ent inv ention

p rec is e p os itioning in the two-p ha s e ex c iting s y s tem or

the one-two p ha s e ex c iting s y s tem c a n be enha nc ed by

this v ery s imp l e c ons truc tion.

The p rec is enes s of the s tep a ng l e 1 . 8 in the s tep p ing

motor of the p res ent inv ention s hown in F IG. 1 (a ) be

c omes -_ * -l . 5 % , wherea s in the c onv entiona l s tep p ing

motor s hown in F IG. 4 (a ) bec omes 1 7 % . It is p ref era

bl e tha t the v a l ue of n in s a id f ormul a s (l ) a nd (2 ) is 2 to

1 0 p ra c tic a l l y , a nd more s p ec i? c a l l y , n is a bout 6 when

the s tep a ng l e is 3 . 6 a nd a bout 7 when the s tep a ng l e is

0 . 9 , f or ex a mp l e.

A c c ording to the p res ent inv ention, p rec is e p os ition

ing in the two-p ha s e ex c iting s y s tem c a n be inc rea s ed

a nd the error in the s tep a ng l e of the s tep p ing motor c a n

be reduc ed by the s tep p ing motor c ons truc tion of the

p res ent inv ention.

5 , 0 3 2 , 7 4 7

, 7 .

It s houl d be unders tood tha t embodiments of the

p res ent inv ention not dis c l os ed herein a re f ul l y intended

to be within the s c op e of the c l a ims .

Wha t is c l a imed is :

1 . In a s tep p ing motor c omp ris ing a s ta tor ha v ing

ma g netic p ol es , eq uidis ta ntl y a p a rt f rom one a nother,

ea c h of s a id ma g netic p ol es ha v ing a winding wound

thereon, a nd a rotor ha v ing p ol e teeth, eq uidis ta ntl y

a p a rt f rom one a nother, f a c ing s a id s ta tor ma g netic

p ol es throug h a g a p , the imp rov ement c ha ra c teriz ed in

tha t the f ol l owing f ormul a is s a tis ? ed:

where W5 ; is s ta tor ma g netic p ol e tooth width, x ; is a n

interv a l of a dja c ent s ta tor ma g netic p ol es , W, ; is rotor

p ol e tooth width, y ; is a n interv a l of a dja c ent rotor p ol e

teeth, a nd n is a n integ er not l es s tha n 2 .

* 2 . In a s tep p ing motor c omp ris ing a s ta tor ha v ing

ma g netic p ol es , eq uidis ta ntl y a p a rt f rom one a nother,

ea c h of s a id ma g netic p ol es ha v e a winding wound

thereon, a nd a rotor ha v ing p ol e teeth, eq uidis ta ntl y

a p a rt f rom one a nother, f a c ing s a id s ta tor ma g netic

p ol es throug h a g a p , the imp rov ement c ha ra c teriz ed in

tha t the f ol l owing f ormul a is s a tis ? ed:

where W3 2 is s ta tor ma g netic p ol e tooth width, x ; is a n

interv a l of a dja c ent s ta tor ma g netic p ol es , W, ; is rotor

1 p ol e tooth width, y ; is a n interv a l of a dja c ent rotor p ol e

teeth, a nd n is a n integ er not l es s tha n 2 .

3 . In a s tep p ing motor c omp ris ing a s ta tor ha v ing

ma g netic p ol es , eq uidis ta ntl y a p a rt f rom one a nother,

ea c h of s a id ma g netic p ol es ha v e a winding wound

thereon, a nd a rotor ha v ing p ol e teeth, eq uidis ta ntl y

a p a rt f rom one a nother, f a c ing s a id s ta tor ma g netic

p ol es throug h a g a p , the imp rov ement c ha ra c teriz ed by

a rotor wherein the f ol l owing f ormul a is s a tis ? ed:

Wr2 = Ws l (- 2 " y 2 ):

a nd a rotor wherein the f ol l owing f ormul a is s a tis ? ed:

WrZ = W:2 +(X 2 ? y z ),

where Wx z is s ta tor ma g netic p ol e tooth width, x ; is a n

interv a l of a dja c ent s ta tor ma g netic p ol es , W, ; is rotor

p ol e tooth width of s a id rotors , y ; is a n interv a l of a dja

c ent rotor p ol e teeth of s a id rotors , a nd n is a n integ er

not l es s tha n 2 , s a id two rotors a re s up erp os ed on ea c h

2 0

2 5

3 5

4 5

5 5

6 5

8

other in a n a x ia l direc tion thereof with the c enters of the

teeth of s a id rotors being a l ig ned with ea c h other.

4 . In a s tep p ing motor c omp ris ing a s ta tor ha v ing

ma g netic p ol es , eq uidis ta ntl y a p a rt f rom one a nother,

ea c h of s a id ma g netic p ol es ha v e a winding wound

thereon, a nd a rotor ha v ing p ol e teeth, eq uidis ta ntl y

a p a rt f rom one a nother, f a c ing s a id s ta tor ma g netic

p ol es throug h a g a p , the imp rov ement c ha ra c teriz ed in

tha t ea c h ma g netic p ol e of s a id s ta tor ha s a t l ea s t one s et

of tooth width p ortions s a tis f y ing the f ol l owing f ormu

l a s , res p ec tiv el y :

where W5 ; is s ta tor ma g netic p ol e tooth width, x ; is a n

interv a l of a dja c ent s ta tor ma g netic p ol es , W, 2 is rotor

p ol e tooth width, y ; is a n interv a l of a dja c ent rotor p ol e

teeth, a nd n is a n integ er not l es s tha n 2 .

5 . In a s tep p ing motor c omp ris ing a s ta tor ha v ing

ma g netic p ol es , eq uidis ta ntl y a p a rt f rom one a nother,

ea c h of s a id ma g netic p ol es ha v e a winding wound

thereon, a nd a rotor ha v ing p ol e teeth, eq uidis ta ntl y

a p a rt f rom one a nother, f a c ing s a id s ta tor ma g netic

p ol es throug h a g a p , the imp rov ement c ha ra c teriz ed in

tha t s a id s ta tor ha s a t l ea s t one ma g netic p ol e s a tis f y ing

the f ol l owing f ormul a :

a nd ha s other ma g netic p ol es ea c h ha v ing a tooth width

of w, ;, where W3 ; is s ta tor ma g netic p ol e tooth width,

x ; is a n interv a l of a dja c ent s ta tor ma g netic p ol es , W, ; is

rotor p ol e tooth width, y ; is a n interv a l of a dja c ent

rotor p ol e teeth, a nd n is a n integ er not l es s tha n 2 .

6 . In a s tep p ing motor c omp ris ing a s ta tor ha v ing

ma g netic p ol es , eq uidis ta ntl y a p a rt f rom one a nother,

ea c h of s a id ma g netic p ol es ha v e a winding wound

thereon, a nd a rotor ha v ing p ol e teeth, eq uidis ta ntl y

a p a rt f rom . one a nother, f a c ing s a id s ta tor ma g netic

p ol es throug h a g a p , the imp rov ement c ha ra c teriz ed in

tha t s a id s ta tor ha s a t l ea s t one ma g netic p ol e s a tis f y ing

the f ol l owing f ormul a :

a nd ha s other ma g netic p ol es ea c h ha v ing a tooth width

of W, ;, where W5 2 is s ta tor ma g netic p ol e tooth width,

x ; is a n interv a l of a dja c ent s ta tor ma g netic p ol es , W, 2 is

rotor p ol e tooth width, y ; is a n interv a l of a dja c ent

rotor p ol e teeth, a nd n is a n integ er not l es s tha n 2 .

i # i i

Anda mungkin juga menyukai

- Marine HoseDokumen9 halamanMarine HosemtajikBelum ada peringkat

- Demag Cranes CatalogDokumen20 halamanDemag Cranes Catalogmadhukarreddy2811100% (2)

- Us 4962706Dokumen8 halamanUs 4962706drivinerBelum ada peringkat

- Iml Tini: (12) United States PatentDokumen54 halamanIml Tini: (12) United States PatentBCristinBelum ada peringkat

- United States Patent (191: Bourne (45) Jan. 27, 1981Dokumen14 halamanUnited States Patent (191: Bourne (45) Jan. 27, 1981Angel Andres GutiérrezBelum ada peringkat

- Concept Report - Northridge/GA-400 Bridge InterchangeDokumen91 halamanConcept Report - Northridge/GA-400 Bridge InterchangeJoe SeconderBelum ada peringkat

- United States Patent: (12) (10) Patent N0.: US 6,523,785 B1Dokumen11 halamanUnited States Patent: (12) (10) Patent N0.: US 6,523,785 B1HRBelum ada peringkat

- United States Patent: Rozum Et A) - (10) Patent N0.: (45) Date of PatentDokumen15 halamanUnited States Patent: Rozum Et A) - (10) Patent N0.: (45) Date of PatentomikamiBelum ada peringkat

- Us 5146749Dokumen6 halamanUs 5146749Juan Sebastian AguirreBelum ada peringkat

- United States Patent (191: Moriya Et A1Dokumen8 halamanUnited States Patent (191: Moriya Et A1a5216730Belum ada peringkat

- United States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentDokumen24 halamanUnited States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentFaizan KhanBelum ada peringkat

- United States Patent 1191 1111 4,030,523: Cram Et A1. (45) 7 June 21, 1977Dokumen5 halamanUnited States Patent 1191 1111 4,030,523: Cram Et A1. (45) 7 June 21, 1977Brunno VasquesBelum ada peringkat

- United States Patent (19) (11) Patent Number: 4,859,054: Harrison (45) Date of Patent: Aug. 22, 1989Dokumen9 halamanUnited States Patent (19) (11) Patent Number: 4,859,054: Harrison (45) Date of Patent: Aug. 22, 1989drivinerBelum ada peringkat

- Us 5343795Dokumen11 halamanUs 5343795drivinerBelum ada peringkat

- Ulllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999Dokumen13 halamanUlllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999kthuang1Belum ada peringkat

- FisaTehnologica-3 2 FT2 - 87Dokumen67 halamanFisaTehnologica-3 2 FT2 - 8717ges100% (1)

- United States Patent (191: Bieniosek (45) Date of Patent: May 23, 1989Dokumen4 halamanUnited States Patent (191: Bieniosek (45) Date of Patent: May 23, 1989harishkumarsinghBelum ada peringkat

- United States Patent (191 4,774,373: Hundeck Et Al. (11) Patent Number: (45) Date of PatentDokumen4 halamanUnited States Patent (191 4,774,373: Hundeck Et Al. (11) Patent Number: (45) Date of PatentChrisna Al HafizBelum ada peringkat

- EarlyvalkyrieDokumen56 halamanEarlyvalkyrieJohn SuttonBelum ada peringkat

- Serdox AppsDokumen13 halamanSerdox AppsCesar MartinezBelum ada peringkat

- Olo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelsDokumen4 halamanOlo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelspabusaoBelum ada peringkat

- United States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentDokumen8 halamanUnited States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentAnonymous LEVNDh4Belum ada peringkat

- Us 5349313Dokumen11 halamanUs 5349313Ervin John Yu DyBelum ada peringkat

- United States Patent: Schoenfeld Et A1. (10) Patent N0.: (45) Date of PatentDokumen10 halamanUnited States Patent: Schoenfeld Et A1. (10) Patent N0.: (45) Date of Patentwerwer44345Belum ada peringkat

- Web 1T: (12) United States PatentDokumen18 halamanWeb 1T: (12) United States PatentadeindrawijayaBelum ada peringkat

- (Rushton, A) VHDL For Logic Synthesis Second Edition (Wiley, 1998) (ISBN 0-471-98325-X)Dokumen390 halaman(Rushton, A) VHDL For Logic Synthesis Second Edition (Wiley, 1998) (ISBN 0-471-98325-X)Mohammed MolhemBelum ada peringkat

- Lecture 42Dokumen0 halamanLecture 42Kazim RazaBelum ada peringkat

- United States Patent (19) : Kondo (11) Patent Number: (45) Date of PatentDokumen7 halamanUnited States Patent (19) : Kondo (11) Patent Number: (45) Date of PatentMeow ChixBelum ada peringkat

- Us 6362718 (US Patent For Free Energy Device)Dokumen15 halamanUs 6362718 (US Patent For Free Energy Device)jajahahaBelum ada peringkat

- CH 12 Rod & Ball MillsDokumen40 halamanCH 12 Rod & Ball Millsismael1806Belum ada peringkat

- Gel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2Dokumen9 halamanGel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2b4rfBelum ada peringkat

- United States Patent: (12) (10) Patent N0.: US 7,011,171 B1Dokumen33 halamanUnited States Patent: (12) (10) Patent N0.: US 7,011,171 B1Murasa2009Belum ada peringkat

- Us 4236157Dokumen8 halamanUs 4236157drivinerBelum ada peringkat

- Development and Testing of Sugarcane Juice Extractor: Agidi GbaboDokumen5 halamanDevelopment and Testing of Sugarcane Juice Extractor: Agidi Gbabomekanic24100% (1)

- Sri Lanka Valve Standard 1184Dokumen15 halamanSri Lanka Valve Standard 1184Allen VargheseBelum ada peringkat

- Denison Calzoni Type MRT Mrte MRTFDokumen24 halamanDenison Calzoni Type MRT Mrte MRTFSilvio RomanBelum ada peringkat

- Ulllted States Patent (10) Patent N0.: US 8,362,408 B2Dokumen11 halamanUlllted States Patent (10) Patent N0.: US 8,362,408 B2werwer44345Belum ada peringkat

- Research 2Dokumen45 halamanResearch 2anaqiaisyahBelum ada peringkat

- Research 3Dokumen22 halamanResearch 3anaqiaisyahBelum ada peringkat

- Instruction Book Part 2Dokumen280 halamanInstruction Book Part 2George Arimana100% (1)

- Pile Driving System-Minimum CostDokumen8 halamanPile Driving System-Minimum CostSACHIN H. DHAMAPURKARBelum ada peringkat

- Dance of The VampiresDokumen228 halamanDance of The VampiresRoelof van der SarBelum ada peringkat

- (12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1Dokumen13 halaman(12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1danceBelum ada peringkat

- CHANDWA List of Designations TGE2745-R03Dokumen13 halamanCHANDWA List of Designations TGE2745-R03suleman247Belum ada peringkat

- Sorvall Rotor Gsa Gs3 Sa600 Se12 Sm24 Ss34 ManualDokumen72 halamanSorvall Rotor Gsa Gs3 Sa600 Se12 Sm24 Ss34 ManualManuel FloresBelum ada peringkat

- Us 3977329Dokumen4 halamanUs 3977329gtr56Belum ada peringkat

- United States Patent (191: PodhraskyDokumen30 halamanUnited States Patent (191: PodhraskySaideepNarasimhanBelum ada peringkat

- United States Patent (10) Patent No.: US 8,301,867 B1Dokumen12 halamanUnited States Patent (10) Patent No.: US 8,301,867 B1Ghouse MohammedBelum ada peringkat

- Demag Hoist Units Vol1Dokumen96 halamanDemag Hoist Units Vol1skeomeopojeoBelum ada peringkat

- Glastic Standoffs InsulatorsDokumen2 halamanGlastic Standoffs Insulatorsdanielliram993Belum ada peringkat

- 2011 Donors Trust 990Dokumen111 halaman2011 Donors Trust 990airlifter2Belum ada peringkat

- Valves Series NA: Electropneumatically Operated G1/4 3/2 - 5/2 - 5/3 Way With Interface According NAMUR StandardDokumen5 halamanValves Series NA: Electropneumatically Operated G1/4 3/2 - 5/2 - 5/3 Way With Interface According NAMUR StandardDiana DrutaBelum ada peringkat

- United States Patent: (10) Patent N0.: (45) Date of PatentDokumen6 halamanUnited States Patent: (10) Patent N0.: (45) Date of Patent89gt89gtBelum ada peringkat

- Umted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Dokumen15 halamanUmted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Phan Trọng NghĩaBelum ada peringkat

- May 1, 1951 E. - Siders 2,550,873: Toy Repeating Rubber Band Pistol ' Filed Jan. 26, 1948 ' 2 Sheets-Sheet LDokumen4 halamanMay 1, 1951 E. - Siders 2,550,873: Toy Repeating Rubber Band Pistol ' Filed Jan. 26, 1948 ' 2 Sheets-Sheet LHéglison MarquesBelum ada peringkat

- Hapag Lloyd Europa 2 2014/2015 Online BrochureDokumen32 halamanHapag Lloyd Europa 2 2014/2015 Online BrochureJames Crossland0% (1)

- Studies On Aerodynamic Behavior and Performance of Aerospike NozzlesDokumen9 halamanStudies On Aerodynamic Behavior and Performance of Aerospike NozzlesAswith R ShenoyBelum ada peringkat

- Electronic Circuit Design Ideas: Edn Series for Design EngineersDari EverandElectronic Circuit Design Ideas: Edn Series for Design EngineersPenilaian: 5 dari 5 bintang5/5 (2)

- International Society for Rock Mechanics: List of Members 1980Dari EverandInternational Society for Rock Mechanics: List of Members 1980Penilaian: 3.5 dari 5 bintang3.5/5 (2)

- Iphone and Its Supply Chain: Identifying Winners Through The ChainDokumen60 halamanIphone and Its Supply Chain: Identifying Winners Through The ChainluanleBelum ada peringkat

- Evaluation of DC Voltage Ripple in Three-Phase PWM Voltage Source InvertersDokumen7 halamanEvaluation of DC Voltage Ripple in Three-Phase PWM Voltage Source InvertersluanleBelum ada peringkat

- Energies: Analysis of Dc-Link Voltage Switching Ripple in Three-Phase PWM InvertersDokumen14 halamanEnergies: Analysis of Dc-Link Voltage Switching Ripple in Three-Phase PWM InvertersluanleBelum ada peringkat

- Evaluation of Current Ripple Amplitude in Three-Phase PWM Voltage Source InvertersDokumen6 halamanEvaluation of Current Ripple Amplitude in Three-Phase PWM Voltage Source InvertersluanleBelum ada peringkat

- Riku Konishi - 09062020 - 0322 PDFDokumen1 halamanRiku Konishi - 09062020 - 0322 PDFluanleBelum ada peringkat

- Kirchoff RuleDokumen19 halamanKirchoff RuleluanleBelum ada peringkat

- PSpice LibraryguideOrCADDokumen11 halamanPSpice LibraryguideOrCADluanleBelum ada peringkat

- MoappDokumen5 halamanMoappluanleBelum ada peringkat

- FS-N10 Um 96141e GB 1012-3Dokumen116 halamanFS-N10 Um 96141e GB 1012-3luanleBelum ada peringkat

- Data Sheet: SpecificationsDokumen2 halamanData Sheet: SpecificationsluanleBelum ada peringkat

- FS-N11N US en-USDokumen3 halamanFS-N11N US en-USluanleBelum ada peringkat

- Castle Creations, Inc.: Edge HV 120Dokumen1 halamanCastle Creations, Inc.: Edge HV 120luanleBelum ada peringkat

- 2RC FilterDokumen14 halaman2RC FilterluanleBelum ada peringkat

- Esp 140131Dokumen2 halamanEsp 140131luanleBelum ada peringkat

- Applying Wireless Sensor Networks in An Online Monitoring and Energy Management System For Industrial MotorsDokumen9 halamanApplying Wireless Sensor Networks in An Online Monitoring and Energy Management System For Industrial MotorsluanleBelum ada peringkat

- Eneorec 46hfDokumen1 halamanEneorec 46hfluanleBelum ada peringkat

- Quick Guide To Precision Measuring InstrumentsDokumen1 halamanQuick Guide To Precision Measuring InstrumentsluanleBelum ada peringkat

- Quick Guide To Precision Measuring InstrumentsDokumen1 halamanQuick Guide To Precision Measuring InstrumentsluanleBelum ada peringkat

- Quick Guide To Precision Measuring Instruments: Catalog No. E11003Dokumen1 halamanQuick Guide To Precision Measuring Instruments: Catalog No. E11003luanleBelum ada peringkat

- CPW-Fed Planar Printed Monopole Antenna With Impedance Bandwidth EnhancedDokumen4 halamanCPW-Fed Planar Printed Monopole Antenna With Impedance Bandwidth EnhancedTâm Trần ĐứcBelum ada peringkat

- Level Sensors Optical Level Switch, MHF15Dokumen5 halamanLevel Sensors Optical Level Switch, MHF15Diego AlejandroBelum ada peringkat

- Physics Imp Derivations + TheoryDokumen6 halamanPhysics Imp Derivations + TheoryAL Surya67% (3)

- 1 Coulombs Law and Principle of SuperpositionDokumen14 halaman1 Coulombs Law and Principle of Superpositionpaulkani-ece100% (11)

- Interference Suppression PCX2 335M Film Capacitors (100 )Dokumen7 halamanInterference Suppression PCX2 335M Film Capacitors (100 )eduinnBelum ada peringkat

- VHF Antenna For WindowDokumen4 halamanVHF Antenna For WindowLeonard AntelizBelum ada peringkat

- Ac Servo Motor LabDokumen23 halamanAc Servo Motor LabHardik SharmaBelum ada peringkat

- Mindray Wato EX-65 Anaesthesia Machine - Service ManualDokumen322 halamanMindray Wato EX-65 Anaesthesia Machine - Service ManualGabriela Sagyta76% (21)

- Replenisher Electrostatic MachineDokumen3 halamanReplenisher Electrostatic MachineStuart LittleBelum ada peringkat

- USTERDokumen5 halamanUSTERchiragBelum ada peringkat

- DLPDokumen5 halamanDLPJonel BarrugaBelum ada peringkat

- NucleusDokumen57 halamanNucleusSuhail KunjavaBelum ada peringkat

- Clemente Figuera, Et AlDokumen9 halamanClemente Figuera, Et AlTomislav JovanovicBelum ada peringkat

- ERRORLESS Unit ND DimensionsDokumen25 halamanERRORLESS Unit ND DimensionsMoon KnightBelum ada peringkat

- Lecture Electromagnetic WavesDokumen14 halamanLecture Electromagnetic WavesBill WhiteBelum ada peringkat

- Electrostates DPP 3 Advance PDFDokumen46 halamanElectrostates DPP 3 Advance PDFMridul GuptaBelum ada peringkat

- NCERT Grade-12 Physics CH 06 Electromagnetic-Induction1Dokumen15 halamanNCERT Grade-12 Physics CH 06 Electromagnetic-Induction1Raunak KumarBelum ada peringkat

- Abort SwitchDokumen1 halamanAbort SwitchYosses Sang NahkodaBelum ada peringkat

- IS 15882-2009 Ballasts For Discharge LampsDokumen17 halamanIS 15882-2009 Ballasts For Discharge Lampsjagadees_eiBelum ada peringkat

- Chemistry Angelini 2021Dokumen70 halamanChemistry Angelini 2021Samuel BabachevBelum ada peringkat

- Table ElectricalDokumen12 halamanTable ElectricalTobias Fan boyBelum ada peringkat

- Spare Parts Catalogue Castel 2020Dokumen90 halamanSpare Parts Catalogue Castel 2020ИгорьBelum ada peringkat

- Radar Jammer in MatlabDokumen42 halamanRadar Jammer in MatlabNag ChallaBelum ada peringkat

- RXSF Flag Relay - UnlockedDokumen20 halamanRXSF Flag Relay - UnlockedDaniel ChristianBelum ada peringkat

- CERN2009a - UnknownDokumen22 halamanCERN2009a - UnknownAnkitBelum ada peringkat

- Wavelength PDFDokumen3 halamanWavelength PDFPranita SharmaBelum ada peringkat

- Admmodule s11 12ps Iiia 1Dokumen27 halamanAdmmodule s11 12ps Iiia 1Lebz Ricaram100% (2)

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Dokumen9 halamanHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilBelum ada peringkat

- Mikro - Power Factor RegulatorDokumen6 halamanMikro - Power Factor Regulatorshawonscribd67% (3)

- Lect 32 33 CycloconverterDokumen37 halamanLect 32 33 CycloconverterVishal MeghwarBelum ada peringkat