ZM r5850

Diunggah oleh

taslim4uJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ZM r5850

Diunggah oleh

taslim4uHak Cipta:

Format Tersedia

BGA Rework Station ZM-R5850

Manual

- 1 -

Preface

Dear customer, Thank you for using the BGA rework station ZM-R6820G of Shenzhen

Zhuo Mao Technology Co., Ltd.

Features of ZMR5850

1. Unique design of three heating areas operating independently to control

temperature more accurately.

2, First / second temperature areas heat independently, which can set up 8 rising

temperature segments and 8 constant temperature segments to control. It can save 10

groups of temperature curves at the same time.

3. The third area uses far-infrared heater to preheat and control the temperature

independently, so that the PCB can be fully preheated during the desoldering process

and it can be free from deformation.

4. Choose imported high-precision K-Sensor and closed-loop to detect the

up/down temperature precisely.

5. After finishing desoldering & soldering, there is an alarming. When the

temperature goes beyond control, the electric circuit can cut off automatically, with

over-heating protection.

6. Use a powerful cross-flow fan to cool the PCB rapidly to prevent it from

deformation and ensure the welding effect.

7. Use a V-groove equipped with a flexible fixture for PCB positioning to protect

the PCB from deformation when heated or cooled.

8. This machine can be connected to a computer to be controlled more

conveniently with a built-in PC serial port and proprietary software attached to it.

9. For large thermal capacity of PCB/CSP/QFP or other high-temperature and

lead-free welding requirements, all can be handled easily.

10. The hot air nozzle can rotate 360 freely and it's easy to replace. Offering

BGA nozzles of different sizes for you to replace easily. Nozzles of special

requirements are customzible.

- 2 -

Shenzhen ZhuoMao Technology Co., Ltd. is a high-technology company located in the western

district of BaoAn. Thanks to its proximity to the international airport and container terminal, this part

of the booming industrial city of Shenzhen is rich in modern business opportunities.

BGA repair turnkey solutions are the heart of ZhuoMao activities. A strong R&D team supports

a dynamic workforce of over fifty people. A well established sales network and after-sales service has

built ZhuoMao a strong reputation in China among high profile customers.

The main products of ZhuoMao are BGA Rework Station (BGA Mounting, BGA Reballing

Machine, and BGA Soldering Machine), BGA Testing Machine (main board testing, video card

testing, digital camera testing, mobile chip testing, and various of ICT, FCT, ATE precise air/hand

testing machines )

Devoted to put in practice the motto Specialized, Innovative and Dedicated, the company is

focused on its customers satisfaction and has set up a network of local offices to tailor its offer to an

expanding market.

Developing new solutions to help customers tackle issues always more diverse and complex

keeps ZhuoMao engineering teams to the forefront of the technology and rewards its products with

the most prestigious awards and recognition in China.

Because ZhuoMao understands BGA repair is a critical activity needing speed, accuracy and

user-friendliness, its machines are designed for you to REGAIN SATISFACTION.

- 3 -

Contents

Item Page

AInstallation of BGA rework station 03-03

B Specifications 03-03

CIntroduction of structure 04-04

DProgram setting and operating instructions 05-19

EThe use of external measuring galvanic 19-22

Freballing process 22-23

GMaintenance 23-25

HSafety Cautious 25-26

Attach 1Temperature Profiles 27-28

- 4 -

1

st

Installation

In order to ensure the validity of BGA Rework Station, the installation

should meet the following requirements.

a. Away from inflammable and explosives;

b. Away from water and other liquids;

c. Ventilated, dry place;

d. Stable and flat, free from tremor.

e. Less dust;

f. No heavy objects on the controlling box;

g. Not affected by airflow of air conditioner, heater or ventilator.

h. Leave a space of 30cm or more behind the rework station for the upper

part to move and rotate.

2

nd

Specifications

1Power supply : AC220V10 50/60Hz

2Power consumption: 4.8KW

3Heater: Main heater: 0.8KW

Sub heater: 1.2KW heating element: 2.7KW ,others:0.1KW

4Electric material: PLCsupport computer communication.

5Temperature control: K-type closed-loop thermocouple, top and

bottom heating independently, temperature error 3.

6Positioning: V-groove fixture for PCB positioning

7PCB size: MAX 410370mm Min 2222

8Machine dimension710680660mm

9Weight40kg

10Machine colorBlack

- 5 -

3

rd

main structure description

(1) Structure description

01 Y-axi s adj ust of t op heat er

02 Z-axi s adj ust of t op heat er

04 work li ght

05 bl ock t emper ature

06 bott omheat er hei ght adj ust

08 over -t emper at ure contr ol

07 t her most ati c contr ol

16 sli der

13 cr oss-fl owfan

18 PCB support er

20 t op hot air adj ust

21 T/Cpl ug

19 l ock screw

23 over -t emper ature

09 cal cul agr aph

12 li ght

14 PCB spli nt

03 t op heat er 15 t op nozzl e

17 bott omnozzl e

24 t op pr ogr ammabl e t her most at

11 st art

10 emer gency

26 cooli ng

27 vacuum

25 bott ompr ogr ammabl e t her most at

22 run

(2) Function introduction

NO Name Function Use method

1 Y-axis adjust of top heater Adjust the top heater Right-backleft-forward

2

Z-axis adjust of top heater

Adjust the top heater Right-upleft-down

3 Top heater Heating BGA when welding Adjust through Z-axis

4 light Work lighting

5 Block temperature

6 Height adjust of bottom heater Adjust the lower height Adjust to a suitable place

7 thermostatically control To set the procedures Over-temperature control

8 Over-temperature control According to setting

- 6 -

9 calculagraph

10 stop

11 Start switch

12 Lighting switch

13 Crow-flow fan Cool the PCB after heating

14 PCB splint To hold up PCB board

15 Top nozzle Make hot air focus on BGA Make a suitable place to BGA

16 Slider Lock screw to support PCB

17 Bottom nozzle Lower heating when welding

18 PCB board supporter

19 Locking screw To fix the splint

20 Top hot-air adjust Adjust the top hot air Turn left and right

21 T/C plug To measure the true temp.

22 run To show it is heating

23 Over-temperature

24 Top programmable thermostat

25 Bottom programmable thermostat

26 Cooling switch

27 Vacuum switch

4

th

Program setting and operating instructions

(1) Program setting:

Meter setting:

Top/bottom PLC are using same meter, some using.

PLC appearance:

- 7 -

PLC panel instruction

Setting process: First turn on the power supply

1) Choose temperature profile: (set groups) press PTN button (can

save 10 groups temperature profiles), Press PTN groups will be changed

- 8 -

(1, 2,3,4,5 0) choose one of them for temperature profiles (We take

1

st

group for example)

PV

SV

PIN

PC410

RUN

STEP PRO

TIME COM

MV MAN

SV AL1

OUT1 OUT2

DISP

SET

PROG

RUN

PIN

AUTO

HAND

PAR

SET

ALTEC

1

2) Preheating: Slope(r)

Press SET button enter into temperature curve,r1 stands for

slope the temperature will rise at the speed of 3 in one second

3.00 stands for 3/second, press number increase button to

adjust. Press PAR button enter next step.

PV

SV

PIN

PC410

RUN

STEP PRO

TIME COM

MV MAN

SV AL1

OUT1 OUT2

DISP

SET

PROG

RUN

PIN

AUTO

HAND

PAR

SET

ALTEC

r1

3.00

1

3) Preheating: Temperature (L),

Press number increase button to adjust,160 stands for preheating

temperature 160. Press PAR button enter to next step.

PV

SV

PIN

PC410

RUN

STEP PRO

TIME COM

MV MAN

SV AL1

OUT1 OUT2

DISP

SET

PROG

RUN

PIN

AUTO

HAND

PAR

SET

ALTEC

L1

160.00

1

4) Preheating: Time (d),

Press number increase button to adjust, D stands for the time how

- 9 -

long the temperature stays at this stage. Press PAR button enter

to next step.

PV

SV

PIN

PC410

RUN

STEP PRO

TIME COM

MV MAN

SV AL1

OUT1 OUT2

DISP

SET

PROG

RUN

PIN

AUTO

HAND

PAR

SET

ALTEC

d1

30

1

5) Preheating 2: Speed setting, press number increase button to

adjust. Press PAR button enter next step.

1

3 . 0 0

r 2

A L T EC

S E T

P AR

H AN D

A U TO

P IN

R U N

P R O G

S E T

D I SP

O U T 2 O U T1

A L 1 S V

M AN M V

C O M T I ME

P R O ST E P

R UN

P C4 1 0

P I N

S V

P V

6) Preheating 2: Temperature setting, press number increase button

to adjust. Press PAR button enter next step.

1

185

L2

AL TEC

S E T

PA R

H AND

A UTO

PIN

R UN

PROG

S E T

DI SP

O U T2 O UT1

A L 1 SV

MAN MV

CO M TI ME

PRO S TEP

R UN

PC41 0

PI N

S V

PV

7) Preheating 2: Time setting, press number increase button to

adjust. Press PAR button enter next step.

- 10 -

1

30

d2

AL TEC

SET

PAR

HAND

AUT O

P IN

RUN

PROG

SET

DI SP

OUT 2 OUT 1

AL1 SV

MAN MV

COM T I ME

PRO STEP

RUN

P C41 0

PIN

S V

PV

8) Preheating 3: Speed setting, press number increase button to

adjust. Press PAR button enter next step.

1

3.00

r3

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

9) Preheating 3: constant temperature setting, press up and down

button to adjust. Press PAR button for confirm.

1

210

L3

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

10) Preheating 3: constant temperature time setting; press up

and down button to adjust. Press PAR button for confirm.

1

30

d3

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

P C410

P IN

SV

PV

11 Welding 4, press number key to change, Press PAR button

- 11 -

For confirm.

1

3.00

r4

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

12) Welding 4: preheating constant temperature setting, press

Up and down button to adjust. And PAR button confirm.

1

225

L4

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

13) Welding 4: constant temperature time setting. press up/

down button to adjust. Press PAR button confirm.

1

35

d4

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

14) Welding 5: the speed of heating setting. Press up and down

button to adjust. Press PAR button for confirm.

- 12 -

1

3.00

r5

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

15) Welding 5: preheating constant temperature setting,

Press up and down button to adjust. Press PAR button for

Confirm.

1

230

L 5

A L T EC

SE T

P AR

HA ND

A UTO

PI N

RUN

P R OG

SE T

DI SP

OUT 2 O UT1

A L1 SV

MA N MV

C OM T IME

P RO S TEP

RU N

P C4 10

P I N

SV

P V

16) Welding 5: Constant temperature time setting, press up and down

button to adjust. And press PAR button for confirm.

1

25

d5

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

17) After finished Temperature curve setting, press Number

Decrease button to show END for closing.

- 13 -

1

End

r8

ALTEC

SET

PAR

HAND

AUTO

PIN

RUN

PROG

SET

DISP

OUT2 OUT1

AL1 SV

MAN MV

COM TIME

PRO STEP

RUN

PC410

PIN

SV

PV

(Note: If you need to increase the temperature then press the upper

button)

18) When the setting finished, it will show as the following

picture. (This function stands for Max. temperature, do not modify)

1

300

Hb

A L TEC

S ET

P AR

H AND

A UTO

PIN

RUN

PR OG

S ET

D ISP

O UT2 OUT1

AL1 SV

MAN MV

COM T IME

P RO S TEP

R UN

P C41 0

P IN

SV

PV

REX--C10 Temperature controller:

Thermostat setting; top over temperature controller; bottom

over temperature controller are adopted REX-C10 temperature

controller, so the usage of them are the same.

PV

SV

RKC REX-C10

SET

sh wo act ual t e mper at ur e

show setti ng t e mper at ur e

nu mber decr ease butt on

nu mber i ncr ease butt on

set

nu mber decr ease butt on

- 14 -

Setting Method:

1) Hold down the adjustment button for 1-2 seconds, then the setting of the

temperature a bit flash, press numerical increase (decrease) key to change.

And then move button to move the modified adjusted value of 10, and

finally to 100, after finished, press the SET to confirm.

Infrared constant temperature settings Proposal setting 180

PV

SV

RKC REX-C10

SET

30

180

(2): The use of the external computer

The device can connect with an external computer, you can observe two

temperature curves of the head of internal heating wire and external measurement of

galvanic through the computer interface, and you also can set the temperature, time and

other parameters through the computer, but also can achieve data transfer between

computer and instrument, store many curves and facilitate to print out. (Note: This

feature is limited to the upper heating control)

Statement: the related temperature parameters of the equipment can be set-up and

stored completely through the instrument age, but in order to set the temperature more

user-friendly, more intuitive, and easy to store, and print the temperature curve, our

- 15 -

company specially developed this software

Software Install

1Lowest requirement for computer configuration.

a. CPUP 800

b. Memory128M

c. Video Card4M

d. CD ROM

e. Serial Communication Interface

2Software Installation

a Put the video into the video card, open CD diverrunV2.08setup appear

language select.

Choose English and Click Next to enter Picture 1

Picture 1 Picture 2

b ClickNextto enter Picture 2

c After enter Picture 2clickNext buttonenter Picture 3

d ClickNextenter Picture 4

- 16 -

e ClickNextenter Picture 5

f ClickInstallenter Picture 6start installing.

g ClickFinishfinish installing process.

Picture 3 Picture 4

Picture 5 Picture 6

Picture 7

Using of software

- 17 -

1Connect the computer series port and machine communication port with the

enclosed date cable.

2Open power of the equipment.

3Click

Zhuomao reworker.lnk

on the desktopenter into temperature curve

recorder system interfacepicture 8

4Set the temperature, time, slope parameter for very segment.

a ClickProfiles settingthe interface will enter into (Picture 9)according to

welding BGA and solder ball to set the parameter for each segment. And for specific

date and operating parameters, please see the construction book for reference.

b Note 1This software is for showing the temperature curve and recorder, the

software does not have the motion control functions, for the movement of the

machine need manual adjustment.

c Note 2The related temperature profiles, you can set through the meter on the

machine. However, in order to facilitate the users for temperature setting, in particular

for the temperature curve showing, save and print, so we develop and expand this

software.

5Manually operation for the machine, make the equipment enter into heating state,

and for specific operation, please see the construction book for reference.

6Click download Controller so the temperature for just setting can be

down load to the programmable controller.

7ClickRun/Stopthe machine will carry out heating motion.

8At this time you can see the temperature curve.

- 18 -

9Curve 1GreenshowsThe actual measurement of heater temperature

10Curve 2(RedshowsExternal Sensor temperature (Testing through the

sensor on the machine)

11During the process of heatingClickRun/Stopor click Stopon the

control panelheating process will be stop.

12ClickExit systemcomputer will exit the application program.

Development Features Instruction

1Upload from ControllerClick this button can upload the internal

instrument parameter from controller to the computer; it can set a group of data each

click.Note: the programmable controller can save 10 groups itself

2download Controller Click this button can download the parameter from

computer to the controller;

3SaveAfter using the software for heatingProfile View curve display

page will show the two temperature curve, use this button can save the curves to

any position on the computer hard disk.

4OpenThrough using this button can pick up the temperature curve stored

in computer.

5) PrintThrough an external printer can easily print the current curve.

6) X-axis max setting (minutes): the max setting of X-axis.

7) Y-axis max setting (cent degree): the max setting of Y-axis.

- 19 -

Picture 8 Picture 9

Picture 10

- 20 -

Picture 11

5

th

The use of external measuring galvanic

1Function

1More accurate to measure the actual temperature of the part to be heated during the welding process.

2It is easy to move, so that it can be convenient to measure the temperature of the different parts of the

welded components during the heating process.

3Calibration role, through appropriate adjustment, it will make the temperature of the welding parts get

close to the set temperature as much as possible.

2Installation

1Check the galvanic lines, whether there are disconnected phenomena or not.

2Insert the galvanic Plug into the "outer galvanic Socket on the control panel according to the positive

and negative mark.

3After GALVANIC installed correctly, click "DiSP SELE" button on the upper instrument panel, (the button

which is used to switch the displaying item), switch to "TIME", the corresponding galvanic current

temperature will be displayed in the second line of instrumentation on the "SV" display window.

Stated: "DiSP SELE" is the button to switch the displaying items, when press it, the downstream sequence

of display windows display setting no., output no., the remainder of the number of segments of running,

corresponding to Panel "SV", "MV", "TIME "indicator light.

- 21 -

3measurement

1PCB board will be installed on the rework station, with the galvanic fixed on the PCB board using foil

stickers.

2Adjust the height of the probe; With the probe galvanic head located in the top 1-2mm of the test site

(as shown in Figure 12)

Picture 12 Picture 13

3Adjust the related mechanical adjustment knob, so that the heating part just below the hot-air tube. (as

shown in Figure 13)

4Adjust the up and down adjustment knob of the hot-air head to make the distance between the edge

of PCB board side and the hot-air head is 3-5mm.

5Implementation of the welding / disordering process, that is to start the process of upper and lower

heater.

6Then it will show two curves of the green and red on the computer monitor screen

7Curve 1, the actual measurement temperature of the internal galvanic of the top heater (green)

8Curve 2, the actual measurement temperature of the external galvanic curve (red)

4Using the outer galvanic to adjust the temperature curve

Statement: In this operation, it may be due to improper operation to cause the temperature deviation

of the device or even lose control, please caution!

Take the upper hot-air tube as an example to make detailed description of adjustment method

1Set the temperature, the time, the slope and so on parameters of the upper heater

2Adjustment process proposed to do on a waste circuit board in order to prevent damage to the circuit

board and on-board electronic components.

3Implementation of the above process (3), installed the outer measured galvanic, in which the top of the

PCB board just below the hot-air tube.

4Close the lower part of the heating process, click on "Start" button to start the heating process, which

will on the computer monitor screen will be displayed on the upper curve of the measured temperature

(green) and external galvanic measuring temperature (red) the two curves

- 22 -

5Green curves represent the actual measurement of the galvanic temperature curve of the upper heating

wire inside, the red curve represents the actual measurement of the galvanic temperature outside. the

smaller the gap between the green curve and red curve, the closer between the actual temperature

and set temperature of the heating parts, more standard of the upper heating process; On the contrary,

the greater the gap between the two curves, the greater the actual temperature deviate from the set

temperature, the more non-standard of the upper part during the heating process.

6If the deviation between the two curves is too much, you should make the appropriate adjustments

7The specific adjustment method is as follows, because of the impact of the system processes and the

environmental, deviations in the objective is inevitable. If the temperature deviation does not affect

the normal welding and desordering, non-professionals should avoid the following corrective actions!

A If the outer galvanic curve (red) lower than the upper one(green), adjust the internal hairdryer

galvanic probe upward;

B If the outer galvanic curve (red) higher than the upper one(green), adjust the internal hairdryer

galvanic probe downward;

C Adjustment must be small, try to control the amplitude of accommodation in 1mm or less;

D Repeated several adjustments;

E During adjustment process, the heated of galvanic probe is strictly prohibited from contacting with

any objects, so as not to affect the accuracy of measuring temperature;

F After temperature adjustment, you should fix the probe, to avoid the probe vibration

measurement of the temperature of the equipment

G The method of the adjustment applies only to the two parallel curves in a smooth uniform

deviation, and it is invalid to the temperature which is from top to bottom jitter free-laws regulating!

H The upper part of the internal galvanic Duct location: Remove the upper heater nozzle, at a

distance of 2-3cm at the edge wind-cone .

I Operate the standard procedure to avoid the high-temperature burns!

8There is no booster thermocouple temperature curve on the bottom of the computer screen, so you

have to adjust the process of the lower part of the heaters by visual.

9fixed the galvanic line with foil stickers on the bottom of PCB board (as opposed to the upper heater set

back on the PCB board), so that the probe of the booster thermocouple is located just 2mm above the

mouth of the bottom hot-air nozzle, and adjust the mechanical parts, make the upper hot-air nozzle

deviate from the heated parts to avoid cold air affect the temperature of the heated parts.

10Set the parameters of the lower heating temperature, while closing the upper part of the heating

process, click on "Start" button to start heating

11Now you can see "SV which displayed on the panel of the upper programmable thermostat (also click

on the "DiSP SELE" button of the upper instrument panel, and switch to the position of the "TIME"

- 23 -

indicator light) is the temperature of the external galvanic, with the abbreviation as the outer

temperature; And PV is the temperature of the internal galvanic, with the abbreviation as the

bottom temperature.

12The caution is same as the top heater.

13The methods of adjustment:

A If the outer temperature is lower than the bottom, you should adjust the lower internal galvanic

probe downward.

B If the outer temperature is higher than the bottom; you should adjust the lower internal galvanic

probe upward.

6

th

Reballing Process

1. Fixed the BGA chip which need to be reballed on the under plate of the

adjustable reballing kit, and then adjust the No-spring slider to fix the

chip.

2. Choose the stencil according to the style of chip, then fix the stencil on

the top cover of the adjustable reballing kit and lock the four M3 screws,

cover the cap. Adjust the four screws of the under plate to fit for the height of the chip.

3. Check the alignment of the hole of the stencil and the welding spot of the

chip, if it is in misalignment, then remove the cover and adjust the fixed

slider until it is in alignment.

4. Lock the fixed slider of the two no-spring slider, take out the BGA chip and wipe a layer of solder

paste, fixed the chip on the adjustable reballing kit again, cover the cap.

5. Put some solder balls into the kit, clutch and shake it to make all the balls

stand on the welding spot, and at the same time, clear the superabundant

balls.

- 24 -

6. Put the reballing kit on the desk, take out the top cover, and bring out the BGA cheap carefully, and

check it whether there are some balls on the wrong place or not, if it is, then make it right with

tweezers.

7. The way of making the balls fixed is using the Reballing machine, It

can heat the cheap medially. Up to now, we finished reballing.

7

th

Maintenance

1Upper heater(Pictured)

1. The replacement of fan:

Remove the heater cover, and remove the insulation fiber block, then you can replace the fan.

2. The replacement of heating wire

Remove the heater cover the insulation fiber block and fan, remove the upper fixed block, then take

out the hot wire. Then it can be replaced.

- 25 -

(2) The lower (second temperature zone) heating wire replacement (pictured)

0 2

0 3

0 4

0 5

0 6

0 7

0 8

0 9

0 1

01 body 02 Heating Duct 03 Heating wire

04 Fan Holder 05 fan 06 Heater cover

07 Fan Holder Bolt 08 Fan Bolt 09 Heater cover bolts

Replacement of the lower hot air heating wire:

1 Remove the heater bolts, and then remove the heater cover,

2 Demolition of fans and fan mounts, remove the hot wire. Then you can replace the

heating wire,

3The bottom heating panel (pictured)

- 26 -

heating pad

lock screw

heating box

heating panel card

fixed plate

Replacement of heating plate:

1. Demolition of locking screws (4), remove the heating plate and the assembly of the fixed plate,

placed on the table which is covered with a sponge (with heating plate surface facing down).

2. Removed the fixed heating plate card, you can break down the fixed plate and heating plate

assembly, remove the heating plate then it can be replaced.

8

th

Safety Precautions

The power supply of ZM-R6820G is AC220V,the temperature can arrive to 400.If

you do not operate inappropriately, it will cause damaging to the machine or even to

the operator. So you must strictly abide by the following matters:

1. Don't blow to the rework station directly when it is working, or there will be a negative

difference from the surface of the heating board, thus some parts will be burnt out.

2. After it is started, the high temperature area should not touch any objects, or it will lead to

a fire or explosion. The PCB and other parts should be put on the PCB bracket.

3. No vibration. Handle it gently.

- 27 -

4. Don't touch the heaters with your hands when it is working, or you will get hurt.

5. Don't use combustible spray, liquefied and flammable gas near the rework station after it is

started.

6. Don't try to re-equip the machine, or there may be a fire or an electric shock.

7. There are high-pressure parts in the circuit box. Don't disassemble it.

8. If some metals fall in the rework station when it is working, turn off the power immediately.

After it is cooled down, get the metal out, and clean the machine. If not, there may a smell

when the machine starts working next time.

9. When the rework station's temperature rises abnormally or smokes, turn off the power and

inform the service technicians to repair it. Turn off the power of the circuit box and the

machine while moving the rework station. Hold the plug when we remove the wire or it will

lead to a poor contact then the machine can't work very well.

10. Turn off the power when stop using it.

11. Don't put the rework station on the wires, or there may be a failure, a fire, or an

electric shock.

12. Before you use the machine, you must read the instructions attentively.

Note: when the machine works, it will produce some smell. So ensure the comfortable,

healthy and safe operation environment, please keep the air in circulation.

Under the following case, if it causes any damage, it will not in our

guarantee;

1Do not operate according to the condition of the environment and methods of operation

that the manual book required;

2The reason out of our product;

3Not the transformation and maintenance of our company;

4Do not operate accordance with the way of use that our company's products required;

5The case that the temporal level of scientific and technological of our company was

impossible to predict;

6Natural disasters or man-made destruction and such non-responsibility of the Company

premises, it will not in guarantee.

- 28 -

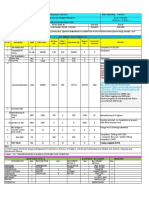

Normal BGA welding and disordering parameters

for reference

The temperature curve of lead welding

41*41 the temperature setting of the BGA welding

38*38 the temperature setting of the BGA welding

31*31 the temperature setting of the BGA welding

The upper is the reference temperature of the lead BGA

preheating insulation heating welding1 welding2 cooling

upper 160 185 210 235 240 225

time 30 30 35 40 20 15

bottom 160 185 210 235 240 225

time 30 30 35 40 20 15

slope 30 30 30 30 30 30

IR 180

preheating insulation heating welding1 welding2 cooling

upper 160 185 210 225 235 215

time 30 30 35 40 20 15

bottom 160 185 210 225 235 215

time 30 30 35 40 20 15

slope 30 30 30 30 30 30

IR 185

preheating insulation heating welding1 welding2 cooling

upper 160 180 200 215 225 215

time 30 30 35 40 20 15

bottom 160 180 200 215 225 215

time 30 30 35 40 20 15

slope 30 30 30 30 30 30

IR 180

- 29 -

The temperature curve of Lead-free welding

41*41 the temperature setting of the BGA welding

38*38 the temperature setting of the BGA welding

31*31 the temperature setting of the BGA welding

The upper is the reference temperature of the lead-free BGA

Such as set 0 when the demolition of the cooling section of BGA

preheating insulation heating welding1 welding2 cooling

upper 165 190 225 245 255 240

time 30 30 35 55 25 15

bottom 165 190 225 245 255 240

time 30 30 35 55 25 15

slope 30 30 30 30 30 30

IR 210

preheating insulation heating welding1 welding2 cooling

upper 165 190 225 245 250 235

time 30 30 35 45 25 15

bottom 165 190 225 245 250 235

time 30 30 35 45 25 15

slope 30 30 30 30 30 30

IR 210

preheating insulation heating welding1 welding2 cooling

upper 165 190 220 240 245 235

time 30 30 35 40 20 15

bottom 165 190 220 240 245 235

time 30 30 35 40 20 15

slope 30 30 30 30 30 30

IR 210

Anda mungkin juga menyukai

- ICS R490说明书(ENGLISH) PDFDokumen14 halamanICS R490说明书(ENGLISH) PDFFurqonudin SejahteraBelum ada peringkat

- 5860C English ManualDokumen22 halaman5860C English ManualFengky Cleons ChouBelum ada peringkat

- HR6000 ManualDokumen18 halamanHR6000 ManualFrancisco Jose Padrino GoyaBelum ada peringkat

- Bauer V4 User Manual (Formal)Dokumen27 halamanBauer V4 User Manual (Formal)Eduardo Adrat100% (1)

- Achi Ir Pro SC ManualDokumen16 halamanAchi Ir Pro SC ManualestebanBelum ada peringkat

- wds-4860 ManualDokumen23 halamanwds-4860 ManualChhay Grace Nor RoeunBelum ada peringkat

- ZM r5850 ManualDokumen34 halamanZM r5850 ManualThưởng Văn LêBelum ada peringkat

- GM330 ManualDokumen18 halamanGM330 ManualLászló KádárBelum ada peringkat

- Scotle IR6000 V3 ManualDokumen17 halamanScotle IR6000 V3 ManualSharon TaylorBelum ada peringkat

- Ir-Pro-Sc ManualDokumen21 halamanIr-Pro-Sc ManualLászló KádárBelum ada peringkat

- BGA Rework Station Touchbga GM5860/GM5860L/GM5860A: User ManualDokumen19 halamanBGA Rework Station Touchbga GM5860/GM5860L/GM5860A: User ManualsasBelum ada peringkat

- SP 360 CmanualDokumen35 halamanSP 360 CmanualencontreelrepuestoBelum ada peringkat

- SV550 English ManualDokumen43 halamanSV550 English ManualRadu Petrica100% (1)

- CMR707 Product DataDokumen7 halamanCMR707 Product Dataandrei_zi123Belum ada peringkat

- P 4740100 InstallDokumen13 halamanP 4740100 InstallAshraf Adel Nashed ZakiBelum ada peringkat

- Manual Dyepro-02Dokumen16 halamanManual Dyepro-02Kharisma PuteraBelum ada peringkat

- ZM r5830Dokumen27 halamanZM r5830Camilo JimenezBelum ada peringkat

- Scotle Technology Group Ltd. Scotle IR6000 V3. BGA Rework Station. User Manual.Dokumen17 halamanScotle Technology Group Ltd. Scotle IR6000 V3. BGA Rework Station. User Manual.zigmund zigmundBelum ada peringkat

- ZM-R5860-BGA Rework Station: Shenzhen Zhuomao Technology Co., LTDDokumen2 halamanZM-R5860-BGA Rework Station: Shenzhen Zhuomao Technology Co., LTDRecon G BonillaBelum ada peringkat

- TU 380 EngDokumen15 halamanTU 380 EngDanielBelum ada peringkat

- BGA Rework Station Touchbga Gm390: User ManualDokumen19 halamanBGA Rework Station Touchbga Gm390: User ManualRecon G BonillaBelum ada peringkat

- HK 5830 PDFDokumen21 halamanHK 5830 PDFSantos EderaldoBelum ada peringkat

- Aoyue 8032 ADokumen6 halamanAoyue 8032 ARohit SinghBelum ada peringkat

- MFL67582201 (Saudi) - 2012 Single Package (60Hz R22) - 0410Dokumen92 halamanMFL67582201 (Saudi) - 2012 Single Package (60Hz R22) - 04101969MAZHARBelum ada peringkat

- (改)LY IR9000 -Manual-EnglishDokumen22 halaman(改)LY IR9000 -Manual-EnglishStopper_Time100% (1)

- Temp Controller Kit Instructions PDFDokumen10 halamanTemp Controller Kit Instructions PDFCarlos Castillo UrrunagaBelum ada peringkat

- Engineering Data Cassette 4 WayDokumen52 halamanEngineering Data Cassette 4 WayCong Viet100% (2)

- Specs of Indoor UnitsDokumen17 halamanSpecs of Indoor UnitsShanmugasundaram RaghuramanBelum ada peringkat

- Kte-6000br Ae100Dokumen91 halamanKte-6000br Ae100zalomxisBelum ada peringkat

- I.C.T Reflow Oven L8 Manual V1.0Dokumen30 halamanI.C.T Reflow Oven L8 Manual V1.0Louis ChewBelum ada peringkat

- SR - Single Package - CO (Const) - Saudi (R410A60Hz) - MFL67452911 - 6CUK0-01A (June 2015) - (7.5 To 15 TR) .Technical DataDokumen41 halamanSR - Single Package - CO (Const) - Saudi (R410A60Hz) - MFL67452911 - 6CUK0-01A (June 2015) - (7.5 To 15 TR) .Technical DataShaikhMazharAhmedBelum ada peringkat

- Instruction Manual: ZM-R7220A Rework StationDokumen35 halamanInstruction Manual: ZM-R7220A Rework StationTSBrianesi OrdensBelum ada peringkat

- 9513 Ins Rupmf XLDDokumen4 halaman9513 Ins Rupmf XLDLuiz ApolinárioBelum ada peringkat

- Ics-490 Bga Rework Station Operation Manual: Files Without This Message by Purchasing Novapdf PrinterDokumen14 halamanIcs-490 Bga Rework Station Operation Manual: Files Without This Message by Purchasing Novapdf PrinterfranzysBelum ada peringkat

- LG AC Package TypeDokumen300 halamanLG AC Package TypepaolocparreraBelum ada peringkat

- Irda-Welder User Manual T-870aDokumen14 halamanIrda-Welder User Manual T-870asat062001Belum ada peringkat

- Galaxy R Service Manual PDFDokumen58 halamanGalaxy R Service Manual PDFPedro Bortot56% (9)

- Irda-Welder User Manual T-870aDokumen15 halamanIrda-Welder User Manual T-870aRogertagalliuBelum ada peringkat

- 48 50a-3wDokumen28 halaman48 50a-3wtecairBelum ada peringkat

- Cameron Temperature Switches Technical Data SheetDokumen28 halamanCameron Temperature Switches Technical Data Sheetvlcmstne04Belum ada peringkat

- LG Arun Gse2Dokumen15 halamanLG Arun Gse2Claudiu RaduBelum ada peringkat

- Corona Multi Service R410A ManualDokumen25 halamanCorona Multi Service R410A Manualautrera100% (1)

- 2 Aire Acondicionado COMPAC I y IIDokumen12 halaman2 Aire Acondicionado COMPAC I y IILuis Enrique GarzonBelum ada peringkat

- Chapter 1: Overview: Standard Features and BenefitsDokumen4 halamanChapter 1: Overview: Standard Features and BenefitsarielfernandomaxBelum ada peringkat

- ps800 AmDokumen62 halamanps800 AmDinesh Kumar100% (1)

- SG808 ManualDokumen2 halamanSG808 ManualzzmeoneBelum ada peringkat

- Rde10 1DHW N3038Dokumen8 halamanRde10 1DHW N3038grouchotasBelum ada peringkat

- Programmable Thermostat With Plug in RF Boiler Control: Model: ST620VBCDokumen44 halamanProgrammable Thermostat With Plug in RF Boiler Control: Model: ST620VBCCristina GiuchiciBelum ada peringkat

- SIME - Metropolis DGT 25 UserDokumen44 halamanSIME - Metropolis DGT 25 UserNeagu CristianBelum ada peringkat

- Technical RoofTopsDokumen64 halamanTechnical RoofTopsnairam2003100% (1)

- Ba en 812202 Terra-NavigatorDokumen44 halamanBa en 812202 Terra-Navigatormdeac2012100% (1)

- ASTM-40 48 ManualDokumen12 halamanASTM-40 48 ManualCristian Barraza GeraldoBelum ada peringkat

- 500 V.2 Desc PDFDokumen6 halaman500 V.2 Desc PDFdanny hBelum ada peringkat

- LY IR6500 v.2 Description ManualDokumen6 halamanLY IR6500 v.2 Description ManualPedro Vera0% (1)

- Bird5000e (RV1)Dokumen23 halamanBird5000e (RV1)Andrea LvszBelum ada peringkat

- Digital LED Thermometer with Microcontroller AVR ATtiny13Dari EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Penilaian: 5 dari 5 bintang5/5 (1)

- Utstar Wireless IIDokumen13 halamanUtstar Wireless IIvimalvenkatBelum ada peringkat

- CommView TutorialDokumen21 halamanCommView Tutorialtaslim4uBelum ada peringkat

- Awesome HTMLDokumen72 halamanAwesome HTMLgarv_sk9100% (2)

- 6600 Boot ProblamDokumen1 halaman6600 Boot Problamtaslim4uBelum ada peringkat

- Nokia DCT4+ Patch Unlock ListDokumen2 halamanNokia DCT4+ Patch Unlock Listtaslim4uBelum ada peringkat

- Awesome HTMLDokumen72 halamanAwesome HTMLgarv_sk9100% (2)

- Kevin Colcomb, Matthew Rymell and Alun Lewis: Very Heavy Fuel Oils: Risk Analysis of Their Transport in Uk WatersDokumen12 halamanKevin Colcomb, Matthew Rymell and Alun Lewis: Very Heavy Fuel Oils: Risk Analysis of Their Transport in Uk WatersSidney Pereira JuniorBelum ada peringkat

- International StrategyDokumen34 halamanInternational StrategymanicatewatiaBelum ada peringkat

- RISC Vs CISC - The Post-RISC Era - Jon "Hannibal" StokesDokumen26 halamanRISC Vs CISC - The Post-RISC Era - Jon "Hannibal" Stokesjlventigan100% (1)

- Fauzan Ariq Santoso From Marine Electrical Engineering ShipsDokumen11 halamanFauzan Ariq Santoso From Marine Electrical Engineering ShipsFauzan Ariq SantosoBelum ada peringkat

- IRobot 510 PackBot AccessoriesDokumen14 halamanIRobot 510 PackBot AccessoriesMirsad34Belum ada peringkat

- Penilaian Kinerja Malcolm BaldridgeDokumen24 halamanPenilaian Kinerja Malcolm BaldridgeHijrah Saputro RaharjoBelum ada peringkat

- Pantaloons FinalDokumen30 halamanPantaloons FinalAnkit SharmaBelum ada peringkat

- Find Study Resources: Answered Step-By-StepDokumen3 halamanFind Study Resources: Answered Step-By-StepJohn KingBelum ada peringkat

- ANSI - Ahri Standard 550-590 (I-P) With Addendum 3Dokumen109 halamanANSI - Ahri Standard 550-590 (I-P) With Addendum 3Afzal KhanBelum ada peringkat

- 10039030M00 - PB560 System Final Test Procedure PDFDokumen12 halaman10039030M00 - PB560 System Final Test Procedure PDFDaniel MarquesBelum ada peringkat

- Strategies To Avoid Communication Breakdown (Part Ii) : Oral Communication in Context For Grade 11Dokumen19 halamanStrategies To Avoid Communication Breakdown (Part Ii) : Oral Communication in Context For Grade 11Elda Mae EsmaneBelum ada peringkat

- GSECL - Daily Progress Report 11.9.21Dokumen2 halamanGSECL - Daily Progress Report 11.9.21krishna mohanBelum ada peringkat

- Non Destructive Testing Tech EnglishDokumen1 halamanNon Destructive Testing Tech Englishvictor hugoBelum ada peringkat

- 1 Starting Time Calculation 2Dokumen15 halaman1 Starting Time Calculation 2Sankalp MittalBelum ada peringkat

- Traditional Healer in Carletonville, Germiston, Johannesburg, Krugersdorp South Africa+27782669503Dokumen139 halamanTraditional Healer in Carletonville, Germiston, Johannesburg, Krugersdorp South Africa+27782669503mama shifahBelum ada peringkat

- Practical 6 Star Delta StarterDokumen4 halamanPractical 6 Star Delta StarterMohammad Nurayzat Johari50% (2)

- Supplied in A Compact and Elegant Enclosure, The A125 Adds Style To The Most Visible Component of An IPTV Deployment.Dokumen2 halamanSupplied in A Compact and Elegant Enclosure, The A125 Adds Style To The Most Visible Component of An IPTV Deployment.Basava RajBelum ada peringkat

- Ducon Construction Chemicals Industries LTD - Concrete Admixtures in BangladeshDokumen3 halamanDucon Construction Chemicals Industries LTD - Concrete Admixtures in BangladeshFounTech612Belum ada peringkat

- NISSOS NIKOURIA - KYKLADES MARITIME - SpecsDokumen2 halamanNISSOS NIKOURIA - KYKLADES MARITIME - SpecsEkvazis TarsachBelum ada peringkat

- Ip Nat Guide CiscoDokumen418 halamanIp Nat Guide CiscoAnirudhaBelum ada peringkat

- Harry BerryDokumen2 halamanHarry BerryLuisBelum ada peringkat

- Doris Graber, 1996, Say It With PicturesDokumen13 halamanDoris Graber, 1996, Say It With PicturesFlorinaCretuBelum ada peringkat

- W667 Job Completion CertificateDokumen5 halamanW667 Job Completion CertificateMohamed ShafeeqBelum ada peringkat

- Watershed SegmentationDokumen19 halamanWatershed SegmentationSan DeepBelum ada peringkat

- PDFDokumen42 halamanPDFMohd Nizamuddin Mohamad NoorBelum ada peringkat

- 080Dokumen10 halaman080Luis Adrián ElguézabalBelum ada peringkat

- Fluorescence Activated Cell SortingDokumen6 halamanFluorescence Activated Cell SortingAjit YadavBelum ada peringkat

- Lab Nov 2013Dokumen35 halamanLab Nov 2013balajigandhirajanBelum ada peringkat

- Audit QuickstartDokumen6 halamanAudit QuickstarthugorduartejBelum ada peringkat

- DD FC Basix ConfDokumen18 halamanDD FC Basix ConfwstanzlBelum ada peringkat