Considerations For Choosing A Controller: Consideration Information To Record Why This Is Important

Diunggah oleh

Rodrigo Iván Latorre Almirall0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

37 tayangan2 halamanThis document provides a checklist for considerations when choosing a programmable logic controller (PLC). It lists 9 key considerations: 1) whether the system is new or existing, 2) environmental issues, 3) discrete I/O requirements, 4) analog I/O requirements, 5) any specialty modules needed, 6) CPU and memory requirements, 7) local vs remote I/O locations, 8) communication requirements, and 9) programming requirements such as PID loops or floating point math. Making determinations for each consideration helps ensure the chosen PLC will meet the needs of the application.

Deskripsi Asli:

Judul Asli

plc_selector.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document provides a checklist for considerations when choosing a programmable logic controller (PLC). It lists 9 key considerations: 1) whether the system is new or existing, 2) environmental issues, 3) discrete I/O requirements, 4) analog I/O requirements, 5) any specialty modules needed, 6) CPU and memory requirements, 7) local vs remote I/O locations, 8) communication requirements, and 9) programming requirements such as PID loops or floating point math. Making determinations for each consideration helps ensure the chosen PLC will meet the needs of the application.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

37 tayangan2 halamanConsiderations For Choosing A Controller: Consideration Information To Record Why This Is Important

Diunggah oleh

Rodrigo Iván Latorre AlmirallThis document provides a checklist for considerations when choosing a programmable logic controller (PLC). It lists 9 key considerations: 1) whether the system is new or existing, 2) environmental issues, 3) discrete I/O requirements, 4) analog I/O requirements, 5) any specialty modules needed, 6) CPU and memory requirements, 7) local vs remote I/O locations, 8) communication requirements, and 9) programming requirements such as PID loops or floating point math. Making determinations for each consideration helps ensure the chosen PLC will meet the needs of the application.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

1 - 8 0 0 - 6 3 3 - 0 4 0 5

eCS-4 Control Systems Overview

Volume 13

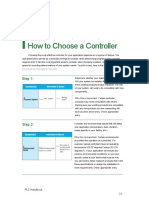

Considerations for Choosing a Controller

Consideration Information to Record Why this is important

1.

Proposed System

____ New system

_____ Existing

system

Determine whether your system is new or existing: Will your system

be installed from scratch or are there existing products already

installed? The rest of your system will need to be compatible with

new components.

Why this is important: Certain controller products may not be

compatible with others. Making sure your existing products are

compatible with any new products you are researching will save

you time and money. Check appropriate entry.

2.

Environmental

Issues

____

Codes/environmental

issues to consider

____ No codes or

environmental

issues to con-

sider

Consider any environmental issues that will affect your application

(temperature, dust, vibration, codes specific to your facility, etc.).

Why this is important: Certain environments may affect the opera-

tion of a controller. For example, typical controllers have an oper-

ating temperature of 0-55 degrees Celsius (32-130 degrees F). If

your application will include any extreme environmental condi-

tions, or you have specific codes at your facility that must be met,

you will need to either research products that meet those specifi-

cations or design the installation to meet requirements. Check

appropriate entry.

3.

Discrete Devices

_____ Total inputs:

_____ AC

_____ DC

_____ Total outputs:

_____ AC

_____ DC

Determine how many discrete devices your system will have. Which

types (AC, DC, etc.) are needed?

Why this is important: The number and type of devices your system

will include is directly linked to the amount of I/O that will be

necessary for your system. You will need to choose a controller

that supports your I/O count requirements and has modules that

support your signal types.Enter quantities and type based on corre-

sponding field devices.

4.

Analog Devices

_____ Total inputs:

____ Voltage

____ Current

____ Thermo

____ RTD

_____ Total outputs:

____ Voltage

____ Current

Determine how many analog devices your system will have.

Which types (voltage, current, temperature, etc.) are needed?

Why this is important: The number and type of devices your system

will include is directly linked to the amount of I/O that will be

necessary for your system. You will need to choose a controller that

supports your I/O count requirements and has modules that

support your signal types. Enter quantities and type based on corre-

sponding field devices.

5.

Specialty

Modules or

Features

(application-

specific)

_____ High speed counter

_____ Positioning

_____ Servo/stepper

_____ BASIC programming

_____ Real-time clock

_____ Others (list)

Determine whether your system will require any specialty features:

Will your application require high-speed counting or positioning?

What about a real-time clock or other specialty feature?

Why this is important: Specialty functions are not necessarily avail-

able in a controller CPU or in standard I/O modules.

Understanding the special functions your system may perform will

help you determine whether or not you will need to purchase addi-

tional specialty modules. Check all features required.

Use the worksheet on the following pages as a checklist of the things to consider when determining

programmable controller requirements. It lists the most important areas to consider when choosing

a system, and provides space for recording determinations of your system needs.

Table continued on the following page

Company

Information

Systems

Overview

Programmable

Controllers

Field I/O

Software

C-more &

other HMI

Drives

Soft

Starters

Motors &

Gearbox

Steppers/

Servos

Motor

Controls

Proximity

Sensors

Photo

Sensors

Limit

Switches

Encoders

Current

Sensors

Pressure

Sensors

Temperature

Sensors

Pushbuttons/

Lights

Process

Relays/

Timers

Comm.

Terminal

Blocks &

Wiring

Power

Circuit

Protection

Enclosures

Tools

Pneumatics

Appendix

Product

Index

Part #

Index

w w w . a u t o m a t i o n d i r e c t . c o m Control Systems Overview

eCS-5

Considerations for Choosing a Controller

Consideration Information to Record Why this is important

6.

CPU Required

Hardware requirements:

________ K program memory required

(estimated)

________ K data memory required

(estimated)

______ Fast scan time required?

______ Battery backup required?

Software/special function

requirements:

____ PID

____ Floating Point Math

Others (see Programming section below)

Determine the type of CPU you will need: How much memory will your

system require? How many devices will your system have (determines data

memory)? How large is your program, and what types of instructions will your

program include (determines program memory)? How fast a scan time do

you need?

Why this is important: Data memory refers to the amount of memory needed

for dynamic data manipulation and storage in the system. For example,

counter and timer instructions typically use data memory to store setpoints,

current values, and other internal flags. If the application requires historical

data retention, such as measured device values over a long period of time,

the size of the data tables required may determine the CPU model you

choose. Program memory is the amount of memory needed to store the

sequence of program instructions that have been selected to perform the

application. Each type of instruction requires a specific amount of program

memory, typically defined in a programming manual. Applications that are

basically sequential in nature can rely on the I/O device rule of thumb to esti-

mate program memory (five words of memory for each I/O device); complex

applications will be more difficult to judge.

If scan time is important in your application, consider the CPU processor

speed as well as instruction execution speed. Some CPUs are faster at

boolean logic but slower with data handling instructions.

If special functions such as PID are required, the CPU you select may make

those functions easier to perform.

For program memory required, follow this rule of thumb: 5 words of pro-

gram memory for each discrete device and 25 words for each analog

device. Check or calculate all requirements that apply.

7.

I/O Locations

_______

Local . . .

only

_______ Remote Locations

Specific remote I/O protocol

required? Which one?

____________________

Determine where your I/O will be located: Will your system require only

local I/O, or both local and remote I/O locations?

Why this is important: If subsystems will be needed at long distances from

the CPU, you will need a controller that supports remote I/O. You will also

have to determine if the remote distances and speeds supported will be

adequate for your application. Serial and Ethernet-based I/O hardware

are two typical choices available for most systems. This I/O may also be

referred to as distributed I/O, and may require a particular protocol, such

as Modbus.

Enter number of physical locations needed, and if/what specific protocol

may be required.

8.

Commuications

_____ Ethernet

_____ PLC to PLC

_____ Modbus RTU

_____ ASCII (interface to serial devices)

_____ Other

Determine your communication requirements: Will your system

be communicating to other networks, systems or field devices?

Why this is important: Communication ports (other than the programming

port) are not always included with a controller. Knowing your system

communication requirements will help you choose a CPU that supports

your communication requirements, or additional communication modules

if necessary. Check any/all communications functions required.

9.

Programming

_____

Floating

point math

_____

Drum

sequencer

_____ PID loops

_____ number of loops needed

_____ Subroutines

_____ Direct interrupts

_____ Others (list)

Determine your programming requirements: Does your application require

only traditional programming instructions, or are special instructions neces-

sary?

Why this is important: Certain controllers may not support every type of instruc-

tion. You will need to choose a model that supports all instructions that you

may need for a specific application. For example, built-in PID functions are

much easier to use than writing your own code to perform closed-loop

process control. Typical instructions such as timers, counters, etc. are available

in most controllers; note any other special instructions required here. Check

any/all programming functions required.

Anda mungkin juga menyukai

- Considerations For Choosing A Controller: Consideration Information To Record Why This Is ImportantDokumen2 halamanConsiderations For Choosing A Controller: Consideration Information To Record Why This Is ImportantMohamed SaadBelum ada peringkat

- PLC - Open ElectricalDokumen4 halamanPLC - Open ElectricalHerman DamanikBelum ada peringkat

- Como Elegir Un PLCDokumen8 halamanComo Elegir Un PLCmario serraBelum ada peringkat

- PLC - Selector PLCs - Programmable Logic Controllers - PLC Controller - Koyo PLC - PLC DirectDokumen2 halamanPLC - Selector PLCs - Programmable Logic Controllers - PLC Controller - Koyo PLC - PLC DirectMd Mainul Hsoen ImonBelum ada peringkat

- Control Systems: Piu Ghosh Instrumentation and Control DepartmentDokumen42 halamanControl Systems: Piu Ghosh Instrumentation and Control Departmentpiu_ghosh9966100% (1)

- Embedded System DesignDokumen98 halamanEmbedded System DesignMohammedBelum ada peringkat

- Voice Controlled Wheel ChairDokumen48 halamanVoice Controlled Wheel ChairAjith manjuBelum ada peringkat

- What Different Selection Citeria For PLC Selection Criteria: AdvantagesDokumen2 halamanWhat Different Selection Citeria For PLC Selection Criteria: AdvantagesMahesh ShendeBelum ada peringkat

- Ece Embed Ed SystemDokumen27 halamanEce Embed Ed SystemlakshmigajendranBelum ada peringkat

- Microcontroller - LectureDokumen29 halamanMicrocontroller - LectureChouaibou MouminiBelum ada peringkat

- What Is A Programmable Controller?Dokumen11 halamanWhat Is A Programmable Controller?Ernesto LeonBelum ada peringkat

- PLC Selection CriteriaDokumen2 halamanPLC Selection CriteriaGUNUPURI MANOHARBelum ada peringkat

- PLC Selection CriteriaDokumen2 halamanPLC Selection Criteriamanuel rangelBelum ada peringkat

- PLC Selection Criteria For MicrocontrollerDokumen2 halamanPLC Selection Criteria For MicrocontrollerAnkush PatilBelum ada peringkat

- Embedded System DesignDokumen22 halamanEmbedded System Designtrail meBelum ada peringkat

- Course FileDokumen36 halamanCourse FileElakkiya N.SBelum ada peringkat

- 5 2marksDokumen22 halaman5 2marksElakkiya N.SBelum ada peringkat

- Embedded Systems Introduction UpdatedDokumen74 halamanEmbedded Systems Introduction UpdatedpolskakamlangeniBelum ada peringkat

- Chapter-1: 1.1 Non Real Time Operating SystemsDokumen58 halamanChapter-1: 1.1 Non Real Time Operating SystemsAnonymous XybLZfBelum ada peringkat

- Notes BE&C 21ELN14-24 Module-3Dokumen23 halamanNotes BE&C 21ELN14-24 Module-3Sharanabasaveshwara H BBelum ada peringkat

- Intro To EsDokumen49 halamanIntro To EsGalal AtefBelum ada peringkat

- Chapter 2 Basic Principles of Industrial Automation 2010 Instrumentation Reference Book Fourth EditionDokumen3 halamanChapter 2 Basic Principles of Industrial Automation 2010 Instrumentation Reference Book Fourth EditionMotasim_mBelum ada peringkat

- Top Embedded Systems Interview - Nikolas Gray PDFDokumen81 halamanTop Embedded Systems Interview - Nikolas Gray PDFMANGAL KUMAR MOHAPATRABelum ada peringkat

- Chapter 1 IntroductionDokumen15 halamanChapter 1 Introductionhamed razaBelum ada peringkat

- Embedded Systems: Quiz 2Dokumen19 halamanEmbedded Systems: Quiz 2171148 171148Belum ada peringkat

- Embedded System UNIT 1st Notes-1Dokumen10 halamanEmbedded System UNIT 1st Notes-1My HackBelum ada peringkat

- Lab 01 - Introduction To PLC Hardware and SoftwareDokumen18 halamanLab 01 - Introduction To PLC Hardware and SoftwareSyed Abdullah Hasan Chishti100% (1)

- Embedded Systems Department of Electrical and Computer Engineering Communication Engineering Focus Area Course Code-Eceg4202Dokumen20 halamanEmbedded Systems Department of Electrical and Computer Engineering Communication Engineering Focus Area Course Code-Eceg4202yacob JacobBelum ada peringkat

- Embedded Systems Today 33333Dokumen14 halamanEmbedded Systems Today 33333ogbunelson2Belum ada peringkat

- 8 TemparatureDokumen31 halaman8 TemparatureDemonfox NarutoUzumakiBelum ada peringkat

- ReportDokumen10 halamanReportJay KevalramaniBelum ada peringkat

- Slide 1 (Introduction)Dokumen33 halamanSlide 1 (Introduction)Amit VishwakarmaBelum ada peringkat

- Es CH - 1Dokumen39 halamanEs CH - 1babishahawiBelum ada peringkat

- CCCCCC CDokumen60 halamanCCCCCC CSanthan ManneBelum ada peringkat

- Embedded System IntroductionDokumen20 halamanEmbedded System IntroductionshubhalaxmiBelum ada peringkat

- MP Appli GendDokumen6 halamanMP Appli GendAshfaq AhamedBelum ada peringkat

- Chapter 1 Introduction To Embedded Systems ObjectivesDokumen45 halamanChapter 1 Introduction To Embedded Systems ObjectivesGurvinder SinghBelum ada peringkat

- ESD MaterialDokumen8 halamanESD MaterialVibhav MahaleBelum ada peringkat

- Minor LastDokumen67 halamanMinor LastMusharraf AliBelum ada peringkat

- Unit 3Dokumen48 halamanUnit 3Sultan BepariBelum ada peringkat

- Assignment 1Dokumen10 halamanAssignment 1Katlego MaplankaBelum ada peringkat

- Chapter 6 - Introduction To An Embedded System and ITs Design - Microcontrollers & Embedded SystemsDokumen16 halamanChapter 6 - Introduction To An Embedded System and ITs Design - Microcontrollers & Embedded SystemsAmish VermaBelum ada peringkat

- Esd 1Dokumen40 halamanEsd 1154Soyal LonareBelum ada peringkat

- 6 - DCS IapcDokumen14 halaman6 - DCS IapcNikita ChaudhariBelum ada peringkat

- CH 2Dokumen110 halamanCH 2delinquent_abhishekBelum ada peringkat

- Solution - Manual The 8051 Microcontroller Based Embedded SystemsDokumen14 halamanSolution - Manual The 8051 Microcontroller Based Embedded Systemsmanishpatel_79Belum ada peringkat

- Lesson 1Dokumen6 halamanLesson 1Kaizuke YoBelum ada peringkat

- Chapter 1 Introduction To Embedded Systems: ObjectivesDokumen39 halamanChapter 1 Introduction To Embedded Systems: Objectivessreen67Belum ada peringkat

- QNX Meeting Early Boot RequirementsDokumen19 halamanQNX Meeting Early Boot RequirementsDiego Carreño RBelum ada peringkat

- Graphical System Design PDFDokumen35 halamanGraphical System Design PDFLaasya ReddyBelum ada peringkat

- Introduction To Embbeded SystemsDokumen42 halamanIntroduction To Embbeded SystemsSaikiran ReddyBelum ada peringkat

- Introduction To Embedded System NewDokumen25 halamanIntroduction To Embedded System NewKeshavamurthy LBelum ada peringkat

- All ESSDokumen97 halamanAll ESSmohammedminer20Belum ada peringkat

- PMIS Chapter IIDokumen11 halamanPMIS Chapter IIjagannadha raoBelum ada peringkat

- MC & ESY NotesDokumen144 halamanMC & ESY NotesgodaserbBelum ada peringkat

- Unit 1Dokumen20 halamanUnit 1prabhavathysund8763Belum ada peringkat

- Tulsiramji Gaikwad-Patil College of Engineering and TechnologyDokumen26 halamanTulsiramji Gaikwad-Patil College of Engineering and TechnologyShruti KambleBelum ada peringkat

- Training ReportDokumen44 halamanTraining Reportshaur20Belum ada peringkat

- A PROJECT REPORT ON Electronic Voting MachineDokumen97 halamanA PROJECT REPORT ON Electronic Voting Machinereddu143Belum ada peringkat

- STD PipingDokumen51 halamanSTD PipingRodrigo Iván Latorre AlmirallBelum ada peringkat

- 2011 Mazda2 Owner's ManualDokumen341 halaman2011 Mazda2 Owner's ManualgonzaloafBelum ada peringkat

- ATEX Rating ChartDokumen1 halamanATEX Rating ChartAshish Joshi67% (3)

- Ansi Isa-95.00.01-2000Dokumen142 halamanAnsi Isa-95.00.01-2000Alexander Dueñas Salazar100% (9)

- 2.1.1 Computer Organization AutosavedDokumen15 halaman2.1.1 Computer Organization AutosavedSnigdha KodipyakaBelum ada peringkat

- Ktxx03na SMDokumen50 halamanKtxx03na SMtoreson20005890Belum ada peringkat

- Hartjes C. - The Grumpy Programmer's PHPUnit Cookbook - 2013Dokumen100 halamanHartjes C. - The Grumpy Programmer's PHPUnit Cookbook - 2013Oana Stefania GusuBelum ada peringkat

- CNR 7402 User GuideDokumen195 halamanCNR 7402 User GuidemalterdjBelum ada peringkat

- Chapter 1Dokumen121 halamanChapter 1Ashraf YusofBelum ada peringkat

- UserGuide - SK FM4 216 ETHERNETDokumen77 halamanUserGuide - SK FM4 216 ETHERNETSmart ClasseBelum ada peringkat

- 230859380ip Xii 3 PDFDokumen133 halaman230859380ip Xii 3 PDFBilal AhmadBelum ada peringkat

- Laporan Harian Team IKR September 2017 1Dokumen194 halamanLaporan Harian Team IKR September 2017 1Apri Moko DokoBelum ada peringkat

- Standalone Access Control: Packing List WiringDokumen1 halamanStandalone Access Control: Packing List WiringAmine AminouBelum ada peringkat

- QPR Electro Magnetic Compatibility (EMC) Rev DDokumen8 halamanQPR Electro Magnetic Compatibility (EMC) Rev DOliver SteinrötterBelum ada peringkat

- Bulletin: ServiceDokumen1 halamanBulletin: Servicedaniel ortegaBelum ada peringkat

- Sigtran-Sctp, M3ua, M2paDokumen16 halamanSigtran-Sctp, M3ua, M2paabhishek sinhaBelum ada peringkat

- What Is Lock - Type of Lock in DBMSDokumen7 halamanWhat Is Lock - Type of Lock in DBMScompiler&automataBelum ada peringkat

- Cloud Hosting Solutions Built For Your BusinessDokumen8 halamanCloud Hosting Solutions Built For Your BusinessOxtrys CloudBelum ada peringkat

- Puppet Server OverviewDokumen11 halamanPuppet Server OverviewpavanlondonBelum ada peringkat

- Manual pm5drhDokumen5 halamanManual pm5drhFabiano SilvaBelum ada peringkat

- PSIM User ManualDokumen224 halamanPSIM User ManualFendi BmkBelum ada peringkat

- Car Antenna Amplifier CircuitDokumen5 halamanCar Antenna Amplifier CircuitSyed Hassan TariqBelum ada peringkat

- COMP Chapter 5 TestDokumen14 halamanCOMP Chapter 5 TestCognac BlackBelum ada peringkat

- Realme 9 Pro - Schematic DiagarmDokumen267 halamanRealme 9 Pro - Schematic DiagarmSatyendra RaikwarBelum ada peringkat

- MTN August Trader 2021Dokumen31 halamanMTN August Trader 2021MECHANICAL ENGINEERINGBelum ada peringkat

- Awrrpt 1 66643 66644Dokumen228 halamanAwrrpt 1 66643 66644Jubair AhmedBelum ada peringkat

- LicaDokumen99 halamanLicaKhanBelum ada peringkat

- PIR Motion SensorDokumen13 halamanPIR Motion SensorSevia Indah PurnamaBelum ada peringkat

- Stm32Cubeide Release V1.7.0Dokumen17 halamanStm32Cubeide Release V1.7.0Dung ManhBelum ada peringkat

- WCM DocumentsDokumen17 halamanWCM DocumentsAvinash GummadiBelum ada peringkat

- Cadangan Power Supply - Mini Projek Sesi Ii 2021-2022Dokumen10 halamanCadangan Power Supply - Mini Projek Sesi Ii 2021-2022syclops3Belum ada peringkat

- G120 Safety FCT Man 0920 en-USDokumen352 halamanG120 Safety FCT Man 0920 en-USCharles BarrosBelum ada peringkat

- Jump StatementsDokumen9 halamanJump StatementsCool CupBelum ada peringkat

- Cpu CabinetDokumen8 halamanCpu CabinetSagar JoonBelum ada peringkat