Hvacrnation 2009 02 f03

Diunggah oleh

norfirdaus83100 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

17 tayangan2 halamanThe document discusses issues with incorrectly sizing refrigeration piping. It notes that some technicians prioritize cost over proper system design, resulting in less efficient operation. Incorrect piping size can cause problems like reduced capacity and compressor failures. Piping needs to be correctly sized to ensure sufficient refrigerant and oil flow. Selecting the right pipe size, thickness, and material is important to ensure safe and efficient system function.

Deskripsi Asli:

Hvacrnation 2009 02 f03

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThe document discusses issues with incorrectly sizing refrigeration piping. It notes that some technicians prioritize cost over proper system design, resulting in less efficient operation. Incorrect piping size can cause problems like reduced capacity and compressor failures. Piping needs to be correctly sized to ensure sufficient refrigerant and oil flow. Selecting the right pipe size, thickness, and material is important to ensure safe and efficient system function.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

17 tayangan2 halamanHvacrnation 2009 02 f03

Diunggah oleh

norfirdaus8310The document discusses issues with incorrectly sizing refrigeration piping. It notes that some technicians prioritize cost over proper system design, resulting in less efficient operation. Incorrect piping size can cause problems like reduced capacity and compressor failures. Piping needs to be correctly sized to ensure sufficient refrigerant and oil flow. Selecting the right pipe size, thickness, and material is important to ensure safe and efficient system function.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

features

www.hvacrnation.com.au February 2009 HVAC&R Nation 23

>>> SEAN McGOWAN REPORTS

As refrigeration system design becomes increasingly

complex in a bid to achieve the greatest energy

efficiency, some technicians on the ground are favouring

cost ahead of system design to the detriment of the

end user.

According to Roger Stringer, national technical manager

at Actrol, a less than perfect system installation will

always result in less than perfect operation and

performance.

Stringer says the drive towards energy efficiency has

seen a rapid introduction of innovations in design

including capacity control, variable refrigerant volume,

floating head pressures and others which all make piping

design and installation more complicated.

The effect is the goal posts keep moving for the

technicians out there trying to ensure a reliable and cost

effective solution, he says.

Nevertheless, he warns that a cost effective installation

is rarely the cheapest, with cheaper installations almost

always resulting in greater energy consumption. As such,

incorrect selection of refrigeration piping, flow control

and accessories is something the industry needs to

avoid.

We live in a new, environmentally aware market with

consumers wanting to do the right thing. If a system

uses more energy to maintain the design conditions as

a result of poor selection, this will directly impact on the

environment, the consumer and the reputation of the

industry.

Three common errors of

incorrect piping selection

Incorrect pipe selection generally falls into three

categories:

Undersizing

According to Graham Boyle, head of programs for

Swan TAFEs metals, technology and safety divisions,

refrigerant piping is often undersized through ignorance,

convenience or through trying to make a cost saving

because smaller pipes cost less.

Undersized piping results in high internal refrigerant

velocities and good oil return but high line per metre

pressure drops and resultant loss in system capacity;

as well as compressor overheating due to compressor

cooling losses and compressor failures.

Undersizing can come about also by using too many

bends and fittings in the pipe run. As with any fluid

flow, friction creates resistance to flow (so) the longer

the pipe run and the more bends and fittings included

creates friction penalties and a pressure drop in the run,

explains Boyle.

A pressure drop will then create capacity reduction

at the compressor in the case of the suction line

and capacity reduction at the expansion device and

evaporator in the case of the liquid line. Bad pipe design

can cause liquid hang up in the condenser which can

reduce capacity and cause erratic operation of the

expansion device.

Oversizing

Oversized refrigeration piping commonly results in low

refrigerant velocities, poor oil return but also low line per

metre pressure drops, thus no resultant system capacity

losses are experienced. But its false economics.

Refrigeration piping selection get it right

The selection and installation of refrigeration piping continues to be the source

of concern and frustration to many members of the industry. Not only can it lead

to inefcient system operation and performance. In some cases it can also lead

to the voiding of manufacturer warranties, which in turn damages the reputation

of the industry in the eyes of consumers, as Sean McGowan discovered.

Roger Stringer

It is poor economics as oversizing can result in

compressor oil losses and compressor failures due to

a lack of lubricant, warns Ian Paul, head teacher of

refrigeration at NSW TAFE.

Incorrect wall thickness and grading

As popular refrigerants such as R410A and R744(CO

2

)

operate at much higher system pressures, it is essential

to ensure the pipe wall thickness and therefore the

maximum safe working pressure of the pipe system and

all line components used are correctly rated.

Incorrect wall thickness can result in pipe work failures

and splitting pipes, leading to refrigerant leaks.

According to Paul, refrigeration and air conditioning

systems must use refrigeration tube that meets AS/

NZS1571 (the RAC standard) and not AS/NZS1432,

the standard used by plumbers. Furthermore, the

BCA requires pipe insulation in many building types

to comply with AS1530.3-1999 which relates to the

behaviour of the insulation in a fire situation.

The industry is becoming more regulated and many

technicians are not aware of the requirement to comply

with not only the relevant Australian Standards but also

the Building Code of Australia (BCA), adds Stringer.

Dos and donts

of pipe selection

Pipe selection and design is based largely on pressure

drop and velocity requirements, and is therefore

different for liquid, suction, wet suction return and

discharge lines.

Since many of the operational problems encountered in

the field can be traced back to improper design and/or

installation of the refrigerant piping and accessories, the

importance of correct design and installation procedures

cannot be over-emphasised, says Paul.

In general, he says refrigerant piping should be designed

and installed so as to:

1. Ensure an adequate supply of refrigerant

to all evaporators.

2. Ensure positive and continuous return of oil

to the compressor crankcase.

3. Avoid excessive refrigerant pressure losses

which unnecessarily reduce the capacity

and efficiency of the system.

4. Prevent liquid refrigerant from entering the

compressor during either the running or off cycles,

or during compressor start-up.

5. Avoid the trapping of oil in the evaporator or

suction line which may subsequently return to the

compressor in the form of a large slug with possible

damage to the compressor.

Careful attention must be given to the proper sizing

of suction, wet return suction, liquid and discharge lines

if the full rated capacity of the refrigeration equipment

is to be achieved.

Excessive pressure drops can lead to reduced system

capacity, while insufficient vapour velocity causes

compressor lubrication problems.

When a self-contained condensing unit is used on a

particular installation the discharge line does not present

a problem, as this is already sized and piped into the

unit. The suction and liquid line, however, must always

be sized correctly, as excessive pressure drop in either of

these lines will impose a severe penalty on the operating

capacity of the refrigeration compressor.

Paul says refrigerant piping has to maintain refrigerant

flow with minimum pressure drop, and sufficient velocity

to return oil to the compressor. To ensure the efficient

operation of the plant, the piping system should also

contain where necessary fittings, traps and correct pitch

on horizontal runs.

Horses for courses

considering the refrigerant

Every refrigerant and every system has specific design

requirements which must be considered if reliability

and system performance is to be achieved. Therefore

the basic principles of pipe design and installation must

be considered every time as every installation will be

different.

Will the velocity be sufficiently high to return the oil to

the compressor?

Will the pressure drop be within acceptable limits to

ensure a more efficient system?

Are the pipe work and system components rated for the

operating pressures of the system, and of the refrigerant?

So long as these basic design principles are adhered

to, all commonly used refrigerants pose no particular

problems, says Stringer. However, CO

2

systems require

many additional safe guards to ensure a safe, reliable

and efficient system, and it is advisable to consult with

manufacturers and suppliers of equipment before

installation of any CO

2

pipe work.

According to Boyle, different refrigerants also entrain the

oil differently, and therefore require different velocities.

They also have different specific volumes and these

factors are built into the pipe sizing charts.

Other factors include proper bracketing to allow

for expansion and contraction of the pipe, as well

as vibration reduction to prevent pipe cracking and

refrigerant leaks, he says.

Avoid being complacent

Boyle warns that while many piping systems may be

badly designed, the refrigeration system will continue

to operate. This is where complacency needs to be

addressed.

The key point is that they are operating inefficiently,

which means they are using more energy than they

should, but they get away with the inefficiency because

they are generally oversized or often required to operate

at full capacity, when they shouldnt be, he says.

Industry bodies, as well as manufacturers and suppliers,

are working hard to ensure those in the field charged

with the responsibility of installing systems correctly,

have the knowledge and support to do so.

But it also requires technicians to seek advice and keep

abreast of the latest regulations and refrigeration design

techniques.

Change is constantly upon us and ongoing training

will always be required to improve customer outcomes,

says Stringer. s

24 HVAC&R Nation February 2009 www.hvacrnation.com.au

Anda mungkin juga menyukai

- Todays Advanced Hose and Hydraulic SystemsDokumen19 halamanTodays Advanced Hose and Hydraulic SystemsJuan Eduardo PFBelum ada peringkat

- Specifying Shell and Tube Heat ExchangersDokumen10 halamanSpecifying Shell and Tube Heat ExchangersMicheal BrooksBelum ada peringkat

- Avoiding Leakage Seals+Sealing Systems Machinery+Piping Chemengonline.cDokumen3 halamanAvoiding Leakage Seals+Sealing Systems Machinery+Piping Chemengonline.cAnonymous nw5AXJqjdBelum ada peringkat

- 10 Steps To Pump ReliabilityDokumen13 halaman10 Steps To Pump ReliabilityfalconesasBelum ada peringkat

- 630-33 Refrigerant Piping by RsesDokumen31 halaman630-33 Refrigerant Piping by RsesminiongskyBelum ada peringkat

- Mech Seal BFPDokumen13 halamanMech Seal BFPmohammad imronBelum ada peringkat

- Tehcnical Paper: Calculating Freezing Times in Blast and Plate Freezers by Dr. Andy PearsonDokumen36 halamanTehcnical Paper: Calculating Freezing Times in Blast and Plate Freezers by Dr. Andy PearsonBerry_1986_Berry100% (1)

- International Standard For ThermowellDokumen7 halamanInternational Standard For ThermowellShahzad JamesBelum ada peringkat

- 10 Steps To Pump ReliabilityDokumen15 halaman10 Steps To Pump ReliabilityaqhammamBelum ada peringkat

- Refrigerant Piping: By: Cecil R. Visger, Past International PipingDokumen18 halamanRefrigerant Piping: By: Cecil R. Visger, Past International PipingBehnam AshouriBelum ada peringkat

- HPAC - Evaluating Deaerator OperationDokumen5 halamanHPAC - Evaluating Deaerator Operationghostamir100% (1)

- Thermal Design Considerations For Centrifugal Compressor Piping SystemsDokumen5 halamanThermal Design Considerations For Centrifugal Compressor Piping SystemsSerge Rinaudo100% (1)

- Refrigerant Piping Rev2Dokumen31 halamanRefrigerant Piping Rev2123john123Belum ada peringkat

- Best Practices - No.29 Steam TracingDokumen4 halamanBest Practices - No.29 Steam Tracingpedromarques10Belum ada peringkat

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDari EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsPenilaian: 4 dari 5 bintang4/5 (6)

- 10 Tips Refrigerant PipingDokumen3 halaman10 Tips Refrigerant PipingAndres CarrascoBelum ada peringkat

- Flow Assurance Nov6Dokumen5 halamanFlow Assurance Nov6Vinh PhamthanhBelum ada peringkat

- SAE J517 Hydraulic Hose RatingsDokumen6 halamanSAE J517 Hydraulic Hose RatingsR L100% (1)

- Air Preheater Retrofit and EnhancementDokumen9 halamanAir Preheater Retrofit and EnhancementVIBHAVBelum ada peringkat

- Especificaciones Tecnicas Desmantelamiento de ConcretosDokumen14 halamanEspecificaciones Tecnicas Desmantelamiento de ConcretoscarlosalbarBelum ada peringkat

- Mechanical Seal Sept10Dokumen4 halamanMechanical Seal Sept10sureshbabu7374Belum ada peringkat

- Select Pumps WroDokumen2 halamanSelect Pumps Wroagrocel_bhv5591Belum ada peringkat

- Evaluating Deaerator OperationDokumen5 halamanEvaluating Deaerator OperationYanuar KrisnahadiBelum ada peringkat

- Clippard Avoid Electrical Hazards ArticleDokumen4 halamanClippard Avoid Electrical Hazards ArticleJohn Melanathy IIBelum ada peringkat

- Here Are The Most Frequently Asked Questions Answered by Our TechniciansDokumen4 halamanHere Are The Most Frequently Asked Questions Answered by Our TechniciansAmit PatelBelum ada peringkat

- Chapter 3 - PlumbingDokumen8 halamanChapter 3 - PlumbingPrabhakaran DakshinBelum ada peringkat

- Service Bulletin: WarningDokumen11 halamanService Bulletin: Warningninzau100% (1)

- Leak Free Diathermic Oil SystemsDokumen10 halamanLeak Free Diathermic Oil SystemsADITYA_PATHAKBelum ada peringkat

- Gas Piping Best Practices Chris WolfeDokumen11 halamanGas Piping Best Practices Chris WolfeZeshanBelum ada peringkat

- Turbine MaintainanceDokumen9 halamanTurbine Maintainanceer_sanjaypatel100% (2)

- The RoTechBoosterDokumen3 halamanThe RoTechBoosterhtdk312Belum ada peringkat

- Equator 1Dokumen48 halamanEquator 1sajkhdjksahdkjBelum ada peringkat

- Automation Basics - Basics of Thermowell Design and Selection - IsADokumen3 halamanAutomation Basics - Basics of Thermowell Design and Selection - IsAFatoni Gea AirlanggaBelum ada peringkat

- Compressor Dry Gas SealsDokumen12 halamanCompressor Dry Gas SealsRajeev Domble100% (3)

- LineSizing (BUFF)Dokumen22 halamanLineSizing (BUFF)towiwaBelum ada peringkat

- Suction & Liquid Line Sizing Charts Using Line Sizing ChartsDokumen22 halamanSuction & Liquid Line Sizing Charts Using Line Sizing ChartsLyndon Lim LominoqueBelum ada peringkat

- Gast Compressed Air Systems enDokumen11 halamanGast Compressed Air Systems enKrzysiek PodsiadłoBelum ada peringkat

- Tecumseh Refrigerant PipingDokumen24 halamanTecumseh Refrigerant Pipingaries26marchBelum ada peringkat

- Pipeline Sizing: Learning ObjectivesDokumen7 halamanPipeline Sizing: Learning ObjectivesRajasekar MeghanadhBelum ada peringkat

- Selection and Design of CondensersDokumen27 halamanSelection and Design of Condensersjdgh1986Belum ada peringkat

- Steam Tracing Design Considerations and InstallationDokumen6 halamanSteam Tracing Design Considerations and InstallationaimangamalBelum ada peringkat

- Chemical Engineering Magazine Abril 2009 PDFDokumen108 halamanChemical Engineering Magazine Abril 2009 PDFFélix Vargas Santillán100% (1)

- W LT32599 07Dokumen14 halamanW LT32599 07vaglohrdBelum ada peringkat

- Coflexip HosesDokumen58 halamanCoflexip HosesAnis Kacem67% (3)

- Cleaning of Pipeline PDFDokumen9 halamanCleaning of Pipeline PDFAnonymous Xy309m9Sm9100% (3)

- QA For Butt FusionDokumen9 halamanQA For Butt Fusionjimbox88Belum ada peringkat

- A Practical Guide To Rotary ValvesDokumen26 halamanA Practical Guide To Rotary ValvesJeEJyZaBelum ada peringkat

- Mechanical Constraints On Thermal Design of Shell and Tube ExchangersDokumen26 halamanMechanical Constraints On Thermal Design of Shell and Tube Exchangersjdgh1986Belum ada peringkat

- Engineering Design Guidelines Boiler Systems Rev WebDokumen20 halamanEngineering Design Guidelines Boiler Systems Rev WebGerald Lim100% (1)

- Reliability Improvement-Integrally Geared Air CompressorsDokumen20 halamanReliability Improvement-Integrally Geared Air CompressorsAbdulrahman AlkhowaiterBelum ada peringkat

- Choosing Between Cold and Hot Runner SystemsDokumen6 halamanChoosing Between Cold and Hot Runner SystemsJereRAESBelum ada peringkat

- Ps Compressed Air ArticlesDokumen59 halamanPs Compressed Air ArticlesFahad Khan100% (1)

- A Practical Guide To Rotary Valves PDFDokumen26 halamanA Practical Guide To Rotary Valves PDFjaime001254Belum ada peringkat

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Dari EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Penilaian: 3.5 dari 5 bintang3.5/5 (3)

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationDari EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationPenilaian: 1 dari 5 bintang1/5 (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsDari EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsBelum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBelum ada peringkat

- Advanced Temperature Measurement and Control, Second EditionDari EverandAdvanced Temperature Measurement and Control, Second EditionBelum ada peringkat

- How to prepare Welding Procedures for Oil & Gas PipelinesDari EverandHow to prepare Welding Procedures for Oil & Gas PipelinesPenilaian: 5 dari 5 bintang5/5 (1)

- Question N Are 4Dokumen3 halamanQuestion N Are 4norfirdaus8310Belum ada peringkat

- Walk-In Evaporator Coils 101: Published byDokumen6 halamanWalk-In Evaporator Coils 101: Published bynorfirdaus8310Belum ada peringkat

- Information Handling Services, 1999 Febuary 10, 1999 11:03:49Dokumen82 halamanInformation Handling Services, 1999 Febuary 10, 1999 11:03:49norfirdaus8310Belum ada peringkat

- Refrigeration TechnologyDokumen98 halamanRefrigeration TechnologyMONA100% (3)

- Notes - Kotza 139-169Dokumen31 halamanNotes - Kotza 139-169norfirdaus8310Belum ada peringkat

- An Evaporator's Temperature Difference: Ice BreakerDokumen1 halamanAn Evaporator's Temperature Difference: Ice Breakernorfirdaus8310Belum ada peringkat

- Digital Design Course FileDokumen191 halamanDigital Design Course FileCharan NethaBelum ada peringkat

- Sony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Dokumen94 halamanSony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Mauro Mendez100% (1)

- Bearer Independent Call Control Protocol (Cs2) and Signalling System No.7 - Isdn User Part General Functions of Messages and ParametersDokumen31 halamanBearer Independent Call Control Protocol (Cs2) and Signalling System No.7 - Isdn User Part General Functions of Messages and Parameterssahil_chandna25Belum ada peringkat

- Differences Between Huawei ATCA-Based and CPCI-Based SoftSwitches ISSUE2.0Dokumen46 halamanDifferences Between Huawei ATCA-Based and CPCI-Based SoftSwitches ISSUE2.0Syed Tassadaq100% (3)

- The Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4Dokumen2 halamanThe Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4ammarhashmi198633% (12)

- Colleg Fee StructureDokumen1 halamanColleg Fee StructureSriram SaiBelum ada peringkat

- Centaour 50 Solar TurbineDokumen2 halamanCentaour 50 Solar TurbineTifano KhristiyantoBelum ada peringkat

- Hydraulic Backhoe MachineDokumen57 halamanHydraulic Backhoe MachineLokesh SrivastavaBelum ada peringkat

- 2.1 LPC2103 Microcontroller: 2.1.1 FeaturesDokumen18 halaman2.1 LPC2103 Microcontroller: 2.1.1 FeaturesBhaskar Rao PBelum ada peringkat

- Ultrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookDokumen84 halamanUltrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookrancidBelum ada peringkat

- R Values For Z PurlinsDokumen71 halamanR Values For Z PurlinsJohn TreffBelum ada peringkat

- Operation & Service Manual: Murzan IncDokumen38 halamanOperation & Service Manual: Murzan IncgokulBelum ada peringkat

- Contact List For All NWGDokumen22 halamanContact List For All NWGKarthickBelum ada peringkat

- Stand-mount/Books Helf Louds Peaker System Product SummaryDokumen1 halamanStand-mount/Books Helf Louds Peaker System Product SummaryCatalin NacuBelum ada peringkat

- STP Tender Document For 08.05.2018Dokumen32 halamanSTP Tender Document For 08.05.2018Arunprasad DurairajBelum ada peringkat

- HR Report ON Moser BaerDokumen77 halamanHR Report ON Moser BaerKomal DhaliwalBelum ada peringkat

- Lab 01 IntroductionDokumen4 halamanLab 01 IntroductiontsikboyBelum ada peringkat

- Application of Pinnipedvibrissae To AeropropulsionDokumen31 halamanApplication of Pinnipedvibrissae To AeropropulsionShahzadBelum ada peringkat

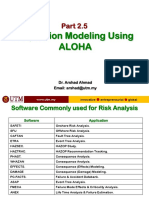

- PLSP 2 6 Aloha PDFDokumen35 halamanPLSP 2 6 Aloha PDFKajenBelum ada peringkat

- Multilin 369Dokumen5 halamanMultilin 369Edo RossBelum ada peringkat

- Edge Wall Final-ModelDokumen1 halamanEdge Wall Final-ModelAbanoub ShakerBelum ada peringkat

- Despiece Completo ThwaittesDokumen60 halamanDespiece Completo ThwaittesJuan Antonio Cano Diaz100% (1)

- Procedure Checklist For Fm200 InstallationDokumen2 halamanProcedure Checklist For Fm200 InstallationJibril Lamai0% (1)

- Sony PMW 200 ManualDokumen141 halamanSony PMW 200 ManualElectra/Off TraxBelum ada peringkat

- CATALO VetivDokumen240 halamanCATALO VetivHữu CôngBelum ada peringkat

- Total Productive Maintenance WorksheetDokumen2 halamanTotal Productive Maintenance WorksheetSeda De Drasnia100% (1)

- Definition of EbookDokumen14 halamanDefinition of EbookNurul IzzahBelum ada peringkat

- Project Reoprt On JSW SteelsDokumen30 halamanProject Reoprt On JSW SteelsSakthi Krishnan100% (1)

- CadDokumen20 halamanCadVivek DesaleBelum ada peringkat

- Adicionando Mais Um Disco (VG) HPUXDokumen4 halamanAdicionando Mais Um Disco (VG) HPUXVinicius SantosBelum ada peringkat