An Introduction to Wire Rope Types and Construction

Diunggah oleh

windgust82Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

An Introduction to Wire Rope Types and Construction

Diunggah oleh

windgust82Hak Cipta:

Format Tersedia

AN INTRODUCTION TO WIRE ROPE

Wire rope is metal in its strongest form. It consists of a group of strands laid helically around a

core. The strands of a wire rope, or cable, consist of a number of individual wires laid about a

central wire.The terms wire rope and cable are used interchangeably. There is some tendency

to use the term wire rope for sizes in. and larger and cable for the smaller sizes. But this is

not uniform practice and either name is correct.

Wire rope is versatile. It can be used to transmit motion through almost any plane or angle, to guy

or tie down, to hold back, launch or control; to counterbalance; to guide or to lift; or to do

hundreds of other jobs. It has a long life and needs little or no maintenance.

Most people do not think of wire rope as a machine, but it is. It is a machine composed of a

number of precise, moving partsall designed to bear a very definite relation to one another. In

fact, some wire ropes contain more moving parts than many complicated mechanisms. A six-

strand rope consisting of 49 wires per strand, laid around an independent wire rope core, contains

a total of 343 individual wires. All of these must be able to blend and move with respect to one

another if the rope is to have the flexibility necessary for successful operation.

BASIC TYPES OF WIRE ROPE

1. Bright wire. Most ropes are made with an uncoated (bright) wire that is manufactured

from high-carbon steel. The chemistry of the steel used and the practice involved in

drawing the wire are varied to supply the ultimate combination of tensile strength, fatigue

resistance, and wear resistance in the finished rope.

2-Galvanized wire. This is often used to improve corrosion resistance of wire ropes. Possible

methods of manufacturing:

Galvanized to finished size wire is first drawn as a bright wire to a predetermined size

thats smaller than the required finished wire size. This wire is then run through the

galvanizing line, and the resultant coating of zinc increases the wire diameter to the

finished size. Galvanized to finished size wire has a strength 10% lower than the same size

and type of bright wire. Ropes made from this wire therefore have a minimum breaking

force thats 10% lower than the equivalent size and grade of bright rope.

Drawn galvanized wire is galvanized before the final drawing to finished size. Since the

galvanized coating also goes through the drawing process, it is much thinner than the

coating on galvanized to finished size wire. Drawn galvanized wires are equal in strength

to the same size and type of bright wire and drawn galvanized rope is equal in strength to

the same size and grade of bright rope.

3-Galvanized aircraft wire. A galvanized wire that has higher tensile strength and fatigue

resistance. Its primary usage is in aircraft control cables.

4-Stainless steel wire. This is a special alloy containing approximately 18% chromium and 8%

nickel. It has high resistance to many corrosive conditions and is used extensively in yachting

ropes and control cables

ROPE MATERIALS

Wire rope, with but few exceptions, is made from cold drawn carbon steel wires. There have been

many different strength grades of rope made. Some are listed below in the order of increasing

strengths:

Iron (actually low carbon steel)

Traction steel

Mild plow steel

Plow steel

Improved plow steel

Extra improved plow steel

The bulk of commercial wire rope is made from Improved Plow Steel (IPS), a high-carbon steel

with a tensile strength of about 260,000 psi. IPS is about 15% stronger than plow steel, which got

its name from the original high-carbon crucible furnace steel used to produce plowshares.

An even higher grade is Extra Improved Plow Steel, which is 15% stronger than IPS. Various

manufacturers have their own name for this grade. It was developed for applications needing

greater safety factors without a diameter increase, such as rotary oil well drillingand for

maximum resistance to abrasive wear, such as draglines in strip mining through rocky terrain. This

premium grade has tensile strength ranging from 280,000 to 340,000 psi. Each of these grades are

usually furnished in bright or self-colored condition, which means that no special metallic or

chemical coating has been applied, except for lubrication.

If operating conditions necessitate greater resistance to corrosion than that provided by the usual

bright carbon steel wires, galvanized wires can be used. The resulting wire ropes usually have

listed strengths 10% less than corresponding types of bright carbon steel rope. Usually the grease

applied to a rope at the point of final twist during manufacture is sufficient to lubricate the rope

against internal abrasion and to protect it against normal oxidation.

Two other grades are iron and traction. Iron is a misnomer; it is a low carbon steel wire of about

100,000 psivery ductile and able to undergo repeated bending stresses around small sheaves.

Although largely replaced by traction, it still remains effective for guys, tillers and sash ropes.

Traction steel gets its name from the traction type elevators on which it has found widespread

acceptance as a hoisting rope. Its tensile strength ranges from 180,000 to 190,000 psi. Its high

resistance to bending fatigue and minimum abrasive force on sheaves and drums are both of

extreme importance for long life in elevator service.

The grades mention above are the important grades used for construction, mining and industrial

equipment. However there are other materials available, such as galvanized aircraft cable and

stainless steel aircraft cable, both of which are for specialized applications. Some bronze ropes are

also available for marine use, and monel metal has occasionally been used for corrosion resistance.

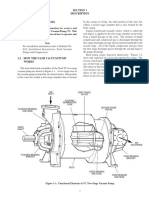

PARTS

GENERAL.

Wire rope is composed of three parts:

WIRES THAT FORM THE STRAND

MULTI-WIRE STRANDS: Laid helically around a core

THE CORE

The basic unit is the wire. A predetermined number of wires of proper size are fabricated in a

uniform geometric arrangement of definite pitch or lay to form a strand of required diameter. The

required number of strands are then laid together symmetrically around a core to form the rope.

CORE TYPE.

In general, wire rope cores are of three types:

Fiber

Wire strand

Independent wire rope

Each type of core serves the basic purpose of affording support to the strands laid around it.

FIBRE CORE (FC)

Adequate for many types of service providing maximum flexibility and elasticity to the wire rope.

Made of hard fibres, usually sisal or manila, most often used today is polypropylene. These latter

cores are useful where conditions surrounding rope use could result in premature failure of natural

fibre cores. Sisal and manila fibre cores are impregnated during the cordage process with a

suitable lubricant having preservative properties. Fiber Core provides excellent flexibility

INDEPENDENT WIRE ROPE CORE (IWRC)

Consists of a 6 x 7 strand steel wire rope with a 7 wire wagge strand. This core finds greatest

use where ropes are subjected to severe pressure while running over sheaves or winding onto

drums. This type of core should be used when a rope operates in temperatures damaging to

natural or man-made fibres. It provides additional strength and less stretch. IWRC (independent

Wire Rope Core) provides good crush resistance and increased strength

STEEL STRAND CORE (WSC)

Consists of a strand of steel wires, nominally 7, 19 or 37 in numbers. It is used occasionally in

running rope of smaller diameters rather than IWRC. It may also be used in stranding ropes,

guys, suspender ropes, etc. Where extra strength, reduced stretch and maximum resistance to

weathering are required.

CORE MATERIAL.

Wire-rope cores are made of fiber, cotton, asbestos, polyvinyl plastic or wire.

Manila or sisal fiber (F.C.) is the type of core often used when loads are not too great. It supports

strands in their relative positions and cushions the wires to prevent their nicking each other.

Cotton fiber is used for small ropes such as sash cord and aircraft cord.

Asbestos cores can be furnished for certain operations where the ripe is used in oven operations.

Wire cores are made in two different forms.

The one used most extensively is a wire rope of suitable size to serve as a core. It is called as

independent wire rope core (IWRC).

The other type of wire core is a wire strand structure (WSC or SC). This consists of a multiple-

wire strand, and may be the same construction as the main rope strands.

Plastic cores include the four following general types:

Polypropylene cores, made up of a multiplicity of synthetic filaments extruded from a

petrochemical resin. These are similar in physical construction to fiber cores.

Plastic impregnated fibre cores are sisal fiber cores impregnated with polyvinyl chloride (PVC).

Solid plastic cores are rods of PVC plastic.

Plastic covered fibre cores have PVC extruded to a specific thickness around the core.

Fiber cores look like an ordinary hemp fiber rope. But in construction and lubrication they will

differ somewhat. Because of its wearing qualities and resiliency this core was for years the most

popular center. But wire cores offer less stretch, have better resistance to heavy crushing loads and

are not affected by heat.

The IWRC type has about the same flexibility as the fiber core rope and can be used

interchangeably without changing sheaves or drums. It increases the rope strength by at least

7.5%.

CHOICE OF CORE.

Fiber cores are adequate for most types of service. Not only do they provide the necessary

foundation, but they also add to the pliability of a wire rope. There are some installations,

however, where conditions are such that a fiber core is inadequate; in these cases a wire strand or

independent wire rope core is used. For service where high operating pressures are encountered,

where resistance to heat, additional strength, or minimum stretch is a prerequisite, either a strand

core or an independent wire rope core is used.

WIRE ROPE ASSEMBLIES

Wire rope become assembly when its ends are altered by some form of splice, or by addition of

fittings. They may be used for operating controls, as a part of machinery and equipment, or for

slings and hoists.

Hand-spliced endings have largely been replaced by other methods of end fitting. Because the

splice efficiency depends entirely upon the skill of the person doing the splicing, this type does not

consistently produce the ropes full strength. Under a tension load the splice may part at a stress

lower than the ropes rated strength and surely less than the actual strength of the rope

Zinced endings: There are three types of zinced endings: A cone is formed from molten zinc

poured into a mold in which a frayed rope end has been inserted; sometimes a ferrule is used as

mold and stays on after pouring the zinc; or sockets are used instead of the ferrule. An open socket

has ears to hold a pin and cotter. A closed socket has a loop or bail. Both are heavy forgings and

find widespread use.

All three zinced on endings need a good deal of preparation. The ropes end must be broomed out,

cleaned with acid and straightened.

Special endings: such as thimbles, clips, and clamps are quicker and easier to apply than a zinc

socket, but efficiency is not as high as with other attachments. These are filed attachments and

inspection is necessary during service to make sure the nuts on the clips remain tight and provide

proper holding power. Clips are U-shaped bolts with a grooved base and nuts to tighten-these and

other grooved devices fit around a rope to form loops, or to provide endings similar to zinced

sockets. In some cases, special thimbles and bolted clamps are used instead of clips.

Mechanical endings: A mechanical splice consists of a loop in the end of a rope and a sleeve

pressed on the rope at the base of the loop to hold the end of the strands in place.

Swaged endings: Swaging is the cold-flowing, under pressure, of metal fittings into the rope body,

between strand sand wires. This pressure, applied by press or by rotary waggers, elongates the

fitting but forces its metal inward so that the bond becomes permanent and compact, yet as strong

as the breaking strength of the rope.

Wire rope slings-Safety is of paramount importance in any wire rope sling. It is important to

remember, where a sling with two or more legs is involved, that consideration must be given to the

fact that the stress in a sling varies with the angle at which the legs are used.

Some of the simpler sling arrangements, or hitches as they are called, are listed below. Space does

not permit a fuller discussion of slings, particularly multiple-leg types, in this issue.

Normally, 6x19 class wire rope is recommended where a diameter in the to 1-1/8 in. range is to

be used, and 6x37 class wire rope where a diameter in the 1-1/4 and larger range is to be used. In

some cases the 6x19 class may be used even in the larger sizes if resistance to abrasion is of

primary importance, and the 6x37 class in the smaller sizes if greater flexibility is desired.

Straight lift hitch is a straight connector between crane hook and load.

Basket hitch may be used with two hooks so that the sides are vertical, or with a single hook with

sides at various angles.

Choker hitch is widely used for lifting bundles of items such as bars, poles and pipe. The choker

hitch holds these items firmly but the load must be balanced so that it rides safely.

Many slings are constructed by braiding several individual wire ropes together.

REFERENCES

www.thomasregister.com

www.mainco.co.uk

www.jhenryholland.com

www.usace.army.mil/publications/eng-manuals/em1110-2-3200/c-5.pdf

Anda mungkin juga menyukai

- An Introduction To Wire RopeDokumen13 halamanAn Introduction To Wire Ropewindgust82Belum ada peringkat

- An Introduction To Wire RopeDokumen10 halamanAn Introduction To Wire Ropenishanth132100% (1)

- WireRopeBasics ClassificationFeaturesDokumen5 halamanWireRopeBasics ClassificationFeaturesbibin2010Belum ada peringkat

- Understanding Wire Rope Components and ConstructionDokumen12 halamanUnderstanding Wire Rope Components and ConstructionZachBelum ada peringkat

- Wire RopesDokumen7 halamanWire RopesZednanreh JessieBelum ada peringkat

- Steel Wire Rope CatalogDokumen148 halamanSteel Wire Rope CatalogEugeniu GudumacBelum ada peringkat

- Everything You Need to Know About Wire RopesDokumen95 halamanEverything You Need to Know About Wire Ropesengrsyoti100% (1)

- Draglineguide9 10Dokumen16 halamanDraglineguide9 10Antonio RibeiroBelum ada peringkat

- Inspection of WiresDokumen12 halamanInspection of Wiresdenis_john_2Belum ada peringkat

- 02 Wire Rope StrandDokumen39 halaman02 Wire Rope Strandmanuelperezz2567% (3)

- Technological Advancements in Wire RopesDokumen6 halamanTechnological Advancements in Wire RopesMinaBasconBelum ada peringkat

- Wire RopeDokumen16 halamanWire Ropesori1386Belum ada peringkat

- Wire Rope: Bright, Galvanized & Stainless SteelDokumen3 halamanWire Rope: Bright, Galvanized & Stainless SteelAvinash SharmaBelum ada peringkat

- Steel Wire RopesDokumen23 halamanSteel Wire RopeskevinBelum ada peringkat

- Chainman Catalogue EditDokumen57 halamanChainman Catalogue EditRem LaraziBelum ada peringkat

- WireDokumen51 halamanWireMadhav Rajpurohit100% (1)

- Lubrication Basics for Wire Ropes: Penetrating and Coating LubricantsDokumen5 halamanLubrication Basics for Wire Ropes: Penetrating and Coating LubricantsSOUMENBelum ada peringkat

- 2) Peak Performance Practices - Wire RopeDokumen40 halaman2) Peak Performance Practices - Wire RopeSM_Ing.Belum ada peringkat

- Catalogue Ropes enDokumen136 halamanCatalogue Ropes enSAKIBBelum ada peringkat

- Elevator-Ropes Usha MartinDokumen24 halamanElevator-Ropes Usha MartinAlberto Tavares100% (2)

- 12 - White Paper - Lubrication Basics For Wire RopesDokumen6 halaman12 - White Paper - Lubrication Basics For Wire RopesJuan David JohnsonBelum ada peringkat

- AustraliaDokumen343 halamanAustraliaChandan KumarBelum ada peringkat

- Wire RopeDokumen32 halamanWire RopeFariz SafarullaBelum ada peringkat

- Wire Rope BookletDokumen27 halamanWire Rope BookletVasanth RaghavanBelum ada peringkat

- 2.2 Wire RopesDokumen20 halaman2.2 Wire Ropesrfelippe8733Belum ada peringkat

- Mining Machinery Nit RourkelaDokumen343 halamanMining Machinery Nit RourkelaNaren Gujjar100% (8)

- Wire Rope ConstructionDokumen3 halamanWire Rope ConstructionLutfi IsmailBelum ada peringkat

- Finals 2 WIRE ROPES Design UploadDokumen11 halamanFinals 2 WIRE ROPES Design UploadDL ArtsBelum ada peringkat

- Project Report On Wire RodDokumen9 halamanProject Report On Wire RodEIRI Board of Consultants and Publishers100% (1)

- Mazzella WireRopeAtAGlance 0919Dokumen5 halamanMazzella WireRopeAtAGlance 0919Tarek HareedyBelum ada peringkat

- 3 Wire RopeDokumen11 halaman3 Wire RopesoniBelum ada peringkat

- Lifting and Crane Safety GuideDokumen41 halamanLifting and Crane Safety GuideSarferi AbdullahBelum ada peringkat

- Material: Rope Wire Helix Wrought Iron SteelDokumen6 halamanMaterial: Rope Wire Helix Wrought Iron Steelrea_rodriguezBelum ada peringkat

- Rope IIIDokumen20 halamanRope IIIDhruv ShindeBelum ada peringkat

- SG 318 2 PDFDokumen13 halamanSG 318 2 PDFChris GodwinBelum ada peringkat

- Lubrication Basics For Wire RopesDokumen5 halamanLubrication Basics For Wire RopesGuru Raja Ragavendran NagarajanBelum ada peringkat

- Wire Rope 101: What Wire Rope Is... Wire Rope Design & ConstructionDokumen1 halamanWire Rope 101: What Wire Rope Is... Wire Rope Design & ConstructionRaghu Dev HosurBelum ada peringkat

- Synthetic Slings PDFDokumen3 halamanSynthetic Slings PDFNeemo FishBelum ada peringkat

- 7 Rigging Rigging Systems Systems: 7-1 IntroductionDokumen72 halaman7 Rigging Rigging Systems Systems: 7-1 IntroductionVICTOR MANUELBelum ada peringkat

- Wire Ropes: Diagram of Wire Rope ComponentsDokumen10 halamanWire Ropes: Diagram of Wire Rope Componentskhairulanuarjun100% (4)

- Kiswire General Purpose RopesDokumen28 halamanKiswire General Purpose Ropesdaviko313Belum ada peringkat

- Bis CodesDokumen65 halamanBis CodesPreksha NahataBelum ada peringkat

- Wire Rope GuideDokumen28 halamanWire Rope GuideEmpayus100% (1)

- Wire RopeDokumen9 halamanWire RopeMitanshu ChadhaBelum ada peringkat

- RopesDokumen2 halamanRopesPetralina NaibahoBelum ada peringkat

- 34RRI19 19x7RotationResistantSteelWireRope (IWRC) PDFDokumen1 halaman34RRI19 19x7RotationResistantSteelWireRope (IWRC) PDFMartin Andrew TugadeBelum ada peringkat

- Manual For Wire RopesDokumen25 halamanManual For Wire RopesAnand Agrawal0% (1)

- Wires FinalDokumen120 halamanWires FinalarshabharataBelum ada peringkat

- Wire Rope Common Terms: Hand Laid & Spliced SlingsDokumen2 halamanWire Rope Common Terms: Hand Laid & Spliced SlingsseawizeBelum ada peringkat

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDari EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsBelum ada peringkat

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDari EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyBelum ada peringkat

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsDari EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsBelum ada peringkat

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesDari EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesBelum ada peringkat

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsDari EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsPenilaian: 5 dari 5 bintang5/5 (1)

- Total Acid NumberDokumen1 halamanTotal Acid Numberwindgust82Belum ada peringkat

- Red Velvet Cheese CakeDokumen1 halamanRed Velvet Cheese Cakewindgust82Belum ada peringkat

- OPERATIONAL COST COMPARISON 450RT Centrifugal and Steam Fired ChillerDokumen1 halamanOPERATIONAL COST COMPARISON 450RT Centrifugal and Steam Fired Chillerwindgust82Belum ada peringkat

- OPERATIONAL COST COMPARISON 450RT Centrifugal and Steam Fired ChillerDokumen1 halamanOPERATIONAL COST COMPARISON 450RT Centrifugal and Steam Fired Chillerwindgust82Belum ada peringkat

- English PhrasesDokumen2 halamanEnglish Phraseswindgust82Belum ada peringkat

- Chocolate Cherry CupcakesDokumen1 halamanChocolate Cherry Cupcakeswindgust82Belum ada peringkat

- Great Leader SayingsDokumen1 halamanGreat Leader Sayingswindgust82Belum ada peringkat

- Liquid Ring Vacuum Pump Construction and WorkingDokumen2 halamanLiquid Ring Vacuum Pump Construction and Workingwindgust82Belum ada peringkat

- Human Performance ToolsDokumen15 halamanHuman Performance Toolswindgust82Belum ada peringkat

- Red Velvet Sheet CakeDokumen1 halamanRed Velvet Sheet Cakewindgust82Belum ada peringkat

- Brownies: IngredientsDokumen2 halamanBrownies: Ingredientswindgust82Belum ada peringkat

- English Phrases Part 1Dokumen2 halamanEnglish Phrases Part 1windgust82Belum ada peringkat

- Waky CakeDokumen1 halamanWaky Cakewindgust82Belum ada peringkat

- Chocolate Cherry CupcakesDokumen1 halamanChocolate Cherry Cupcakeswindgust82Belum ada peringkat

- Monitor blower pressure, temperature, and noiseDokumen5 halamanMonitor blower pressure, temperature, and noisewindgust82Belum ada peringkat

- Chocolate Chip CookiesDokumen1 halamanChocolate Chip Cookieswindgust82Belum ada peringkat

- FMEDokumen9 halamanFMEwindgust82Belum ada peringkat

- Latte Tea RecipeDokumen3 halamanLatte Tea Recipewindgust82Belum ada peringkat

- English Direct IndirectDokumen1 halamanEnglish Direct Indirectwindgust82Belum ada peringkat

- FMEDokumen9 halamanFMEwindgust82Belum ada peringkat

- Russian TeaDokumen1 halamanRussian Teawindgust82Belum ada peringkat

- Lemon CakeDokumen2 halamanLemon Cakewindgust82Belum ada peringkat

- GTAW TIG Welding GuideDokumen17 halamanGTAW TIG Welding Guidewindgust82Belum ada peringkat

- Machining Time CalculationDokumen2 halamanMachining Time Calculationwindgust82Belum ada peringkat

- Designing Effective PowerPoint PresentationDokumen48 halamanDesigning Effective PowerPoint Presentationwindgust82Belum ada peringkat

- Effective English WritingDokumen89 halamanEffective English Writingwindgust82Belum ada peringkat

- Effective English WritingDokumen89 halamanEffective English Writingwindgust82Belum ada peringkat

- The Load Extensions Curve For Metallic Wire and Hence Determine The Modulus of Elasticity of Material of WireDokumen5 halamanThe Load Extensions Curve For Metallic Wire and Hence Determine The Modulus of Elasticity of Material of Wirewindgust82100% (1)

- Wire Rope General InformationDokumen16 halamanWire Rope General Informationwindgust82Belum ada peringkat

- Comparision of CTE Values of Different MaterialsDokumen107 halamanComparision of CTE Values of Different MaterialsPurvesh NanavatiBelum ada peringkat

- Estimation Methods For Strain-Life Fatigue Properties From HardnessDokumen15 halamanEstimation Methods For Strain-Life Fatigue Properties From HardnessAmanda SmithBelum ada peringkat

- Tufftride - Qpq-Process: Technical InformationDokumen19 halamanTufftride - Qpq-Process: Technical InformationSinan YıldızBelum ada peringkat

- Synthetic Slag For Secondary SteelmakingDokumen6 halamanSynthetic Slag For Secondary SteelmakingWaqas Ahmed100% (2)

- A 470 - 03 Piezas ForjadasDokumen8 halamanA 470 - 03 Piezas ForjadasWILLIAM ROMEROBelum ada peringkat

- Workshop Manual 2016 PDFDokumen62 halamanWorkshop Manual 2016 PDFgiridharrajeshBelum ada peringkat

- Metallurgy Quiz: Key Concepts and ProcessesDokumen312 halamanMetallurgy Quiz: Key Concepts and ProcessesAditya PrasadBelum ada peringkat

- Effective Cycle Chemistry ControlDokumen29 halamanEffective Cycle Chemistry ControlclesncronBelum ada peringkat

- 204 Mineral Accounts - PhilippinesDokumen43 halaman204 Mineral Accounts - PhilippinesRyca Angela D.Belum ada peringkat

- Off Engine Lube Oil System Cleanliness - Gas GeneratorDokumen3 halamanOff Engine Lube Oil System Cleanliness - Gas GeneratorDenis JimenezBelum ada peringkat

- Material Selection 1-5Dokumen45 halamanMaterial Selection 1-5Abdallah Hashem100% (11)

- Science g7 (1st 2nd Quarter - Tos, Questionnaire, Answer KeyDokumen11 halamanScience g7 (1st 2nd Quarter - Tos, Questionnaire, Answer KeyMariah Thez69% (48)

- Research - What Makes Pascalite WorkDokumen8 halamanResearch - What Makes Pascalite WorkpaulxeBelum ada peringkat

- Physical and Chemical Properties of Minerals and RocksDokumen21 halamanPhysical and Chemical Properties of Minerals and RocksJedidiah Suib II100% (1)

- 701 Armox Workshop RecommendationsDokumen11 halaman701 Armox Workshop RecommendationssudhavelBelum ada peringkat

- Shahuindo Technical Report 2015Dokumen307 halamanShahuindo Technical Report 2015Diego Eslava BrionesBelum ada peringkat

- Acids and Bases Weebly FileDokumen5 halamanAcids and Bases Weebly Fileapi-240469044Belum ada peringkat

- 17 Samss 008Dokumen13 halaman17 Samss 008sindalisindiBelum ada peringkat

- Chemical Formulae and Equations Part 2Dokumen18 halamanChemical Formulae and Equations Part 2Mohd NorihwanBelum ada peringkat

- G 15 - 04 - Rze1 PDFDokumen5 halamanG 15 - 04 - Rze1 PDFRahmat Ramadhan PasaribuBelum ada peringkat

- Cement Refractory Manufacturing ProcessDokumen36 halamanCement Refractory Manufacturing ProcessJunaid MushtaqBelum ada peringkat

- Arcelormittal A514 and T-1Dokumen6 halamanArcelormittal A514 and T-1Ali Varmazyar0% (1)

- Igcse Electrochemistry Review PDFDokumen7 halamanIgcse Electrochemistry Review PDFbilly ogadaBelum ada peringkat

- Metals and Alloys: Unit 3Dokumen26 halamanMetals and Alloys: Unit 3AshBelum ada peringkat

- Reaction Stoichiometry Balancer & Atom Economy CalculatorDokumen14 halamanReaction Stoichiometry Balancer & Atom Economy CalculatorshikaswaBelum ada peringkat

- Water Softening MethodsDokumen34 halamanWater Softening MethodsAjitsingh Jagtap100% (1)

- Grade 10 Paper 2Dokumen8 halamanGrade 10 Paper 2jfkdmfmdfBelum ada peringkat

- Conductivity Sorted by Resistivity Eddy Current TechnologyDokumen14 halamanConductivity Sorted by Resistivity Eddy Current TechnologyKalai VananBelum ada peringkat

- Topic.4 Chemical Bonding and CatalysisDokumen19 halamanTopic.4 Chemical Bonding and Catalysispoonamwaingade_20095Belum ada peringkat

- Speeds and Feeds: © 2013 Project Lead The Way, Inc. Computer Integrated ManufacturingDokumen28 halamanSpeeds and Feeds: © 2013 Project Lead The Way, Inc. Computer Integrated ManufacturingAbel David Olmos BotelloBelum ada peringkat