GDS113 Filtros Pall PDF

Diunggah oleh

John Avila DelgadilloDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GDS113 Filtros Pall PDF

Diunggah oleh

John Avila DelgadilloHak Cipta:

Format Tersedia

Fuels and Chemicals

PhaseSep

Y Series

Liquid/Liquid Coalescer

EFFECTI VELY SEPARATES EMULSI ONS

GDS113

c

o

a

l

e

s

c

e

r

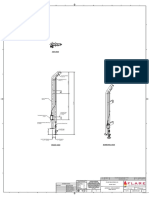

Polyolefin Cage

Flow Through Cartridge

Polyolefin End Cap

Flow Direction

Through Media

Flow Direction

Into Cartridge

Coarse Media Layer

Releases large drops

Coarse Media Layer

Extends life as pre-filter

Fine Media Layer

Breaks emulsions

Polyolefin Core

PhaseSep Y Series Coalescer: Cutaway showing flow direction

Introduction

The Pall PhaseSep

Y Series Coalescer is

the latest member of the PhaseSep

coalescer family and is a high efficiency

separation cartridge that is constructed

entirely of FDA listed polyolefin material.

This allows the PhaseSep Y series

coalescer to be used in a wide range of

liquid/ liquid separations in the chemical,

flavour & fragrance, and biotechnology

industries where metal is not

compatible and/or where FDA listed

materials are required.

The coalescer media contains a three

layered tapered pore construction.

The emulsion first enters at the inside of

the cartridge and passes through a coarse

pre-filter layer to extend the service life.

The fluid then encounters a fine media layer

that initiates the coalescing process

starting the enlargement of the droplets.

The coalescing process is completed by a

coarse media layer that maximizes the

coalesced drop size before the fluid

departs from the outside layer of the

coalescer cartridge.

The presence of difficult to separate

emulsions can be a costly problem in

the chemical, flavour & fragrance, and

biotechnology industries. Liquid

contaminants can cause final products to

be off-specification, deactivate expensive

catalysts, foul contactor and stripping trays,

lead to corrosion and delays in downstream

storage tanks, and increase the costs for

wastewater treatment.

Breaking stable emulsions can be a difficult

task depending on the physical properties

of the oil, water, and surfactant system.

Important parameters in determining the ease of

separating emulsions are the interfacial tension (IFT),

difference in density, and viscosity. The IFT is a good

way to assess the stability of an emulsion and is a

measure of how much energy is required to create

additional water /oil surface area. For very stable

emulsions, the IFT can be very low and conventional

glass fibre coalescers can lose their efficiency when the

IFT reaches below 20 dyne/cm.

Compatibility is also a key issue when selecting a

coalescer type. Pall offers a wide range of coalescers

including various polymers and fluoropolymers.

Materials of Construction

Item Materials

End Caps/Support Cage Polyolefin

Support/Drainage Layers Polyolefin

Medium Polyolefin

Gasket Ethylene-Propylene-Diene

(EPDM)*

* also available in Buna N, Viton A, Ethylene Propylene (EPM), and Silicone

Typical Applications

Separation of oil from ammonia

Separation of oil from urea

Separation of oil from acid streams

Separation of oil from caustic streams

Separation of citric oils from alcohol-water

Separation of organics from acid/caustic

pharmaceutical extractants

Performance of PhaseSep Y Series Coalescers:

Remove liquid contamination to a level of 5 ppmw

based on gravimetric analysis

Handle inlet dispersed liquid contaminant

concentrations as high as 10%

Separate emulsions with interfacial tensions as low

as 0.5 dyne/cm

Note: each application for the PhaseSep Y Series L/L Coalescer should be

reviewed by Pall Corporation for technical feasibility.

Description

The Pall pre-filter and horizontal liquid/liquid coalescer

system is depicted on the last page. The first stage

consists of a pre-filter housing that is used to remove

solids from the inlet emulsion stream to protect the

coalescer and ensure long service life. The pre-filter also

functions as a pre-coalescer and starts the fine droplets in

the emulsion on their route to forming larger intermediate

drops that continue to enlarge in the coalescer medium.

In the coalescer housing, the liquid/liquid emulsion enters

the PhaseSep Y series coalescing element and flows

inside to outside. Dispersed phase droplets suspended in

the continuous phase merge together in the fiber medium,

or coalesce, as the emulsion moves through the

coalescer medium.

The large coalesced droplets of the dispersed phase

leave the coalescer cartridges and are separated by the

difference in density between the two phases in the

settling zone of the horizontal housing.

The drops collect in a sump where an interface level is

monitored, typically with automated level control and

valves. Depending on the difference in the density

between the two phases, the sump can be located on

the top or the bottom of the coalescer housing.

Feature

All plyolefin construction

Tapered pore structure

High void volume medium

FDA listed materials

Advantage

Wide chemical and low

temperature compatibility

Coalescense performance not

impaired by presence

of surfactants

Can separate liquids that have

low interfacial tension

Long service life

Meets government regulations

Benefit

Better to withstand upsets

in pH and temperature

Eliminates need for emulsion

breaking chemicals

Excellent fluid quality

Enhanced protection of

downstream equipment

Lower separation costs

Allows improved emulsion

separation in flavour &

fragrance/biotech industries

Ordering Information - Coalescer

Part Description Nominal Nominal

Number Diameter Length*

LCY2Y2YJ PhaseSep 2

3

4 in. 20 in.

Y Series (70 mm) (510 mm)

L/L Coalescer

* Stackable for extended lengths

Compatibility

The PhaseSep Y series coalescer is compatible with

many corrosive solvents encountered in the chemical,

flavour & fragrance, and biotechnology industries including

ammonia, urea, acids, caustics, brines, amines, alcohols,

and many other organic solvents. For compatibility

information with a specific chemical, please contact your

local Pall office.

Ordering Information - Housing

Part No. Rated Flow Nominal Inlet/Outlet

Number Coalescer per Housing Housing Flange

Diameter Diameter

(gpm/lpm) (in/mm) (in/mm)

3HAQLS0501F 1 3 16/60 5/127 1/25.4

8HAQLS1202F 1 8 42/160 12/305 2/50.8

15HAQLS2002F 1 15 80/300 20/508 2/50.8

35HAQLS2804F 1 35 185/700 28/711 4/101.6

Code Pressure Rating for

Carbon Steel Vessels

285 285 psig (19.7 barg)

740 740 psig (51.0 barg)

Code ASME B16.5 Flanges

1 150 #

3 300 #

Performance Claims and Specifications

Maximum Temperature: 122F (50C)

Minimum Temperature: -40F (-40C)

Initial Pressure Drop: 2 psid (0.14 bar)

Recommended Changeout: 15 psid (1.03 bar)

Burst Pressure Drop: 50 psid (3.5 bar)

Code Housing Metallurgy

None Carbon Steel Vessel,

304 Stainless Steel Tube Sheet

S3 304L Stainless Steel

S8 304 Stainless Steel

L3 316L Stainless Steel

L8 316 Stainless Steel

New York - USA

888 873 7255 toll free in the USA

+1 516 484 5400 phone

+1 516 484 0364 fax

fuelsandchemicals@pall.com

Portsmouth - Europe

+44 (0)23 9230 3303 phone

+44 (0)23 9230 2506 fax

fuelsandchemicals@pall.com

Pall Corporation has offices and plants throughout the world in locations including:

Argentina, Australia, Austria, Belgium, Brazil, Canada, China, France, Germany, Hong Kong,

India, Indonesia, Ireland, Italy, Japan, Korea, Malaysia, Mexico, the Netherlands, New

Zealand, Norway, Poland, Puerto Rico, Russia, Singapore, Spain, South Africa, Sweden,

Switzerland, Taiwan, Thailand, United Kingdom, the United States and Venezuela.

Distributors are located in all major industrial areas of the world.

Visit us on the Web at www.pall.com

Because of developments in technology these data or procedures may be subject to

change. Consequently we advise users to review their continuing validity annually.

29274/CS4M/09.2002

Copyright 2002, Pall Corporation. Pall and are trademarks of Pall Corporation.

Indicates a Pall trademark registered in the USA. is a service mark

of Pall Corporation. Pure-Flo is a registered trademark of ITT industries, Inc.

Fuels and Chemicals

Liquid/Liquid Coalescer

Pre-conditioning Filters

Inlet

Pall L/L Coalescer Heavy

Phase

Sump

Outlet

Light Phase

Pall Corporation

A Powerful Resource For Control

Protection and Teamwork

Pall Corporation brings over 50 years of filtration and

separations experience to your plants processes. With

the industrys widest range of advanced products, Pall

can design a system specifically for your plant, based on

a thorough evaluation of your needs.

Youll receive technical consultation and support from our

Scientific and Laboratory Services Department (SLS).

This is a network of over 400 scientists and engineers

working from more than 30 Pall laboratories worldwide.

Pall continues to develop new products and methods to

advance the state of the art of phase separation. No

other company offers such a strong core competency in

coalescing technology to help you reduce operating and

maintenance costs through improved product control,

plant protection and teamwork.

To determine if the PhaseSep Y series coalescer can help

you with your emulsion problems, call the Pall Corporation

Fuels and Chemicals Division or visit our web site at

www.pall.com.

Anda mungkin juga menyukai

- AB Emflon PFRDokumen2 halamanAB Emflon PFRsaulookBelum ada peringkat

- Ultipor HT For Hot Liquid ServiceDokumen2 halamanUltipor HT For Hot Liquid ServiceMustafa DaoudBelum ada peringkat

- PWC 70 20S Doe PDFDokumen6 halamanPWC 70 20S Doe PDFWorapat PuttakasemBelum ada peringkat

- 02.01-01 - AEF-390 Fab - Guide - ULTISEP Rev 01 9-Aug-18Dokumen13 halaman02.01-01 - AEF-390 Fab - Guide - ULTISEP Rev 01 9-Aug-18yoselin Ayala RamosBelum ada peringkat

- Seprasol Plus: Liquid/Gas CoalescersDokumen4 halamanSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiBelum ada peringkat

- FILTROSDokumen24 halamanFILTROSJessica MontenegroBelum ada peringkat

- FL1627Dokumen2 halamanFL1627Isaac Montero BarreraBelum ada peringkat

- Special Closures Literature2Dokumen2 halamanSpecial Closures Literature2ruben'sBelum ada peringkat

- 3.0 Systems Division-FiltersDokumen8 halaman3.0 Systems Division-Filtersmatteo2009Belum ada peringkat

- SeparatorDokumen8 halamanSeparatorIra Purnama SariBelum ada peringkat

- Compressed Air Filters Sample FiltersDokumen46 halamanCompressed Air Filters Sample FiltersMohsinShaikhBelum ada peringkat

- CMPAPPP Separator Vessel and Filter Design GuideDokumen18 halamanCMPAPPP Separator Vessel and Filter Design GuideJWilson73Belum ada peringkat

- DeZURIK KCG Knife Gate ValvesDokumen12 halamanDeZURIK KCG Knife Gate ValvesKithkarnonBelum ada peringkat

- Coalescer PallDokumen16 halamanCoalescer PallJeEJyZaBelum ada peringkat

- MAHLE IF PremiumSelectElements ENDokumen6 halamanMAHLE IF PremiumSelectElements ENJamin SmtpngBelum ada peringkat

- Products Valves Sanitary PBM Series 9, 2 WayDokumen40 halamanProducts Valves Sanitary PBM Series 9, 2 Waydingobk1Belum ada peringkat

- Filtration / Separation Products & Services: Making The World Safer, Healthier and More ProductiveDokumen16 halamanFiltration / Separation Products & Services: Making The World Safer, Healthier and More Productivesuraj pandeyBelum ada peringkat

- Shell MESC Number 774133.010.1 (NEAREST)Dokumen2 halamanShell MESC Number 774133.010.1 (NEAREST)Ehsan Ur Rehman100% (1)

- Ledeen Actuator Control SolutionsDokumen28 halamanLedeen Actuator Control SolutionsAbgNakalLaBelum ada peringkat

- MODELS 4, 6, 8 High-Capacity Strainers and FiltersDokumen6 halamanMODELS 4, 6, 8 High-Capacity Strainers and Filterspeter2mBelum ada peringkat

- Flare Tip Supplier Cathalogue - AEREON PDFDokumen25 halamanFlare Tip Supplier Cathalogue - AEREON PDFJabel Oil Services Technical DPTBelum ada peringkat

- Strainer Type 305Dokumen5 halamanStrainer Type 305alexiel1806Belum ada peringkat

- VGS Vane Separators Are Recommended ForDokumen1 halamanVGS Vane Separators Are Recommended ForSanthu PeelaBelum ada peringkat

- H2O2 Hydrogen Peroxide Passivation ProcedureDokumen7 halamanH2O2 Hydrogen Peroxide Passivation ProcedureLion TigerBelum ada peringkat

- AIT & IIT Construction (Carbon & Stainless Steel) : 3 Way Ball Valves PN 16Dokumen4 halamanAIT & IIT Construction (Carbon & Stainless Steel) : 3 Way Ball Valves PN 16Jefferson OliveiraBelum ada peringkat

- FItrLTERS PDFDokumen4 halamanFItrLTERS PDFAriz Joelee ArthaBelum ada peringkat

- Kimre - Innovative Clean Air TechnologiesDokumen16 halamanKimre - Innovative Clean Air TechnologiesKimre Inc100% (1)

- General Arrangement For Mod 245 Pilot, SS316 PDFDokumen1 halamanGeneral Arrangement For Mod 245 Pilot, SS316 PDFJabel Oil Services Technical DPTBelum ada peringkat

- 1 - 2015 Enimex Ball ValvesDokumen55 halaman1 - 2015 Enimex Ball ValvesNoytsias KostantinosBelum ada peringkat

- Samson Valve For High Temperature PDFDokumen36 halamanSamson Valve For High Temperature PDFNARENDRA PATELBelum ada peringkat

- Standard Hook-Up Wires & Cables For ElectronicsDokumen124 halamanStandard Hook-Up Wires & Cables For ElectronicsdlstoneBelum ada peringkat

- Level Gauges Definition Types Measuring Range Ordering InformationDokumen3 halamanLevel Gauges Definition Types Measuring Range Ordering Informationkamala 123Belum ada peringkat

- Manual Flare Sim ExproDokumen69 halamanManual Flare Sim ExproJuan Pablo AlonsoBelum ada peringkat

- PR 900 PDFDokumen26 halamanPR 900 PDFsanjay ukalkarBelum ada peringkat

- 10 1016@j Jngse 2016 01 016Dokumen37 halaman10 1016@j Jngse 2016 01 016saiful bahriBelum ada peringkat

- 399ADokumen24 halaman399ADana Mera100% (2)

- Ro-Flo Parts Book ENGDokumen86 halamanRo-Flo Parts Book ENGedI_restrepo_1Belum ada peringkat

- Gas Filter Separators 4Dokumen8 halamanGas Filter Separators 4Anonymous bHh1L1Belum ada peringkat

- Jaeger Column InternalsDokumen15 halamanJaeger Column Internalslazy5Belum ada peringkat

- Pillard - Packlight Buk 117 CDokumen2 halamanPillard - Packlight Buk 117 CAlfonso Blanco100% (1)

- DeepFlex BrochureDokumen4 halamanDeepFlex Brochureribeiro30Belum ada peringkat

- Flare Tip Industries Sales@Dokumen60 halamanFlare Tip Industries Sales@Erin BradyBelum ada peringkat

- Clarify: 740 Premium SeriesDokumen7 halamanClarify: 740 Premium SeriesnodyyyBelum ada peringkat

- DeepFlex Overview March-2014Dokumen32 halamanDeepFlex Overview March-2014bzkxt100% (1)

- Floating Production TechnologyDokumen19 halamanFloating Production TechnologyHtin Lin AungBelum ada peringkat

- Sample2 DrawingDokumen1 halamanSample2 DrawingganeshBelum ada peringkat

- Air AssistedDokumen2 halamanAir Assistedandy131078Belum ada peringkat

- Shell Corena S3 R 68: Performance, Features & BenefitsDokumen3 halamanShell Corena S3 R 68: Performance, Features & BenefitsjkamraBelum ada peringkat

- Sok7305252 003 A 001Dokumen107 halamanSok7305252 003 A 001muhammad nazmiBelum ada peringkat

- Compressed Air Dryer: Industrial Ammonia SystemsDokumen8 halamanCompressed Air Dryer: Industrial Ammonia Systemsfernando_tkm_65065Belum ada peringkat

- Swing Check ValvesDokumen5 halamanSwing Check Valveslilama45-1Belum ada peringkat

- MP60P70Dokumen28 halamanMP60P70903352Belum ada peringkat

- Catrdige Filter Cost Chang OutDokumen4 halamanCatrdige Filter Cost Chang OutmigelBelum ada peringkat

- Mesh & Vane Mist Eliminator: FiltersDokumen16 halamanMesh & Vane Mist Eliminator: Filtersgeorgadam1983Belum ada peringkat

- Vacuum Booster Application of Bernoulli's PrincipleDokumen9 halamanVacuum Booster Application of Bernoulli's PrincipleDouglas OngomBelum ada peringkat

- EATON Filtration FilterCartridgesDokumen20 halamanEATON Filtration FilterCartridgeschris110Belum ada peringkat

- Pleated Media Filter Cartridges: High Efficiency, Long Life Cartridges For Industrial FluidsDokumen4 halamanPleated Media Filter Cartridges: High Efficiency, Long Life Cartridges For Industrial FluidsWarlexBelum ada peringkat

- 305855no Bake HADokumen9 halaman305855no Bake HAAshok KhannaBelum ada peringkat

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDari EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (3)

- CSWASampleExam PDFDokumen33 halamanCSWASampleExam PDFThịnh NguyễnBelum ada peringkat

- SolidWize CSWP Sample Exam 1 Segment 3Dokumen17 halamanSolidWize CSWP Sample Exam 1 Segment 3gordansim100% (2)

- SolidWize CSWP Sample Exam 2 Segment 3 PDFDokumen16 halamanSolidWize CSWP Sample Exam 2 Segment 3 PDFparin advani100% (3)

- CSWP MTLS PDFDokumen5 halamanCSWP MTLS PDFbontrager13060% (1)

- CSWASampleExam PDFDokumen33 halamanCSWASampleExam PDFThịnh NguyễnBelum ada peringkat

- Basket StrainersDokumen15 halamanBasket StrainersYarlagadda Harsha VardhanBelum ada peringkat

- 24-Ts Filtros Tee CanastaDokumen4 halaman24-Ts Filtros Tee CanastaJohn Avila DelgadilloBelum ada peringkat

- Visor de Nivel PenberthyDokumen35 halamanVisor de Nivel PenberthyJohn Avila Delgadillo100% (1)

- Brochure Filtros Temporales y CanastasDokumen7 halamanBrochure Filtros Temporales y CanastasJohn Avila DelgadilloBelum ada peringkat

- 40th Caterpillar Performance HandbookDokumen372 halaman40th Caterpillar Performance Handbookcarlos_córdova_8100% (11)

- Profitability Analysis (Sapphire Fibres Limited)Dokumen5 halamanProfitability Analysis (Sapphire Fibres Limited)Aqsa MoizBelum ada peringkat

- Doctrine of Indoor ManagementDokumen4 halamanDoctrine of Indoor ManagementRavi KtBelum ada peringkat

- Chats: Dini-Ay TriciaDokumen1 halamanChats: Dini-Ay Triciaaiyana sopiaudaundoBelum ada peringkat

- C10G - Hardware Installation GD - 3 - 12 - 2014Dokumen126 halamanC10G - Hardware Installation GD - 3 - 12 - 2014Htt Ếch CốmBelum ada peringkat

- NEBOSH IGC IG1 Course NotesDokumen165 halamanNEBOSH IGC IG1 Course NotesShagufta Mallick100% (13)

- Queen Elizabeth Olympic Park, Stratford City and Adjacent AreasDokumen48 halamanQueen Elizabeth Olympic Park, Stratford City and Adjacent AreasRavi WoodsBelum ada peringkat

- Space Vector Modulation - An Introduction - TutoriDokumen11 halamanSpace Vector Modulation - An Introduction - TutorileonardoBelum ada peringkat

- GTA TaxonomyDokumen12 halamanGTA Taxonomyalvaropiogomez1Belum ada peringkat

- Debt RestructuringDokumen4 halamanDebt Restructuringjano_art21Belum ada peringkat

- Silverio Nuanez Verified ComplaintDokumen10 halamanSilverio Nuanez Verified ComplaintMichael_Lee_RobertsBelum ada peringkat

- Gas Turbine Performance CalculationDokumen7 halamanGas Turbine Performance CalculationAtiqur RahmanBelum ada peringkat

- Kamaka Company Catalogue 2016 PDFDokumen13 halamanKamaka Company Catalogue 2016 PDFWendy0% (3)

- Thermister O Levels Typical QuestionDokumen4 halamanThermister O Levels Typical QuestionMohammad Irfan YousufBelum ada peringkat

- Conventional and Computed TomographyDokumen29 halamanConventional and Computed TomographyJerome D FlorentinoBelum ada peringkat

- ManualDokumen36 halamanManual2009tamerBelum ada peringkat

- Color Management Handbook Vol2Dokumen28 halamanColor Management Handbook Vol2ianjpr100% (2)

- Writing Case StudyDokumen2 halamanWriting Case Studyerankit.sapBelum ada peringkat

- A Case Study On Mahindra's Blue Sense Application Project by RohitDokumen43 halamanA Case Study On Mahindra's Blue Sense Application Project by RohitrohitBelum ada peringkat

- Performance Online - Classic Car Parts CatalogDokumen168 halamanPerformance Online - Classic Car Parts CatalogPerformance OnlineBelum ada peringkat

- 1st Activity in EthicsDokumen2 halaman1st Activity in EthicsAleiah Jane Valencia AlverioBelum ada peringkat

- 147380-1 Motoman XRC Controller Fieldbus (XFB01) Instruction ManualDokumen102 halaman147380-1 Motoman XRC Controller Fieldbus (XFB01) Instruction Manualrubi monBelum ada peringkat

- Package Contents: Ariadni DivaDokumen4 halamanPackage Contents: Ariadni DivaShadi AbdelsalamBelum ada peringkat

- Neo Lighting Control Console: User Manual AddendumDokumen14 halamanNeo Lighting Control Console: User Manual AddendumSamuelRômanceMuñozBelum ada peringkat

- Statistics For Absolute Beginners (Second Edition) (Oliver TheobaldDokumen144 halamanStatistics For Absolute Beginners (Second Edition) (Oliver Theobaldcispas2000Belum ada peringkat

- FPO Policy-1Dokumen96 halamanFPO Policy-1shashanksaranBelum ada peringkat

- ERP Final PPT 22-4Dokumen10 halamanERP Final PPT 22-4ramesh pokhriyaalBelum ada peringkat

- Lect7 Grinding Advanced ManufacturingDokumen33 halamanLect7 Grinding Advanced Manufacturingsirac topcuBelum ada peringkat

- Account Statement 060922 051222Dokumen51 halamanAccount Statement 060922 051222allison squad xXBelum ada peringkat

- Electricity at Work - Safe Working Practices HSG85Dokumen27 halamanElectricity at Work - Safe Working Practices HSG85Sivakumar NatarajanBelum ada peringkat