CIP15-Chemical Admixtures For Concrete PDF

Diunggah oleh

7774R1050 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

151 tayangan2 halamanAdmixtures are used to give special properties to fresh or hardened concrete. Entrained air improves the concrete's resistance to damage caused by freezing and thawing. Water reducers reduce water-reducing retarders and accelerators.

Deskripsi Asli:

Judul Asli

CIP15-Chemical Admixtures for Concrete.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAdmixtures are used to give special properties to fresh or hardened concrete. Entrained air improves the concrete's resistance to damage caused by freezing and thawing. Water reducers reduce water-reducing retarders and accelerators.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

151 tayangan2 halamanCIP15-Chemical Admixtures For Concrete PDF

Diunggah oleh

7774R105Admixtures are used to give special properties to fresh or hardened concrete. Entrained air improves the concrete's resistance to damage caused by freezing and thawing. Water reducers reduce water-reducing retarders and accelerators.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

NRMCA

What, Why & How?

Chemical Admixtures

for Concrete

CONCRETE IN PRACTICE CIP 15

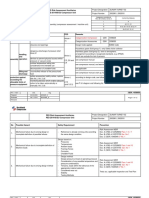

L to R: HRWR, Air-Entraining Agent, Retarder

Relative quantities for one cu.yd.

Chemical Admixtures for Concrete

WHAT are Admixtures?

Admixtures are natural or manufactured chemicals

added to the concrete before or during mixing. The

most often used admixtures are air-entraining agents,

water reducers, water-reducing retarders and accel-

erators.

WHY Use Admixtures?

Admixtures are used to give special properties to fresh

or hardened concrete. Admixtures may enhance the du-

rability, workability or strength characteristics of a

given concrete mixture. Admixtures are used to over-

come difficult construction situations, such as hot or

cold weather placements, pumping requirements, early

strength requirements, or very low water-cement ratio

specifications.

HOW to Use Admixtures

Consult your ready mixed concrete supplier about which

admixture(s) may be appropriate for your application.

Admixtures are evaluated for compatibility with

cementitious materials, construction practices, job speci-

fications and economic benefits before being used.

Follow This Guide to Use Admixtures

1. AIR-ENTRAINING ADMIXTURES are liquid chemicals added

during batching concrete to produce microscopic air

bubbles, called entrained air, when concrete is mixed.

These air bubbles improve the concretes resistance

to damage caused by freezing and thawing and deic-

ing salt application. In plastic concrete entrained air

improves workability and may reduce bleeding and

segregation of concrete mixtures. For exterior flatwork

(parking lots, driveways, sidewalks, pool decks, patios)

that is subject to freezing and thawing weather cycles,

or in areas where deicer salts are used, specify a nor-

mal air content of 4% to 7% of the concrete volume

depending on the size of coarse aggregate (see Table

on the next page). Air entrainment is not necessary for

interior structural concrete since it is not subject to

freezing and thawing. It should be avoided for con-

crete flatwork that will have a smooth troweled finish.

In high cement content concretes, entrained air will

reduce strength by about 5% for each 1% of air added;

but in low cement content concretes, adding air has

less effect and may even cause a modest increased

strength due to the reduced water demand for required

slump. Air entraining admixtures for use in concrete

should meet the requirements of ASTM C 260, Speci-

fication for Air-Entraining Admixtures for Concrete.

2. WATER REDUCERS are used for two different purposes:

(1) to lower the water content in plastic concrete and

increase its strength; (2) to obtain higher slump with-

out adding water. Water-reducers will generally reduce

the required water content of a concrete mixture for a

given slump. These admixtures disperse the cement

particles in concrete and make more efficient use of

cement. This increases strength or allows the cement

content to be reduced while maintaining the same

Copyrighted information from the National Ready Mixed Concrete Association. All rights reserved.

Reproduction prohibited without permission. Print copies can be obtained from NRMCA (301) 587-1400 x 101

National Ready Mixed Concrete Association.

All rights reserved.

No part of this publication may be reproduced in any form, including

photocopying or other electronic means, without permission in writing

from the National Ready Mixed Concrete Association.

Technical information prepared by

National Ready Mixed Concrete Association

900 Spring Street

Silver Spring, Maryland 20910

References

1 . ASTM C 260 C 494, C 1017, D 98, American Society for Test-

ing and Materials (ASTM), West Conshohocken, PA,

www.astm.org.

2. Chemical and Air-Entraining Admixtures for Concrete, ACI

Educational Bulletin, E4, American Concrete Institute,

Farmington Hills, MI, www.aci-int.org.

3. Chemical Admixtures for Concrete, ACI 212.3R, American

Concrete Institute, Farmington Hills, MI.

4. Building Code Requirements for Structural Concrete, ACI 318,

American Concrete Institute, Farmington Hills, MI.

5. Understanding Chloride Percentages, NRMCA Publication No.

173, NRMCA, Silver Spring, MD, www.nrmca.org.

National Ready Mixed Concrete Association.

All rights reserved.

No part of this publication may be reproduced in any form, including

photocopying or other electronic means, without permission in writing

from the National Ready Mixed Concrete Association.

Technical information prepared by

National Ready Mixed Concrete Association

900 Spring Street

Silver Spring, Maryland 20910

Printed in U.S.A. Copyright NATIONAL READY MIXED CONCRETE ASSOCIATION, 1987 AND 1989, 2001 CIP 15/1090/10.0/DMSC

strength. Water-reducers are used to increase slump

of concrete without adding water and are useful for

pumping concrete and in hot weather to offset the in-

creased water demand. Some water-reducers may

aggravate the rate of slump loss with time. Water-re-

ducers should meet the requirements for Type A in

ASTM C 494 Specification for Chemical Admixtures

for Concrete.

Mid-range water reducers are now commonly used and

they have a greater ability to reduce the water con-

tent. These admixtures are popular as they improve

the finishability of concrete flatwork. Mid-range water

reducers must at least meet the requirements for Type

A in ASTM C 494 as they do not have a separate clas-

sification in an admixture specification.

3. RETARDERS are chemicals that delay the initial setting

time of concrete by an hour or more. Retarders are

often used in hot weather to counter the rapid setting

caused by high temperatures. For large jobs, or in hot

weather, specify concrete with retarder to allow more

time for placing and finishing. Most retarders also func-

tion as water reducers. Retarders should meet the re-

quirements for Type B or D in ASTM C 494.

4. ACCELERATORS reduce the initial set time of concrete

and give higher early strength. Accelerators do not act

as an antifreeze; rather, they speed up the setting and

rate of strength gain, thereby making concrete stron-

ger to resist damage from freezing in cold weather.

Accelerators are also used in fast track construction

requiring early form removal, opening to traffic or load

application on structures. Liquid accelerators meeting

the requirements for ASTM C 494 Types C and E are

added to the concrete at the batch plant. There are

two kinds of accelerating admixtures: chloride based

and non-chloride based. One of the more effective and

economical accelerators is calcium chloride, which is

available in liquid or flake form and must meet the re-

quirements of ASTM D 98. For non-reinforced con-

crete, calcium chloride can be used to a limit of 2% by

the weight of the cement. Because of concerns with

corrosion of reinforcing steel induced by chloride, lower

limits on chlorides apply to reinforced concrete. Pre-

stressed concrete and concrete with embedded alu-

minum or galvanized metal should not contain any

chloride-based materials because of the increased po-

tential for corrosion of the embedded metal. Non-chlo-

ride based accelerators are used where there is con-

cern of corrosion of embedded metals or reinforce-

ment in concrete.

5. HIGH RANGE WATER REDUCERS (HRWR) is a special class

of water-reducer. Often called superplasticizers, HRWRs

reduce the water content of a given concrete mixture

from 12 to 25%. HRWR are therefore used to increase

strength and reduce permeability of concrete by reduc-

ing the water content in the mixture; or to greatly in-

crease the slump to produce flowing concrete without

adding water. These admixtures are essential for high

strength and high performance concrete mixtures that

contain higher contents of cementitious materials and

mixtures containing silica fume. For example, adding a

normal dosage of HRWR to a concrete with a slump of

3 to 4 inches (75 to 100 mm) will produce a concrete

with a slump of about 8 inches (200 mm). Some HRWRs

may cause a higher rate of slump loss with time and

concrete may revert to its original slump in 30 to 45

minutes. In some cases, HRWRs may be added at the

jobsite in a controlled manner. HRWRs are covered by

ASTM Specification C 494 Types F and G, and Types 1

and 2 in ASTM C 1017. Specification for Chemical Ad-

mixtures for Use in Producing Flowing Concrete.

Besides these standard types of admixtures, there are

products available for enhancing concrete properties for

a wide variety of applications. Some of these products

include: Corrosion inhibitors, shrinkage reducing admix-

tures, anti-washout admixtures, hydration stabilizing or

extended set retarding admixtures, admixtures to reduce

potential for alkali aggregate reactivity, pumping aids,

damp-proofing admixtures and a variety of colors and

products that enhance the aesthetics of concrete. Con-

tact your local ready mixed concrete producer for more

information on specialty admixture products and the

benefits they provide to concrete properties.

Recommended Air Content in Concrete

4

Nominal max

aggregate size,

mm (in.)

Air content, percent

Severe Moderate

exposure exposure

9.5 (3/8) 7.5 6

12.5 (1/2) 7 5.5

19.0 (3/4) 6 5

25.0 (1) 6 4.5

37.5 (1

1

2) 5.5 4.5

50 (2) 5 4

75 (3) 4.5 3.5

Severe exposure concrete in cold climate will be

continuously in contact with water prior to freezing or

where deicing salts are used.

Moderate exposure concrete in a cold climate will be

only occasionally exposed to moisture prior to freezing and

not exposed to deicing salt application.

Anda mungkin juga menyukai

- Piping Design CriteriaDokumen15 halamanPiping Design CriteriaSubash Chandrabose0% (1)

- Concrete Admixture GuideDokumen26 halamanConcrete Admixture Guideshahbaghi100% (4)

- Sub-Clause 4.3 - Contractor's RepresentativeDokumen1 halamanSub-Clause 4.3 - Contractor's Representative7774R105Belum ada peringkat

- Index: Sr. No. Title Page NoDokumen48 halamanIndex: Sr. No. Title Page NoajayBelum ada peringkat

- Construction Materials - Chemical AdmixturesDokumen46 halamanConstruction Materials - Chemical AdmixturesWelday TsegayBelum ada peringkat

- 9103Dokumen17 halaman9103amcenergy100% (1)

- Characteristics of Concrete With Admixtures PDFDokumen6 halamanCharacteristics of Concrete With Admixtures PDFTran Huynh NamBelum ada peringkat

- Passivation of Welded AISI 316L Stainless SteelDokumen12 halamanPassivation of Welded AISI 316L Stainless SteelKarna2504Belum ada peringkat

- Concrete AdmixturesDokumen3 halamanConcrete AdmixturesKlenz CuraBelum ada peringkat

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldDari EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldPenilaian: 3 dari 5 bintang3/5 (2)

- ACI 517.2 (1992) Accelerated Curing of Concrete at Atmospheric PressureDokumen17 halamanACI 517.2 (1992) Accelerated Curing of Concrete at Atmospheric Pressurephilipyap67% (3)

- Concrete AdmixturesDokumen14 halamanConcrete AdmixturesKhaja MohiddinBelum ada peringkat

- 10 - Duplex Stainless Steel Offer For Oil & GasDokumen44 halaman10 - Duplex Stainless Steel Offer For Oil & GasbaluBelum ada peringkat

- One City’s Wastewater is Another City’s Water SupplyDokumen51 halamanOne City’s Wastewater is Another City’s Water SupplyDia' M. T. Ghanem100% (2)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDari EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeBelum ada peringkat

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringDari EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringPenilaian: 4 dari 5 bintang4/5 (5)

- BS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFDokumen10 halamanBS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFKING OF VIDEO GAMES xBelum ada peringkat

- Admixtures in ConcreteDokumen15 halamanAdmixtures in ConcreteSundara LingamBelum ada peringkat

- Admixtures For ConcreteDokumen5 halamanAdmixtures For ConcreteShahril ZainulBelum ada peringkat

- Concrete AdmixturesDokumen27 halamanConcrete AdmixturesXiaohua ChenBelum ada peringkat

- AdmixturesDokumen8 halamanAdmixturesHaroon AkbarBelum ada peringkat

- Chemical Admixtures Uses and DevelopmentsDokumen51 halamanChemical Admixtures Uses and DevelopmentsObulareddy ChemikalaBelum ada peringkat

- Corrosion in Oil and Gas Industry - Rev06titlingeditDokumen12 halamanCorrosion in Oil and Gas Industry - Rev06titlingeditbayoe_PLN100% (2)

- Selecting and Sourcing Bridge Coating Systems - JPCLDokumen32 halamanSelecting and Sourcing Bridge Coating Systems - JPCLBoubakerBaazizBelum ada peringkat

- Is 9103 2004Dokumen17 halamanIs 9103 2004Nafeez Ahmed100% (2)

- SPD Centrifugal Pumps CatalogueDokumen14 halamanSPD Centrifugal Pumps CatalogueWell Site RangerBelum ada peringkat

- Cooling Tower Institute Win 10 JournalDokumen92 halamanCooling Tower Institute Win 10 JournalprakashBelum ada peringkat

- Concrete in PracticeDokumen2 halamanConcrete in PracticeZaher J. YazejiBelum ada peringkat

- CIP #15 - Chemical Admixtures For ConcreteDokumen4 halamanCIP #15 - Chemical Admixtures For ConcreteFurqanam196Belum ada peringkat

- CIP 15 - Chemical Admixtures For ConcreteDokumen2 halamanCIP 15 - Chemical Admixtures For ConcreteCorreoBelum ada peringkat

- Cadman, Inc AdmixturesDokumen2 halamanCadman, Inc Admixturesajmalhasan28Belum ada peringkat

- Admixtures Are Materials Other Than CementDokumen5 halamanAdmixtures Are Materials Other Than CementAlaa KarroumBelum ada peringkat

- AdmixturesDokumen1 halamanAdmixturesapuhapuh_153349Belum ada peringkat

- Chemical AdmixturesDokumen11 halamanChemical AdmixturesegemenazazBelum ada peringkat

- Concrete Admixtures: Types and UsageDokumen6 halamanConcrete Admixtures: Types and UsageAdil Javed ChaudharyBelum ada peringkat

- Types of Concrete Chemicals and Their ApplicationsDokumen6 halamanTypes of Concrete Chemicals and Their ApplicationsVengaiah ChowdaryBelum ada peringkat

- Analysis of Increasing of Concrete Compression Strength To Concrete'S Age Due To Adding Admixture of Sikament-163Dokumen6 halamanAnalysis of Increasing of Concrete Compression Strength To Concrete'S Age Due To Adding Admixture of Sikament-163Mahnoor asadBelum ada peringkat

- AdmixtureDokumen6 halamanAdmixtureDunvillBelum ada peringkat

- Concrete AdmixturesDokumen7 halamanConcrete AdmixturesGage Floyd BitayoBelum ada peringkat

- Chemical Admixtures For Concrete - An OverviewDokumen11 halamanChemical Admixtures For Concrete - An OverviewMoatz HamedBelum ada peringkat

- Cement Replacing MaterialsDokumen9 halamanCement Replacing MaterialsAnish PandeyBelum ada peringkat

- Admixtures For ConcreteDokumen27 halamanAdmixtures For ConcreteBoobalan RijhoBelum ada peringkat

- SaprodgdeDokumen6 halamanSaprodgdeA MahmoodBelum ada peringkat

- Highway Research: Water ReducingDokumen13 halamanHighway Research: Water ReducingRobi N DraBelum ada peringkat

- Concrete Admixtures GuideDokumen15 halamanConcrete Admixtures GuideRajanRanjanBelum ada peringkat

- Common Admixtures in ConcrerteDokumen15 halamanCommon Admixtures in ConcrerteDEDAN KIMATHIBelum ada peringkat

- Effect of Admixtures On Strength of ConcreteDokumen7 halamanEffect of Admixtures On Strength of ConcreteDipakBelum ada peringkat

- Types of Concrete AdmixturesDokumen3 halamanTypes of Concrete AdmixturesVicces P. EstradaBelum ada peringkat

- AdmixtureDokumen3 halamanAdmixtureArafat RahmanBelum ada peringkat

- CBD-103 Admixtures in Portland Cement ConcreteDokumen6 halamanCBD-103 Admixtures in Portland Cement ConcreteVaibhav KushBelum ada peringkat

- Infrastructure Admixtures Improve Concrete QualityDokumen1 halamanInfrastructure Admixtures Improve Concrete QualityNaveen VeeramaniBelum ada peringkat

- Admixtures in ConcreteDokumen60 halamanAdmixtures in ConcreteTeo Peng KeatBelum ada peringkat

- CRMCA Flatwork Finisher Constr Maint Best Practices 2017 05Dokumen20 halamanCRMCA Flatwork Finisher Constr Maint Best Practices 2017 05Anthony HudymaBelum ada peringkat

- 4.3 Chemical: Entraining AdmixtureDokumen10 halaman4.3 Chemical: Entraining AdmixtureRubén Paucar BenitesBelum ada peringkat

- CONSTRUCTION ADMIXTURESDokumen16 halamanCONSTRUCTION ADMIXTURESNikita ThosarBelum ada peringkat

- 21 AdmixtureDokumen21 halaman21 AdmixtureKrutaganasinh KathiyaBelum ada peringkat

- Concrete admixture effects and typesDokumen17 halamanConcrete admixture effects and typesسجاد محمدBelum ada peringkat

- TechBrief Air Entraining AdmixturesDokumen2 halamanTechBrief Air Entraining AdmixturesgayathriBelum ada peringkat

- ADMIXTURES FOR CONCRETE and Hardened ConcreteDokumen13 halamanADMIXTURES FOR CONCRETE and Hardened ConcreteMwaniki WilBelum ada peringkat

- Concrete Basics 1Dokumen16 halamanConcrete Basics 1Rey Balza TornoBelum ada peringkat

- Chemical Admixtures: Home Cement & Concrete Applications Concrete Materials Chemical AdmixturesDokumen3 halamanChemical Admixtures: Home Cement & Concrete Applications Concrete Materials Chemical AdmixturesMoatz HamedBelum ada peringkat

- Different Types of Admixtures in Concrete Structure - A Review PDFDokumen8 halamanDifferent Types of Admixtures in Concrete Structure - A Review PDFKalyanasundaram Thirugnanasambandam100% (1)

- Accelerating AdmixturesDokumen3 halamanAccelerating AdmixturesHariom ThakkarBelum ada peringkat

- Part 7 - Admixtures For ConcreteDokumen10 halamanPart 7 - Admixtures For ConcreteAvinash MaratheBelum ada peringkat

- Chemicals in ConstructionDokumen17 halamanChemicals in ConstructionDevyani TotlaBelum ada peringkat

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDari EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsBelum ada peringkat

- Control Contact Intre Piese C133Dokumen1 halamanControl Contact Intre Piese C1337774R105Belum ada peringkat

- Sub-Clause 17.4 - Consequences of Employer's RiskDokumen1 halamanSub-Clause 17.4 - Consequences of Employer's Risk7774R105Belum ada peringkat

- Fig 1a Compensare FururiDokumen1 halamanFig 1a Compensare Fururi7774R105Belum ada peringkat

- Fig 6 PDFDokumen1 halamanFig 6 PDF7774R105Belum ada peringkat

- Sub-Clause 20.4 - Obtaining Dispute Adjudication Board's Decision I DissatisfactionDokumen1 halamanSub-Clause 20.4 - Obtaining Dispute Adjudication Board's Decision I Dissatisfaction7774R105Belum ada peringkat

- Sub-Clause 18 - InsurancesDokumen1 halamanSub-Clause 18 - Insurances7774R105Belum ada peringkat

- Sub-Clause 4.7 - Setting Out ErrorDokumen1 halamanSub-Clause 4.7 - Setting Out Error7774R105Belum ada peringkat

- Souda Flex 45 HMDokumen2 halamanSouda Flex 45 HM7774R105Belum ada peringkat

- Sub-Clause 2.1 - Access To Site - InterferenceDokumen1 halamanSub-Clause 2.1 - Access To Site - Interference7774R105Belum ada peringkat

- Sub-Clause 20.2 - Appointment of The Dispute Adjudication Board One MemberDokumen1 halamanSub-Clause 20.2 - Appointment of The Dispute Adjudication Board One Member7774R105Belum ada peringkat

- Sub-Clause 20.2 - Appointment of The Dispute Adjudication BoardDokumen1 halamanSub-Clause 20.2 - Appointment of The Dispute Adjudication Board7774R105Belum ada peringkat

- Norme Metodologice Lege 230-2007Dokumen23 halamanNorme Metodologice Lege 230-20077774R105Belum ada peringkat

- Model Letters For Use by The Contractor: Letter To The Employer C.C. Engineer ML 20.2bDokumen1 halamanModel Letters For Use by The Contractor: Letter To The Employer C.C. Engineer ML 20.2b7774R105Belum ada peringkat

- Sub-Clause 4.2 - Performance SecurityDokumen1 halamanSub-Clause 4.2 - Performance Security7774R105Belum ada peringkat

- Sub-Clause 4.2 - Performance SecurityDokumen1 halamanSub-Clause 4.2 - Performance Security7774R105Belum ada peringkat

- Sub-Clause 3.3 - Instructions of The Engineer 2Dokumen1 halamanSub-Clause 3.3 - Instructions of The Engineer 27774R105Belum ada peringkat

- Sub-Clause 12.4 - OmissionsDokumen1 halamanSub-Clause 12.4 - Omissions7774R105Belum ada peringkat

- Sub-Clause 3.3 - Instructions of The Engineer 2Dokumen1 halamanSub-Clause 3.3 - Instructions of The Engineer 27774R105Belum ada peringkat

- Sub-Clause 4.24 - Fossils - ClaimDokumen1 halamanSub-Clause 4.24 - Fossils - Claim7774R105Belum ada peringkat

- Sub-Clause 18 - InsurancesDokumen1 halamanSub-Clause 18 - Insurances7774R105Belum ada peringkat

- Sub-Clause 6.5 - Working HoursDokumen1 halamanSub-Clause 6.5 - Working Hours7774R105Belum ada peringkat

- Sub-Clause 4.24 - Fossils - ClaimDokumen1 halamanSub-Clause 4.24 - Fossils - Claim7774R105Belum ada peringkat

- Sub-Clause 10.1 - Taking Over by The Employer - Whole of The WorksDokumen1 halamanSub-Clause 10.1 - Taking Over by The Employer - Whole of The Works7774R105Belum ada peringkat

- Sub-Clause 2.5 - Employer's ClaimsDokumen1 halamanSub-Clause 2.5 - Employer's Claims7774R105Belum ada peringkat

- Sub-Clause 3.3 - Instructions of The EngineerDokumen1 halamanSub-Clause 3.3 - Instructions of The Engineer7774R105Belum ada peringkat

- Sub-Clause 2.2 - Permits, Licences or ApprovalDokumen1 halamanSub-Clause 2.2 - Permits, Licences or Approval7774R105Belum ada peringkat

- Sub-Clause 3.3 - Instructions of The Engineer 2Dokumen1 halamanSub-Clause 3.3 - Instructions of The Engineer 27774R105Belum ada peringkat

- Sub-Clause 3.3 - Instructions of The Engineer 2Dokumen1 halamanSub-Clause 3.3 - Instructions of The Engineer 27774R105Belum ada peringkat

- Manufacture substances in industryDokumen20 halamanManufacture substances in industryShazleen SamhanaBelum ada peringkat

- Voltage Stabilizers ManufacturersDokumen16 halamanVoltage Stabilizers ManufacturersZodinBelum ada peringkat

- S572x Series Compression Platens: Application RangeDokumen2 halamanS572x Series Compression Platens: Application RangeRodrigoBracaBelum ada peringkat

- Categories According To PED 2014/68/EU Annex II Conformity Modules I A II A2, D1, E1 III B+D, B+F, B+E, B+C2, H IV B+D, B+F, G, H1Dokumen12 halamanCategories According To PED 2014/68/EU Annex II Conformity Modules I A II A2, D1, E1 III B+D, B+F, B+E, B+C2, H IV B+D, B+F, G, H1Mohit SharmaBelum ada peringkat

- Jota Epoxy FillerDokumen4 halamanJota Epoxy FillersanthoshBelum ada peringkat

- CBB Exam Prospectus for Competent PersonsDokumen33 halamanCBB Exam Prospectus for Competent PersonsrassdriverBelum ada peringkat

- Rules & Guidelines: Code EditionDokumen7 halamanRules & Guidelines: Code EditionElvis HuvBelum ada peringkat

- 18che121 PDFDokumen2 halaman18che121 PDFRutikBelum ada peringkat

- Materials of Art and ArchaeologyDokumen23 halamanMaterials of Art and ArchaeologysimpleidBelum ada peringkat

- OCP and Cathodic Conditioning 1 PDFDokumen11 halamanOCP and Cathodic Conditioning 1 PDFEr Dikshant MalhotraBelum ada peringkat

- Iso 8501-1Dokumen8 halamanIso 8501-1Luis Barrios ArandaBelum ada peringkat

- Corrosion Rate of Underground Steel TankDokumen4 halamanCorrosion Rate of Underground Steel TankAlessio ScarabelliBelum ada peringkat

- Modern Periodic Table ExplainedDokumen165 halamanModern Periodic Table ExplainedgunalprasadgBelum ada peringkat

- Estado de SuperficiesDokumen33 halamanEstado de SuperficiesamilcarsoaresBelum ada peringkat

- Design of Cobalt Electrowinning Unit OperationDokumen43 halamanDesign of Cobalt Electrowinning Unit Operationjoseph kafumbilaBelum ada peringkat

- GWC - Company ProfileDokumen4 halamanGWC - Company Profileelrajil100% (1)

- False CelingDokumen7 halamanFalse Celinggoldie84Belum ada peringkat

- Fammsi5a 000032Dokumen148 halamanFammsi5a 000032Ukasyah AzuhanBelum ada peringkat

- Ur 45 NDokumen8 halamanUr 45 NpauldidiBelum ada peringkat

- Food Contact Surfaces 2Dokumen27 halamanFood Contact Surfaces 2AliBelum ada peringkat

- Use Caution When Specifying "Seal Welds": Design FileDokumen4 halamanUse Caution When Specifying "Seal Welds": Design FilePrabhat K KarnaBelum ada peringkat

- Porosity in Gold Coatings On Metal Substrates by Paper ElectrographyDokumen5 halamanPorosity in Gold Coatings On Metal Substrates by Paper ElectrographyDanZel DanBelum ada peringkat